Method for detecting and sorting self-discharge performance of lithium iron phosphate battery

A lithium iron phosphate battery and self-discharge technology, which is applied in sorting and other directions, can solve the problems of high detection cost and shortened detection time, and achieve the effects of improving sorting accuracy, simple sorting method, and shortening sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

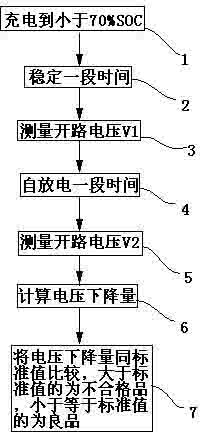

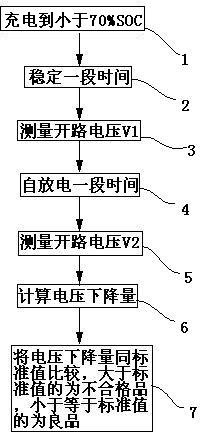

Method used

Image

Examples

Embodiment 1

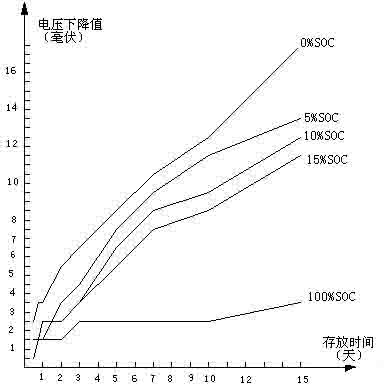

[0030] Embodiment 1, charge 10 lithium iron phosphate batteries to 15% SOC, after 10 hours of stabilization, measure the voltage drop value when the self-discharge time is 5 days, the voltage drop value when the self-discharge time is 10 days, and the self-discharge time is 15 days. Table 2 shows the data obtained by sorting the voltage drop value of the day and hour according to the corresponding voltage drop standard.

Embodiment 2

[0031] Embodiment 2, charge 10 lithium iron phosphate batteries to 10% SOC, after 3 hours of stabilization, measure the voltage drop value when the self-discharge time is 5 days, the voltage drop value when the self-discharge time is 10 days, and the self-discharge time is 15 days. Table 3 shows the voltage drop value during the day, and the data obtained by sorting according to the corresponding standard.

Embodiment 3

[0032] Embodiment 3, charge 10 lithium iron phosphate batteries to 5% SOC, after 7 hours of stabilization, measure the voltage drop value when the self-discharge time is 5 days, the voltage drop value when the self-discharge time is 10 days, and the self-discharge time is 15 days. Table 4 shows the data obtained by sorting the voltage drop value of the day and hour according to the corresponding standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com