Patents

Literature

35results about How to "Avoid manual detection errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

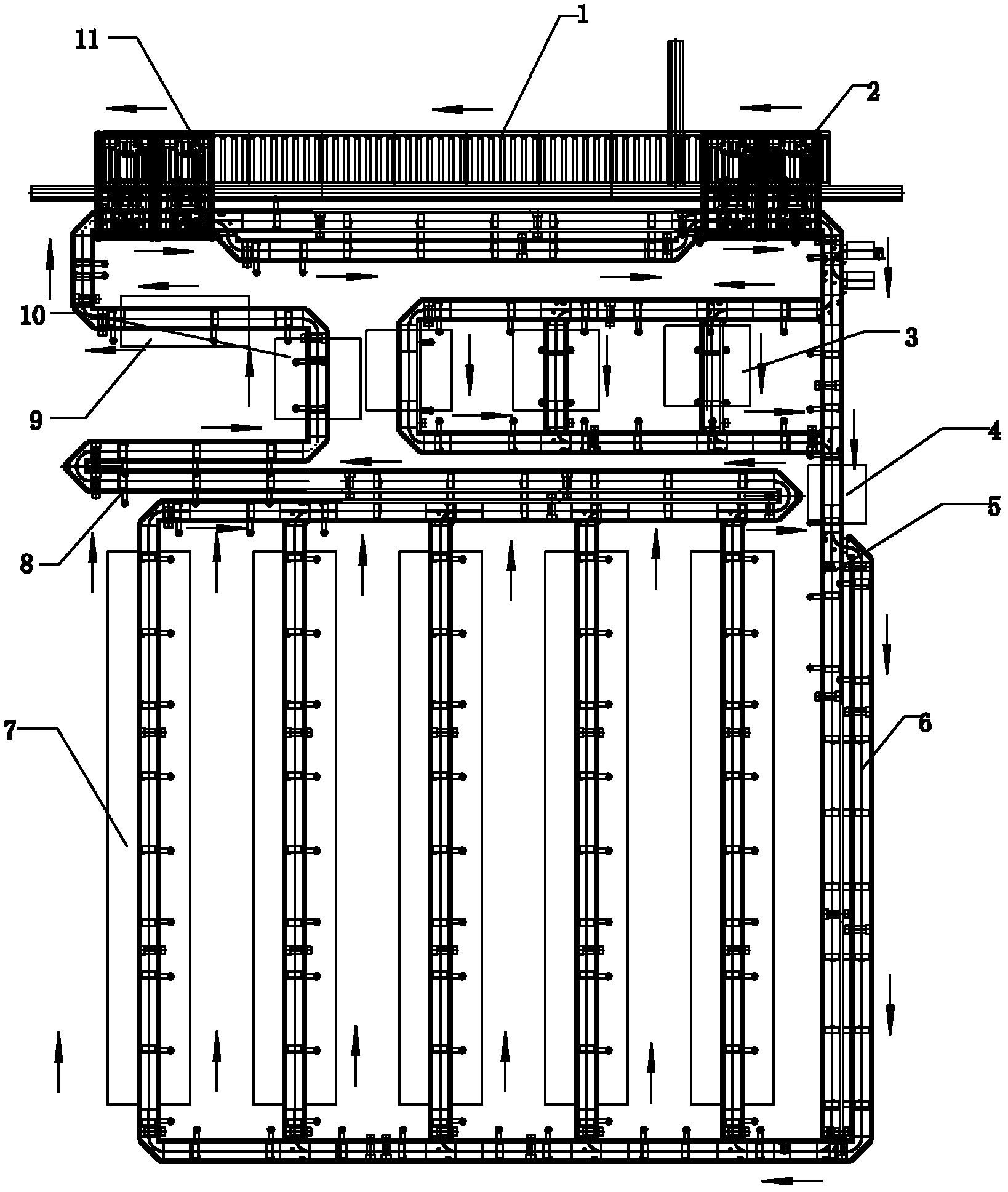

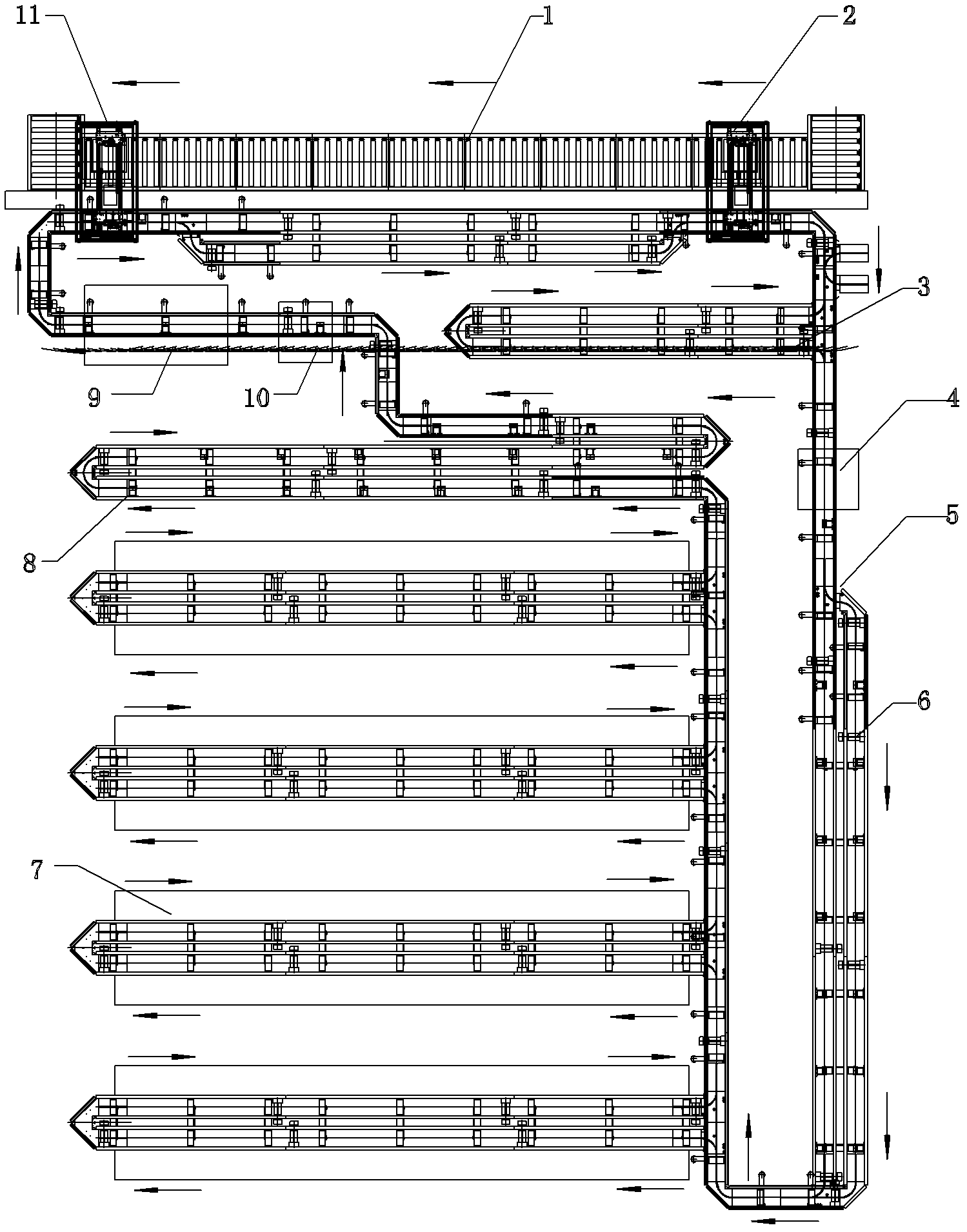

Electric energy meter verification unit and working method thereof

ActiveCN102323564ARealize fully automatic verificationEasy to manageMaterial analysis by optical meansElectrical testingLogistics managementComputer module

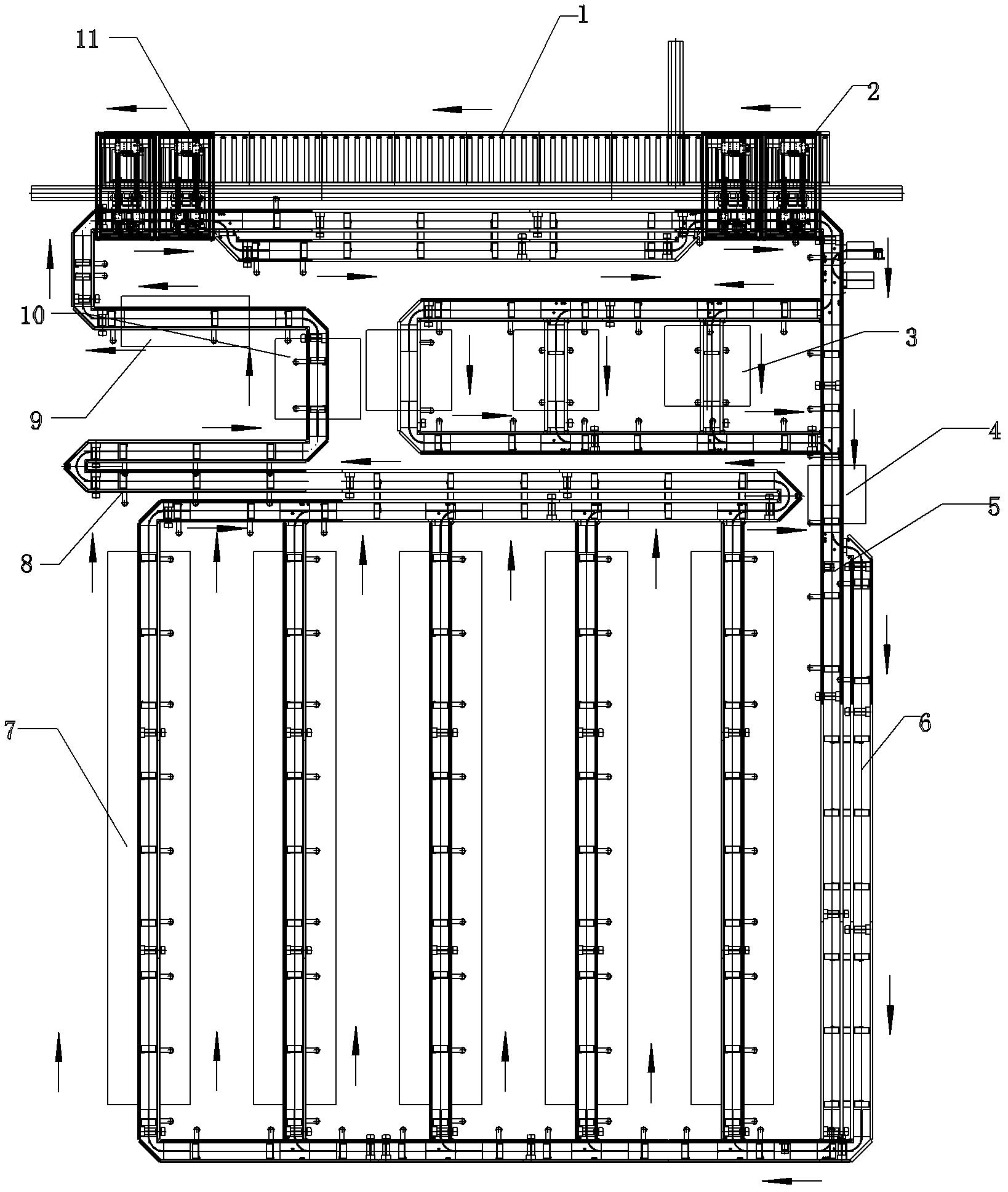

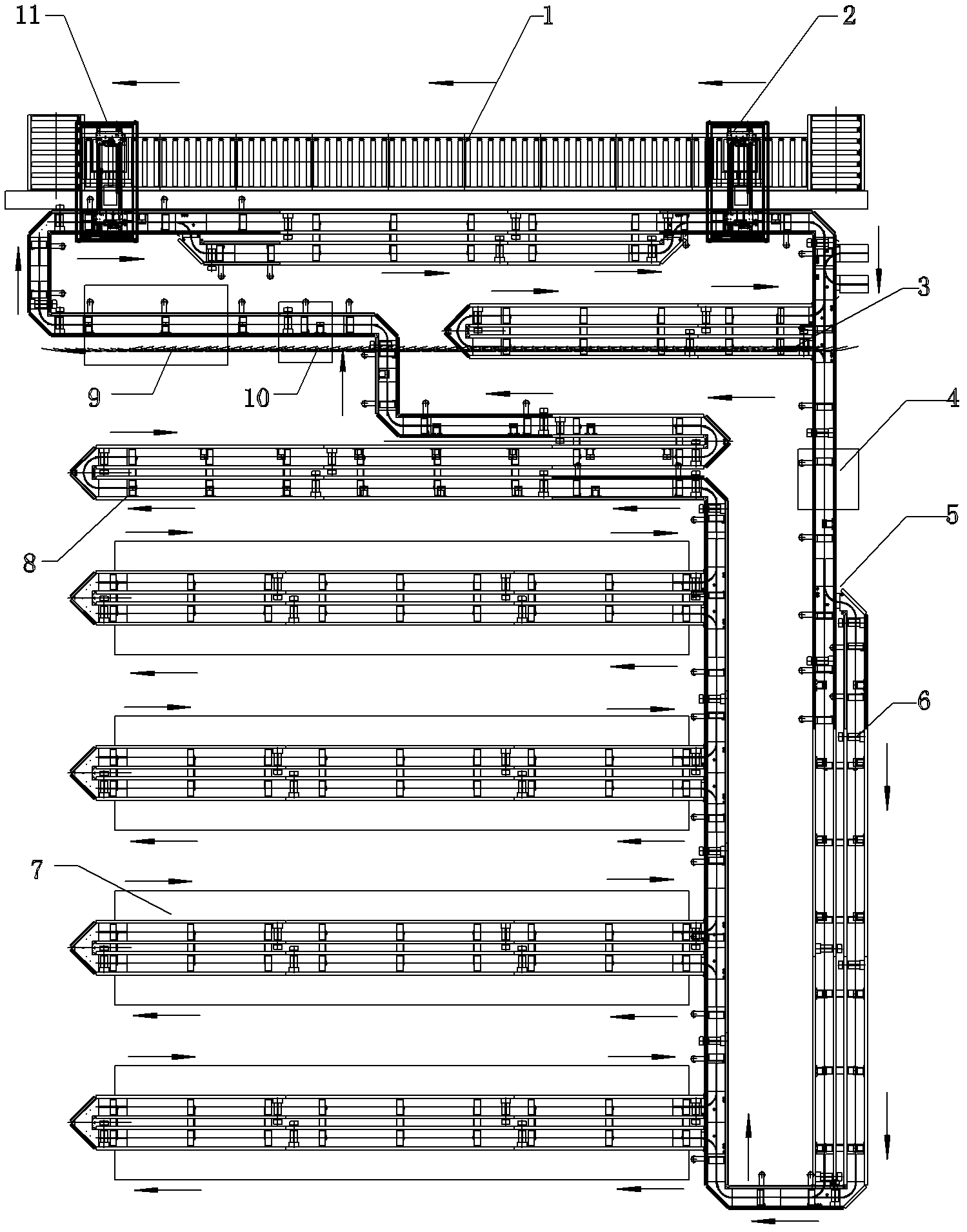

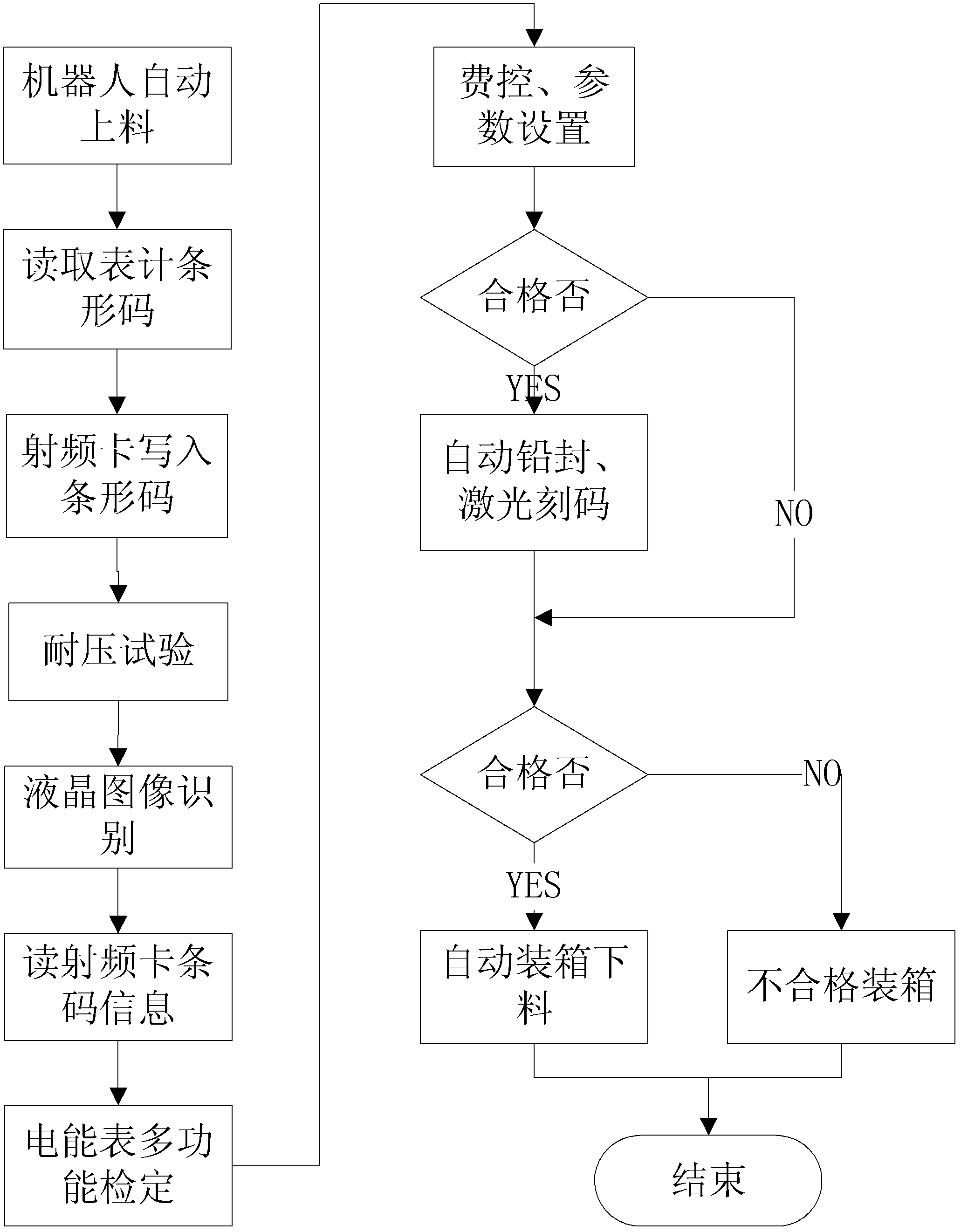

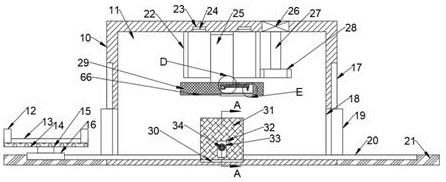

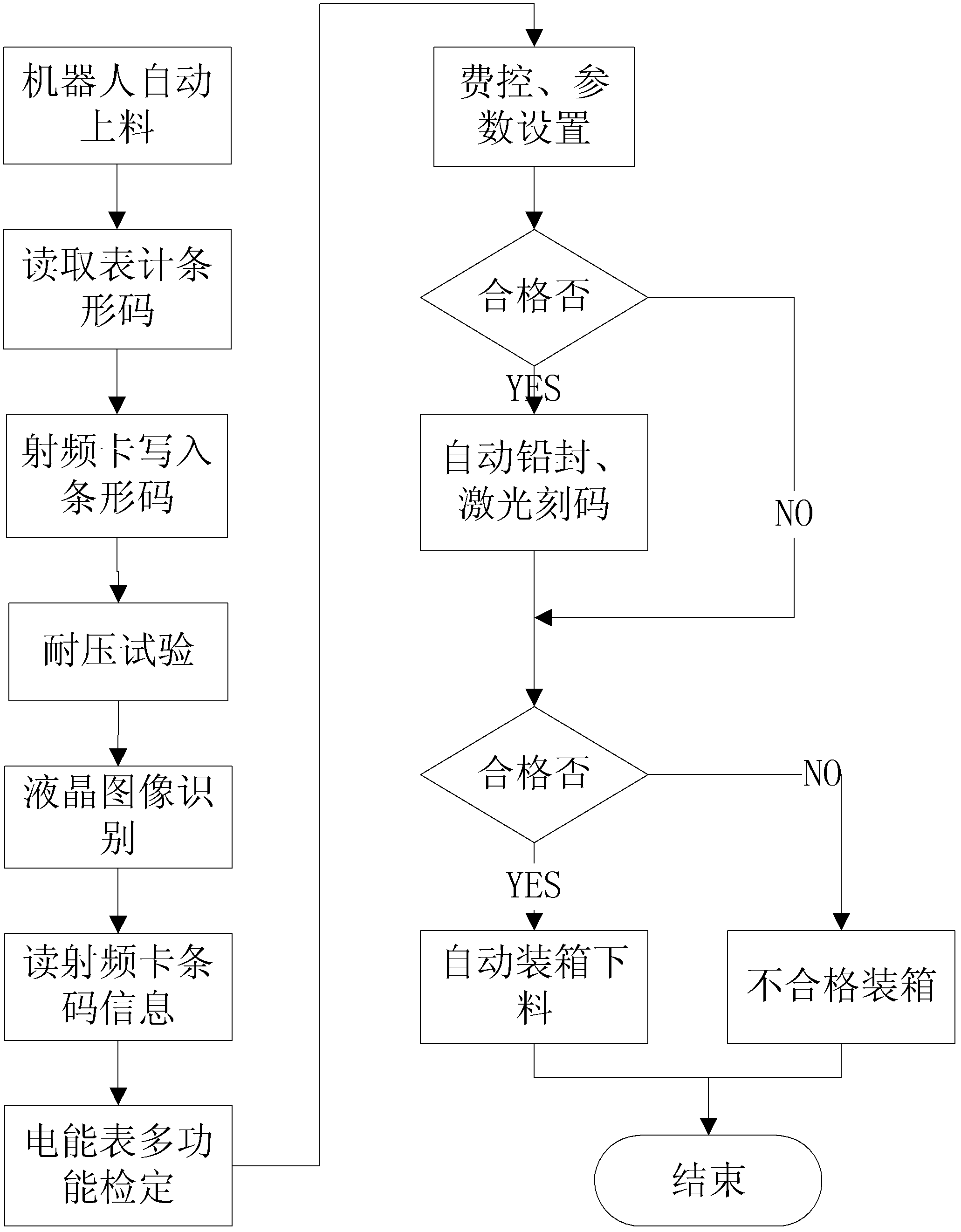

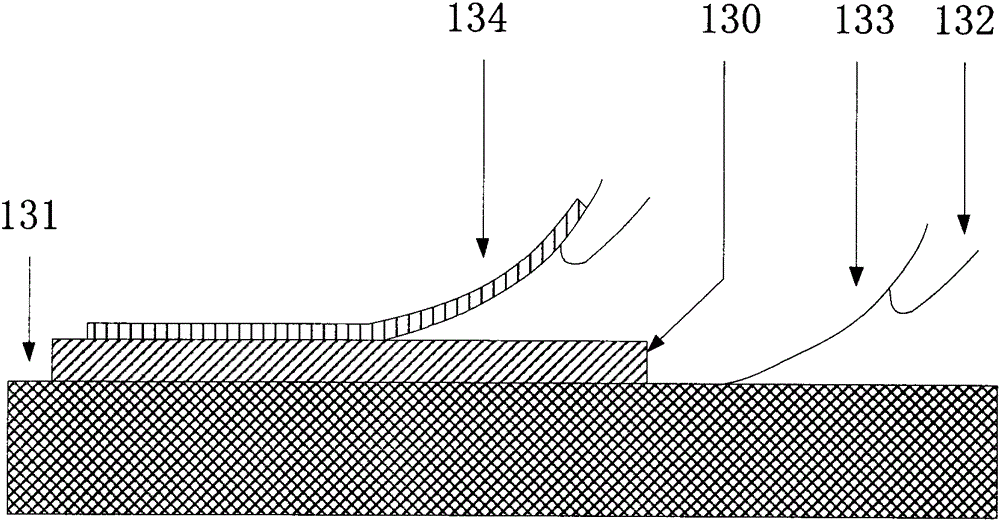

The invention claims an electric energy meter verification unit and a working method thereof, relates to a single-phase, three-phase electric energy meter verification unit and the working method thereof. At present, in the electric energy meter verification process, a verification system is artificial and mainly comprises a plurality of groups of artificial detection table bodies, and the method has the disadvantages of large labor intensity, manual errors and slow integral verification speed. The electric energy meter verification unit provided by the invention comprises a logistics conveying line, a feeding device, a verification conveying line, a pressure withstand testing device, a program switch triggering device, a verification device, a lead seal and laser making device, a discharging device and an electric energy meter verification management module, wherein the feeding device, the pressure withstand testing device, the program switch triggering device, the verification device, the lead seal and laser marking device and the discharging device are orderly arranged along a forward direction of the verification conveying line. The electric energy meter is in full automatic verification, high in efficiency, free from of manual detection errors, and can improve the accuracy of sorting; and the laser marking replaces the traditional form of sticking a certification so that the electric energy meter is convenient for management and use.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

