Method for guaranteeing high separation precision of coal slime heavy medium hydrocyclone

A dense medium cyclone and coal slime technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems that the pressure parameters are difficult to meet the requirements, and the liquid level of the qualified medium tank of coal slime cannot be guaranteed to be stable. , achieve good sorting index, ensure high sorting accuracy, and stabilize the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

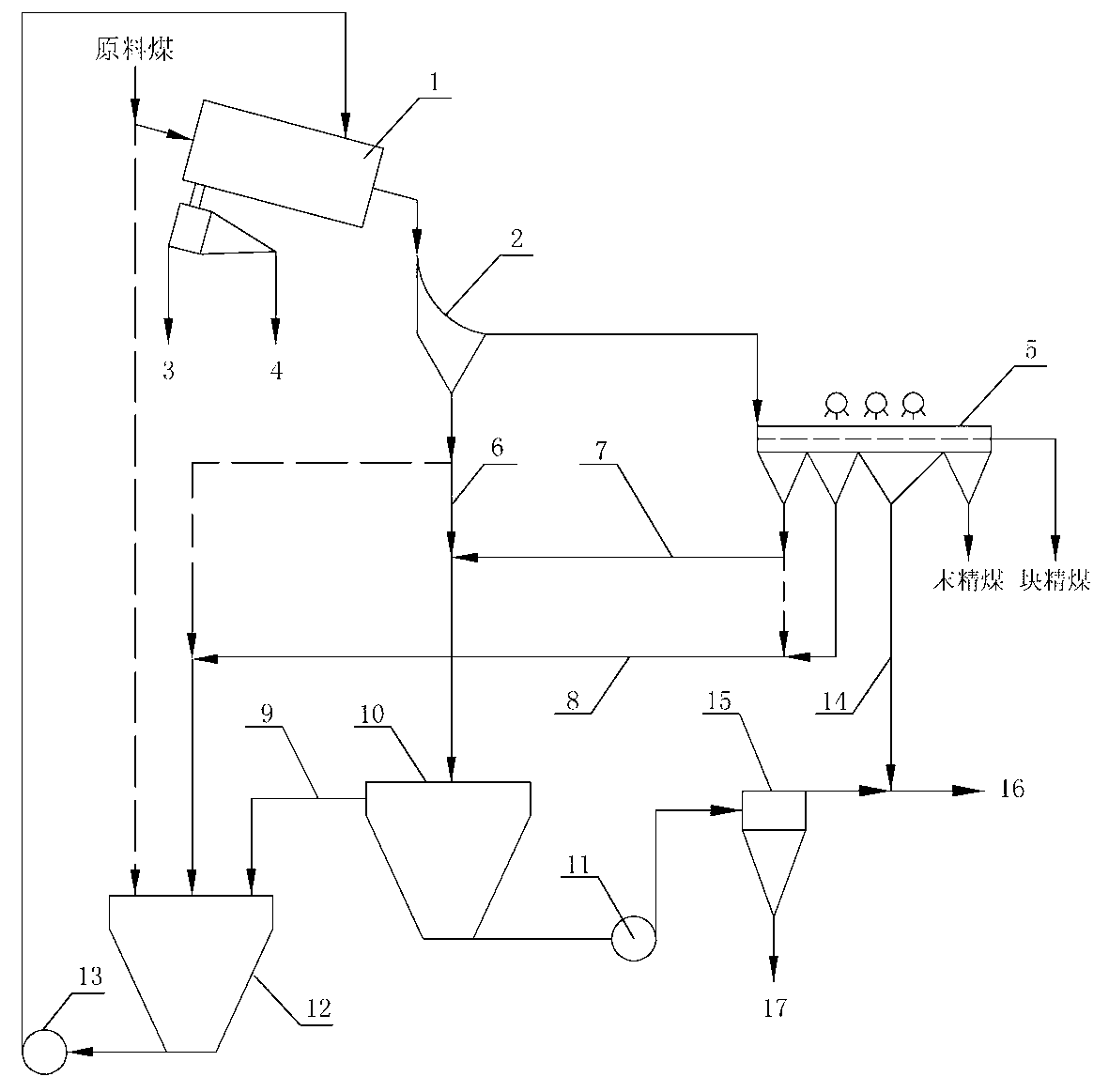

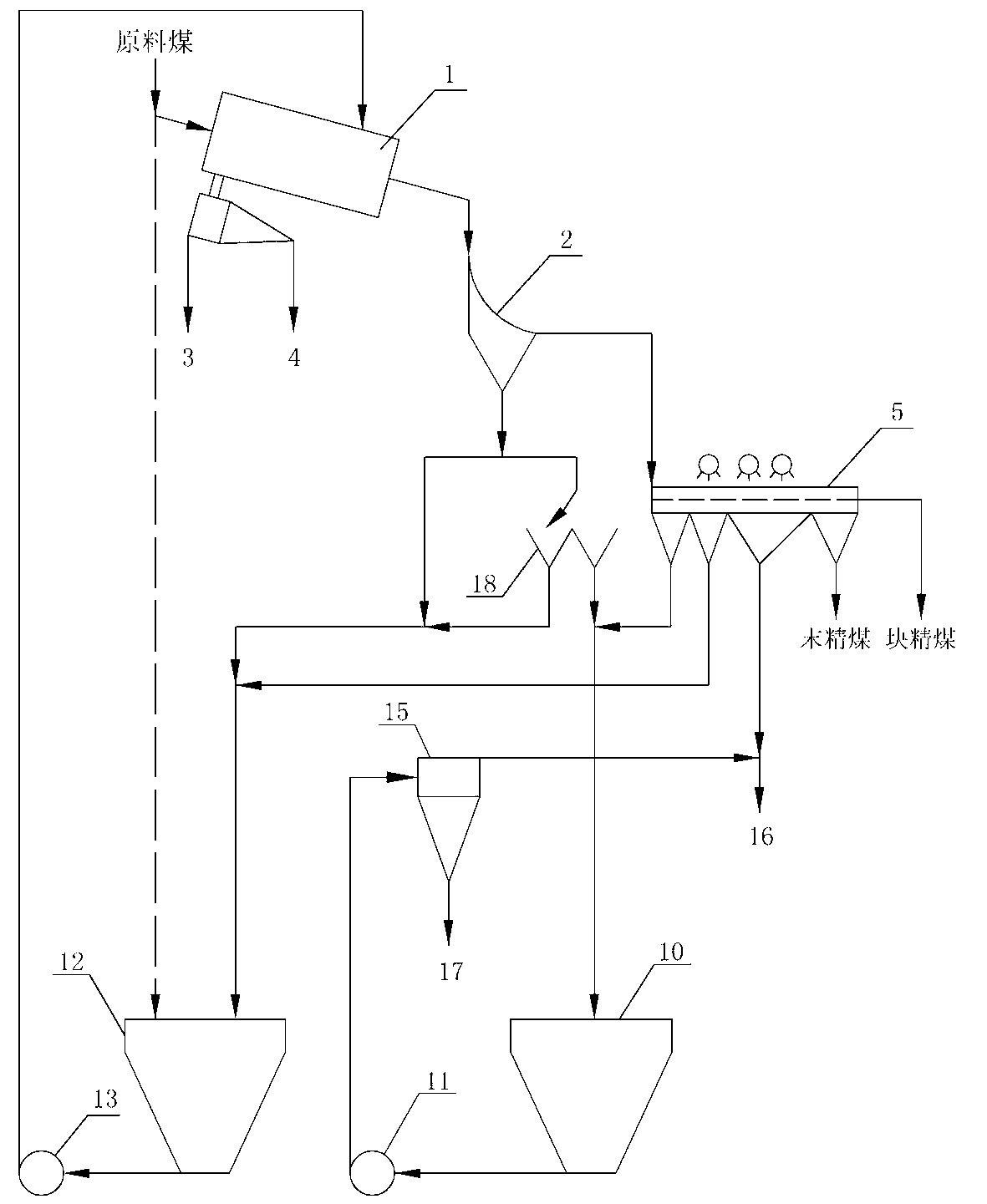

[0019] figure 1 Shown is the process flow chart of the present invention to ensure the high separation accuracy of the slime dense medium cyclone. figure 2 Disclosed is a process flow chart of a coal slime dense medium cyclone in the prior art. figure 1 and figure 2 In comparison, the device used in the present invention is: three-product dense medium cyclone 1, clean coal discharge medium arc screen (or fixed screen) 2, clean coal medium removal screen 5, coal slime qualified medium barrel 10, coal slime qualified Medium pump 11, raw coal qualified medium barrel 12, raw coal qualified medium pump 13, coal slime dense medium cyclone 15 and related pipelines.

[0020] The difference between the present invention and the prior art is that the device used in the present invention cancels the splitter 18, and the chute under the screen of the clean coal release screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com