Coal gangue sorting process

A coal gangue sorting technology, applied in the direction of the swirling flow can reverse the axial direction of the device, swirl device, etc., can solve the problems of low processing capacity, difficult discharge, low processing capacity, etc., to improve economic benefits, separation The effect of high selection accuracy and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

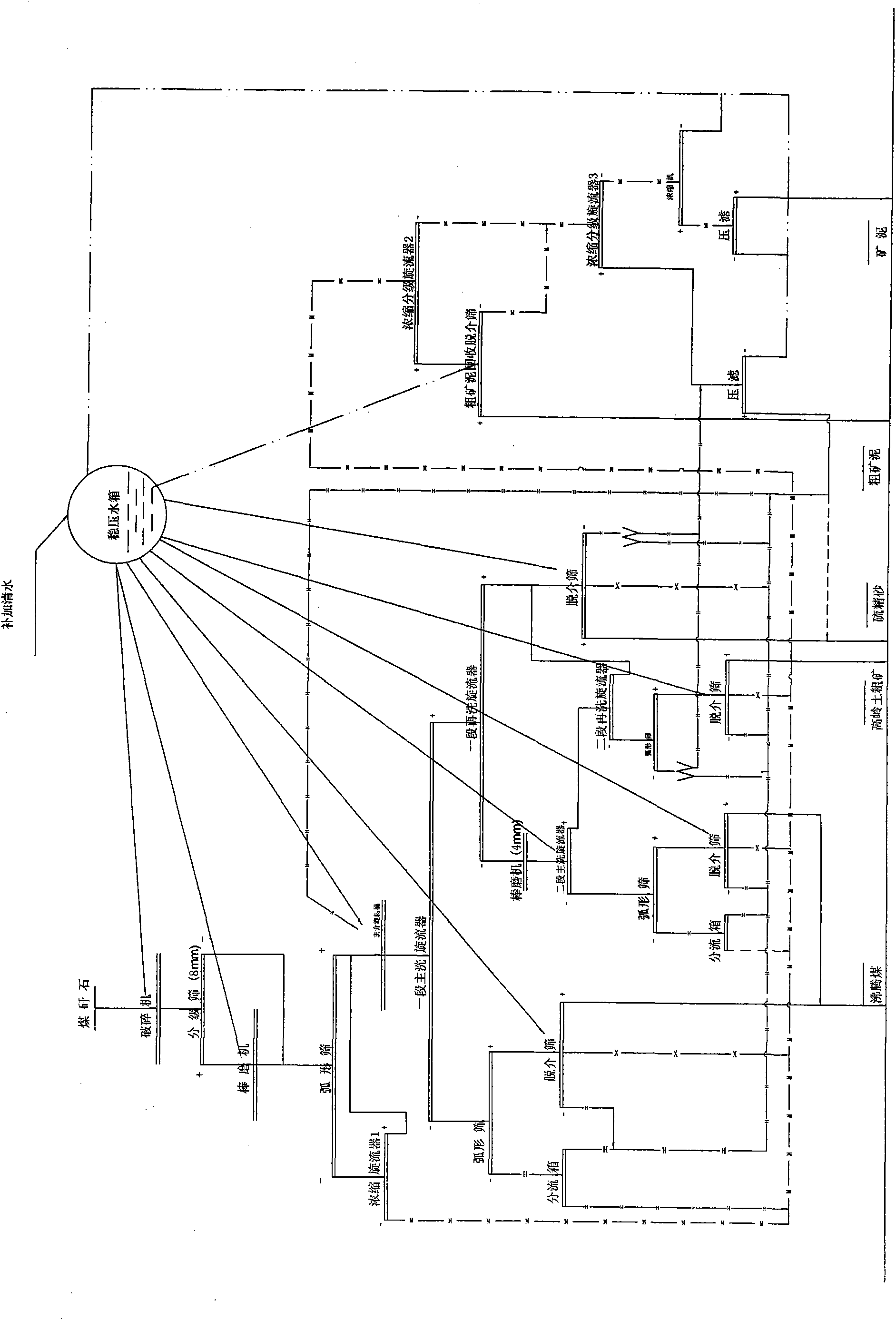

[0032] A sorting process of coal gangue (referring to attached figure 1), first coal gangue is dissociated to 8-0 mm by crusher and rod mill, and after being sieved and dehydrated by curved sieve, the undersize is classified by concentration cyclone 1, and the underflow and the oversize of curved sieve are passed through The pump is delivered to the main washing cyclone (the cone angle is 80 degrees, the cone angle ratio is 0.7:1, the feed density is 1.70kg / l, and the pressure is 0.23Mpa), the overflow of the main washing cyclone passes through the arc After the separation between the sieve and the boiling coal sieve, the sieve is used as boiling coal, and part of the qualified suspension under the curved sieve is returned to the main mixing tank with the suspension under the boiling coal separation sieve, and the other part is mixed with the boiling coal The dilute medium under the de-mediation sieve and the overflow of the concentration cyclone 1 are classified together in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com