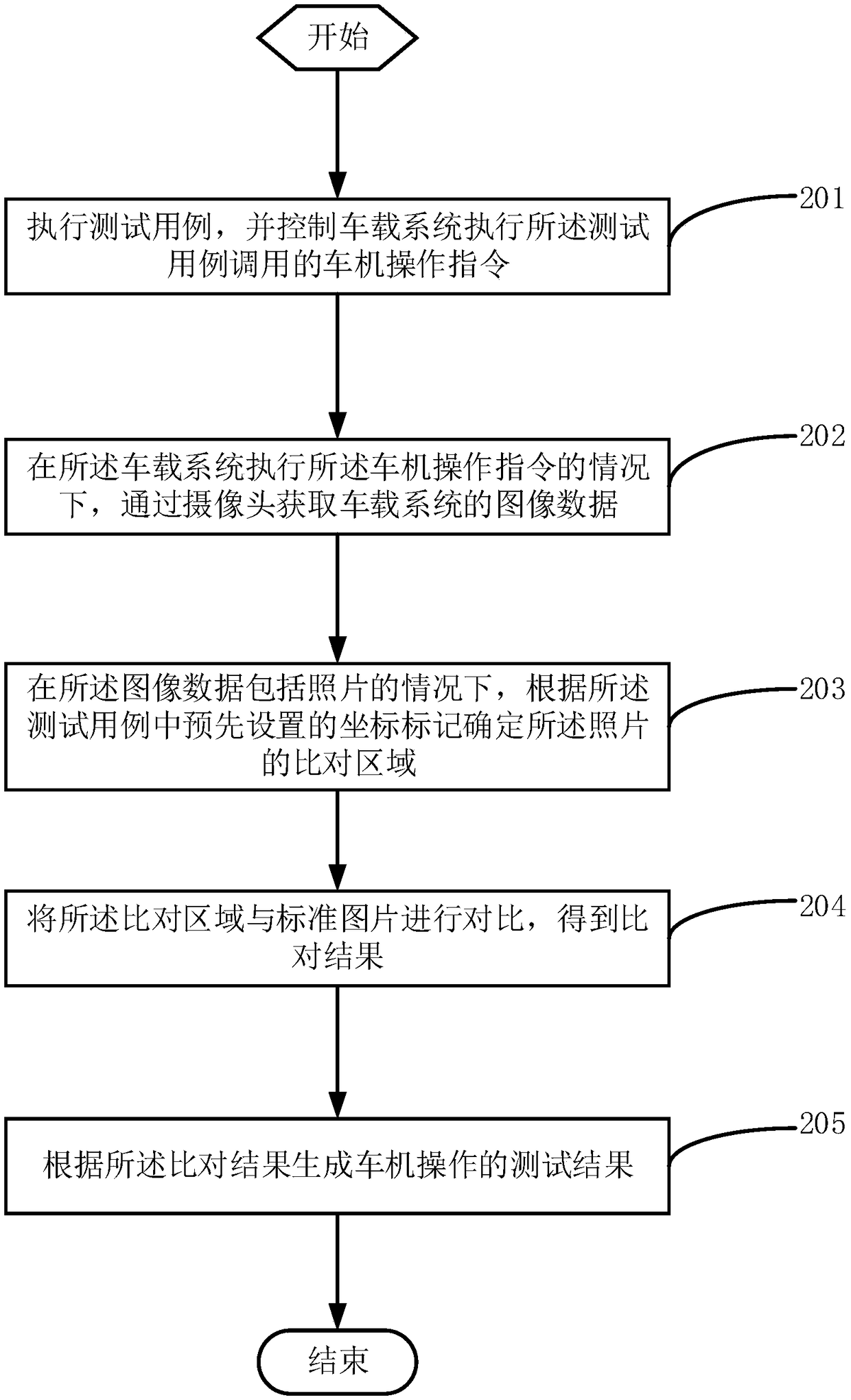

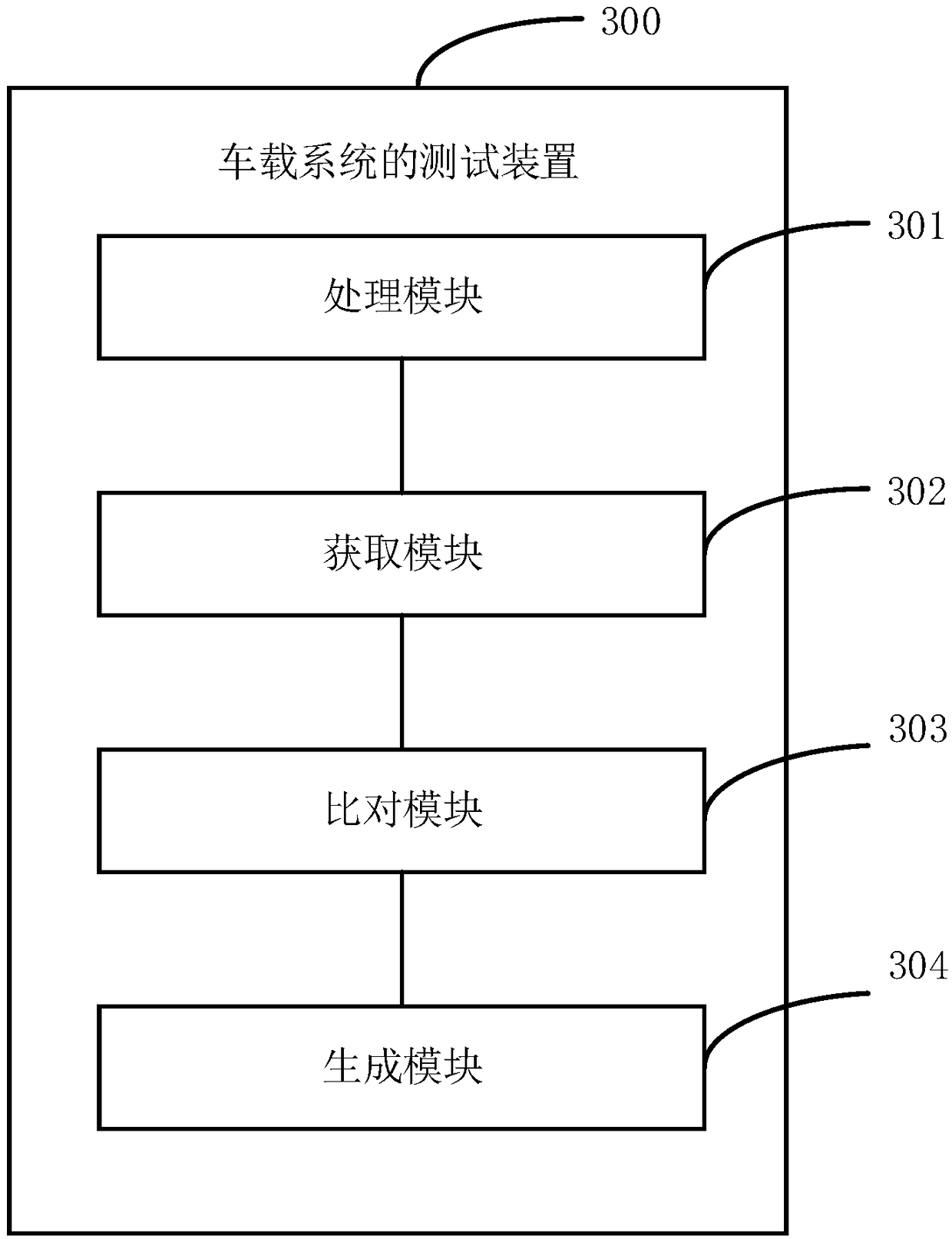

A test method of a vehicle-mounted system and related equipment

ActiveCN109165162AImprove accuracyAvoid manual detection errorsCharacter and pattern recognitionSoftware testing/debuggingComputer hardwareOn board

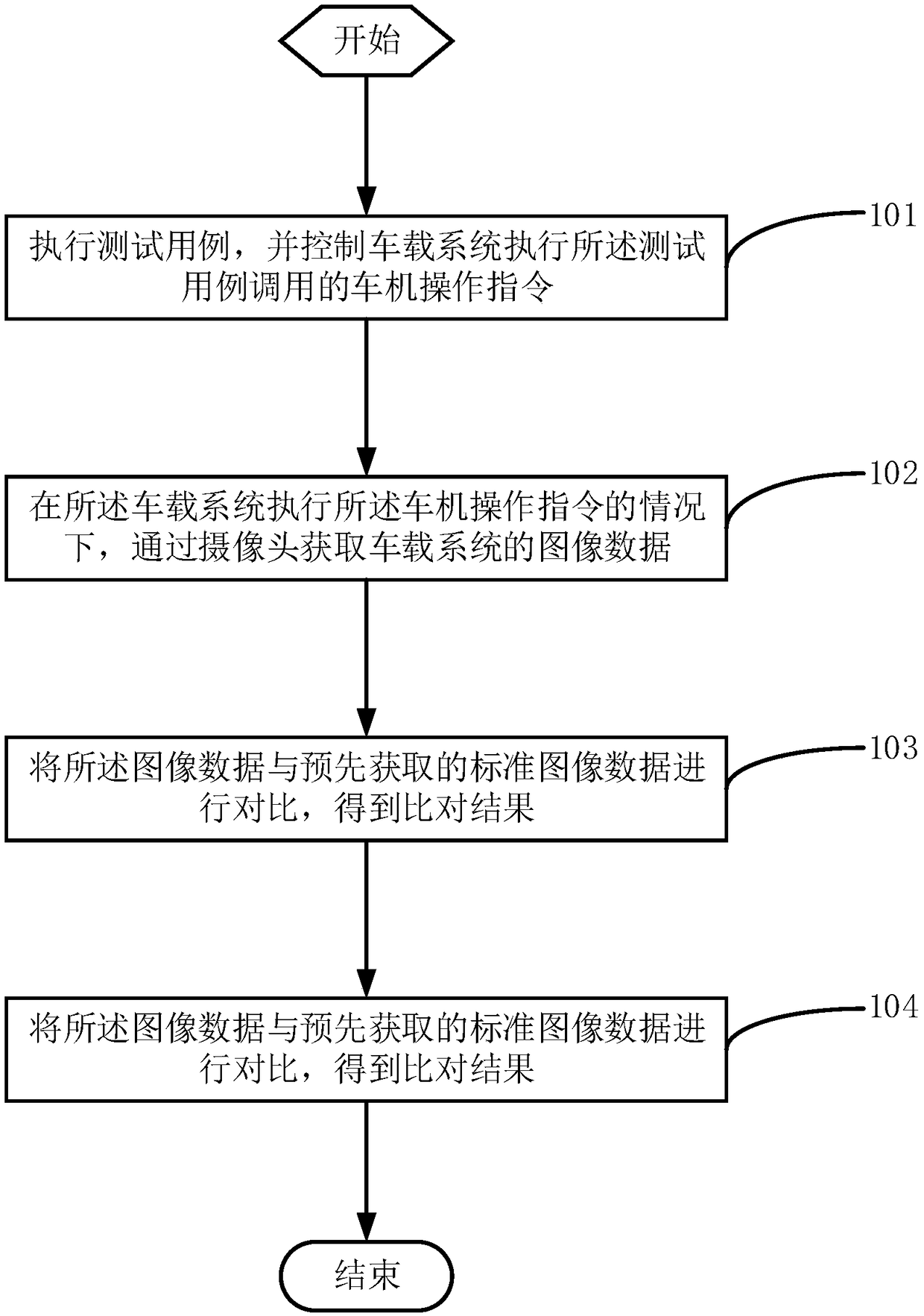

Embodiments of the present disclosure provide a test method of a vehicle-mounted system and related equipment. The method includes: executing a test case and controlling the on-board system to executea vehicle-machine operation instruction called by the test case; obtaining image data of the vehicle-mounted system through a camera under the condition that the vehicle-mounted system executes the vehicle-mounted operation instruction; comparing the image data with the standard image data acquired in advance to obtain an alignment result; generating a test result of vehicle-machine operation according to the comparison result. According to the method for testing a vehicle-mounted system provided by the invention, since the image data can accurately record the real-time operation result whenthe vehicle-machine operation instruction is executed, the test result of the vehicle-machine operation generated according to the comparison result of the image data and the standard image data is more accurate. In addition, since the test result of the vehicle-machine operation is automatically generated without manual detection, the error of the manual detection can be effectively avoided and the accuracy of the test result of the vehicle-machine operation can be effectively improved.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

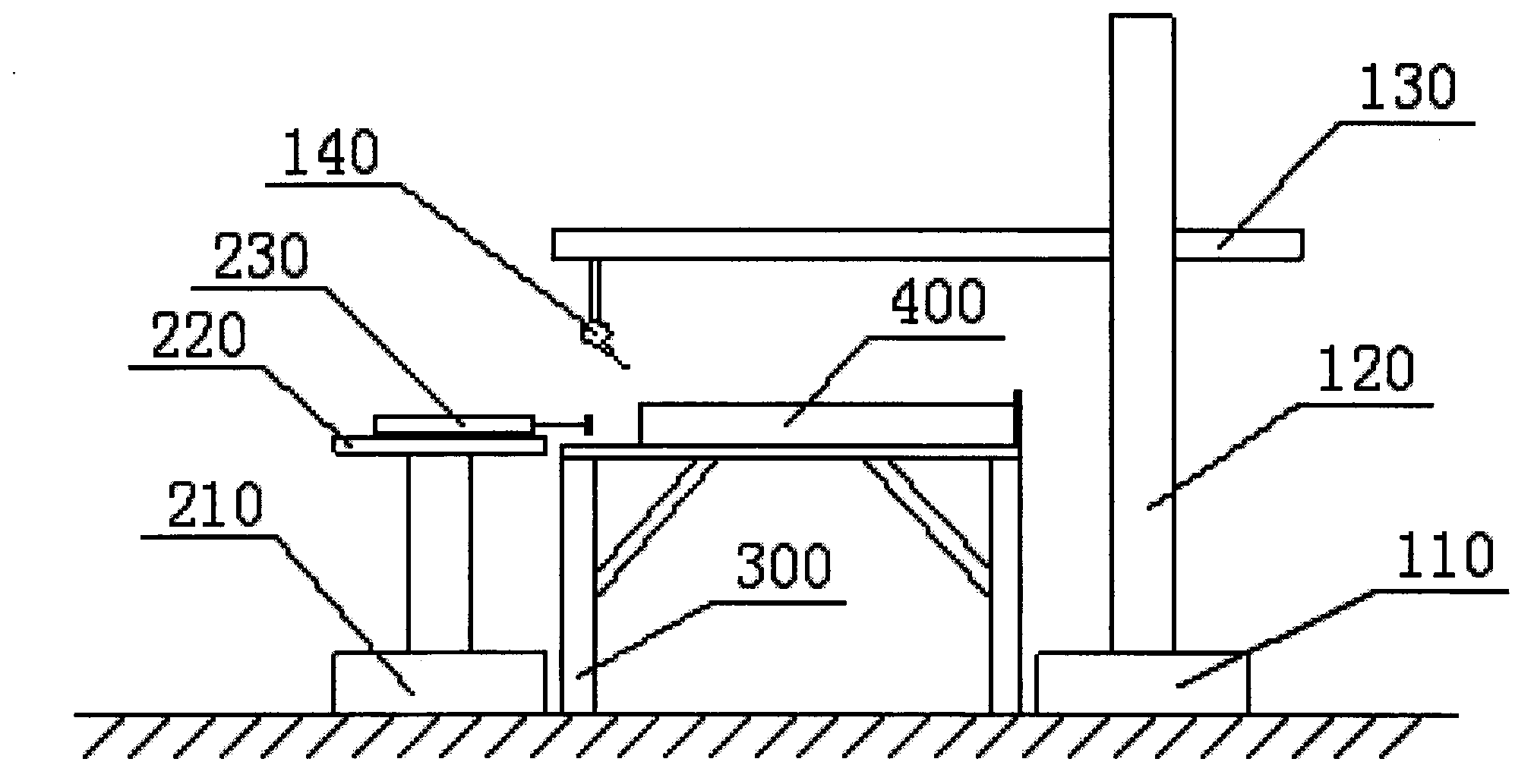

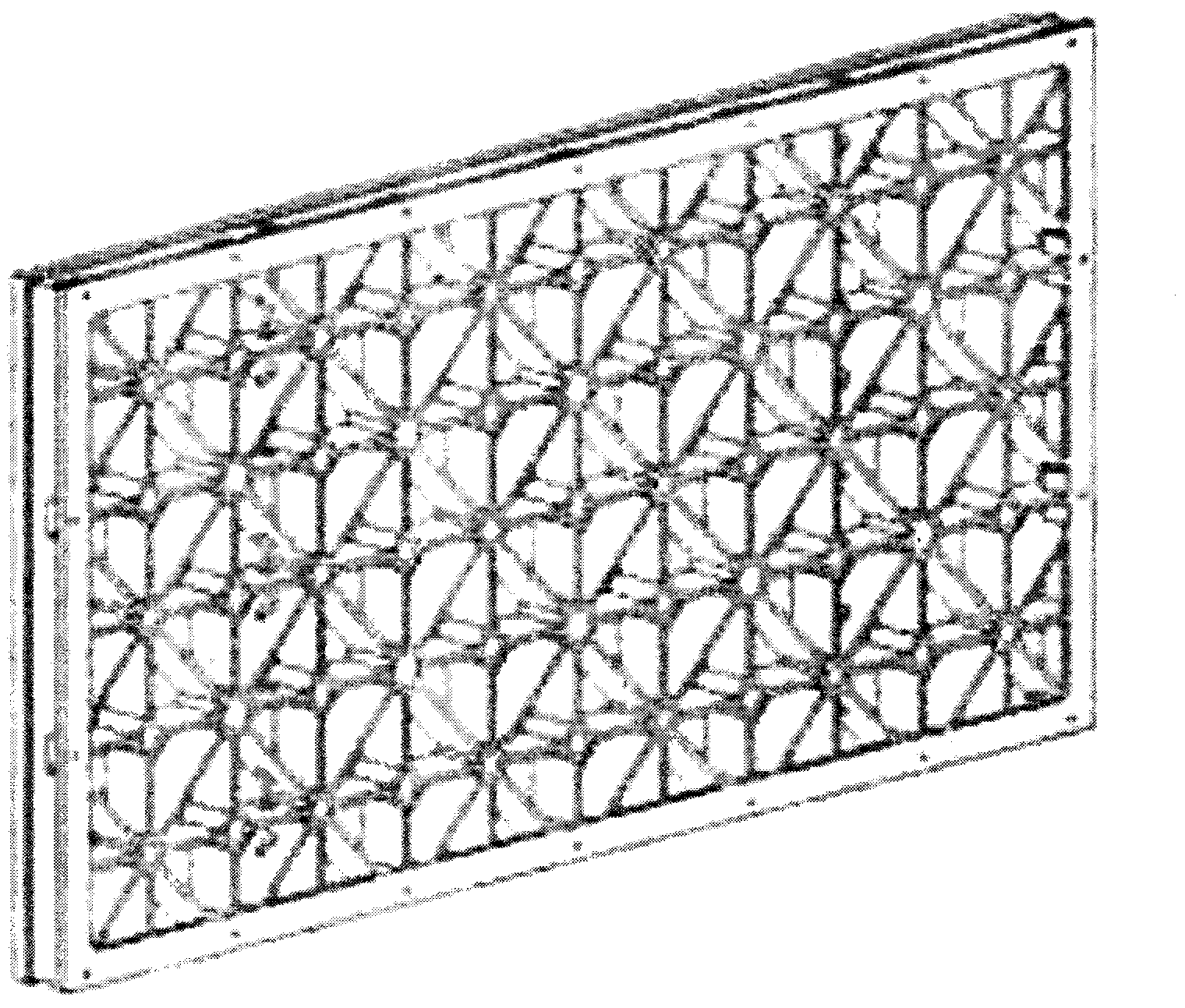

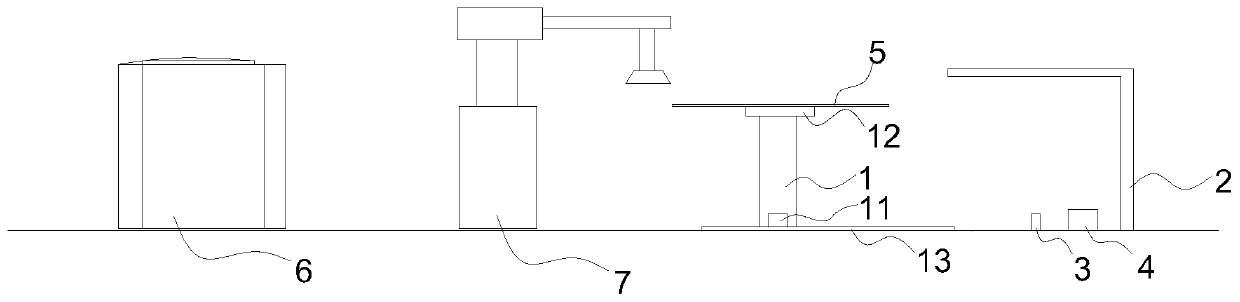

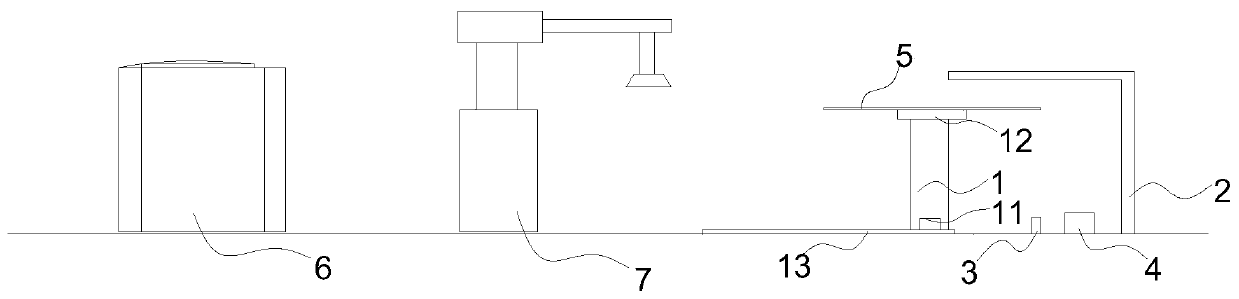

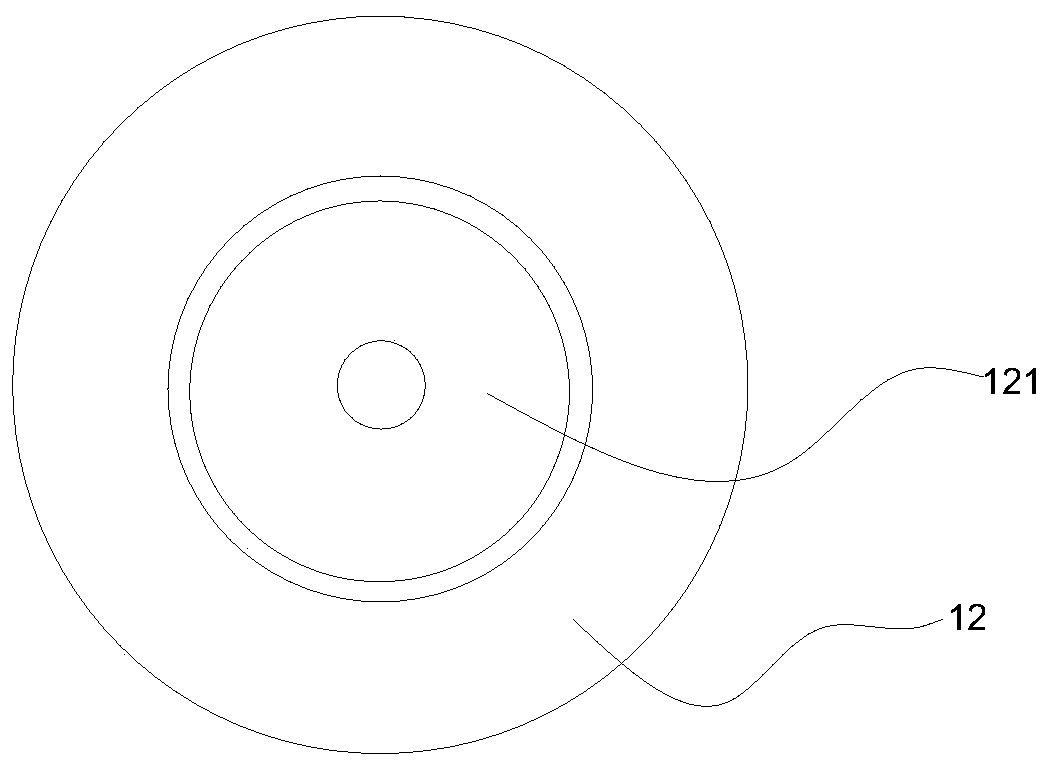

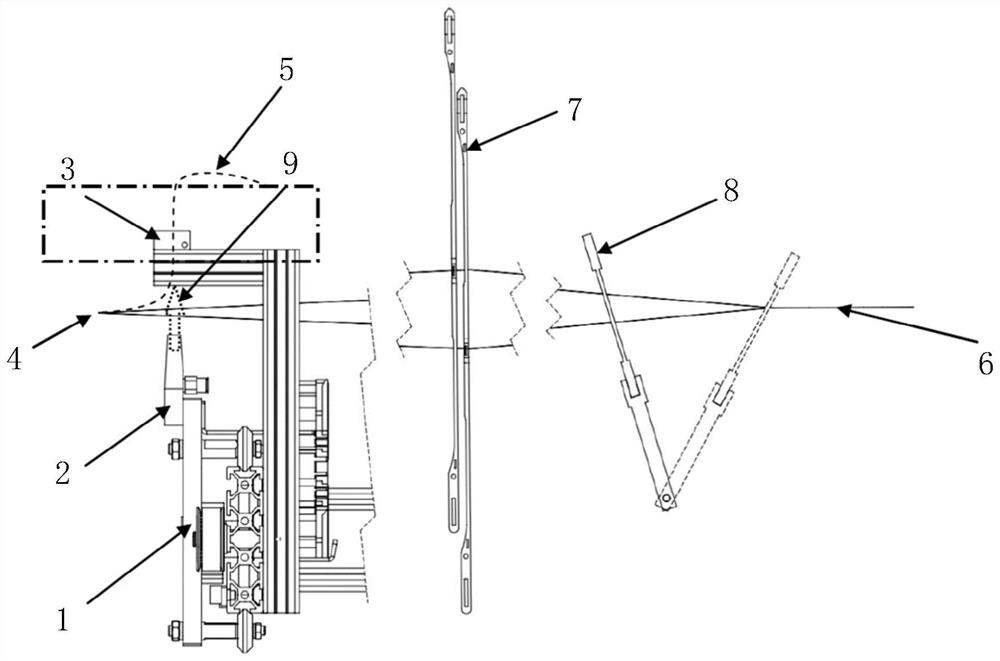

Online detector for frame assemblies

InactiveCN103234506ANo manual intervention requiredAvoid manual detection errorsMeasurement devicesVehicle frameControl system

The invention discloses an online detector for frame assemblies. The online detector for frame assemblies comprises a reference platform, a detection master, a support, a pneumatic correcting trolley, and a control system. The detection master is used for three-dimensionally detecting technical indicators such as linearity, planarity, parallelism, diagonals, coaxiality and width for a frame assembly. The support is used for storing the frame assembly to be detected. The pneumatic correcting trolley is used for calibrating the position of the frame assembly stored on the support. The frame assembly to be measured is supported by the support and is automatically calibrated by the pneumatic correcting trolley, and the technical indicators of the detection master such as linearity, planarity, parallelism, diagonals, coaxiality and width are measured by the detection master. All operations are automatically completed by the control system with no need of manual operation intervention, measurement is more efficient, artificial errors are avoided effectively, and measurement is more precise.

