Patents

Literature

32results about How to "Circumferential force uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

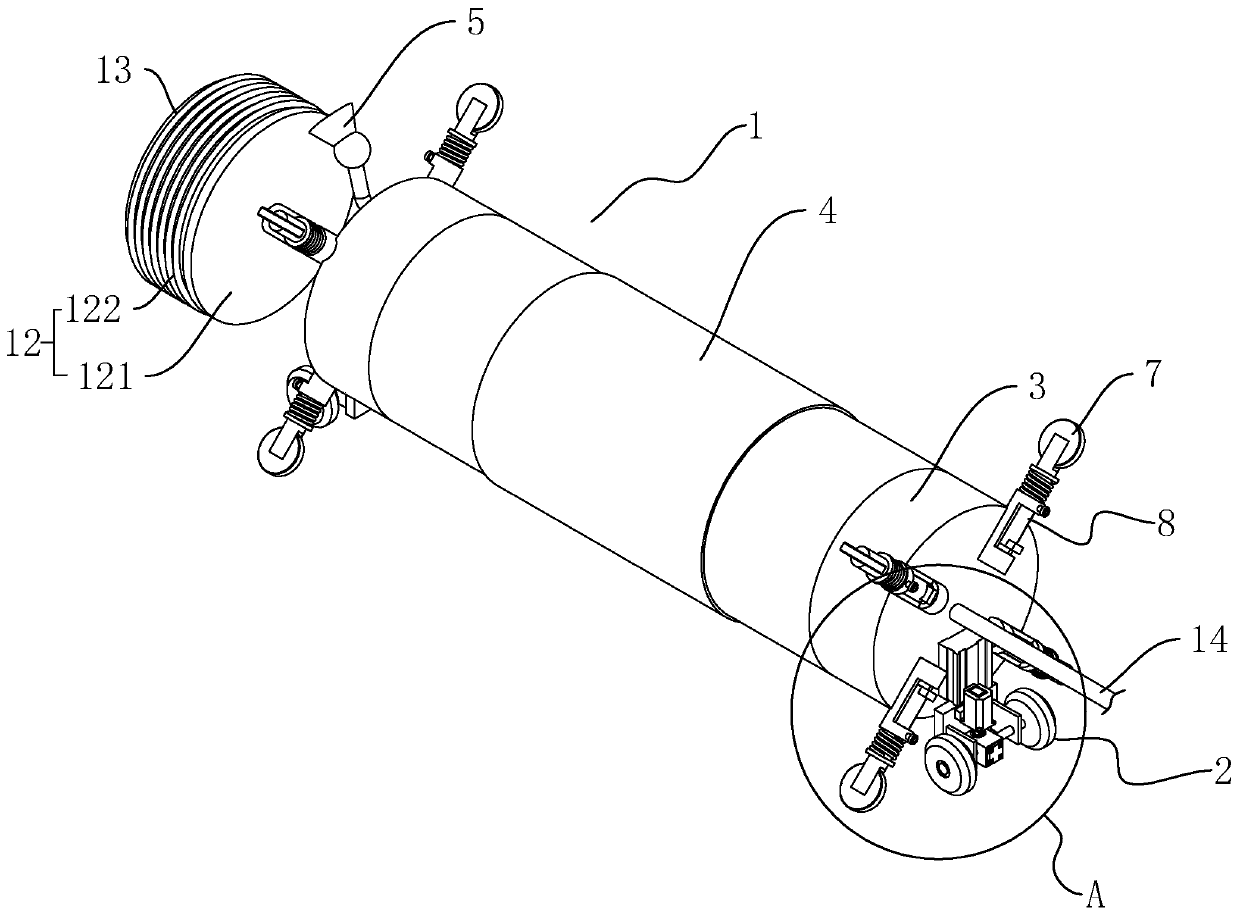

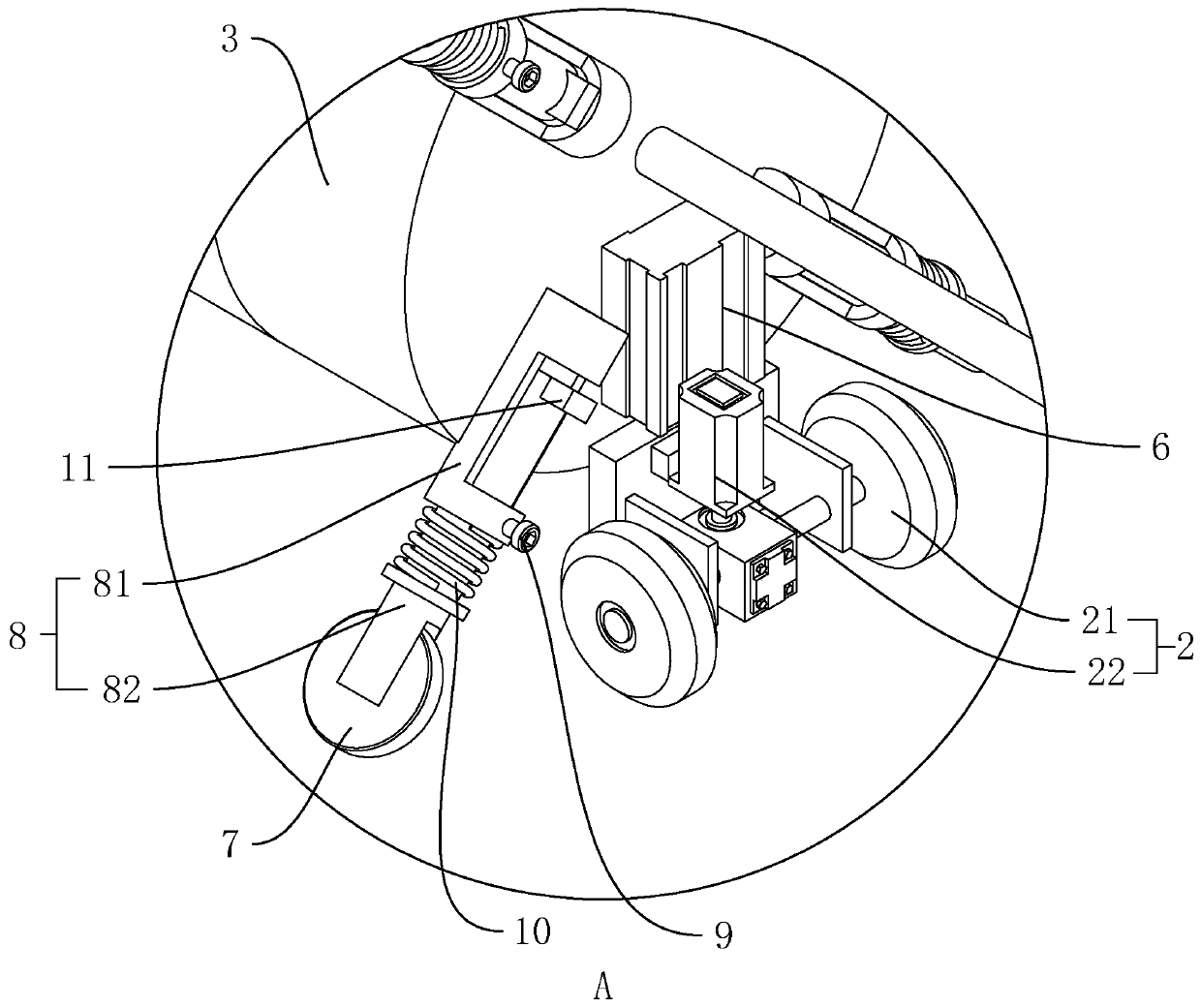

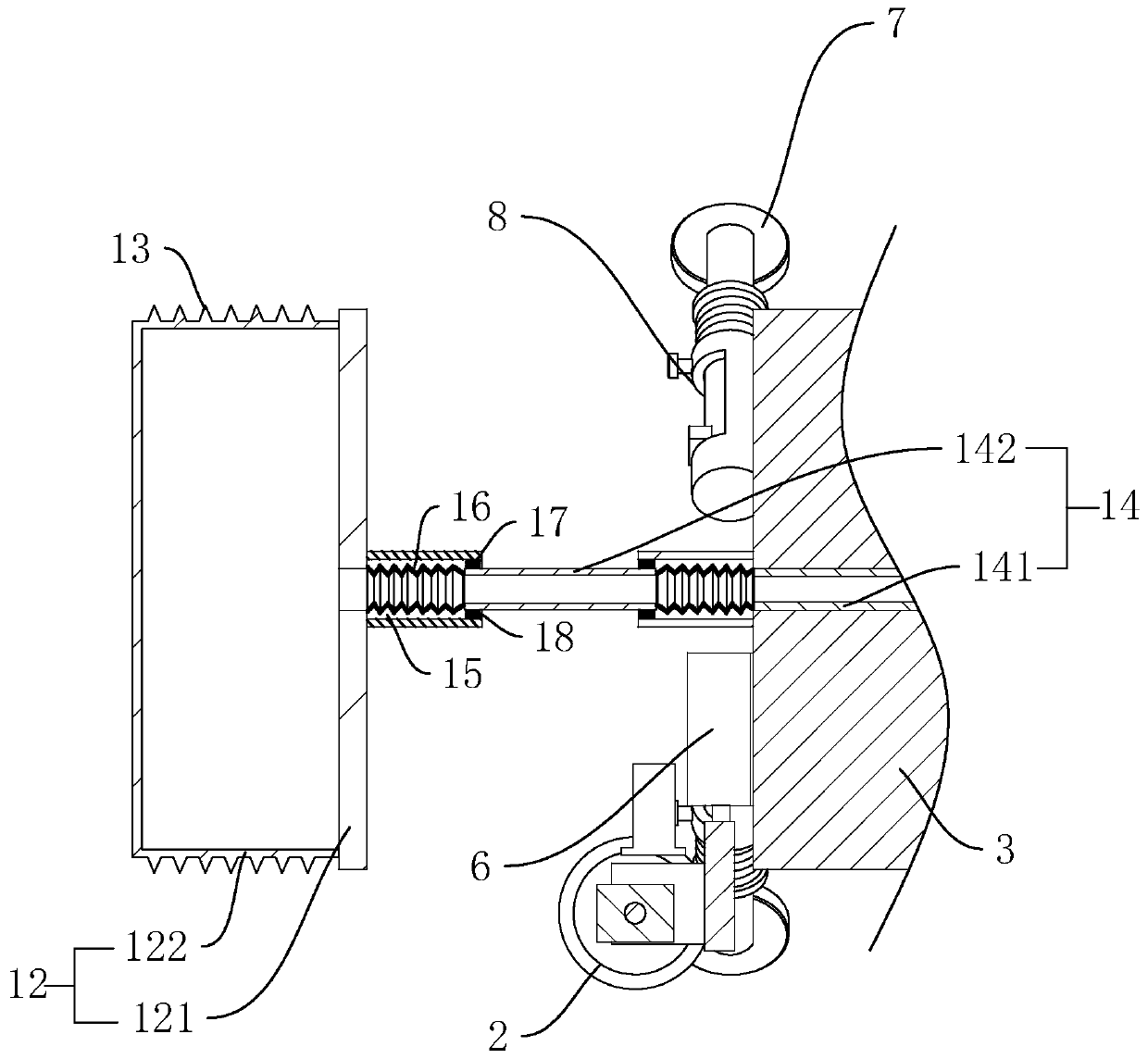

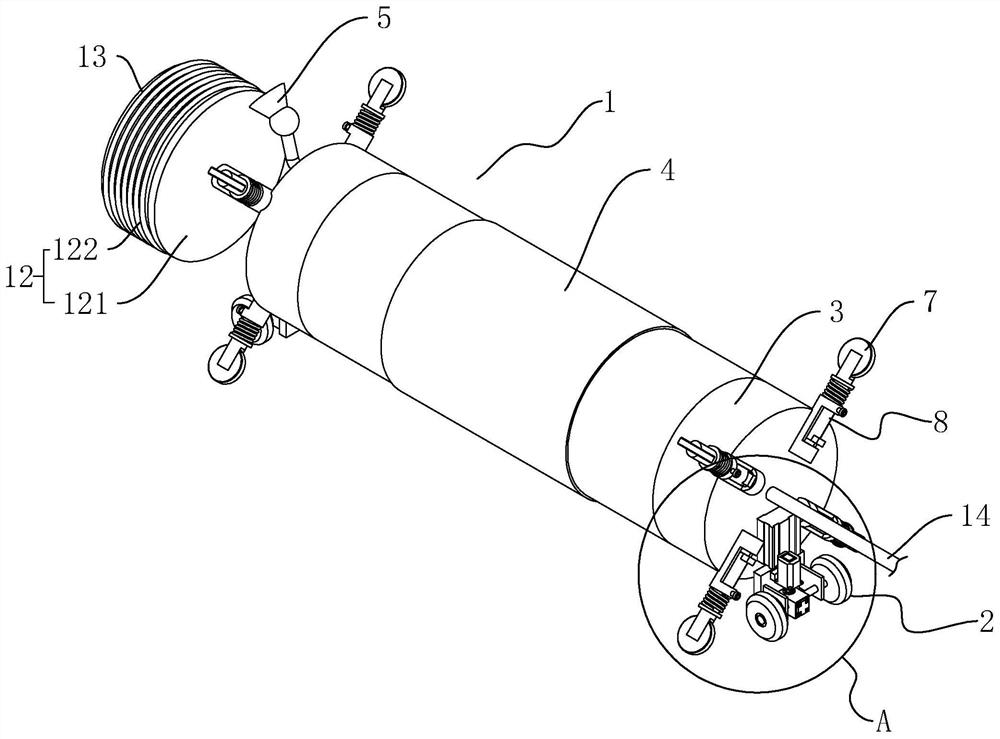

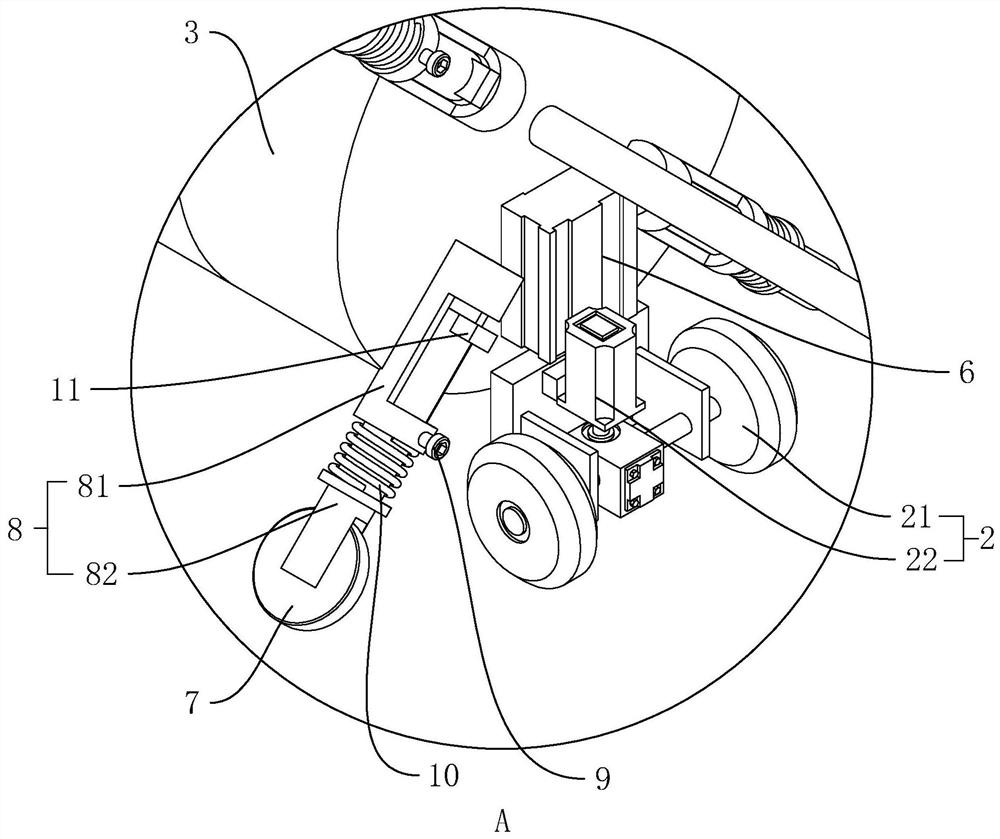

Robot for repairing inner wall of pipeline

The invention discloses a robot for repairing the inner wall of a pipeline, and relates to the technical field of pipeline maintenance. According to the technical scheme, the robot is characterized bycomprising a pipeline repairing support frame body, a repairing device driving device and an operation control device; the main pipeline repairing support frame body comprises a main support frame; the main support frame is a cylindrical frame and is provided with a repairing device; a pipeline positioning camera is arranged at the front end of the main support frame; the main support frame is further provided with a cleaning assembly; the cleaning assembly comprises a mounting frame arranged on the front end part of the main support frame and a cleaning air bag, and the cleaning air bag is arranged on the side, away from the main support frame, of the mounting frame; and an air inlet pipe is connected to the cleaning air bag and is used for being connected to an air source to enable thecleaning air bag to expand so as to adhere to the inner wall of the pipeline for cleaning. The cleaning assembly can clean the inner wall of the pipeline before the pipeline is repaired, and meanwhilecan form the effect of choking and isolating, so that hot-melt photocurable adhesive of a colloid adsorption layer is firmly attached to the inner wall of the pipeline, and the pipeline repairing effect is better.

