Automatic sorting equipment of red date cockles

An automatic sorting and jujube technology, which is applied in sorting, solid separation, filtering and screening, etc., can solve the problems of unstable sorting quality, restricting the development of enterprises, and low sorting efficiency, so as to reduce labor costs and improve sorting efficiency. The effect of improving the selection accuracy and improving the sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

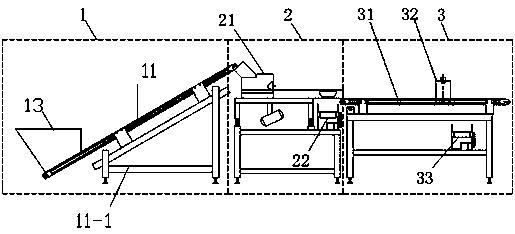

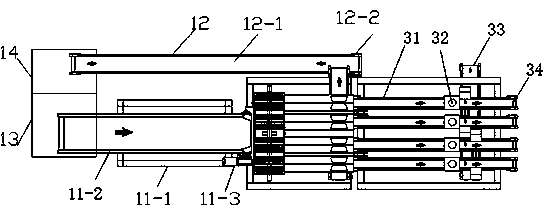

[0019] Such as Figure 1 to Figure 5 As shown, the automatic sorting equipment for jujube wrinkled skin, the whole machine includes a feeding mechanism, a feeding sorting mechanism 2 and a grading mechanism 3;

[0020] Feeding mechanism 1 is made of hoist 11, descender 12, feed hopper 13 and surplus hopper 14, and hoist 11 comprises lifting frame 11-1, lifting conveyer belt 11-2 and belt drive part 11-3; Including a descending conveyor belt 12-1 and a belt drive part 12-1;

[0021] The lower opening of the feeding hopper 13 is connected to the feeding end of the lifting conveyor belt 11-2, and the discharging end of the lifting conveyor belt 11-2 is connected to the feeding end of the feeding sorting mechanism 2;

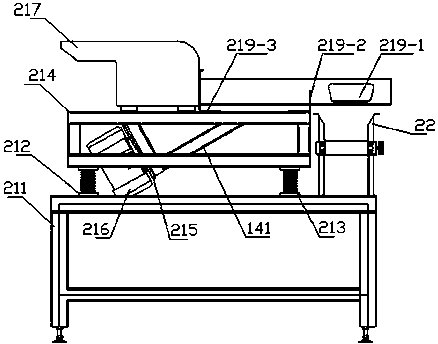

[0022] Feeding sorting mechanism 2 comprises screening mechanism 21 and recovery line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com