Owner:JILIN SAIJINDE INTELLIGENT MACHINERY MFG

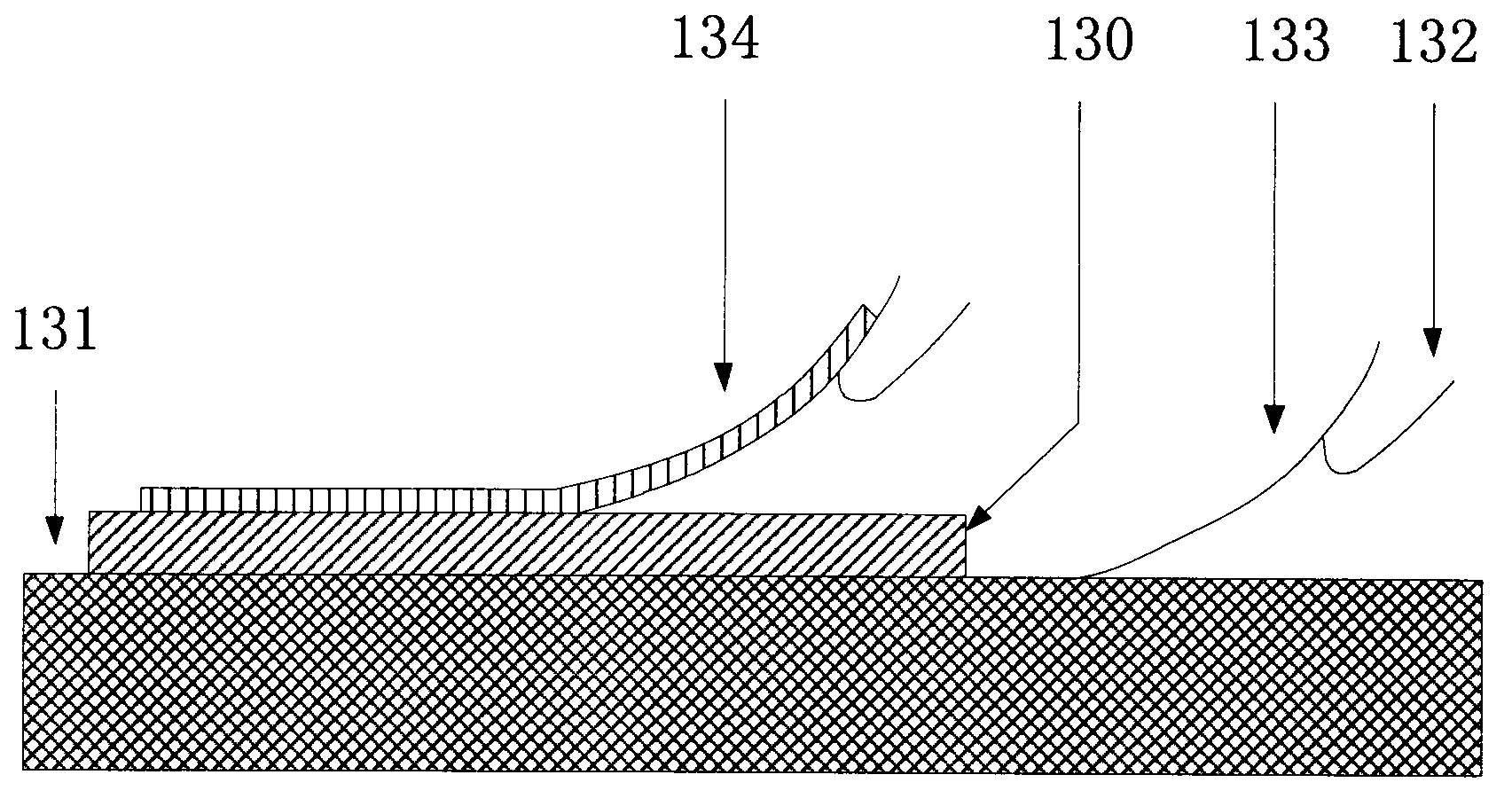

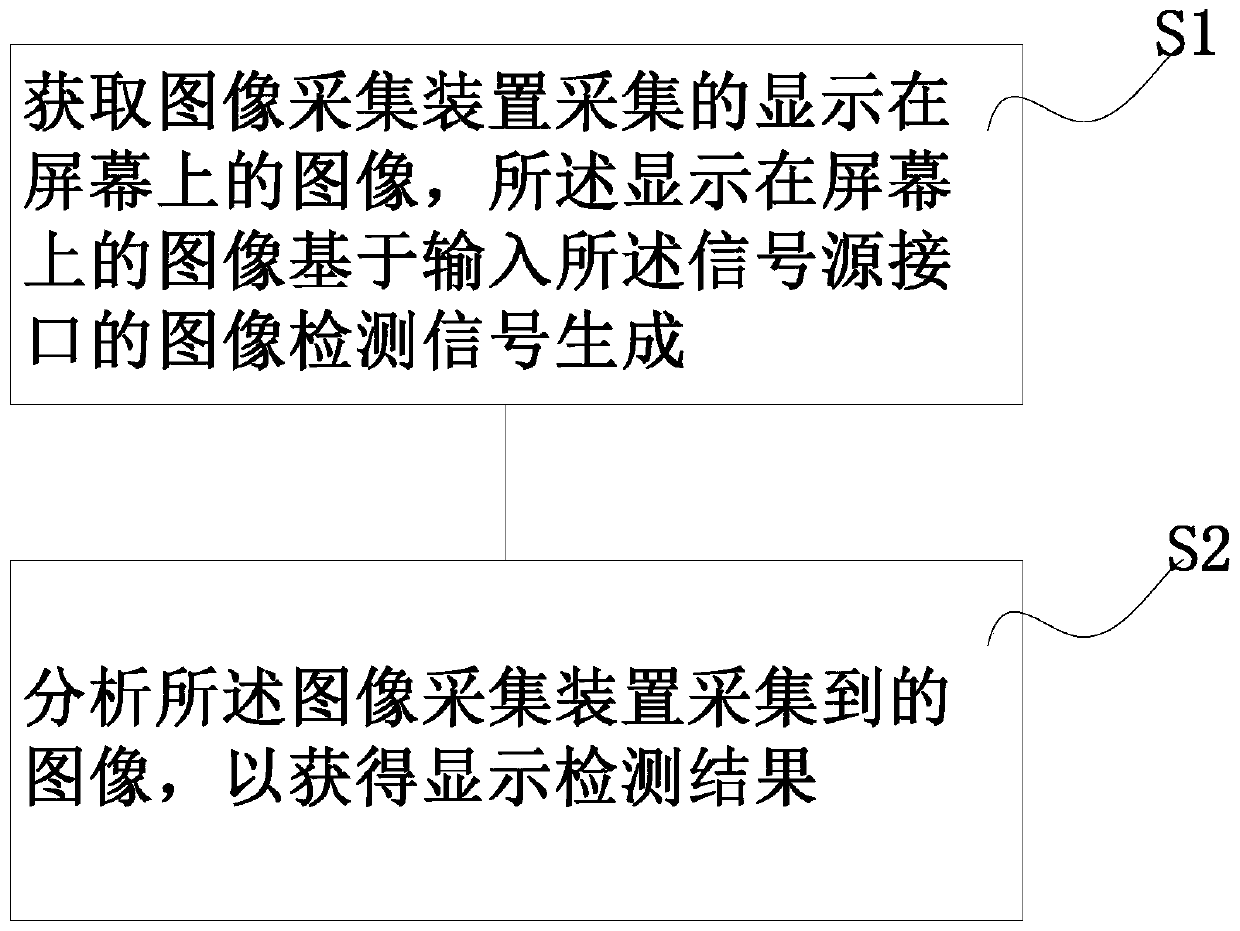

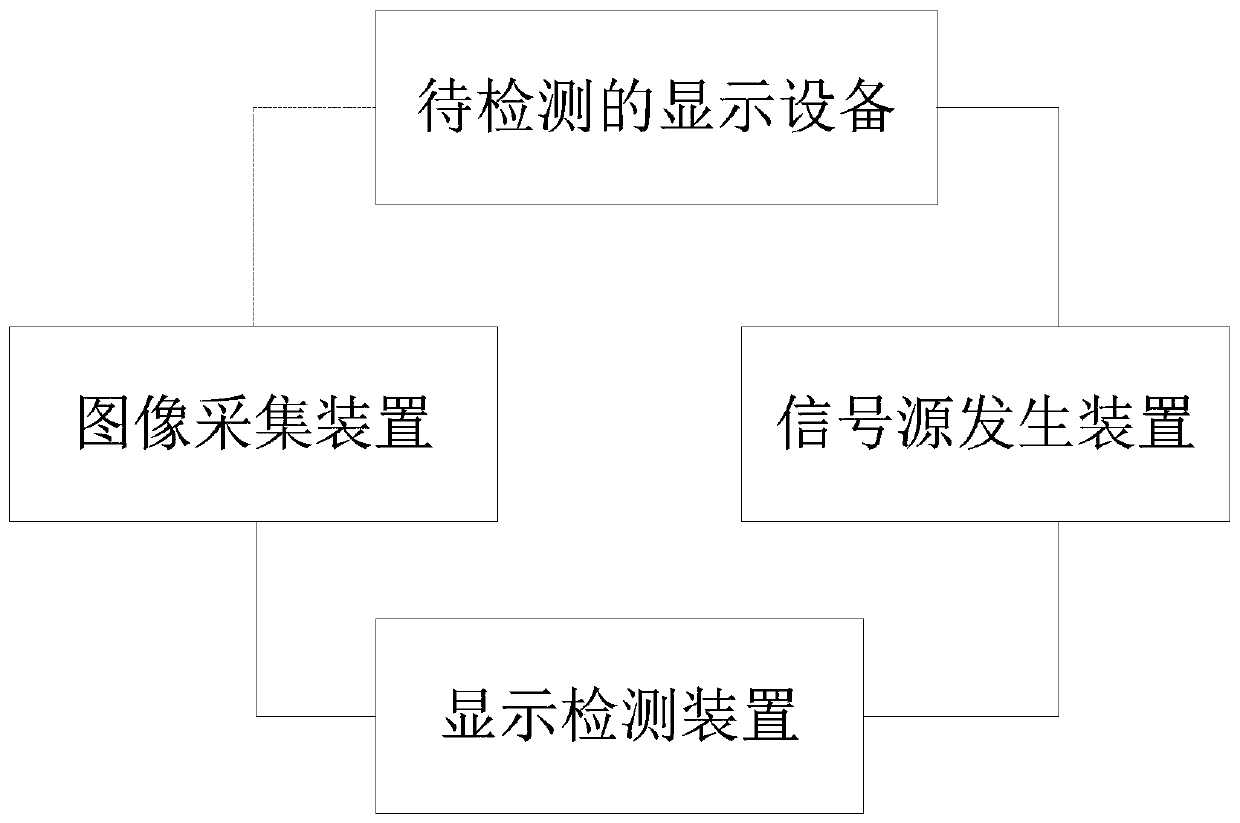

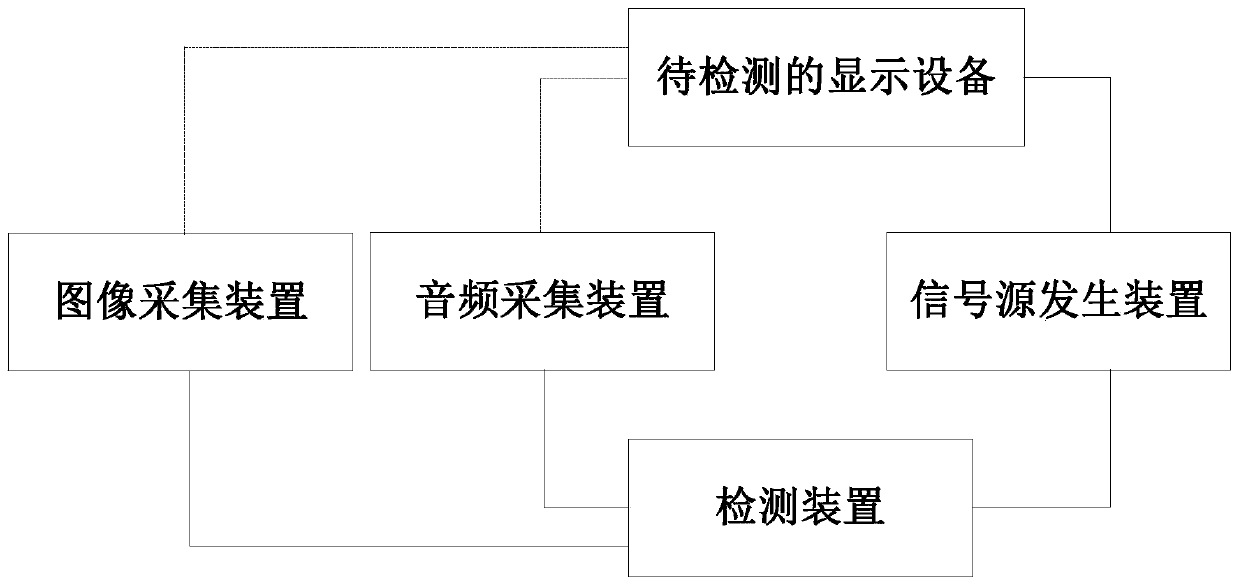

Display detection method, device and system of display equipment

InactiveCN110010044AThe test result is accurateSave time and costStatic indicating devicesOptical apparatus testingImage detectionSignal source

The invention discloses a display detection method, device and system for display equipment. According to the display detection method of the display equipment, the display equipment comprises a signal source interface, the display detection method comprises the following steps that an image, collected by an image collection device, displayed on a screen is obtained, and the image displayed on thescreen is generated on the basis of an image detection signal input into the signal source interface; and the image acquired by the image acquisition device is analyzed to obtain a display detectionresult. The display detection method provided by the invention can be used for replacing workers to detect the display equipment so as to avoid manual detection errors, such as missing detection, wrong detection and the like.

Owner:FREESENSE IMAGE TECH

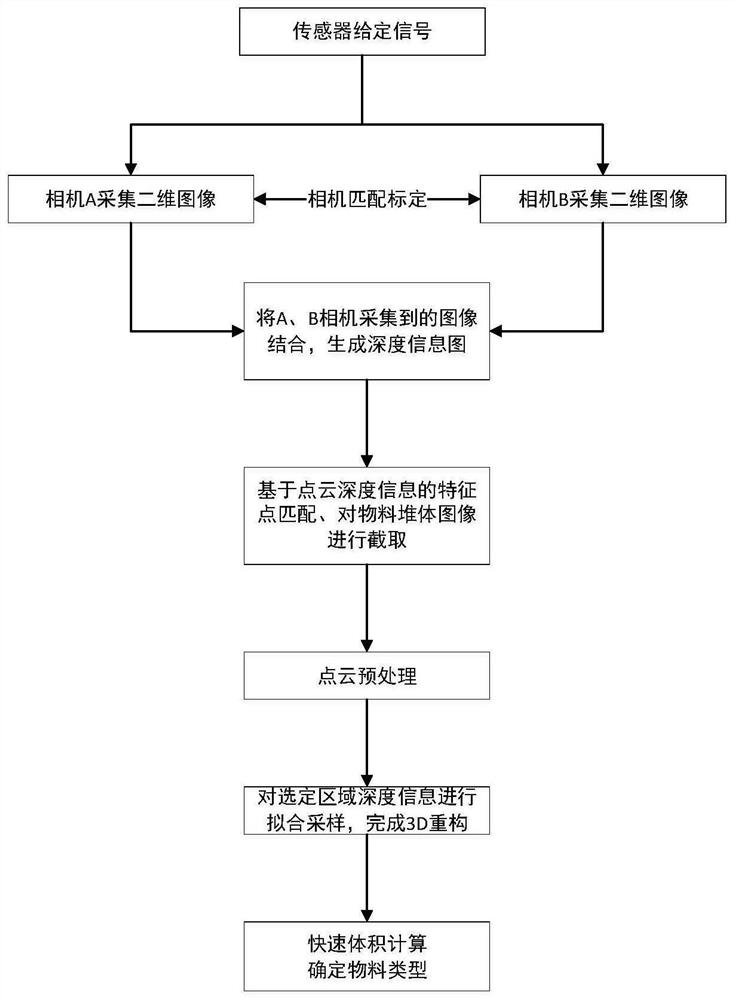

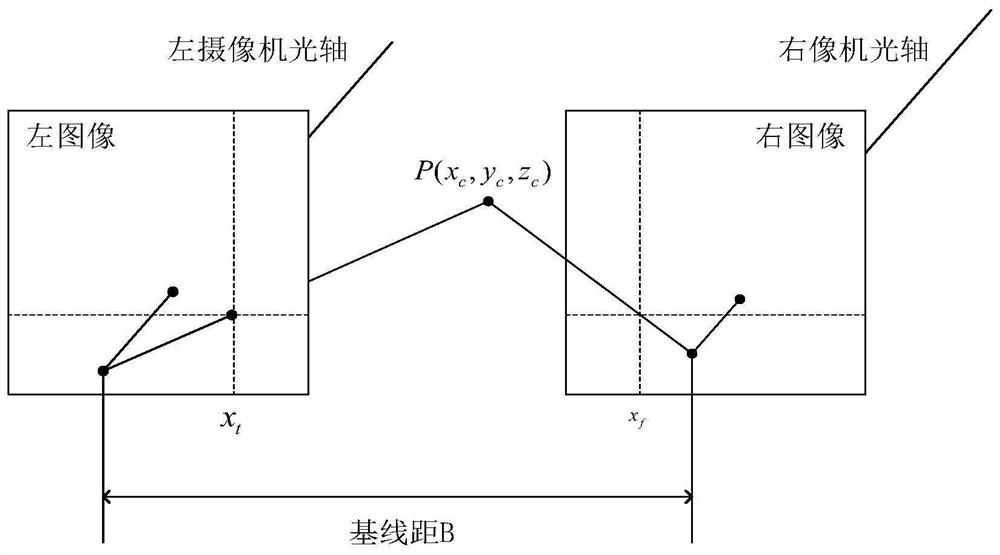

Complex material volume measurement method based on deep learning

PendingCN112053324AAvoid errorsImprove efficiencyImage enhancementImage analysisEngineeringMaterial resources

The invention provides a complex material volume measurement method based on deep learning, and the method comprises the steps: collecting a multi-angle visual field image above a pile body by employing a binocular vision camera according to the characteristic that a complex material pile body target has no obvious feature points; subjecting the depth information to fitting sampling through the relevance between images collected by a left camera and a right camera, restoring the three-dimensional model of the feature space and rapidly performing volume calculation is and inputting the calculation into the system. A binocular system not only avoids the defect that a common industrial camera cannot obtain the depth information of the reactor body, but also avoids energy loss caused by the fact that a structured light technology measurement method and the like are not used and special modulated waves need to be emitted for measurement, is associated with the recording system, and associates rapid and automatic volume measurement with the whole recording management system. The volume measurement and management of the complex slag material pile body are intelligent, the precision and efficiency of earthwork volume measurement are improved, a large amount of manpower and material resources are saved, and the volume measurement and record management process of the complex material pile body becomes simple and convenient.

Owner:SHANGHAI DIANJI UNIV

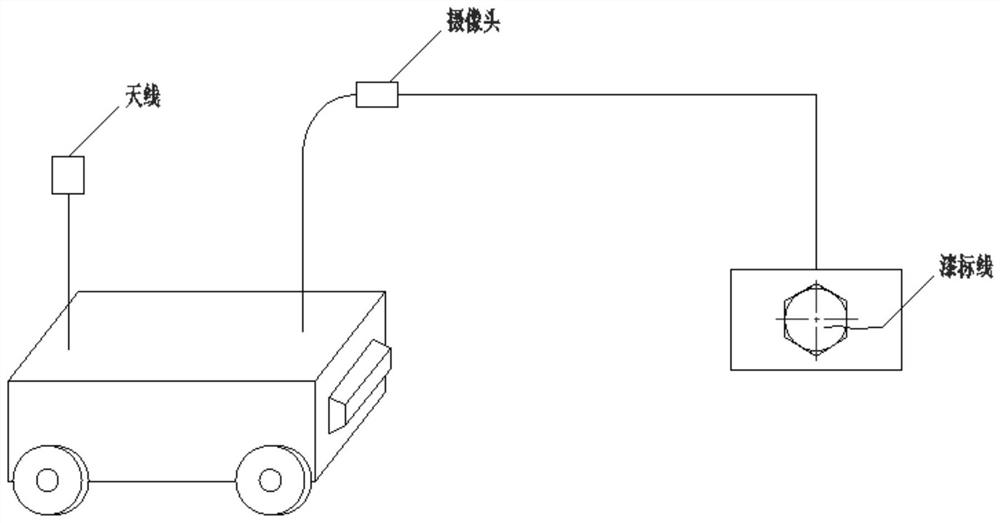

Bolt looseness detection device based on visual monitoring

InactiveCN112945437AConvenient queryAvoid detection impactMeasurement of torque/twisting force while tighteningForce measurement by measuring optical property variationVisual monitoringObstacle avoidance

The invention discloses a bolt looseness detection device based on visual monitoring. The bolt looseness detection device comprises an equipment shell, a power supply for providing power for equipment, a moving unit and an obstacle avoidance unit, the moving unit moves the equipment, and the obstacle avoidance device performs active avoidance movement when the equipment moves and encounters an obstacle; and the data acquisition module is mounted on the equipment shell and is used for identifying the anti-loosening wire on the head of the bolt or the nut. According to the technical scheme of the invention, 1, the influence of space limitation on detection is avoided; 2, the labor and time are saved, and convenience and rapidness are achieved; 3, the device is portable and mobile and adapts to various working conditions. 4, intelligent detection is achieved, rapidness and high efficiency are achieved, and errors caused by manual detection are avoided. and 5, automatic data storage, classified management, later maintenance construction and historical data query are relatively convenient.

