A frame assembly on-line inspection machine

A detection machine and assembly technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as unsatisfactory efficiency and measurement accuracy, and achieve the effect of improving measurement efficiency, avoiding manual detection errors, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

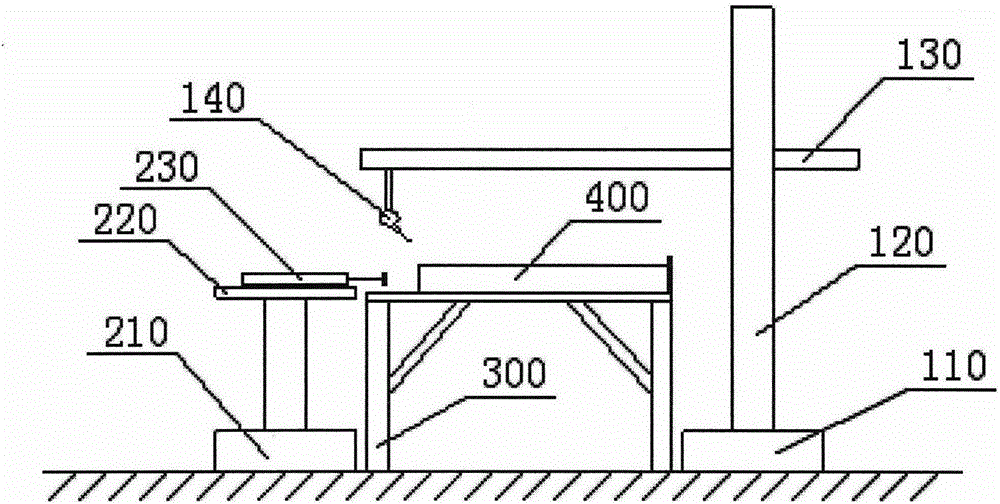

[0022] The frame assembly online detection machine of the present invention is composed of a mechanical structure and a control system. The mechanical structure is mainly composed of four parts: a reference platform, a detection mechanism, a support frame, and a pneumatic calibration. The function is to perform online detection of the frame assembly. Various technical indicators. The control system includes hardware and software. The control system hardware mainly includes: operation console, programmable logic controller (PLC), magnetic grid position measurement of X and Z axes, position measurement of encoder of Y axis, probe system, photoelectric sensor Positioning, etc., realize the automatic control of the detection machine.

[0023] Such as figure 1 As shown, there is a support frame in the middle of the frame assembly online detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com