Owner:浙江越歌科技有限公司

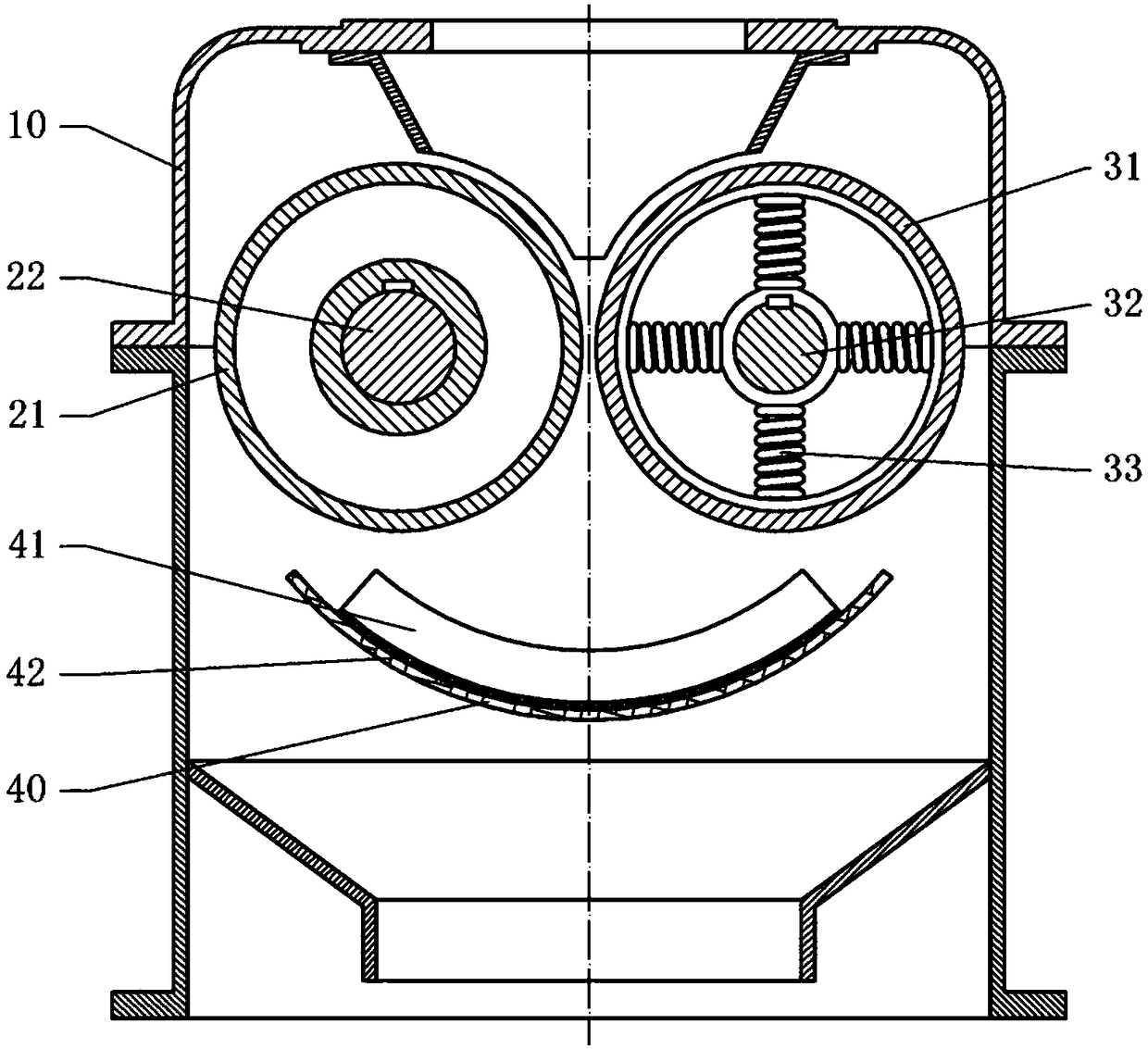

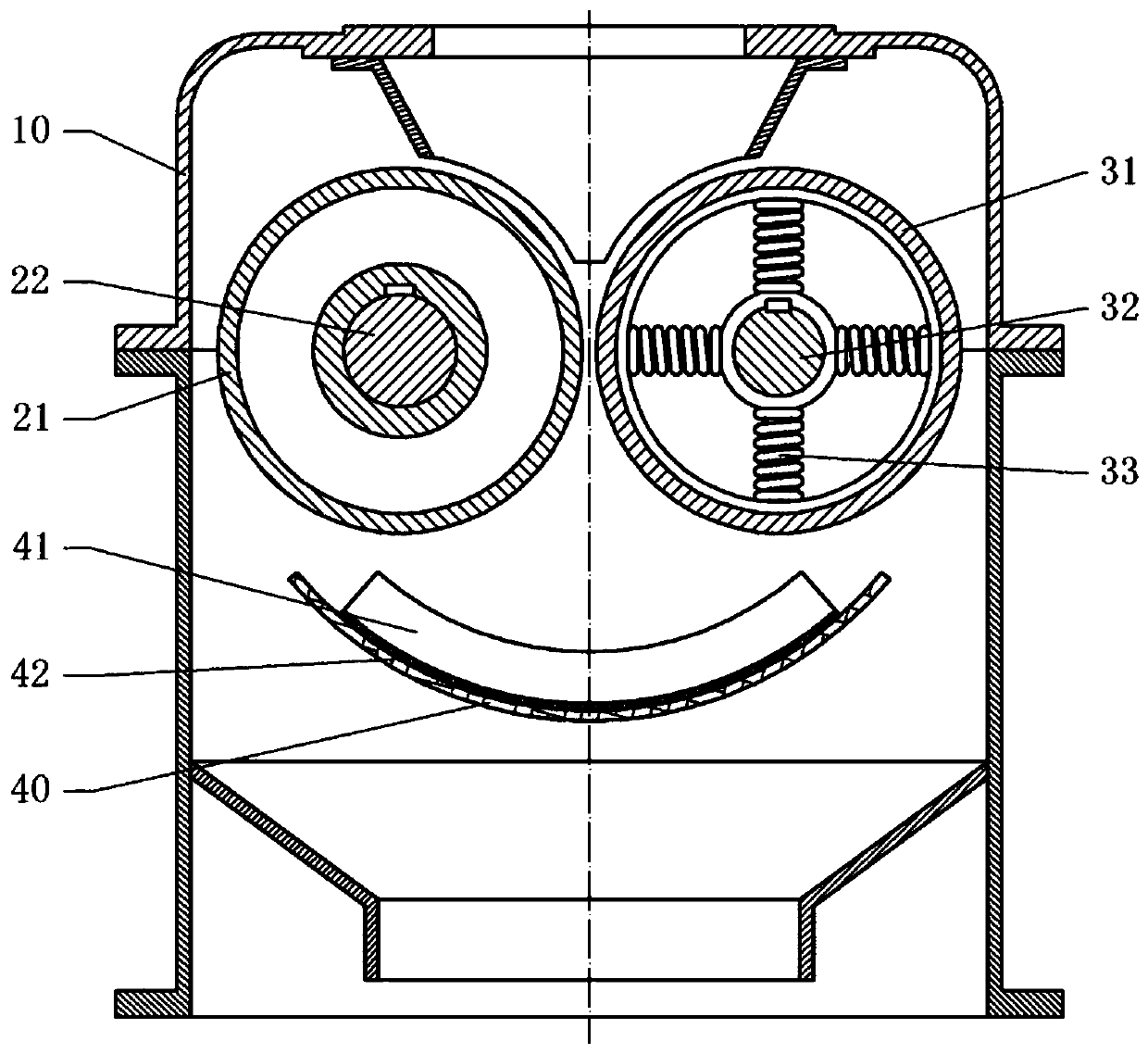

Pair roller crushing machine

The invention relates to a crushing device, and particularly discloses a pair roller crushing machine. The pair roller crushing machine is provided with a driving roller assembly and a driven roller assembly, wherein when too hard materials pass through a position between the driving roller assembly and the driven roller assembly, the driven roller assembly can realize the active avoiding. A sievescreen is arranged under the driving roller assembly and the driven roller assembly; the sieve screen is driven to swing by a crank rocker mechanism; a material pushing plate is arranged on the sievescreen and is driven by an air cylinder; gas is supplied to the air cylinder by a gas generating mechanism; the material pushing plate is driven to do clearance reciprocating movement, so that wastematerials on the sieve screen can be discharged. Through the sieve screen arranged under the driving roller assembly and the driven roller assembly, after the retreating avoidance of the driven roller, uncrushed raw materials can be mixed into the crushed raw materials; through the sieve screen, unqualified waste materials are screened out.