Owner:优势博研(北京)科技有限公司

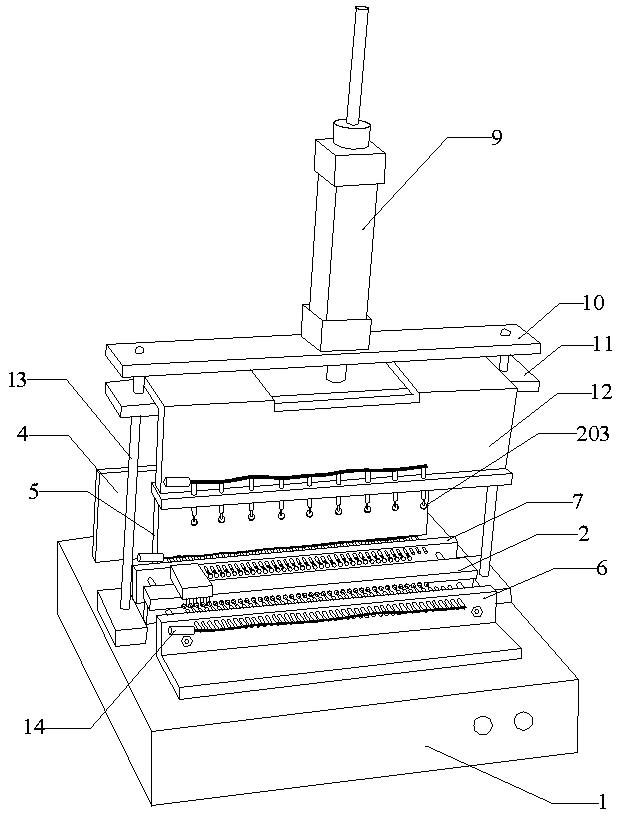

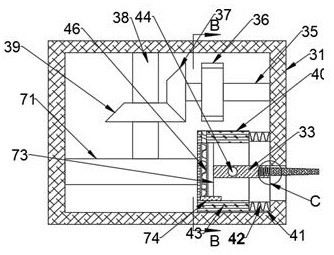

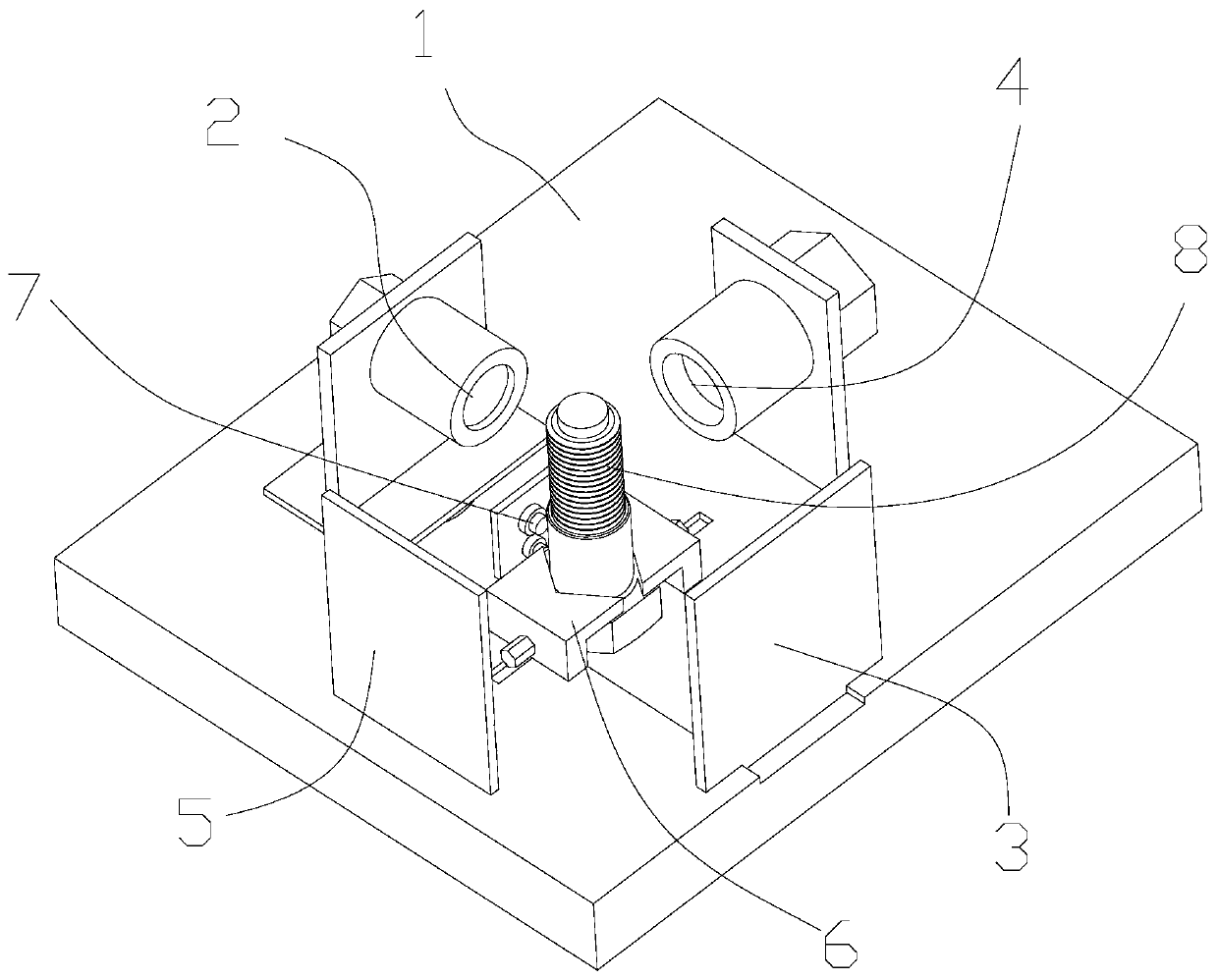

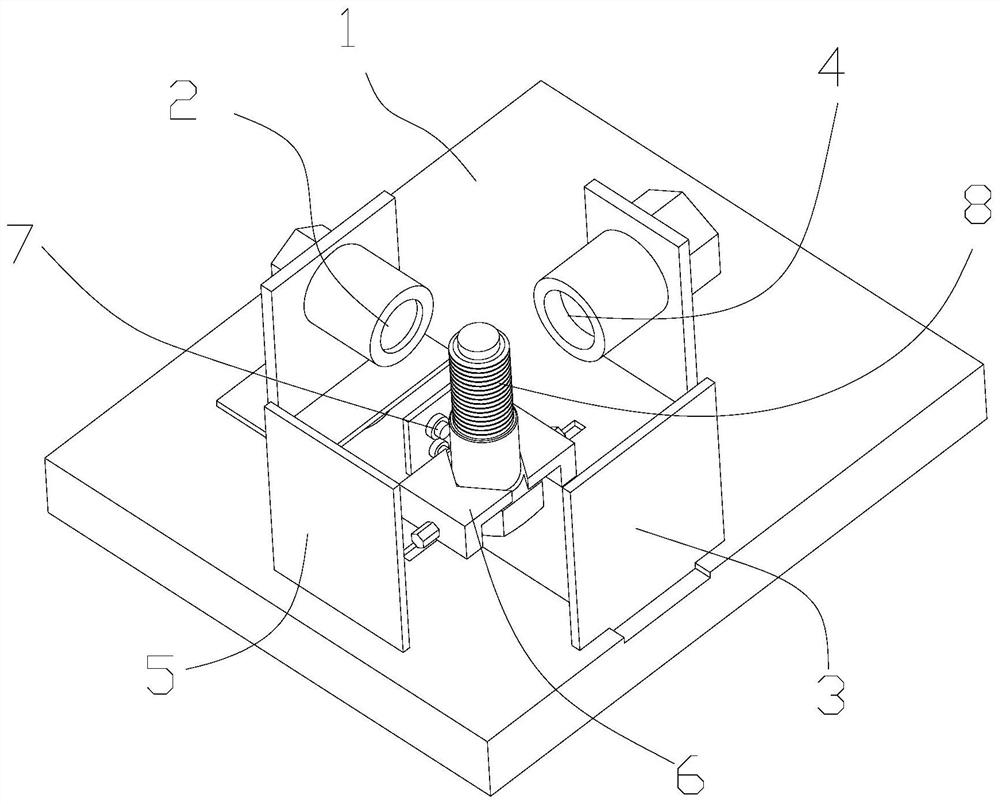

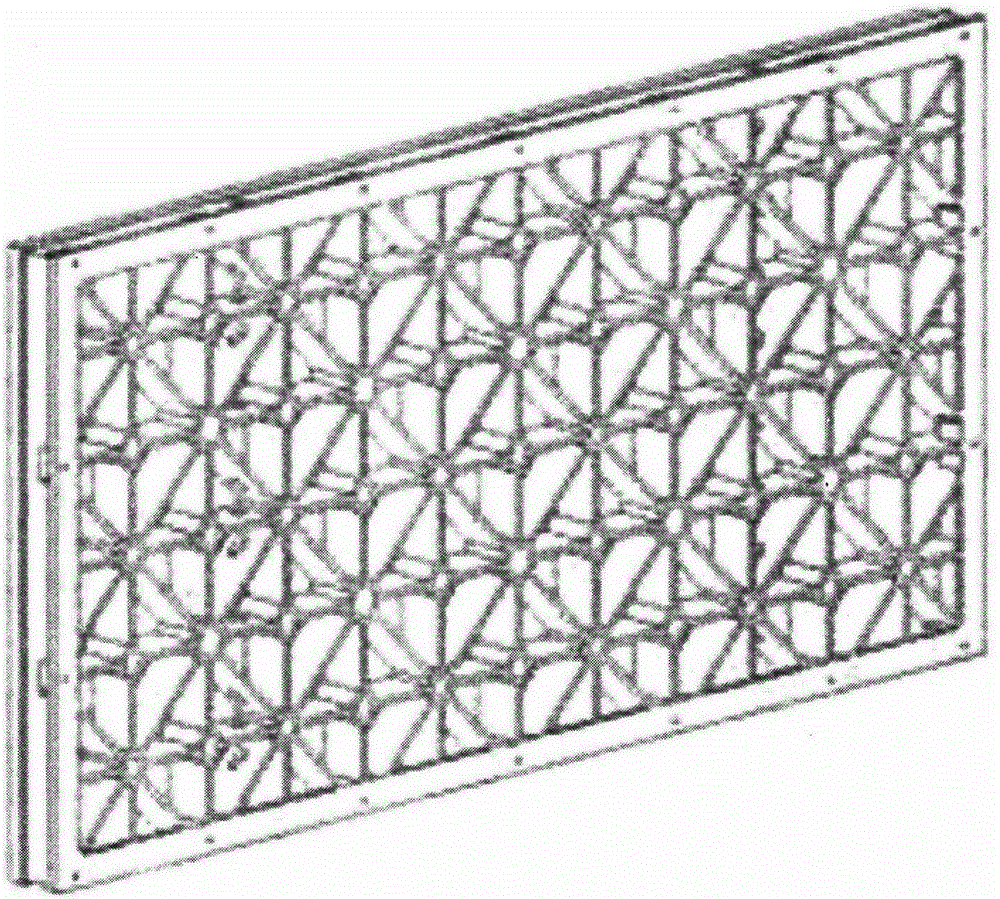

Transformer core pressure resistant test fixture

InactiveCN103267935ASimple structureEasy to operateTesting dielectric strengthTransformerEngineering

The invention discloses a transformer core pressure resistant test fixture which comprises a base and a placing board. The transformer core pressure resistant test fixture is characterized by further comprising a horizontal test assembly and a vertical test assembly. The horizontal test assembly comprises a front probe unit, a rear probe unit and a horizontal actuating mechanism used for driving the front probe unit and the rear probe unit to be close to each other. The vertical test assembly comprises an upper probe unit and a vertical actuating mechanism used for driving the upper probe unit to be close to the placing board. The transformer core pressure resistant test fixture has the advantages of being capable of testing pressure resistant performance of multiple transformer cores at a time, simple in structure, convenient to operate and capable of avoiding errors of manual tests and improving test accuracy.

Owner:KUNSHAN HEWANG ELECTRONICS

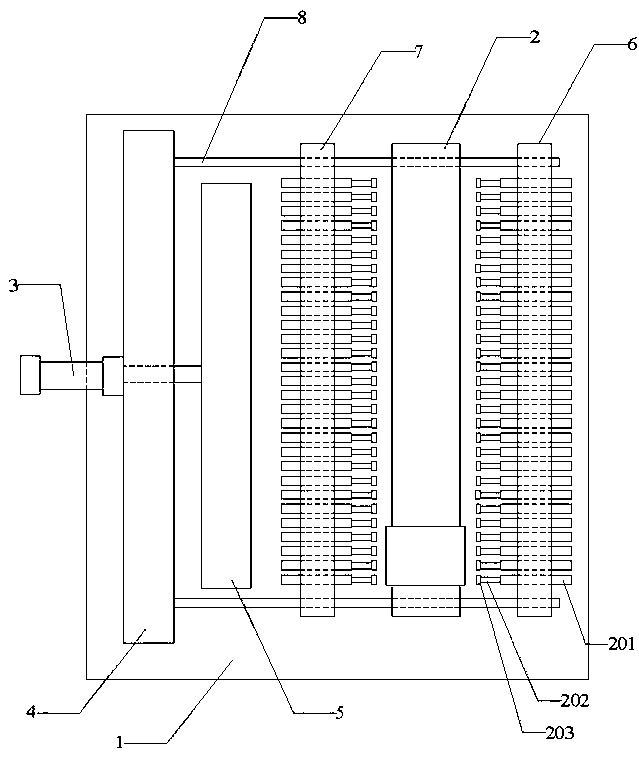

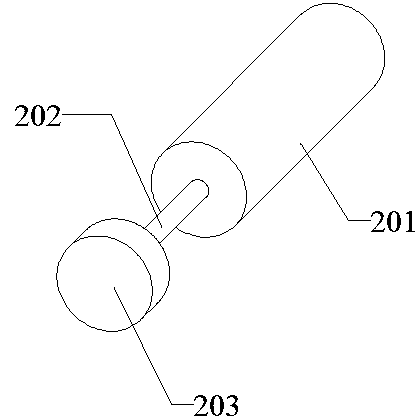

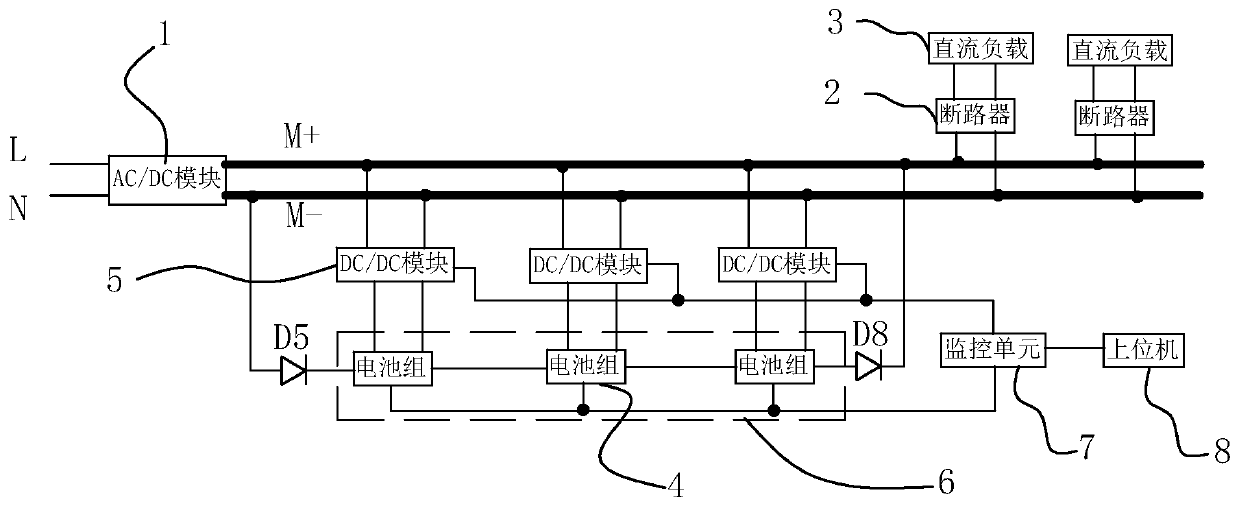

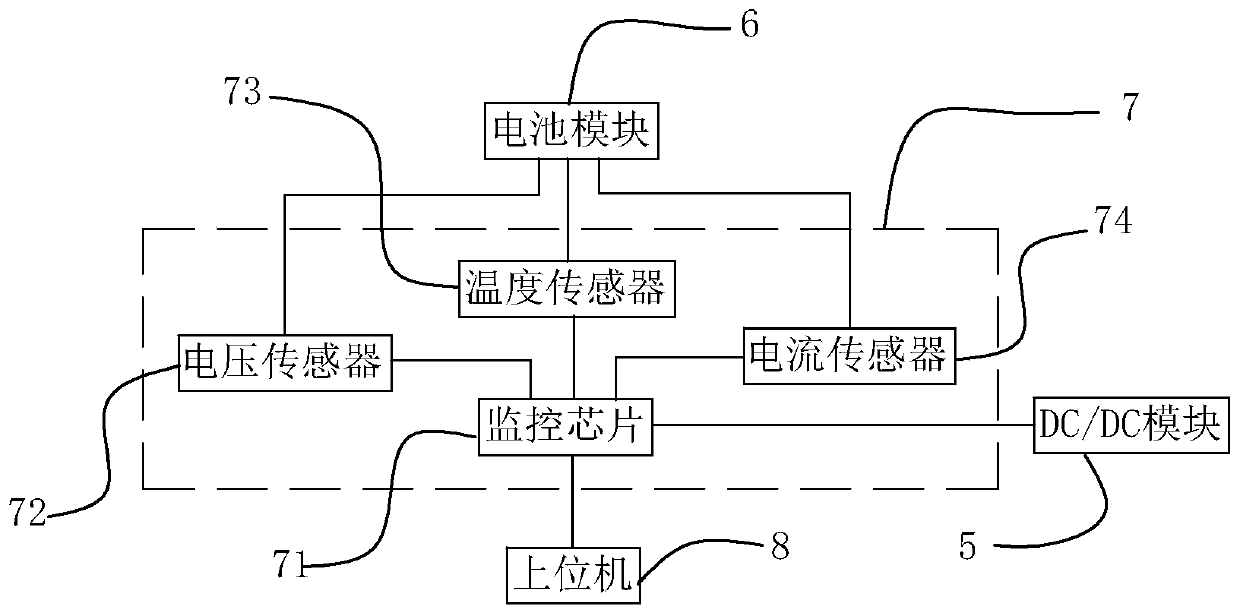

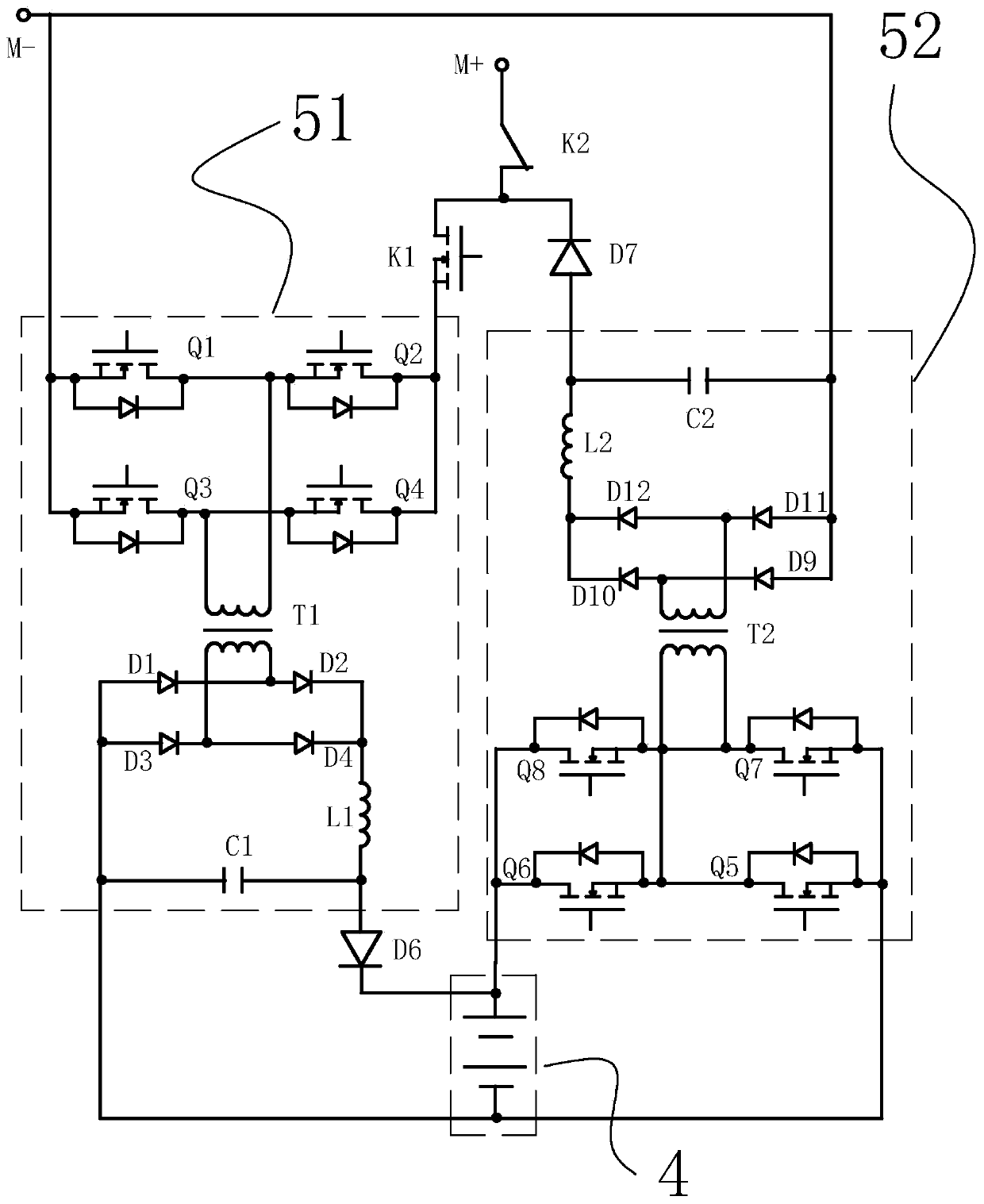

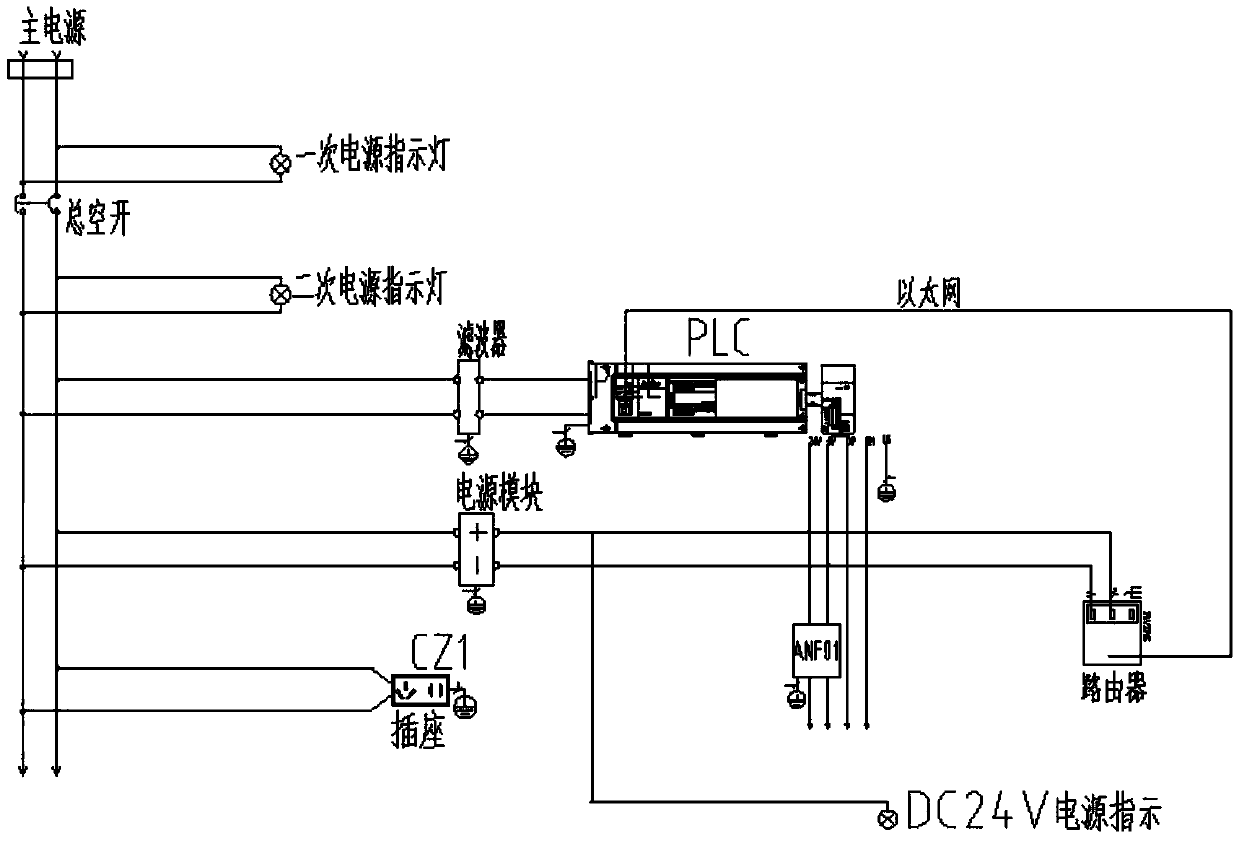

High-reliability direct-current power supply for transformer substation and inspection method

ActiveCN111049245AExtend your lifeImprove reliabilityCharge equalisation circuitDc-dc conversionElectrical batteryControl engineering

