A service life testing method for metal joint bearings in fixed hinges of low-floor vehicles

A technology of joint bearing and low-floor car, which is applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of complex structure of metal joint bearing, difficult disassembly and assembly, and low detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: as Figure 1 to Figure 4 As shown, a method for detecting the service life of the metal joint bearing in the fixed hinge of the low-floor vehicle, the metal joint bearing in the fixed hinge of the low-floor vehicle is set as the outer seat cover 1 of the metal joint, the outer rolling ball sleeve 2 and the inner rolling ball 3 three set the outer rolling ball sleeve 2 inside the metal joint outer seat cover 1, the inner rolling ball 3 is arranged inside the outer rolling ball sleeve 2, and between the metal joint outer seat cover 1 and the outer rolling ball sleeve 2. A wear-resistant bushing 4 is provided; between the inner rolling ball 3 and the outer rolling ball sleeve 2 and between the outer rolling ball sleeve 2 and the wear-resistant bushing 4 are all in contact with the spherical surface, and the outer seat of the metal joint is fixed by the screw 5 Sleeve 1, outer rolling ball sleeve 2, inner rolling ball 3 and wear-resistant bush-4 form an integr...

Embodiment 2

[0071] Embodiment 2: as Figure 9 As shown, there is a gap between the other end surface P3 of the axial extension part 212 of the outer rolling ball sleeve and the inner bottom surface P4 of the closed end of the metal joint outer seat sleeve 1. Preferably, the axial extension of the outer rolling ball sleeve The other end surface P3 of the outlet part 212 is set as a plane. Compared with the embodiment 1, the difference of this embodiment is that a distance measuring device 17 is arranged on the inner bottom surface P4 of the closed end of the metal joint outer seat cover 1. The distance-measuring device-17 can use devices such as a rangefinder or a distance sensor. The distance-measuring device-17 is used to measure the position of the other end face P3 of the axial extension of the outer rolling ball sleeve, that is, to measure the axis of the outer rolling ball sleeve. The vertical distance between the other end face P3 of the protruding part and the distance measuring de...

Embodiment 3

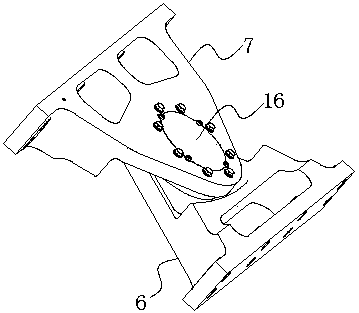

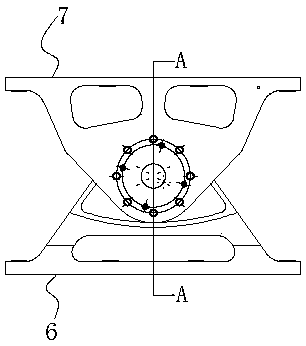

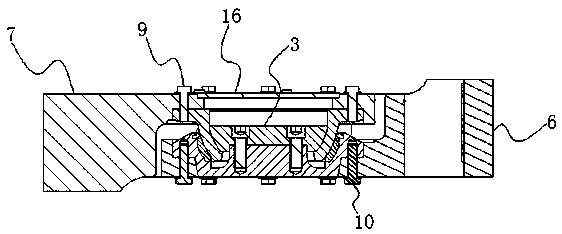

[0078] Embodiment 3: A flange 113 is provided on the outer peripheral surface of the sleeve body 111 of the metal joint outer seat sleeve and is located at one end of the sleeve body opening, and a threaded hole 8 is opened on the flange 113, and the base 211 of the outer rolling ball sleeve is also provided. There is a threaded hole 8; threaded into the threaded hole 8 on the base 211 of the outer rolling ball sleeve through the upper fixed support 7 through the connecting screw one 9 and screwed into the lower fixed support 6 through the connecting screw two 10 In the threaded hole 8 on the flange 113 of the metal joint outer seat cover body, thereby the integral metal joint bearing is arranged between the upper fixed support and the lower fixed support, as Figure 10 to Figure 12 As shown, compared with Embodiment 1, this embodiment differs in that: a horizontal detection through hole 18 is provided on the lower fixed support 6, and a horizontal detection hole is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com