Owner:重庆市南川区王小平机械制造有限公司

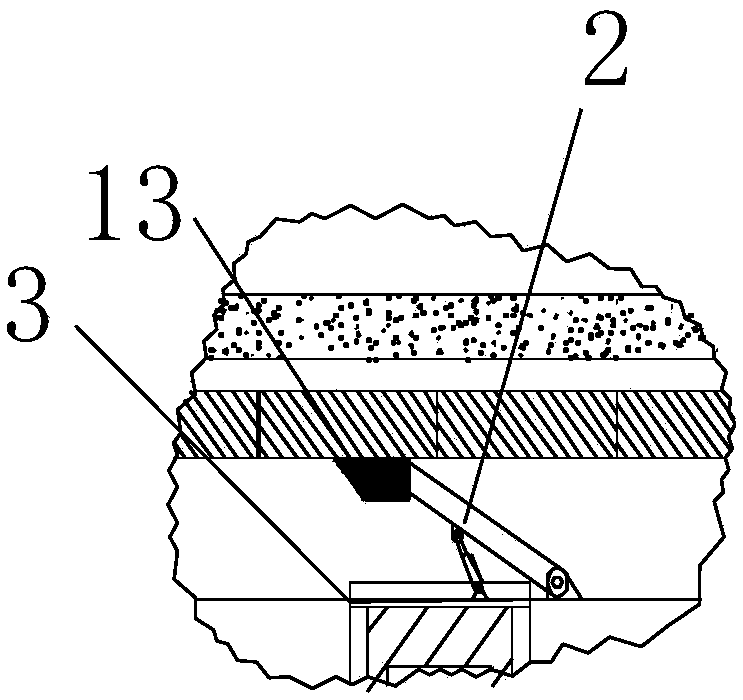

Construction method for internally penetrating steel pipes for top pipe of water diversion project

ActiveCN113339585AFlexible height changeStrong penetrating powerPipe laying and repairArchitectural engineeringWater diversion

The invention discloses a construction method for internally penetrating steel pipes for a top pipe of a water diversion project. The construction method comprises the following steps that (a) construction preparation is conducted; (b) the first steel pipe is in place; (c) the first steel pipe is positioned; and (d) the pipes are penetrated one by one. According to the construction method, the construction difficulty is low, the efficiency is high, flexibility and applicability are achieved, the front and back steps are orderly, control is convenient, the construction quality is ensured, steel pipe pushing is convenient and fast, the equipment input cost is low, the front steel pipe and the back steel pipe are connected firmly, the structure is stable, the sealing performance is high, and the service life is long.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