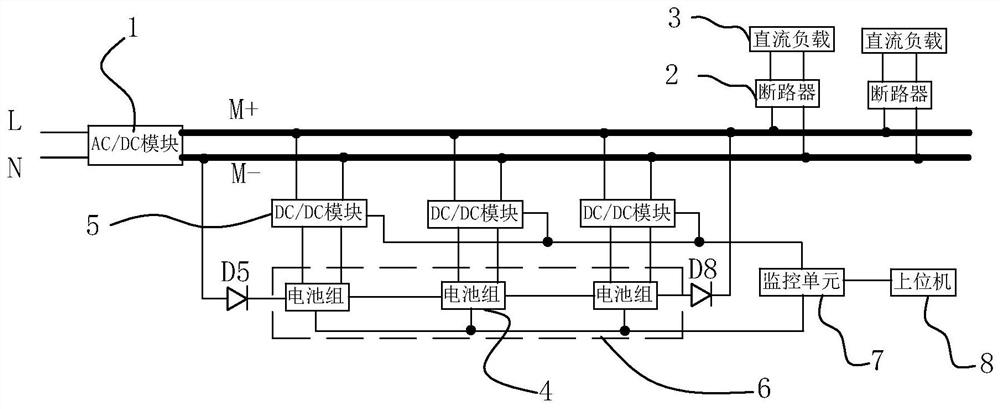

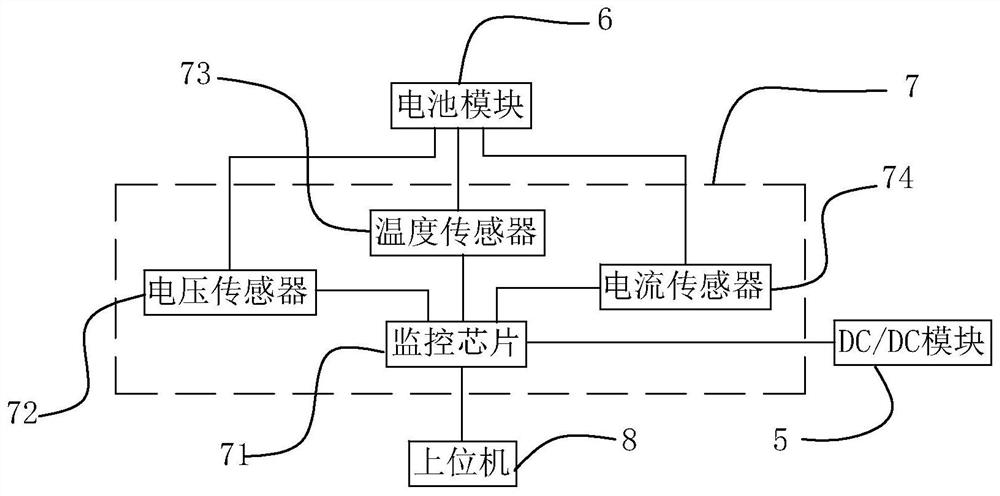

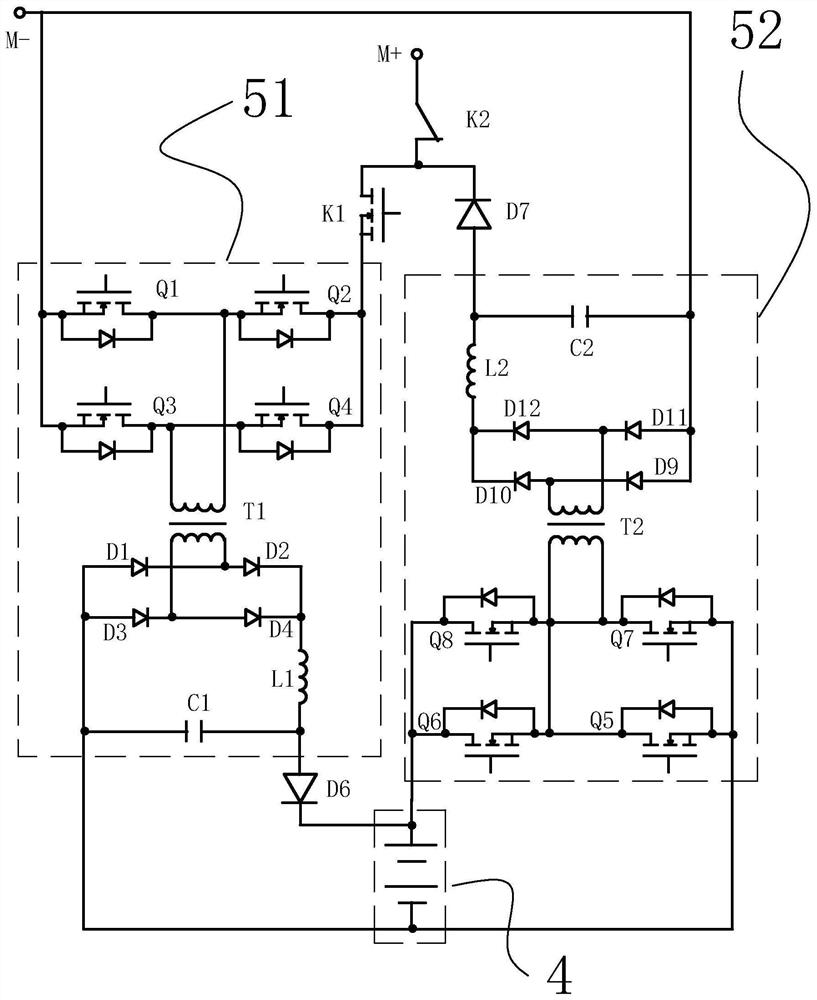

The invention discloses a high-reliability direct-current power supply for a transformer substation and an inspection method. In the prior art, direct-current power supply system battery packs are connected in series and have poor reliability; and battery fault hidden troubles cannot be completely found in a charging and discharging experiment. In order to overcome the above problems, the power supply and the method are provided in the invention. The power supply comprises a bus, an AC / DC module, a circuit breaker, a DC load, a battery module, a bidirectional DC / DC module, a monitoring unit and an upper computer, wherein the battery module includes a plurality of battery packs connected in parallel; the bidirectional DC / DC module is arranged between the direct-current bus and the battery module and indirectly controls charging and discharging of the battery module; the monitoring unit is used for monitoring data of the battery module, judging a state of the battery module according tothe data and controlling an output voltage of the bidirectional DC / DC module; and the upper computer is connected with the monitoring unit through a communication protocol, receives and stores the monitoring data, and remotely issues a control command. Power supply of a direct-current system is guaranteed, a single battery pack lag effect is avoided, and reliability is improved; the battery pack is smoother and simple in process; and 100% rated capacity check discharge of the direct-current power supply can be realized, and fault hidden dangers can be completely found.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

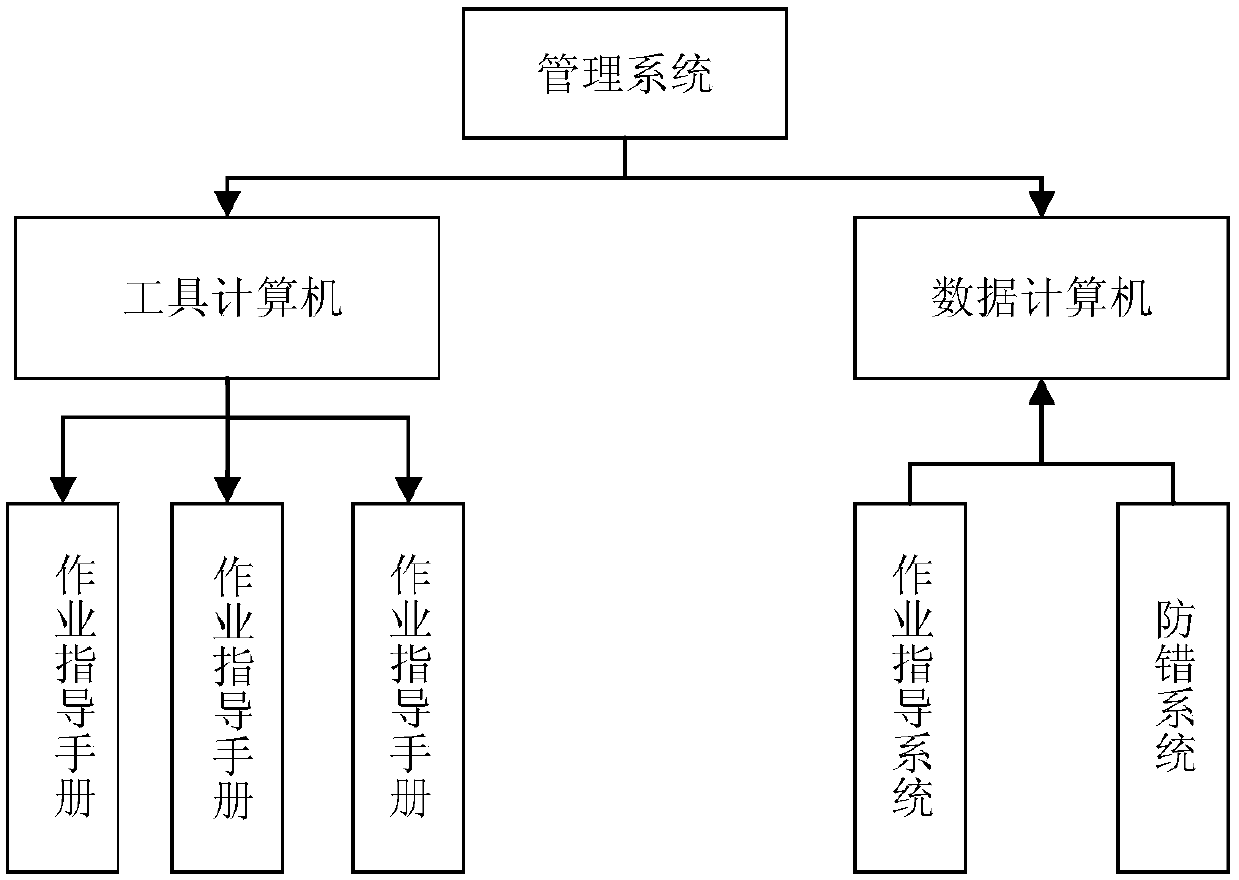

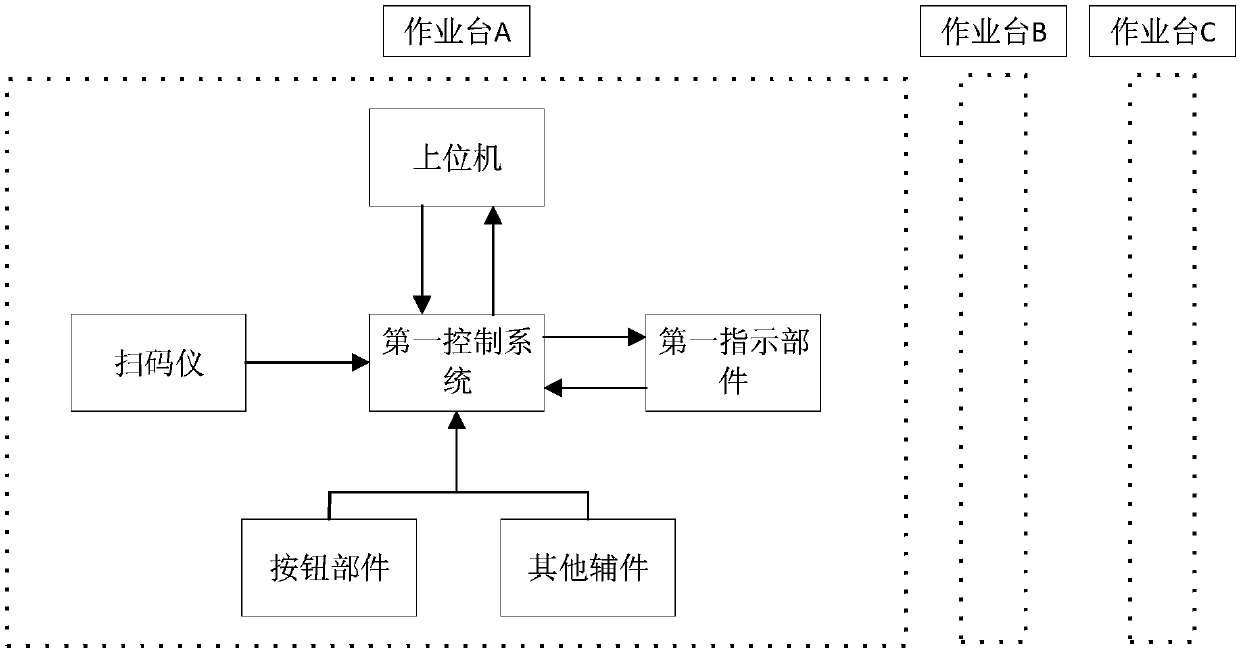

Intelligent production system and production control method for manual operation

PendingCN109542037AReduce training timeStandardization of work stepsElectrical appliancesProgramme control in sequence/logic controllersGuidance systemProduction line

The invention discloses an intelligent production system and production control method for manual operation. The system includes a management system, work guidance systems, and an error proofing system. The management system is used to manage and control the work guidance system and the error proofing system. The work guidance system is used to guide the production of a unit having multiple varieties and a small amount of products of each workbench. The error proofing system is used for prompting to prevent erroneous operations. The intelligent production system and production control method for the manual operation is oriented to a production site of the unit having multiple varieties and a small amount of products of several workbenches, and the work guidance system is used on each workbench. The entire production line is equipped with the error proofing system. At the same time, the C / S-based work guidance systems generate work instructions to synchronize to each operation station to guide the production in time. The intelligent system can standardize the process and the production and reduce the training time for newcomers so that the newcomers can directly produce according tothe instructions to avoid mistakes, thereby greatly improving the production efficiency of the manual operation.

Owner:NANJING PANDA ELECTRONICS +1

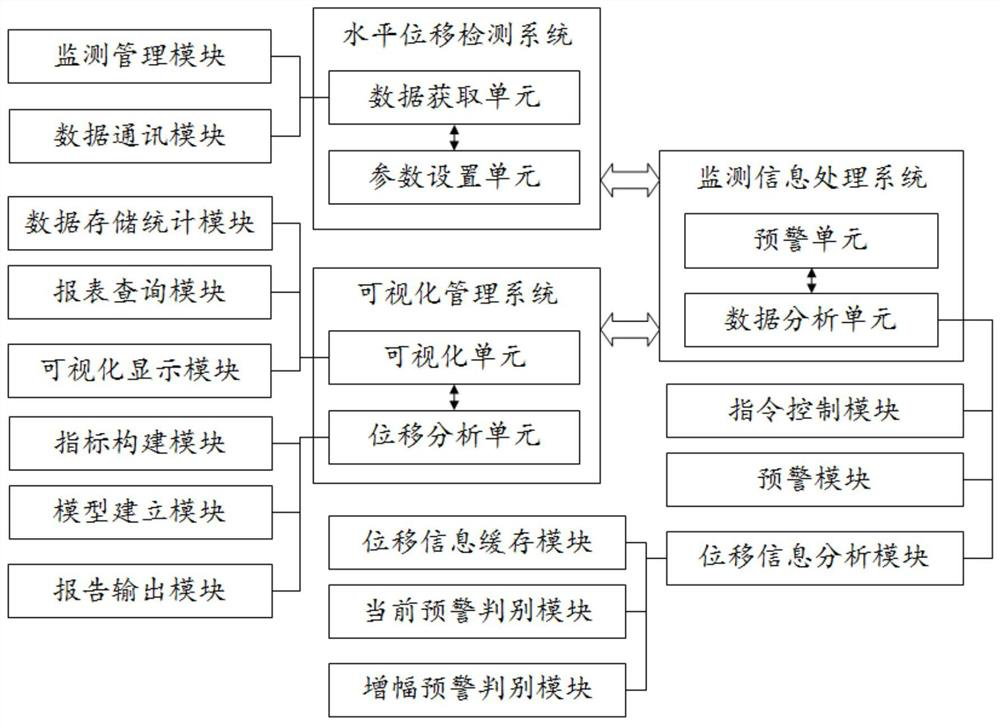

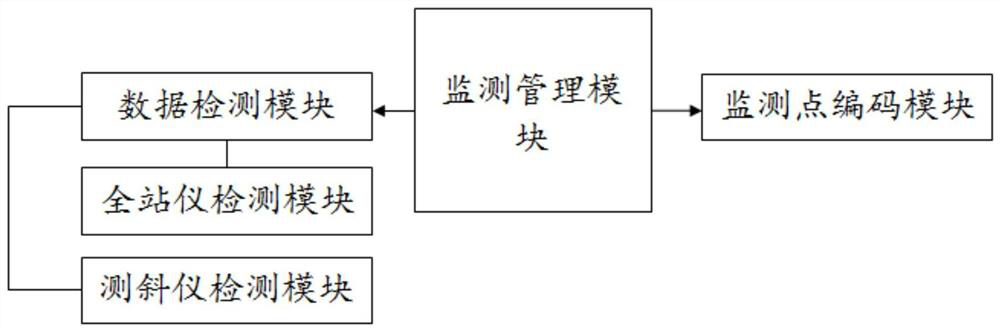

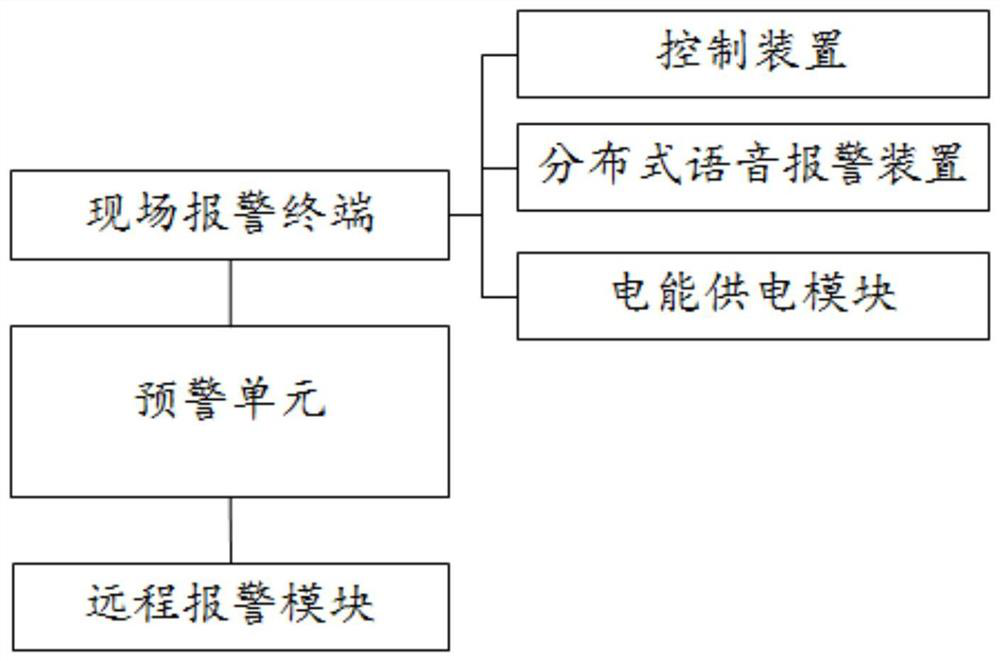

Safety monitoring system for horizontal displacement of foundation pit slope

InactiveCN113155071AAvoid manual detection errorsImprove detection accuracyMeasurement devicesInformation processingMonitoring site

The invention provides a safety monitoring system for horizontal displacement of a foundation pit slope. The safety monitoring system comprises a horizontal displacement detection system, a monitoring information processing system and a visual management system, the horizontal displacement detection system comprises a data acquisition unit and a parameter setting unit, the data acquisition unit is used for acquiring initial reading of a monitoring point and data information of each displacement change, and the parameter setting unit is used for setting acquisition parameters and an early warning judgment mode according to a user instruction; the monitoring information processing system is used for analyzing the monitoring information and outputting early warning judgment information based on an analysis result; the visual management system is connected with the monitoring information processing system, and the visual management system is used for carrying out visual display and displacement factor analysis on the monitoring data, so that manual detection errors can be effectively avoided, the detection precision and efficiency are improved, meanwhile, abnormal alarm is carried out in time, and the change influence factors of the horizontal displacement are automatically analyzed.

Owner:WENZHOU POLYTECHNIC

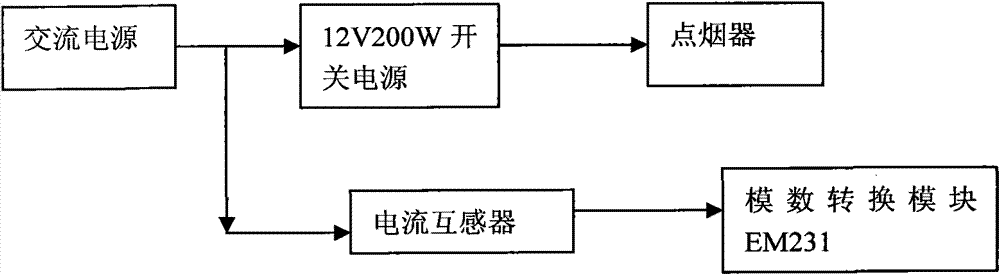

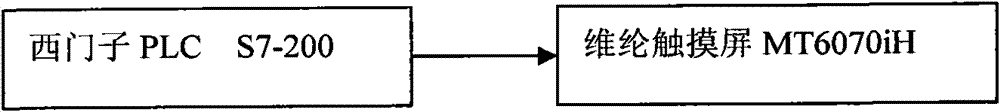

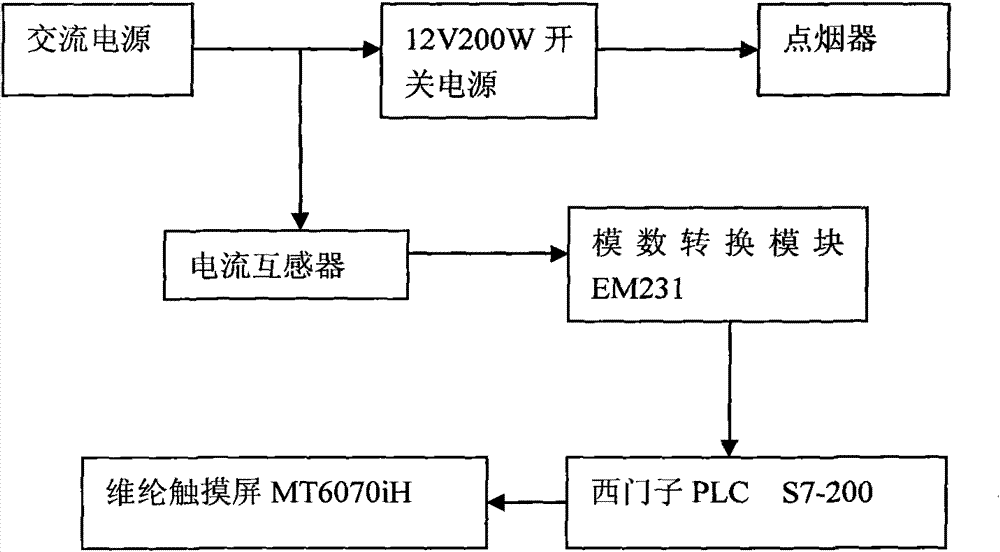

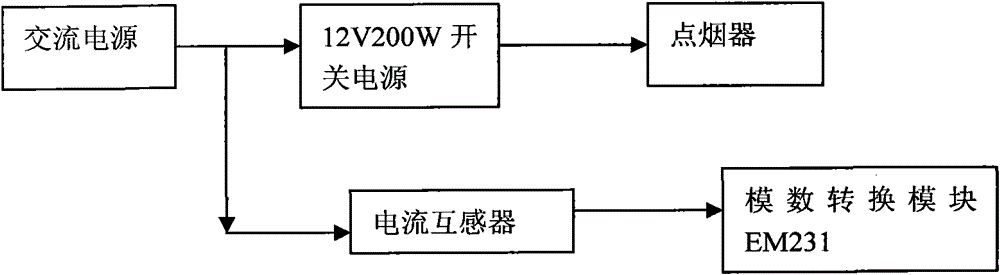

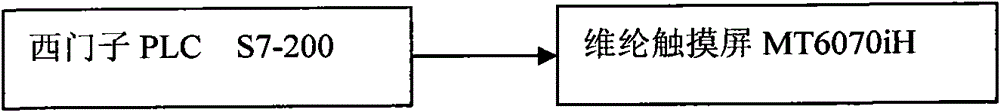

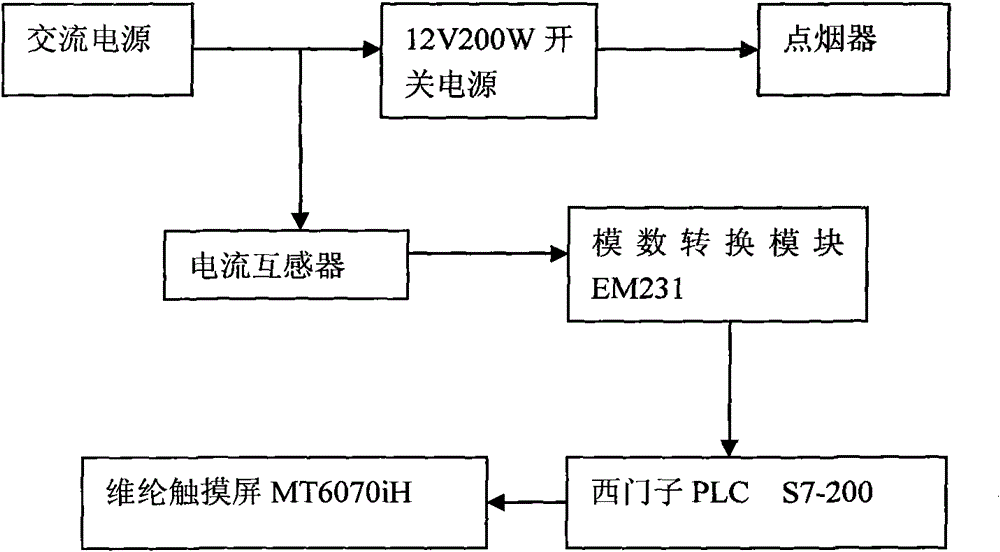

Detector of cigar lighter

InactiveCN102734835ASimple equipmentEasy to operateCombustion ignitionAnalog to digital conversionProgrammable logic controller

The invention discloses a detector of a cigar lighter. The detector comprises a signal detection acquisition system and a data detection process and display system, wherein the signal detection acquisition system consists of alternating current, a switching power supply, a current transformer and an analog-to-digital conversion module EM231, the alternating current is electrically connected with the switching power supply, the switching power supply is electrically connected with the cigar lighter, the current transformer is in parallel connection with a branch circuit which is connected with the cigar lighter, and the current transformer is connected with the analog-to-digital conversion module EM231; and the data detection process and display system consists of a SIMENS PLC (programmable logic controller) and a touch screen, and the SIMENS PLC S7-200 is connected with the analog-to-digital conversion module EM231 by signals and is electrically connected with the touch screen. The detector of the cigar lighter, disclosed by the invention, can finally detect a finished product of the cigar lighter, avoids unknown errors in an assembly process, and has the advantages of simple device, convenience for operation and good visualization effect.

Owner:QINGDAO HUATE AUTOMATION EQUIP

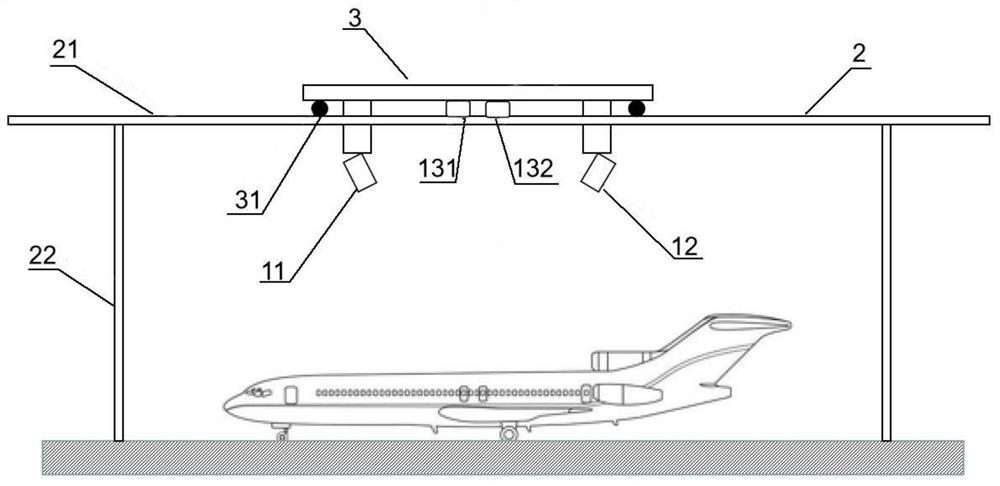

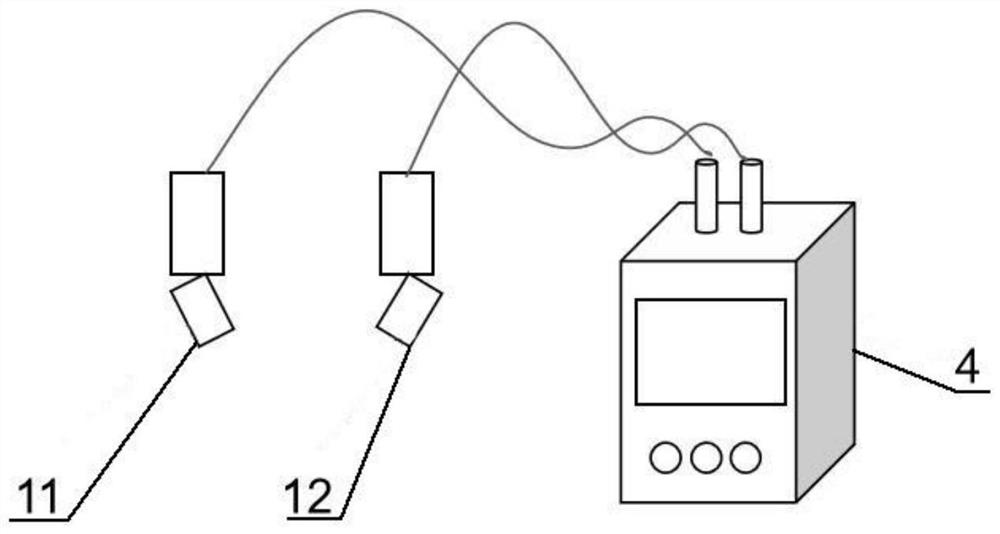

Aircraft deformation scanning detection equipment and detection method

The invention relates to airplane deformation scanning detection equipment and a detection method. The detection equipment comprises a detection system, a sliding track, a sliding platform and a data processing and control box, the detection system comprises a structured light emitting module, a structured light receiving module and a deformation analysis system, the structured light emitting module comprises a laser, a structured light lens and a laser controller, and the structured light receiving module comprises an industrial camera, a lens and a camera controller. The deformation analysis system comprises a laser and industrial camera synchronization system, a laser and industrial camera position detection module, a non-deformation aircraft template database and a data comparison system. And the data processing and control box realizes query of the non-deformation airplane template database, and completes comparison through the data comparison system so as to judge whether the airplane is deformed or not. Structured light is combined with a computer vision technology, so that the detection equipment and the detection method are high in feasibility, simple to operate and accurate in detection.

Owner:HENAN UNIV OF SCI & TECH

Manual carving and machine carving automatic distinguishing device

InactiveCN112577963APrevent being cheatedAvoid manual detection errorsOptically investigating flaws/contaminationBilateral symmetryIndustrial engineering

The invention discloses a manual carving and machine carving automatic distinguishing device which comprises a machine body and a detection cavity formed in the machine body. Entrances and exits communicating with the outside are symmetrically formed in the left wall and the right wall of the detection cavity, a first electric sliding rail is arranged on the bottom wall of the detection cavity, afirst sliding block is arranged on the first electric sliding rail in a sliding mode, an electric rotating shaft is rotationally arranged at the upper end of the first sliding block, a bottom plate isfixedly arranged on the electric rotating shaft, a second electric sliding rail is arranged at the upper end of the bottom plate, and clamping blocks are arranged on the second electric sliding railin a bilateral symmetry sliding mode. The radian of the convex part on the carving image can be automatically detected. If the radian of the convex part is more smooth, the work is carved by a machine, so that manual detection is not needed, errors caused by manual detection are avoided, meanwhile, whether the lower end of the convex part of the image sinks inwards or not can be detected, whetherthe work is carved manually or not is judged, the detection accuracy is improved, and a purchaser is prevented from being cheated easily.

Owner:广州钇普科技有限公司

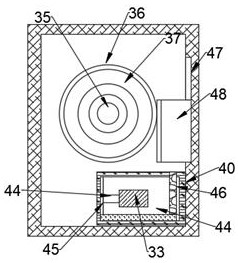

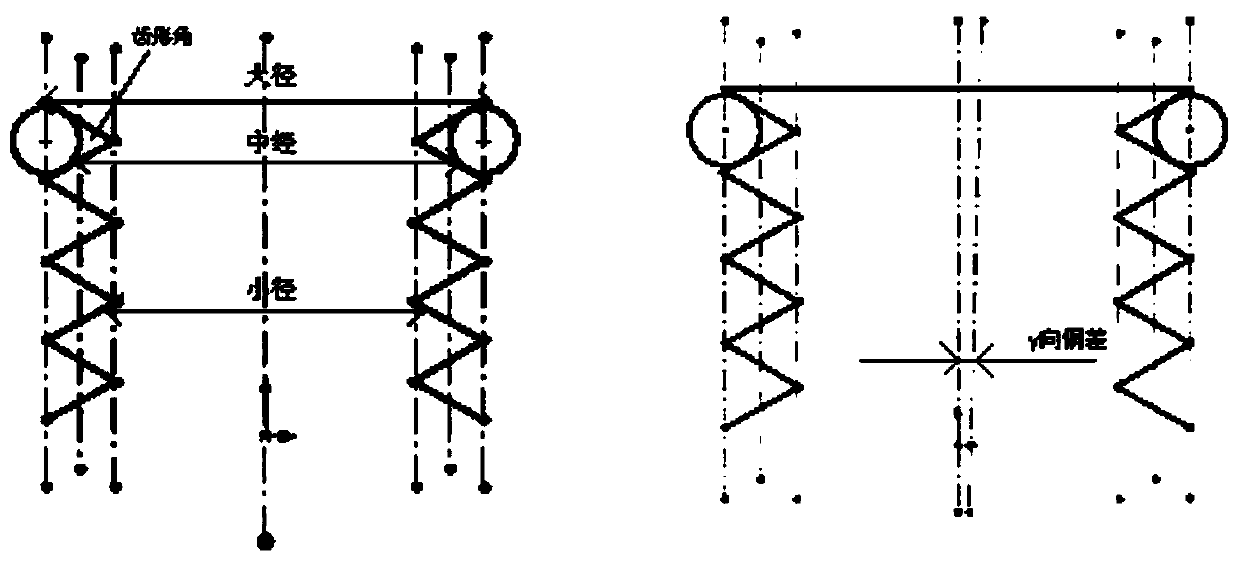

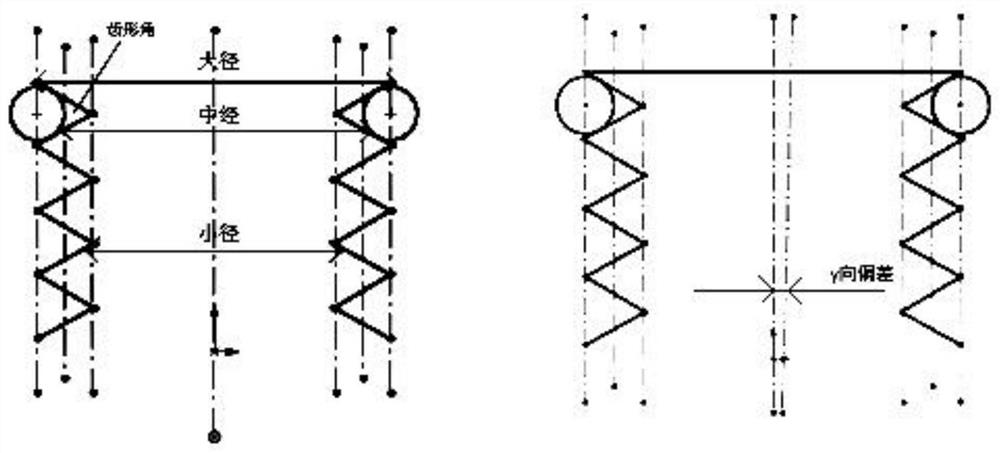

Screw thread go/no-go detection device and detection method

ActiveCN110631490AImplement automatic image detectionAvoid manual detection errorsUsing optical meansEngineeringWorkbench

The invention relates to a screw detection device, in particular, a screw thread go / no-go detection device and detection method. The device comprises a workbench; the workbench is provided with a clamping mechanism used for clamping a to-be-tested screw; the workbench is also provided with an X-direction main camera; a first backlight plate is opposite to the X-direction main camera; the workbenchis further provided with a Y-direction auxiliary camera; and a second backlight plate is opposite to the Y-direction auxiliary camera. According to the screw thread go / no-go detection device and detection method of the invention, the X-direction camera and the Y-direction camera are adopted for obtaining and correcting parameters such as screw tooth shapes under a backlight condition, and the automatic image detection of screw threads is achieved.

Owner:JIANGSU UNIV OF TECH

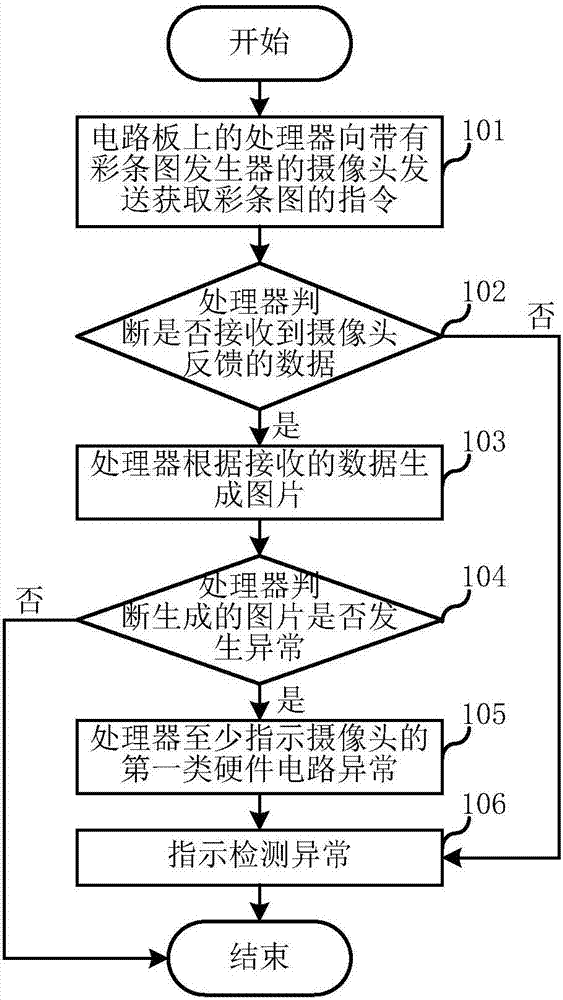

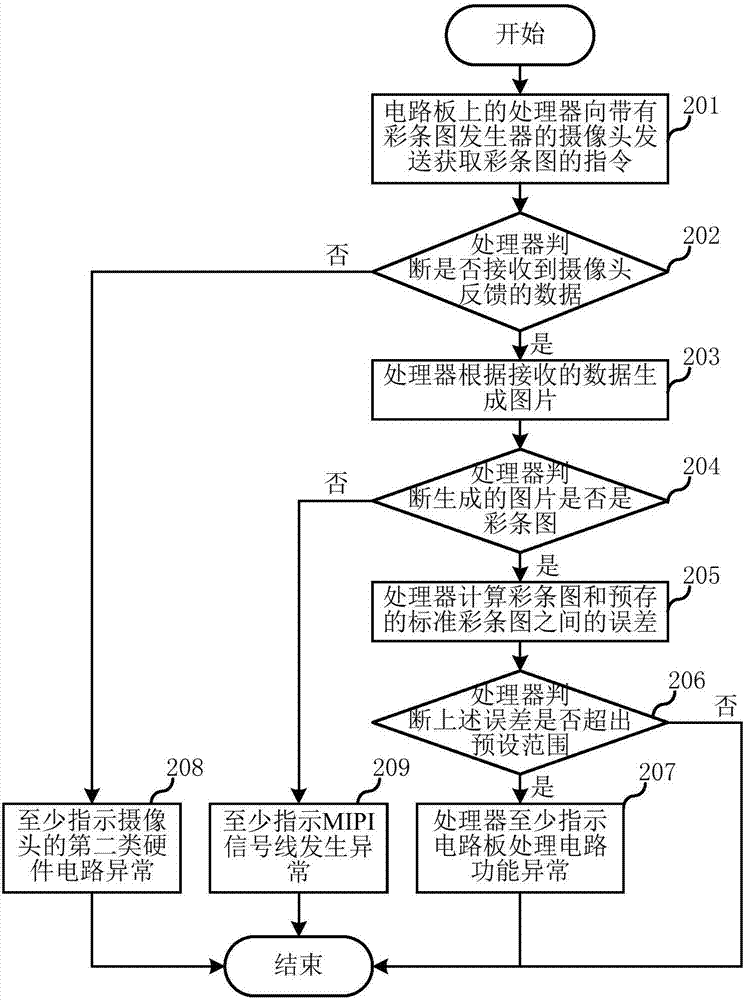

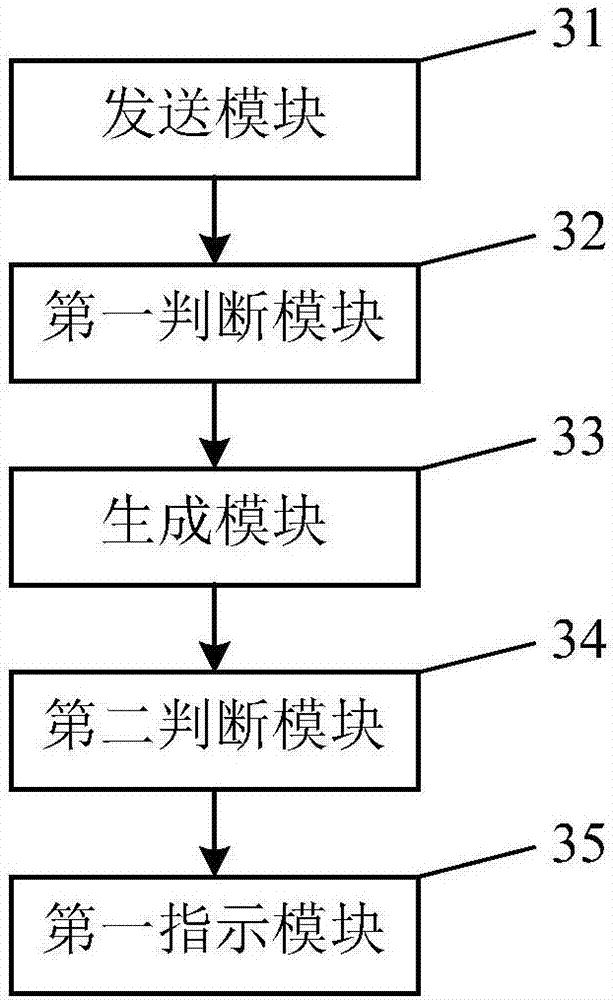

Method, device and system for detecting camera hardware circuit

InactiveCN106973286ARealize automated detectionShort test cycleTelevision systemsComputer hardwareMaterial resources

The invention relates to the field of communication, and discloses a method, device and system for detecting a camera hardware circuit. The method for detecting the camera hardware circuit comprises the following steps: sending an instruction of acquiring color bar patterns to a camera with a color bar pattern generator; when receiving the data fed back by the camera, generating a picture according to the data; and when the generated picture is abnormal, at least indicating that the first type of hardware circuit of the camera is abnormal. The invention also discloses a device and system for detecting the camera hardware circuit. Compared with the prior art, by adopting the method, device and system disclosed by the invention, the automatic detection of the camera hardware circuit can be achieved to ensure that the testing cycle is shorter and the detection result is more accurate, errors caused by manual detection can be avoided, the manpower and material resources can be saved, and the cost of production and manufacturing can be saved.

Owner:SHANGHAI YUDE TECH CO LTD

Wafer center calibration method and device

ActiveCN110729226AQuick filterImprove calibration efficiencySemiconductor/solid-state device manufacturingInformation controlWafer

The invention relates to a wafer center calibration device. The wafer center calibration device comprises a carrying platform, a blocking platform, a distance measuring sensor and a controller; the top surface of the carrying table is higher than the distance measuring sensor; the distance measuring sensor is arranged on one side of the carrying table; the blocking platform is located over the distance measuring sensor; the carrying platform is used for carrying a wafer and driving the wafer to move; the distance measuring sensor is used for acquiring horizontal distance information and vertical distance information; and the controller is connected with the distance measuring sensor and is used for controlling the carrying platform to rotate by a preset angle or controlling the carrying platform to move close to or away from the distance measuring sensor. According to the wafer center calibration device of the invention, the controller is used for processing the information of the distance measuring sensor and judging a wafer of which the center position deviates. With the wafer center calibration device adopted, the wafer of which the center position deviates can be rapidly screened out; the center calibration efficiency of the wafer is improved; and errors of manual detection are effectively avoided.