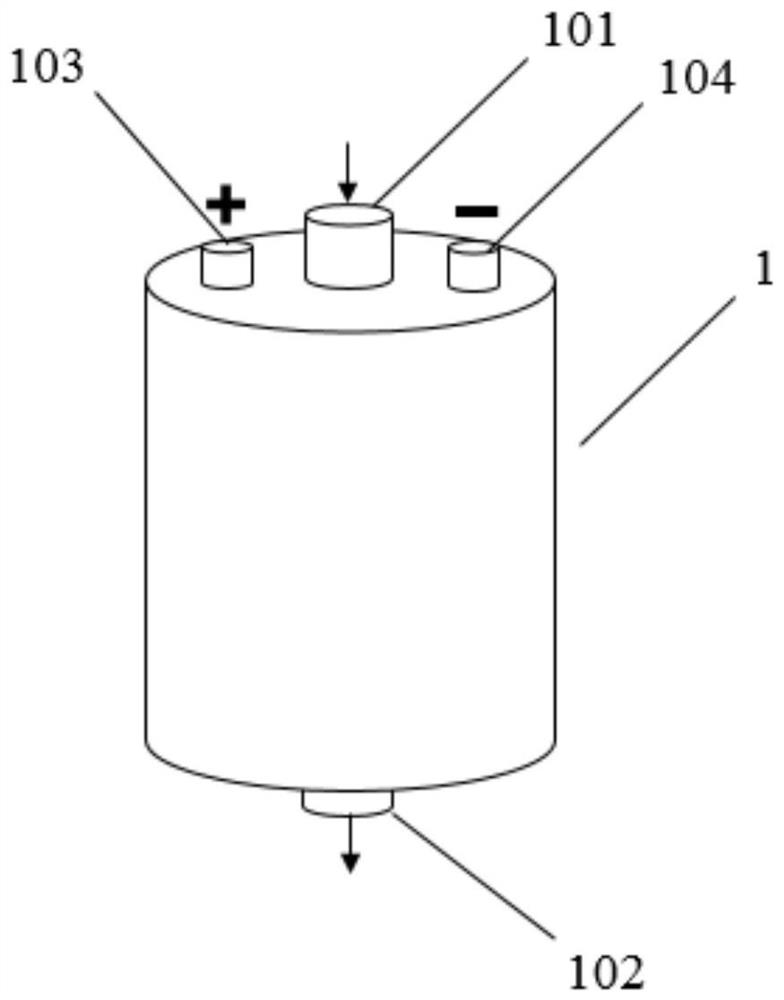

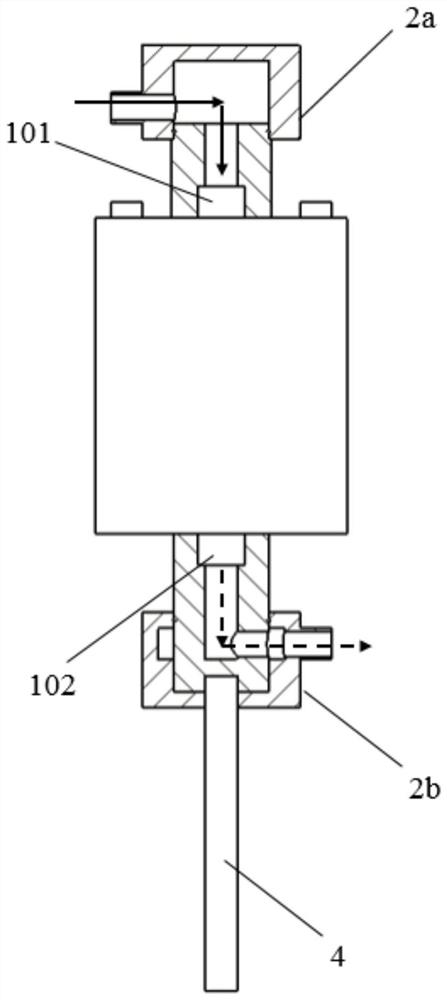

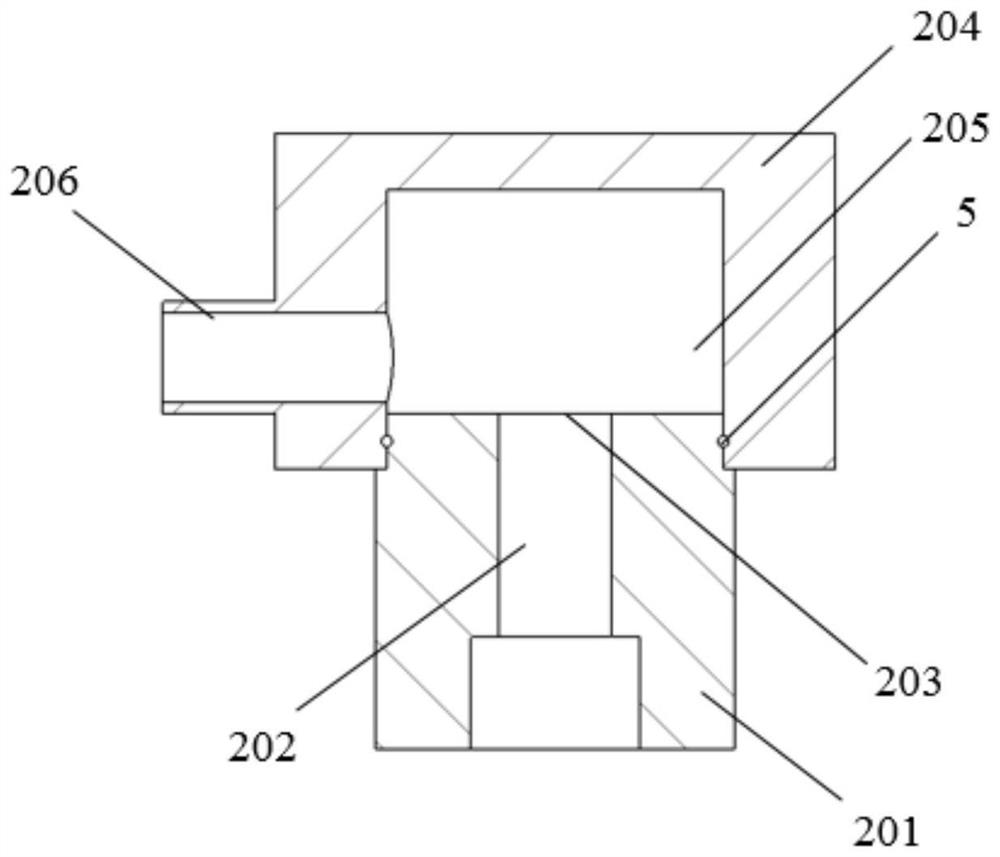

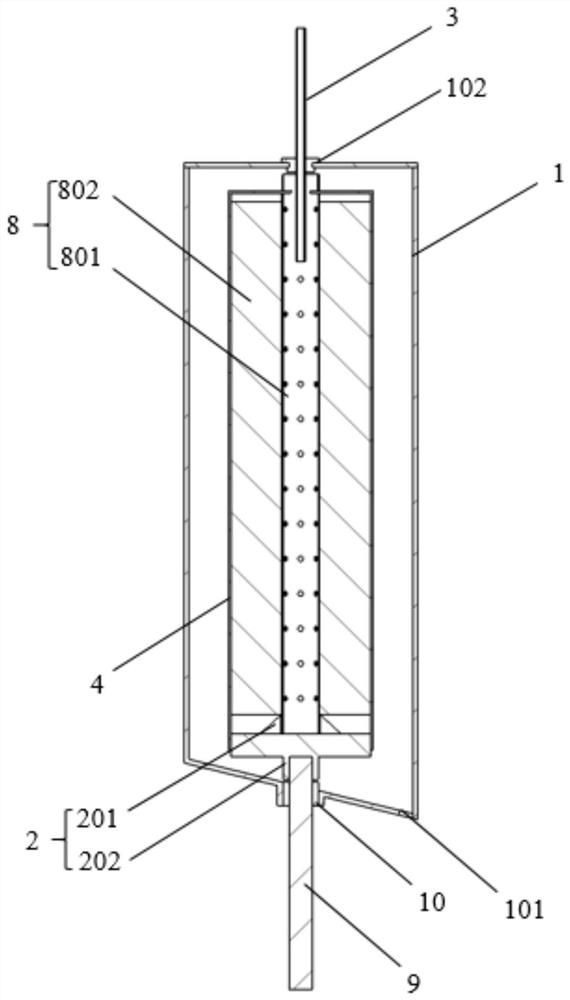

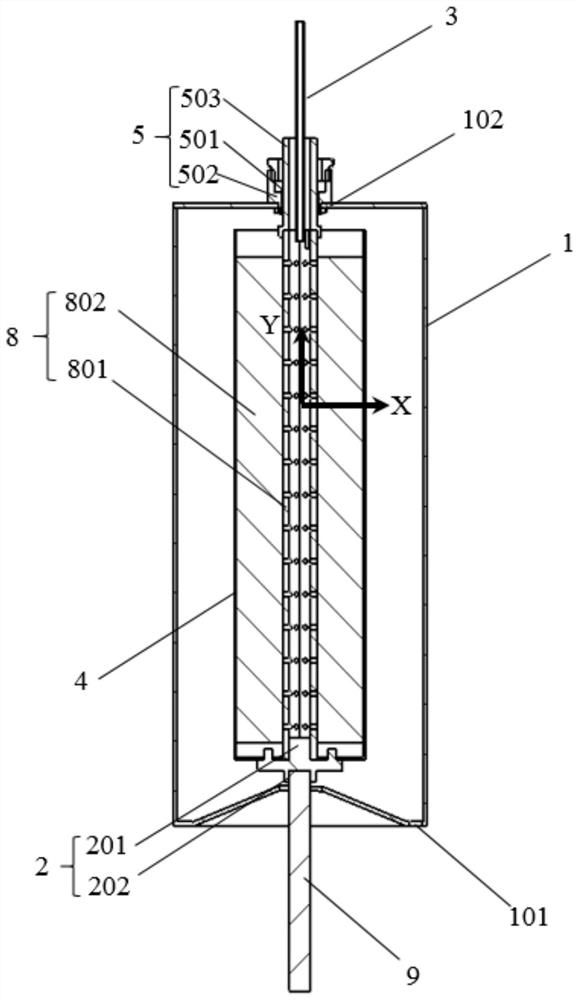

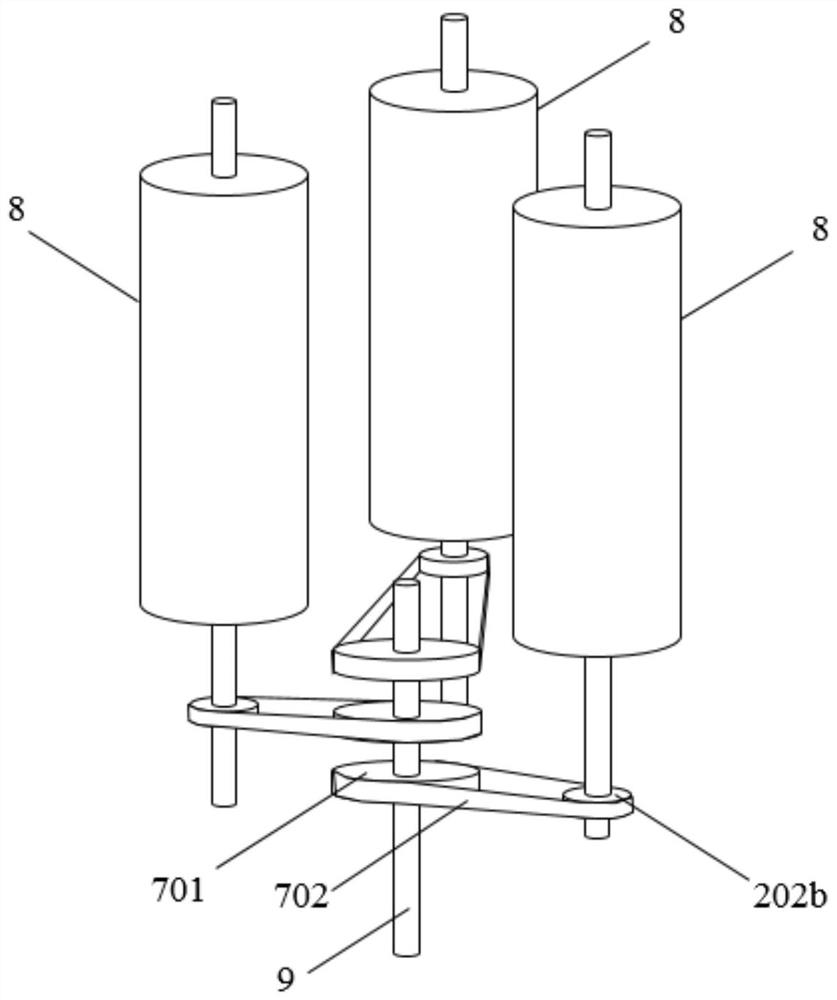

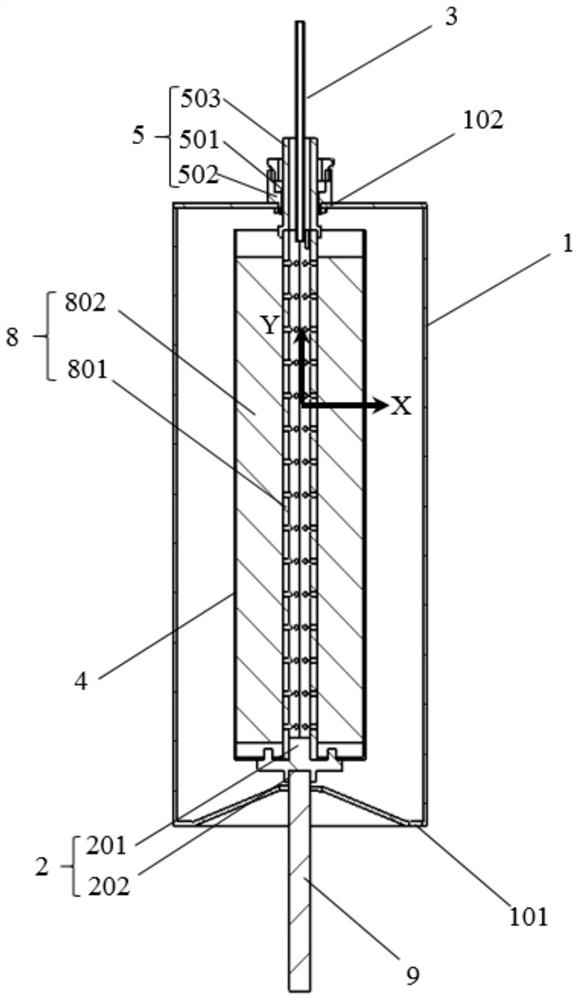

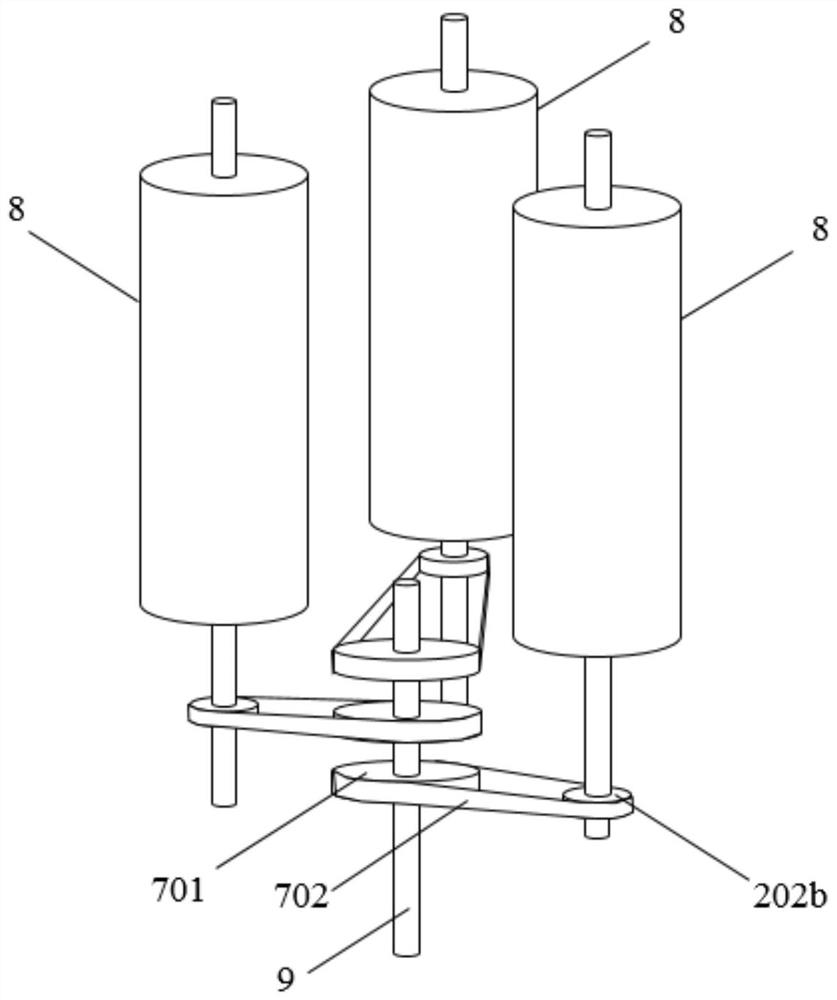

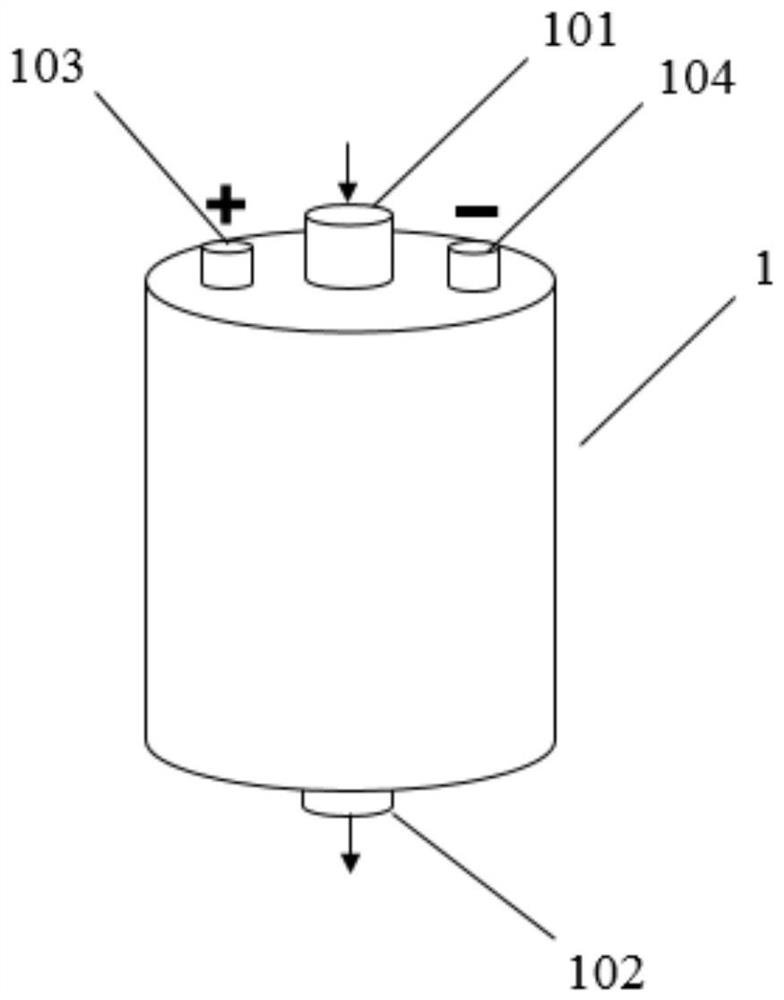

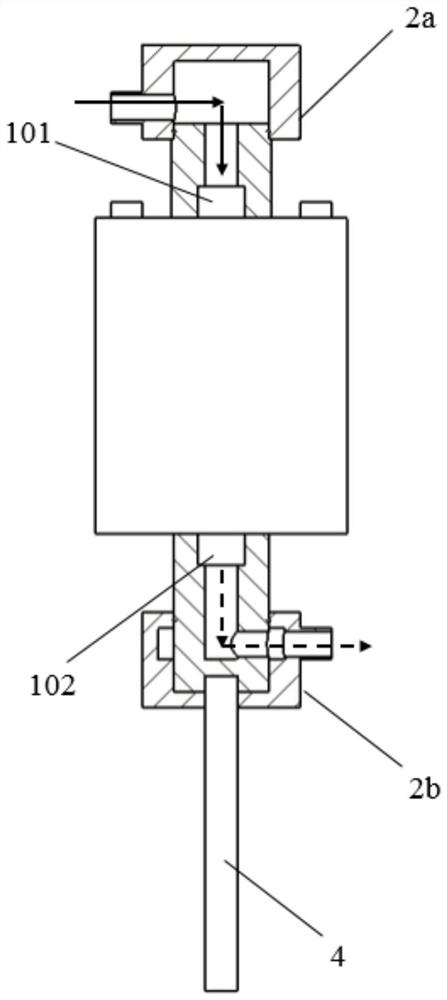

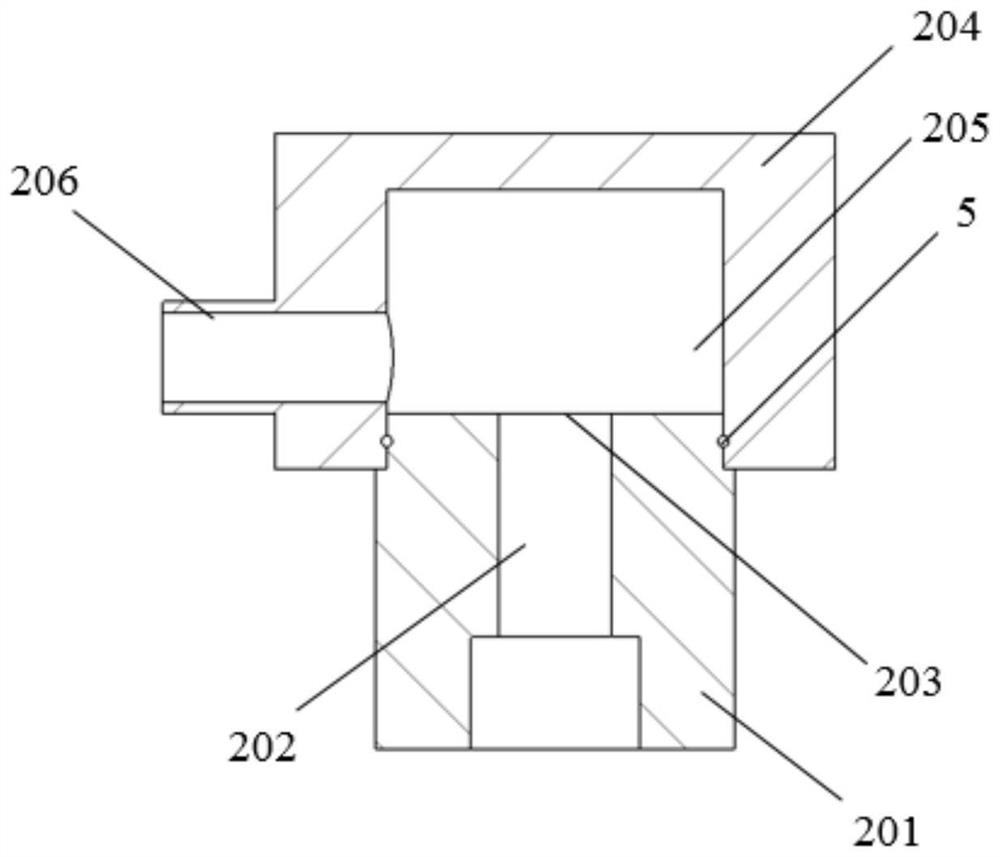

Device and method for liquid injection and liquid replacement of cylindrical battery

ActiveCN111785906AImprove infiltration efficiencyDrain fastCell component detailsPhysicsElectric machinery

The invention provides a liquid injecting and liquid replacing device for a cylindrical battery, wherein the liquid injecting and liquid replacing device is provided with a liquid injecting and discharging device and a battery rotating device. According to the invention, the battery rotating device can be fixedly connected with at least one part of a cylindrical battery, and the battery rotating device can be connected with the rotating shaft of a motor, so that the motor drives the battery rotating device to rotate so as to further drive the cylindrical battery to rotate; the liquid injectingand discharging device comprises a rotating part rotating together with the cylindrical battery and a fixing part used for being in butt joint with an external fluid storage device / fluid recovery device, wherein the fixing part is connected to the rotating part in a sleeving manner and is internally in fluid communication, so that the cylindrical battery can be in fluid communication with the external stationary fluid storage device / fluid recovery device while rotating; and under the action of centrifugal force, the liquid injected into the cylindrical battery can fully infiltrate the whole battery core, or the liquid in the battery core in the cylindrical battery can be thrown out and new liquid can be continuously injected to quickly replace the original liquid.