Owner:福建省福联集成电路有限公司

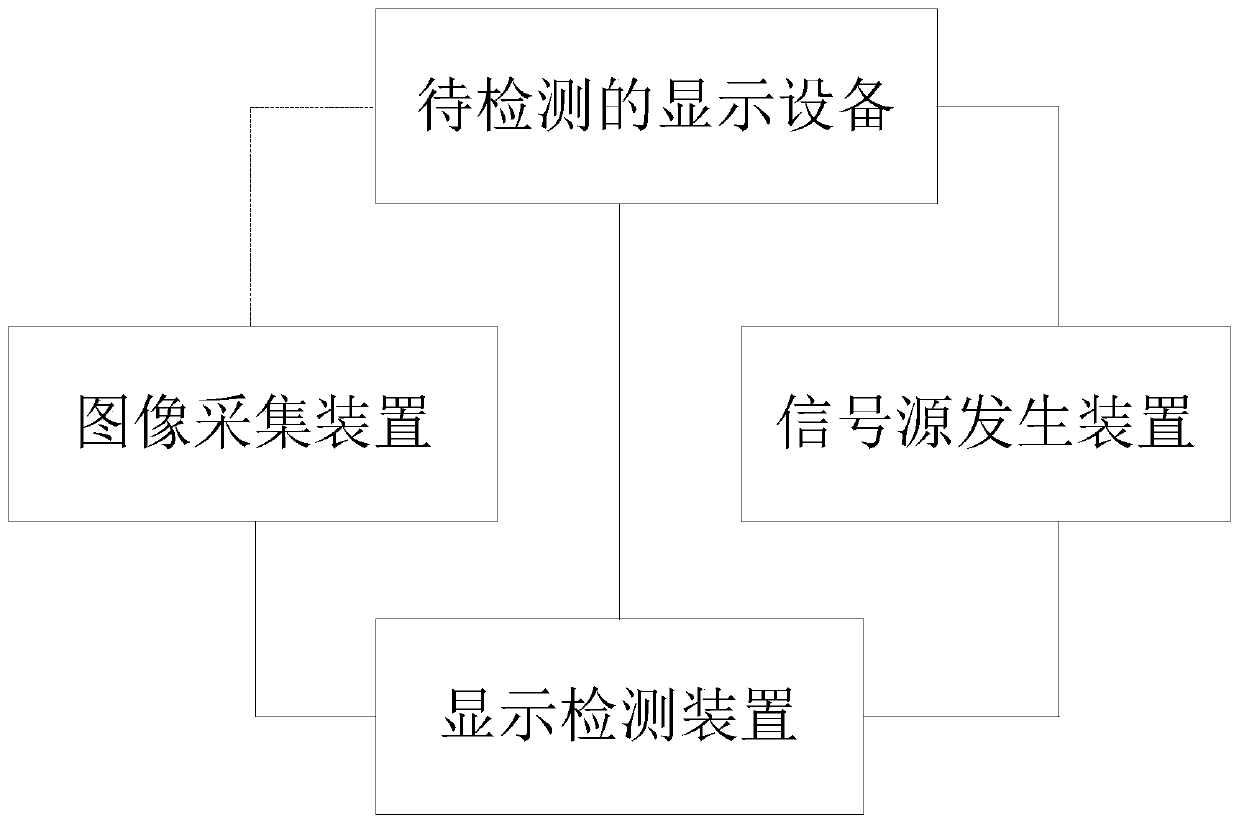

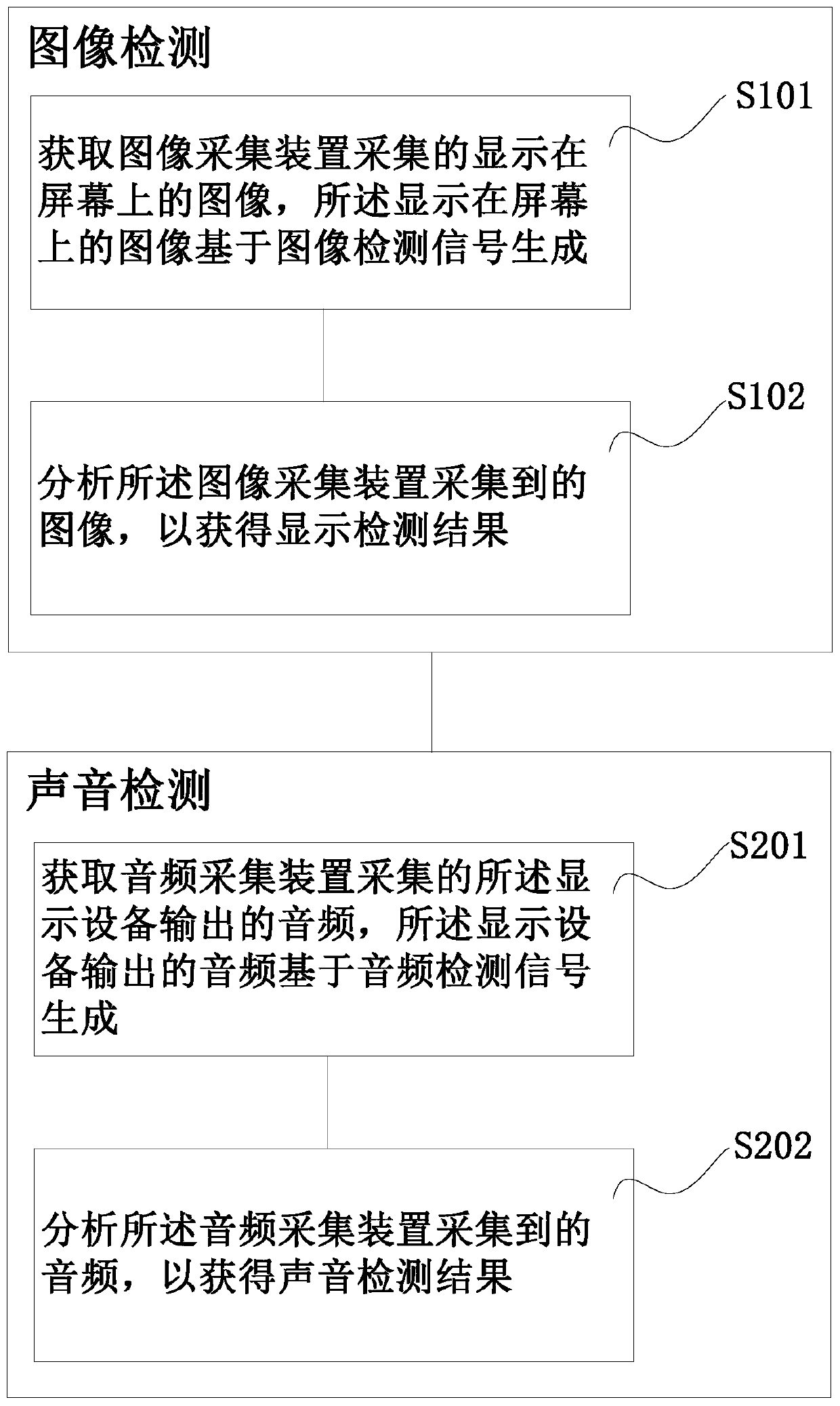

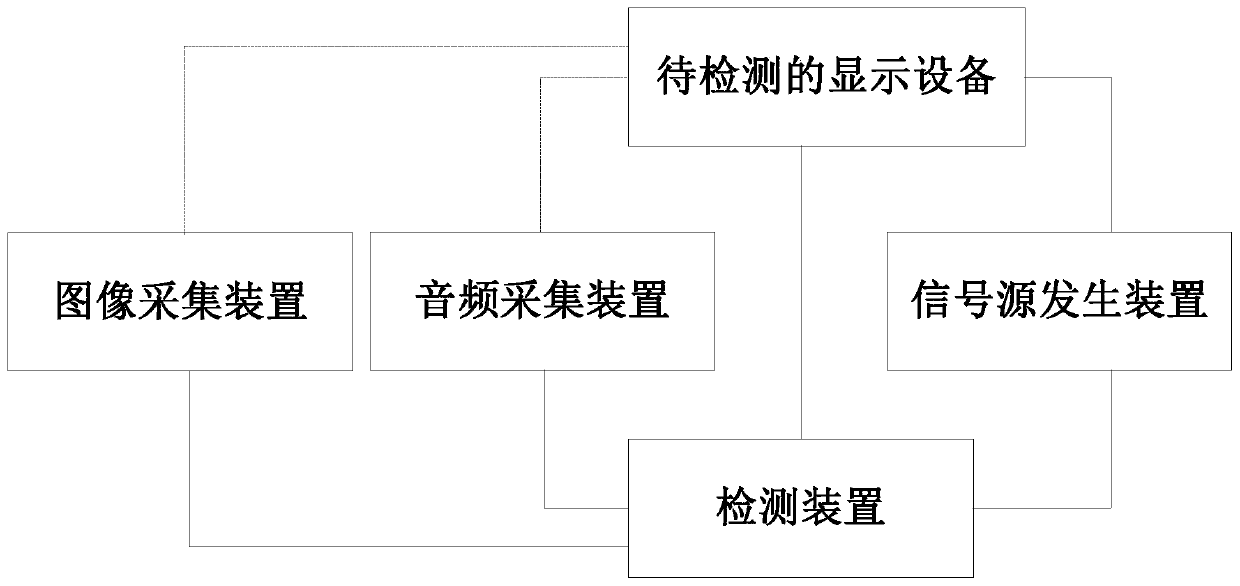

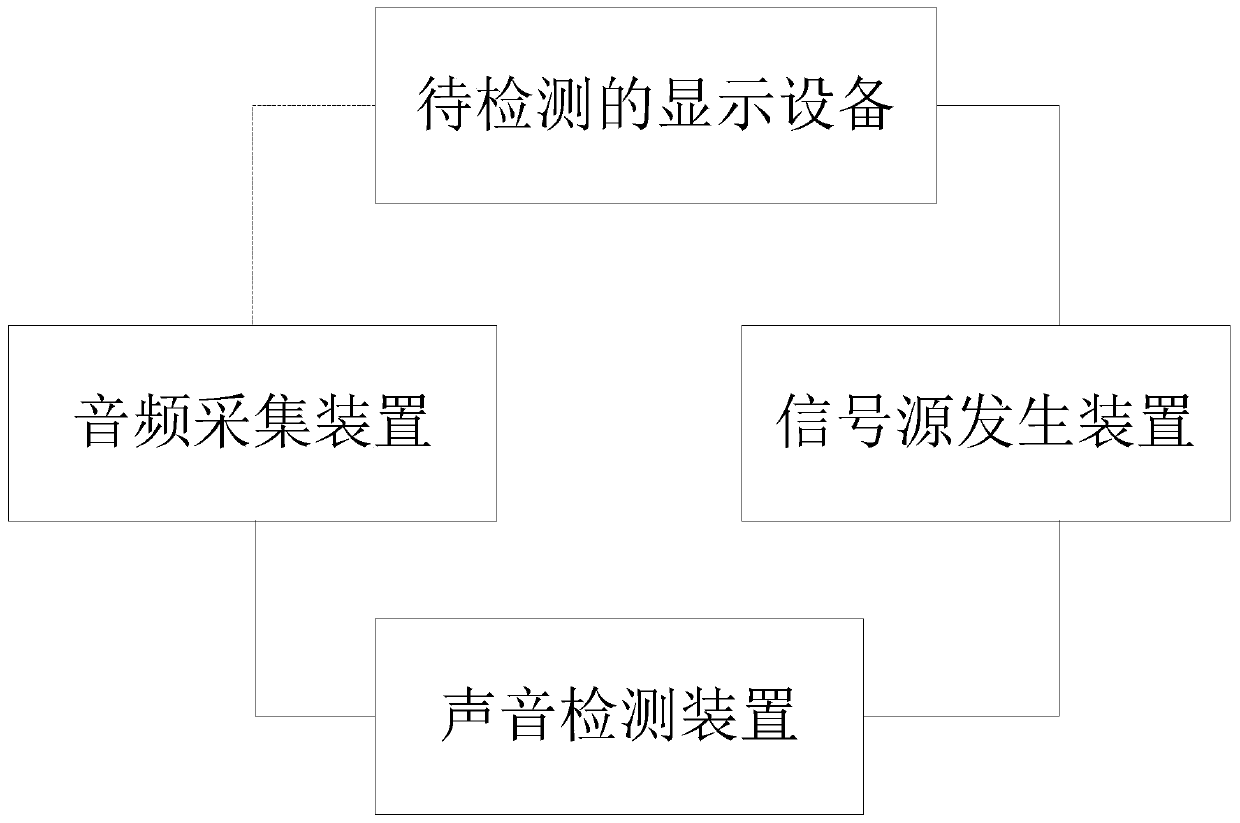

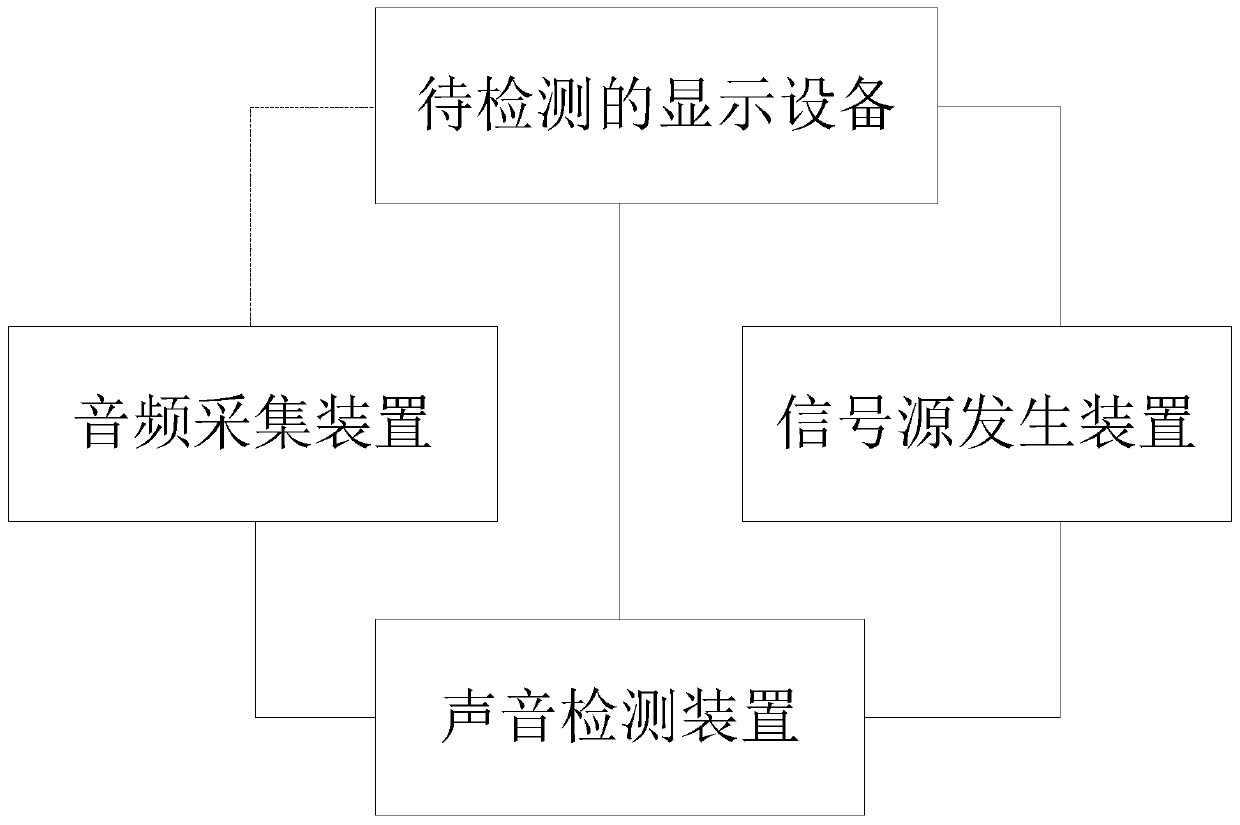

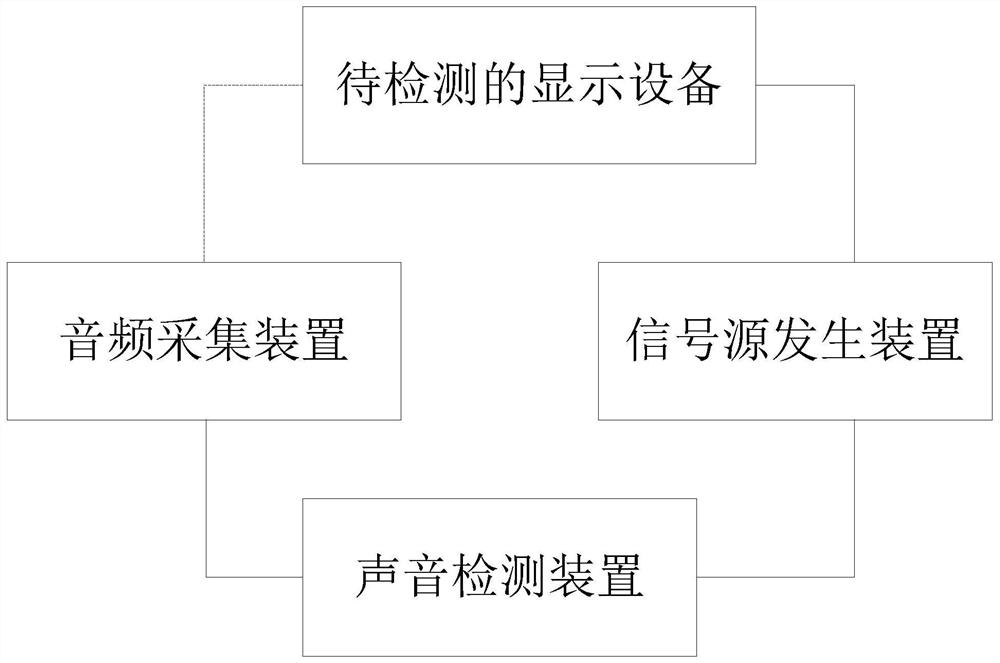

Display equipment detection method, device and system

InactiveCN110010045AThe test result is accurateEasy to findStatic indicating devicesSpeech analysisSound detectionImage detection

The invention discloses a display equipment detection method, device and system, the display equipment comprises a signal source interface, and the detection method comprises image detection and sounddetection; the image detection comprises the following steps: acquiring an image displayed on a screen collected by an image collection device, wherein the image displayed on the screen is generatedbased on an image detection signal; analyzing the image acquired by the image acquisition device to obtain a display detection result; the sound detection comprises the following steps: obtaining an audio output by the display equipment and collected by an audio collection device, wherein the audio output by the display equipment is generated based on an audio detection signal; analyzing the audiocollected by the audio collection device to obtain a sound detection result; wherein the image detection signal and the audio detection signal are respectively input into the signal source interface,or the image detection signal and the audio detection signal are contained in a video detection signal input into the signal source interface.

Owner:FREESENSE IMAGE TECH

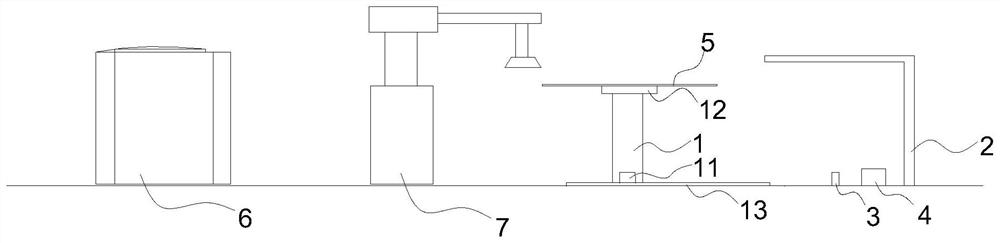

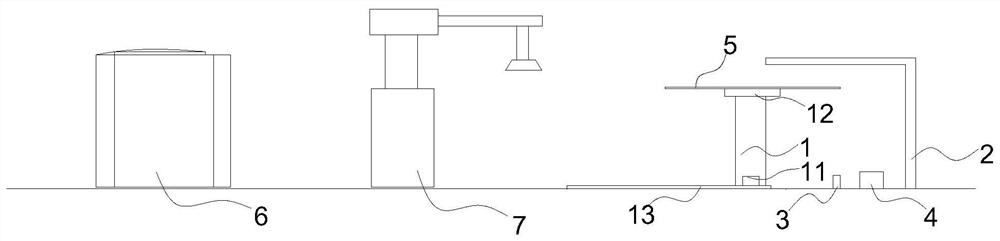

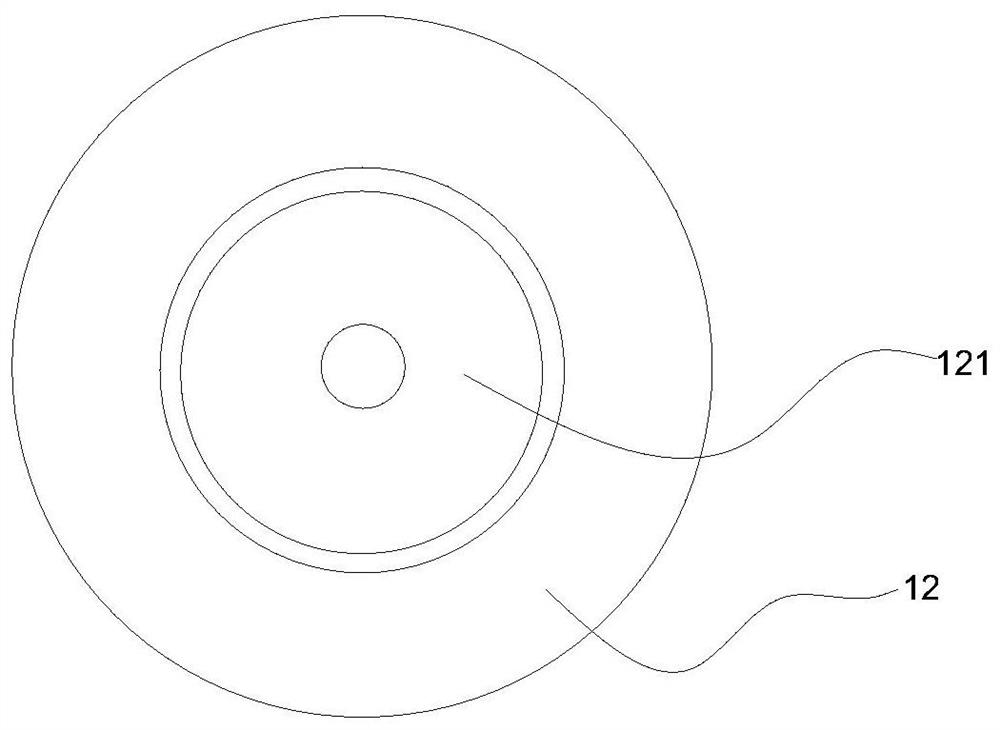

Electric energy meter verification unit and working method thereof

ActiveCN102323564BRealize fully automatic verificationEasy to manageMaterial analysis by optical meansElectrical testingEngineeringTest fixture

The invention claims an electric energy meter verification unit and a working method thereof, relates to a single-phase, three-phase electric energy meter verification unit and the working method thereof. At present, in the electric energy meter verification process, a verification system is artificial and mainly comprises a plurality of groups of artificial detection table bodies, and the method has the disadvantages of large labor intensity, manual errors and slow integral verification speed. The electric energy meter verification unit provided by the invention comprises a logistics conveying line, a feeding device, a verification conveying line, a pressure withstand testing device, a program switch triggering device, a verification device, a lead seal and laser making device, a discharging device and an electric energy meter verification management module, wherein the feeding device, the pressure withstand testing device, the program switch triggering device, the verification device, the lead seal and laser marking device and the discharging device are orderly arranged along a forward direction of the verification conveying line. The electric energy meter is in full automatic verification, high in efficiency, free from of manual detection errors, and can improve the accuracy of sorting; and the laser marking replaces the traditional form of sticking a certification so that the electric energy meter is convenient for management and use.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

A high-reliability DC power supply for a substation and its inspection method

ActiveCN111049245BReduce the number of batteriesImprove reliabilityCharge equalisation circuitDc-dc conversionDC-BUSBattery cell

The invention discloses a high-reliability DC power supply for a substation and a testing method. In order to overcome the problem that the battery packs of the prior art DC power supply system are connected in series and have poor reliability; the charging and discharging experiments cannot fully discover the hidden dangers of battery failure; the present invention adopts a busbar, AC / DC module, circuit breaker and DC load; The battery pack; the bidirectional DC / DC module is set between the DC bus and the battery module to indirectly control the charging and discharging of the battery module; the monitoring unit monitors the data of the battery module, judges the state of the battery module according to the data, and controls the bidirectional DC / DC The output voltage of the module; the host computer is connected with the monitoring unit through a communication protocol, receives and stores monitoring data, and sends control commands remotely. Guarantee the power supply of the DC system, avoid the lagging effect of a single battery pack, and improve reliability; the smoother process of the battery pack is simple; it can realize the checking discharge of 100% of the rated capacity of the DC power supply, and completely find out the hidden dangers of failure.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

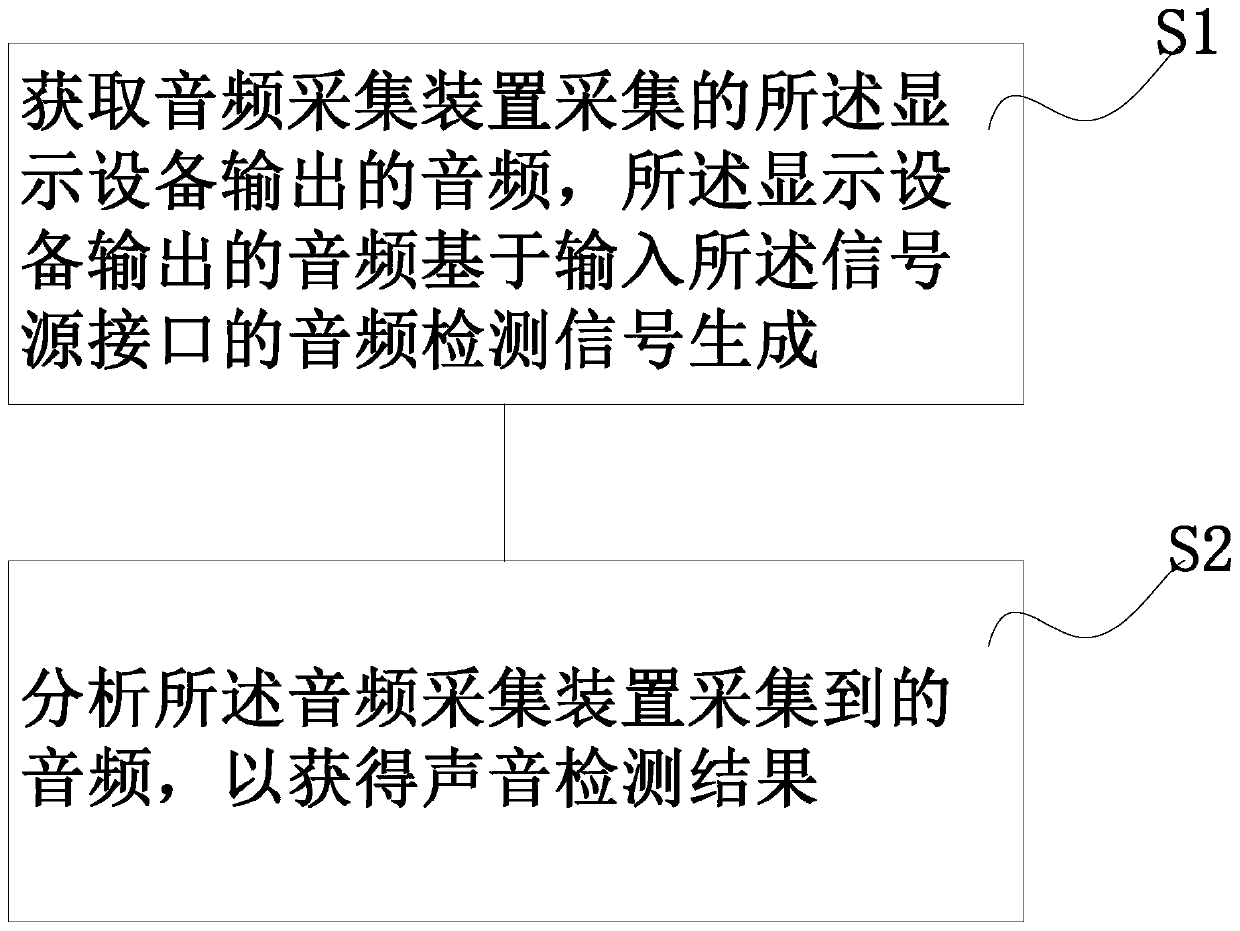

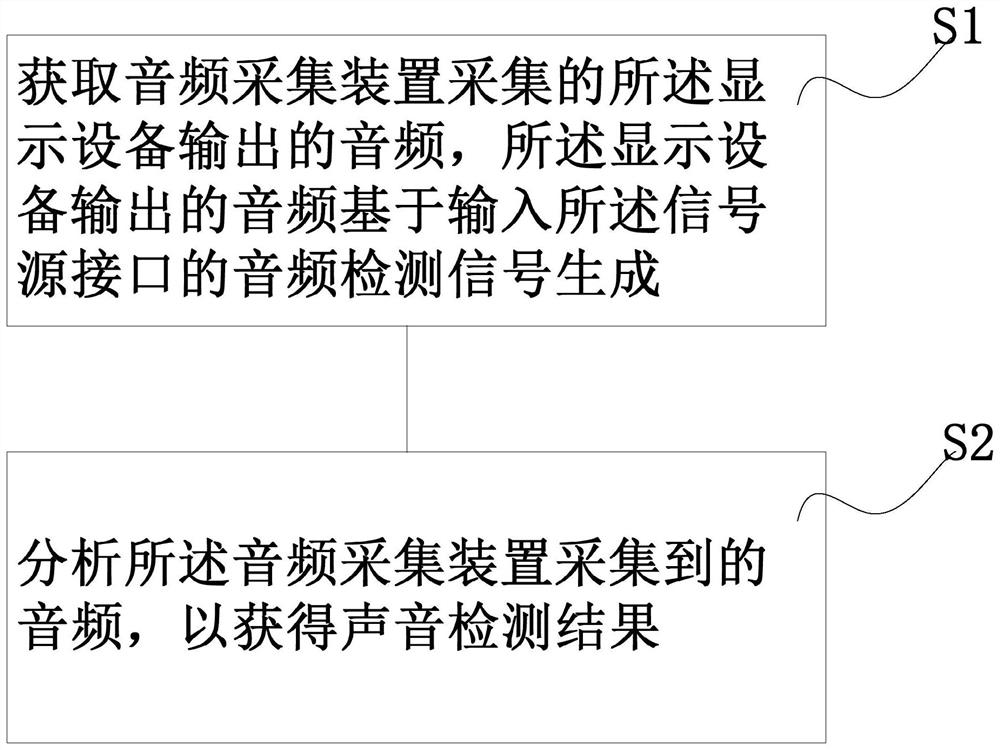

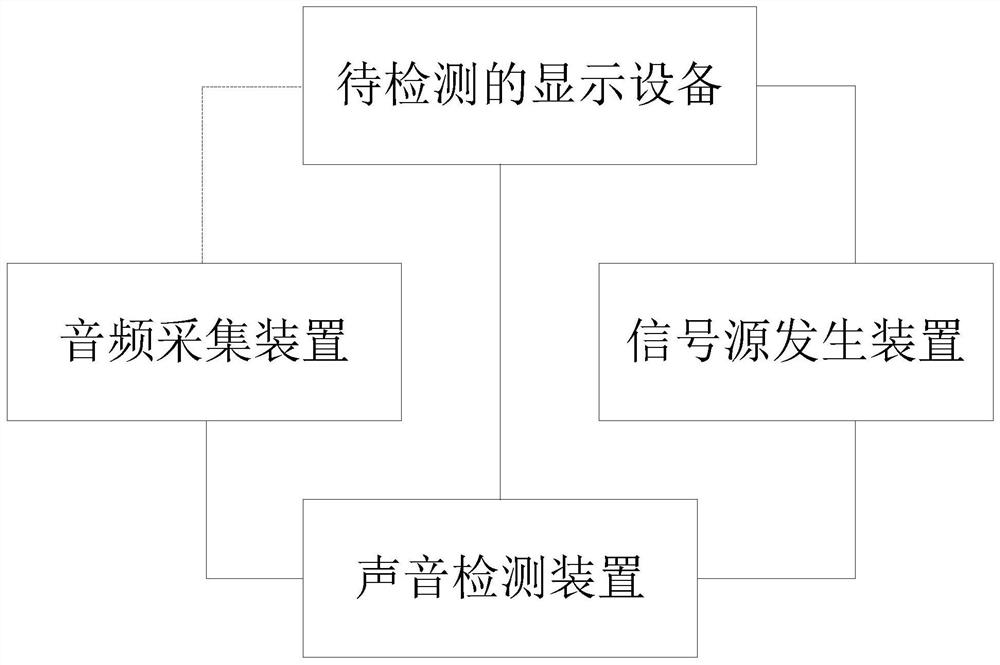

Voice detection method, device and system of display equipment

ActiveCN110033788AAvoid manual detection errorsThe test result is accurateSpeech analysisSelective content distributionAudio frequencySignal source

The invention discloses a voice detection method, device and system of display equipment. The display equipment comprises a signal source interface. The voice detection method includes following steps: acquiring audio frequency output by the display equipment and collected by an audio frequency collection device, wherein the audio frequency output by the display equipment is generated on the basisof an audio frequency detection signal input to the signal source interface; analyzing the audio frequency collected by the audio frequency collection device to acquire a voice detection result. Thedisplay detection method can replace workers to detect the display equipment to avoid manual detection errors like missing detection and mistaken detection.

Owner:FREESENSE IMAGE TECH

A sound detection method, device and system for a display device

ActiveCN110033788BAvoid manual detection errorsThe test result is accurateSpeech analysisSelective content distributionSound detectionDisplay device

Owner:FREESENSE IMAGE TECH

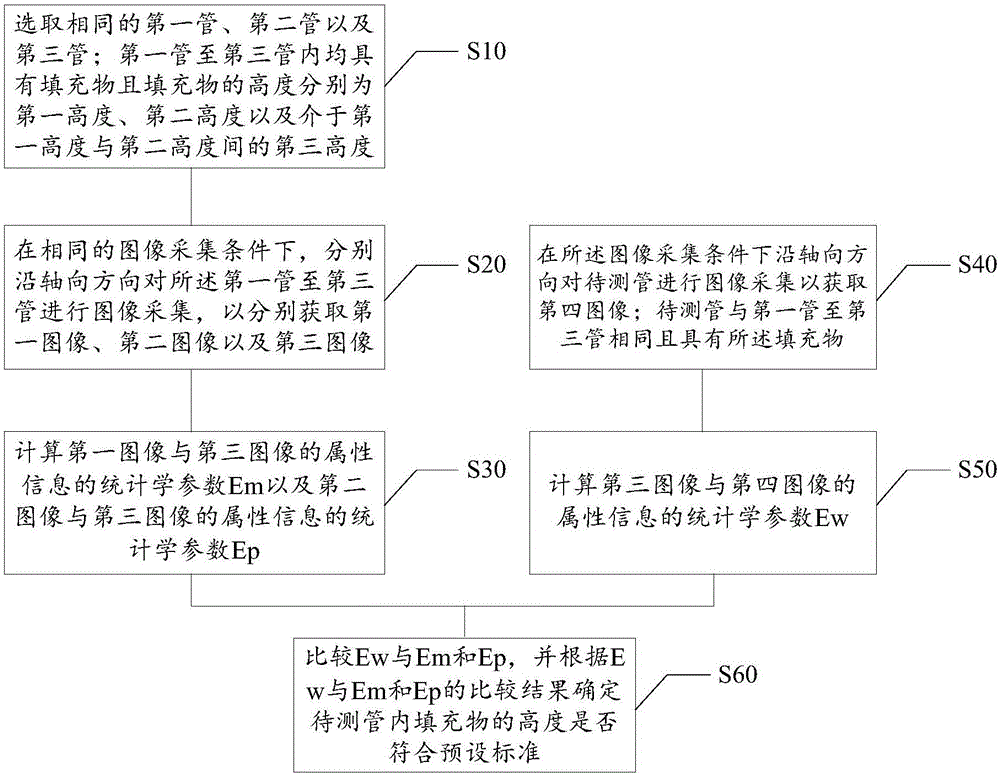

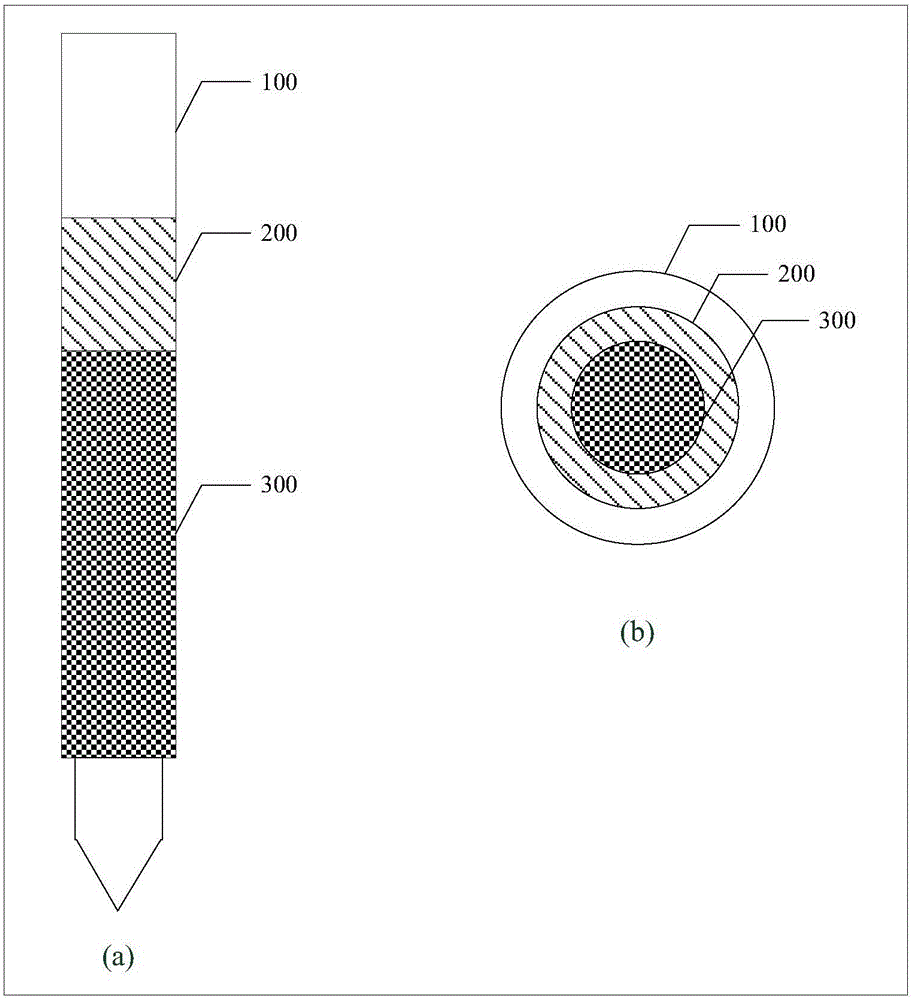

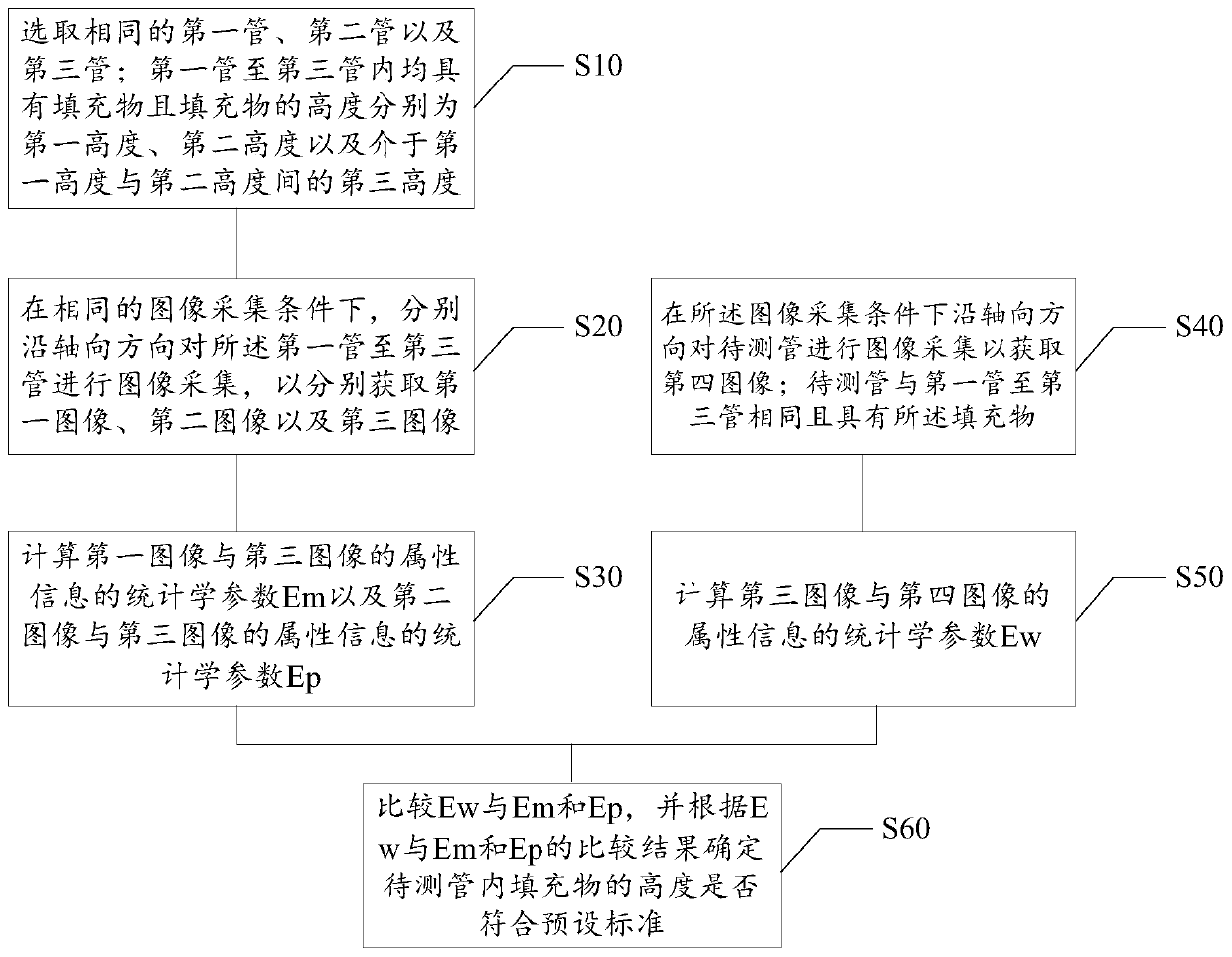

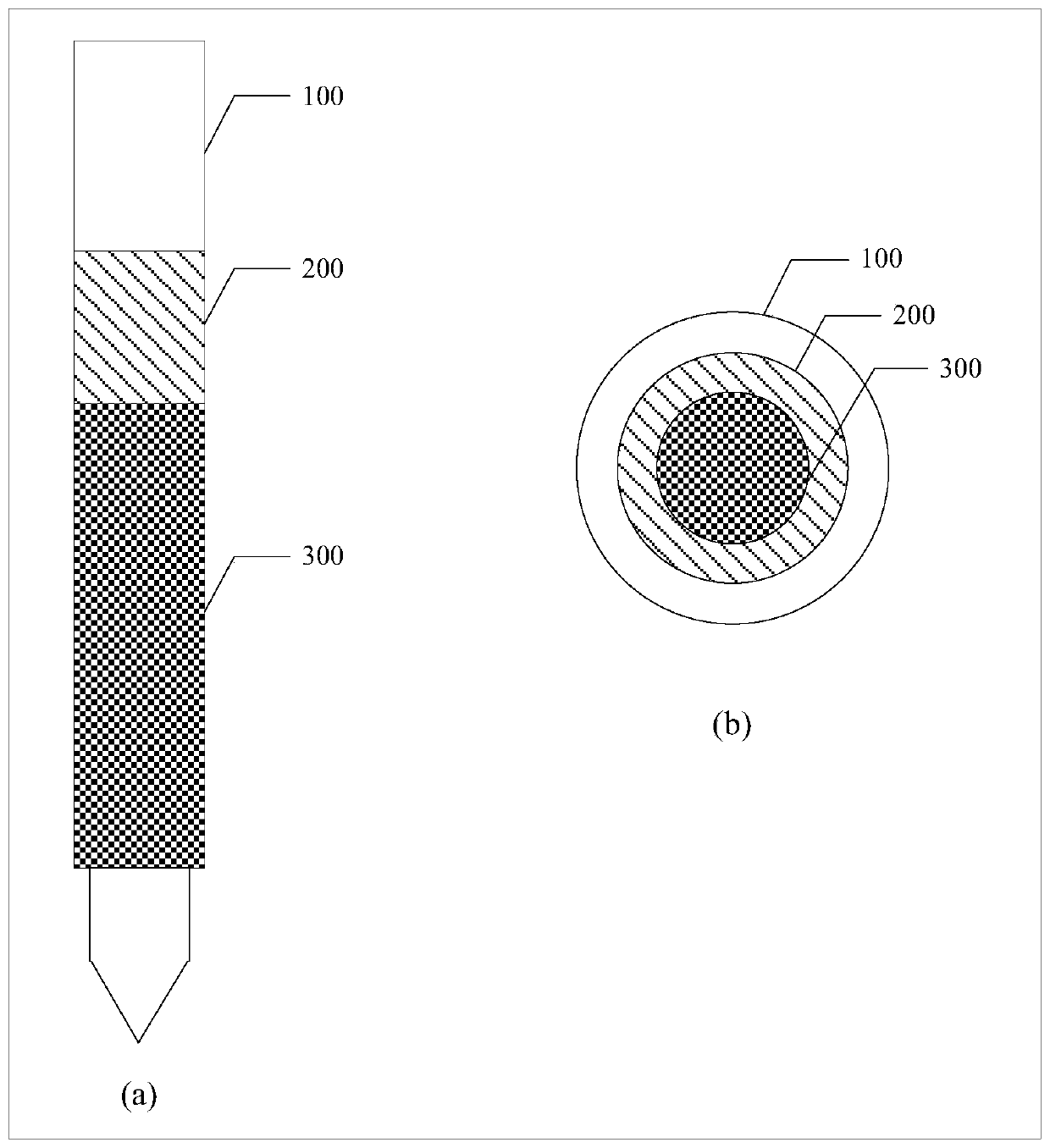

Method and device for detecting position of filling material in pipe

ActiveCN106780431AAvoid manual detection errorsImprove detection efficiencyImage analysisOptically investigating flaws/contaminationFilling materialsEngineering

The invention relates to a method and device for detecting the position of a filling material in a pipe, and the method comprises the steps: selecting a first pipe, a second pipe and a third pipe, which are all provided with the filling materials; respectively carrying out the image collection of the first, second and third pipes under the same image collection condition, so as to respectively obtain a first image, a second image and a third image; calculating the statistics parameter Em of the attribute information of the first and third images and the statistics parameter Ep of the attribute information of the second and third images; carrying out the image collection of a to-be-detected pipe, so as to obtain a fourth image, wherein the to-be-detected pipe is the same as the first, second and third pipes and has the filling material; calculating the statistics parameter Ew of the attribute information of the third and fourth images; comparing Ew with Em and Ep, and determining whether the height of the filling material in the to-be-detected pipe accords with a preset standard or not according to the comparison result of Ew, Em and Ep. The method improves the detection efficiency of the position of the filling material in the pipe.

Owner:SHANGHAI M&G STATIONERY INC +1

Method and device for calibrating wafer center

ActiveCN110729226BQuick filterImprove calibration efficiencySemiconductor/solid-state device manufacturingInformation controlWafer

The invention relates to a device for calibrating the center of a wafer, comprising: a stage, a stopper, a distance measuring sensor and a controller; the top surface of the stage is higher than the distance measuring sensor, and the distance measuring sensor is arranged on one side of the stage , the block is located directly above the ranging sensor; the carrier is used to place the wafer and drive the wafer to move; the ranging sensor is used to obtain horizontal and vertical spacing information; the controller is connected to the ranging sensor to control The controller is used to control the carrier to rotate at a preset angle, or to control the carrier to move in a direction approaching or away from the distance measuring sensor. The information of the ranging sensor is processed by the controller to determine the wafer whose center position is shifted. It is possible to quickly screen out wafers whose center position is shifted, improve the efficiency of wafer center calibration, and effectively avoid manual detection errors.

Owner:福建省福联集成电路有限公司

Method and device for detecting the position of filler in pipe

ActiveCN106780431BImprove accuracyGuaranteed accuracyImage analysisOptically investigating flaws/contaminationAlgorithmFilling materials

The invention relates to a method and device for detecting the position of a filling material in a pipe, and the method comprises the steps: selecting a first pipe, a second pipe and a third pipe, which are all provided with the filling materials; respectively carrying out the image collection of the first, second and third pipes under the same image collection condition, so as to respectively obtain a first image, a second image and a third image; calculating the statistics parameter Em of the attribute information of the first and third images and the statistics parameter Ep of the attribute information of the second and third images; carrying out the image collection of a to-be-detected pipe, so as to obtain a fourth image, wherein the to-be-detected pipe is the same as the first, second and third pipes and has the filling material; calculating the statistics parameter Ew of the attribute information of the third and fourth images; comparing Ew with Em and Ep, and determining whether the height of the filling material in the to-be-detected pipe accords with a preset standard or not according to the comparison result of Ew, Em and Ep. The method improves the detection efficiency of the position of the filling material in the pipe.

Owner:SHANGHAI M&G STATIONERY INC +1

cigarette lighter detector

InactiveCN102734835BImprove detection efficiencyEasy to operateCombustion ignitionElectricityProgrammable logic controller

The invention discloses a detector of a cigar lighter. The detector comprises a signal detection acquisition system and a data detection process and display system, wherein the signal detection acquisition system consists of alternating current, a switching power supply, a current transformer and an analog-to-digital conversion module EM231, the alternating current is electrically connected with the switching power supply, the switching power supply is electrically connected with the cigar lighter, the current transformer is in parallel connection with a branch circuit which is connected with the cigar lighter, and the current transformer is connected with the analog-to-digital conversion module EM231; and the data detection process and display system consists of a SIMENS PLC (programmable logic controller) and a touch screen, and the SIMENS PLC S7-200 is connected with the analog-to-digital conversion module EM231 by signals and is electrically connected with the touch screen. The detector of the cigar lighter, disclosed by the invention, can finally detect a finished product of the cigar lighter, avoids unknown errors in an assembly process, and has the advantages of simple device, convenience for operation and good visualization effect.

Owner:QINGDAO HUATE AUTOMATION EQUIP

A thread pass-stop detection device and detection method

ActiveCN110631490BImplement automatic image detectionAvoid manual detection errorsUsing optical meansComputer hardwareImage detection

The invention relates to a screw detection device, in particular to a screw thread detection device and detection method, including a workbench, which is provided with a clamping mechanism for clamping the screw to be tested, and an X-direction clamp is also provided on the workbench. For the main camera, a first backlight panel is arranged opposite to the main camera in the X direction, and an auxiliary camera in the Y direction is arranged on the workbench, and a second backlight panel is arranged on the opposite side of the auxiliary camera in the Y direction. The present invention adopts two vertical direction cameras of X and Y The acquisition and correction method of parameters such as screw tooth shape under the condition of backlight is carried out, and the automatic image detection of thread is realized.

Owner:JIANGSU UNIV OF TECH

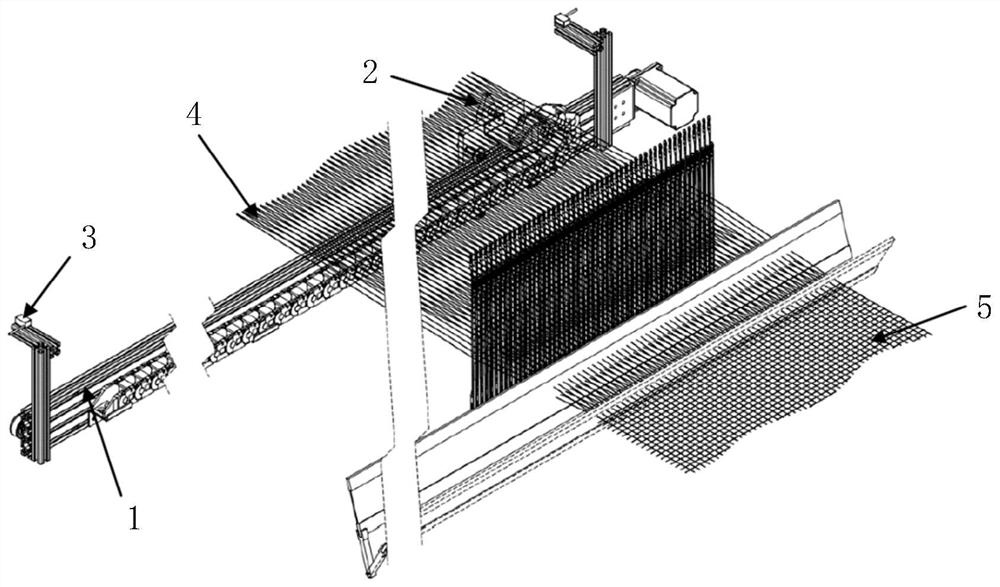

Broken yarn detection device and loom

The invention discloses a broken yarn detection device and a loom. The broken yarn detection device comprises a rack, at least one air nozzle and at least one broken yarn detection sensor, wherein the at least one air nozzle and the at least one broken yarn detection sensor are installed on the rack; and when yarn is broken, gas sprayed by the air nozzle blows the broken yarn into a detection area where the broken yarn detection sensor is located. Compared with the prior art, the working intensity of knitters can be greatly reduced, the inspection mode is optimized, and a large amount of labor cost is saved; and errors caused by manual detection are avoided by detecting the broken yarn through equipment, accurate and timely detection can be realized, and the production quality of workshop cloth is greatly improved.

Owner:SHENZHEN HAYHON EQUIP TECH

A frame assembly on-line inspection machine

InactiveCN103234506BNo manual intervention requiredAvoid manual detection errorsMeasurement devicesVehicle frameControl system

The invention discloses an online detector for frame assemblies. The online detector for frame assemblies comprises a reference platform, a detection master, a support, a pneumatic correcting trolley, and a control system. The detection master is used for three-dimensionally detecting technical indicators such as linearity, planarity, parallelism, diagonals, coaxiality and width for a frame assembly. The support is used for storing the frame assembly to be detected. The pneumatic correcting trolley is used for calibrating the position of the frame assembly stored on the support. The frame assembly to be measured is supported by the support and is automatically calibrated by the pneumatic correcting trolley, and the technical indicators of the detection master such as linearity, planarity, parallelism, diagonals, coaxiality and width are measured by the detection master. All operations are automatically completed by the control system with no need of manual operation intervention, measurement is more efficient, artificial errors are avoided effectively, and measurement is more precise.

Owner:JILIN SAIJINDE INTELLIGENT MACHINERY MFG

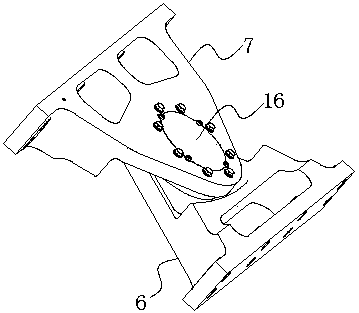

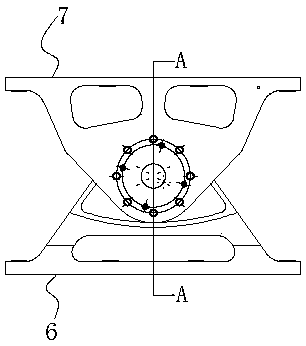

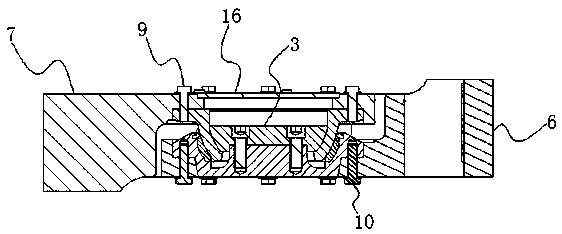

A service life testing method for metal joint bearings in fixed hinges of low-floor vehicles

ActiveCN107462417BMeet operational needsReduce the difficulty of disassemblyMachine bearings testingWear resistantPetroleum engineering

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

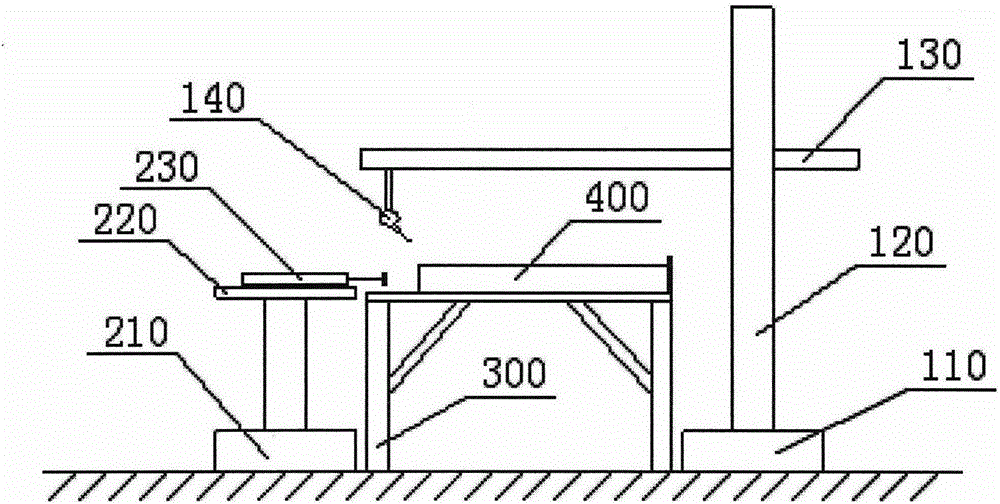

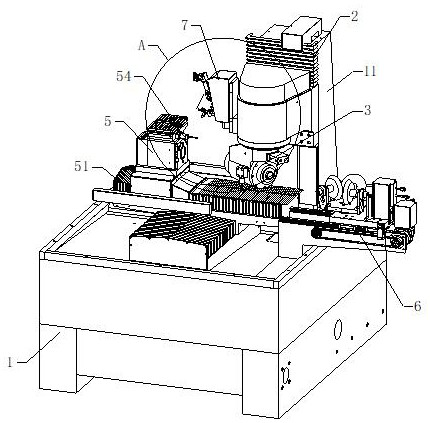

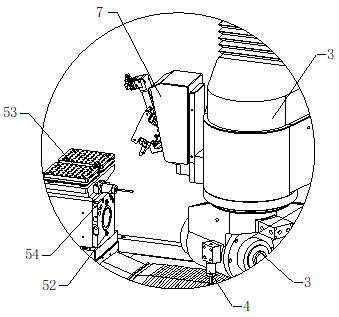

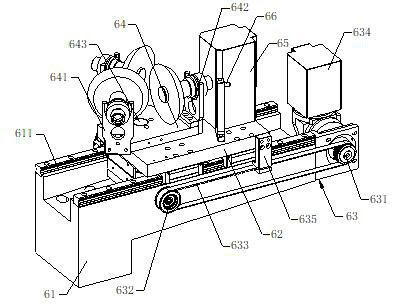

Five-axis cutter grinding machine

InactiveCN114523343AGuarantee processing qualityRapid positioningGrinding wheel securing apparatusGrinding carriagesRobot handStructural engineering

The invention provides a five-axis cutter grinding machine. Comprising a lathe bed, a stand column arranged on one side of the lathe bed, a Z-axis module arranged on the stand column, a grinding wheel spindle assembly arranged at the output end of the Z-axis module, a workpiece probe assembly arranged on one side of the grinding wheel spindle assembly and an X-axis feeding module arranged on the lathe bed. The portable replaceable assembly is arranged at one end of the X-axis feeding module; the carrying manipulator assembly is arranged on one side of the Z-axis module; the X-axis feeding module comprises an X-axis module, a workpiece shaft in sliding fit with the X-axis module, a material disc unit arranged above the workpiece shaft and a grinding wheel probe arranged on one side of the workpiece shaft. According to the five-axis cutter grinding machine, automatic feeding, machining, discharging and grinding wheel replacement of workpiece bars are achieved.

Owner:苏州哈勒智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com