Owner:BEIJING HAWAGA POWER STORAGE TECH

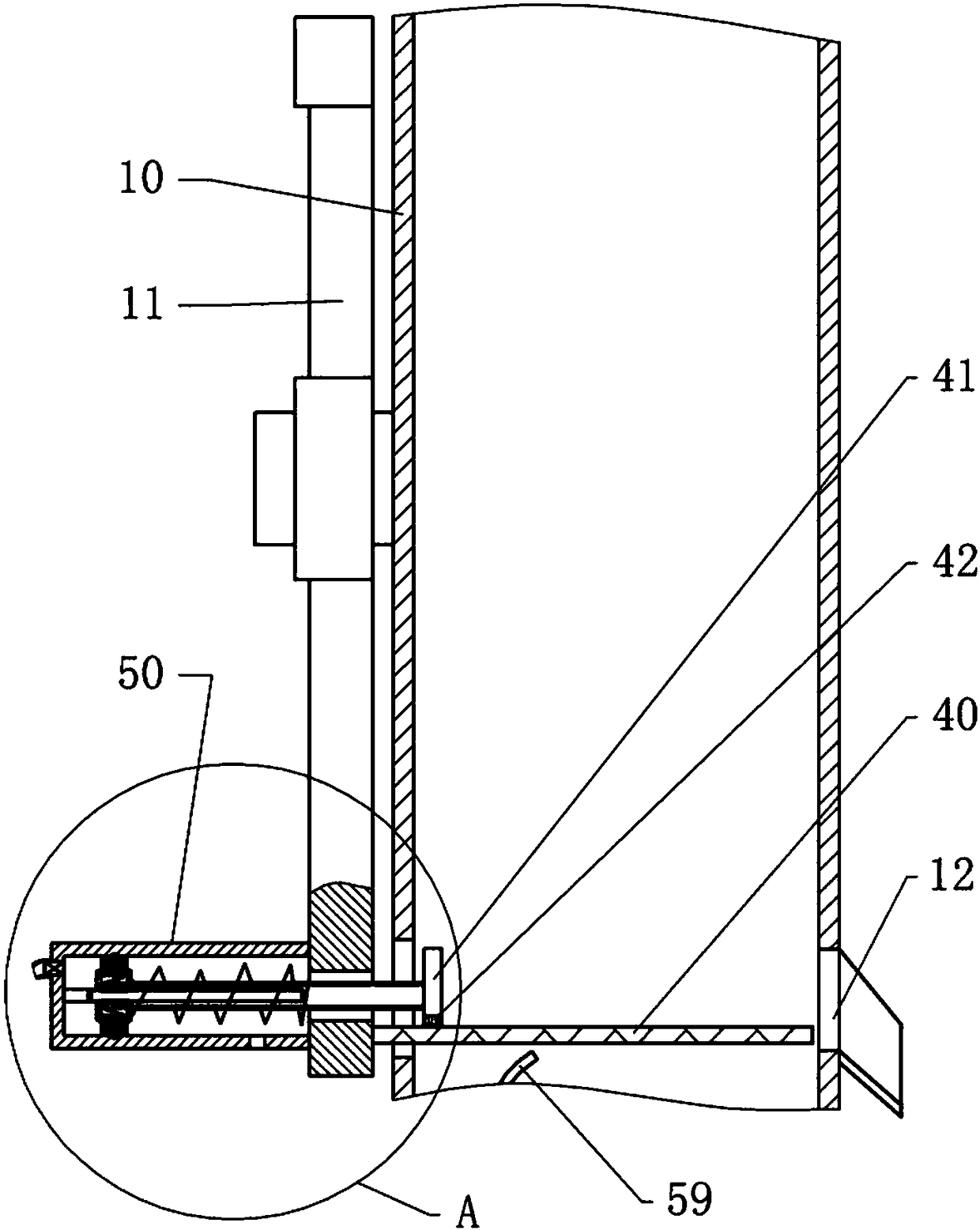

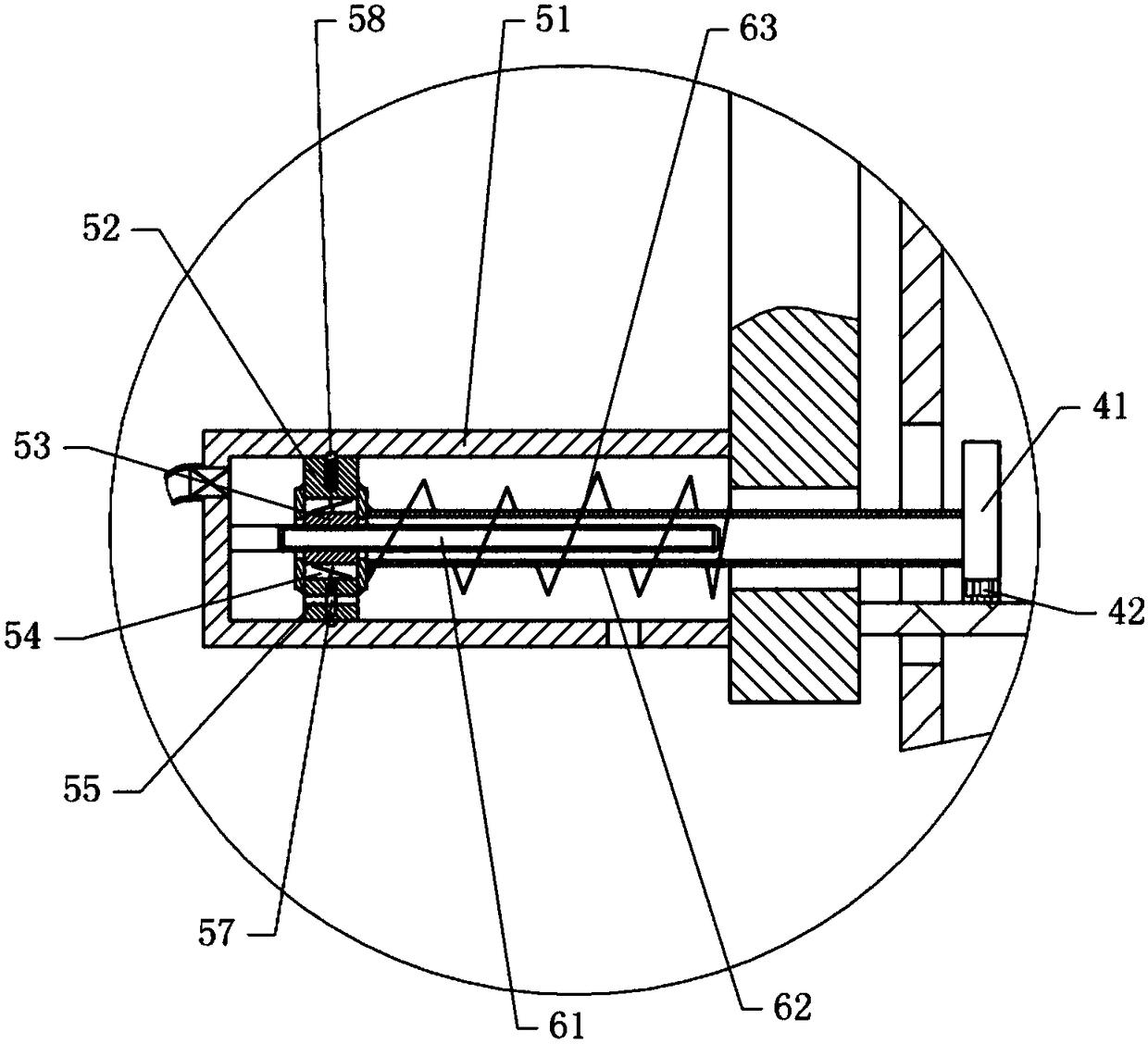

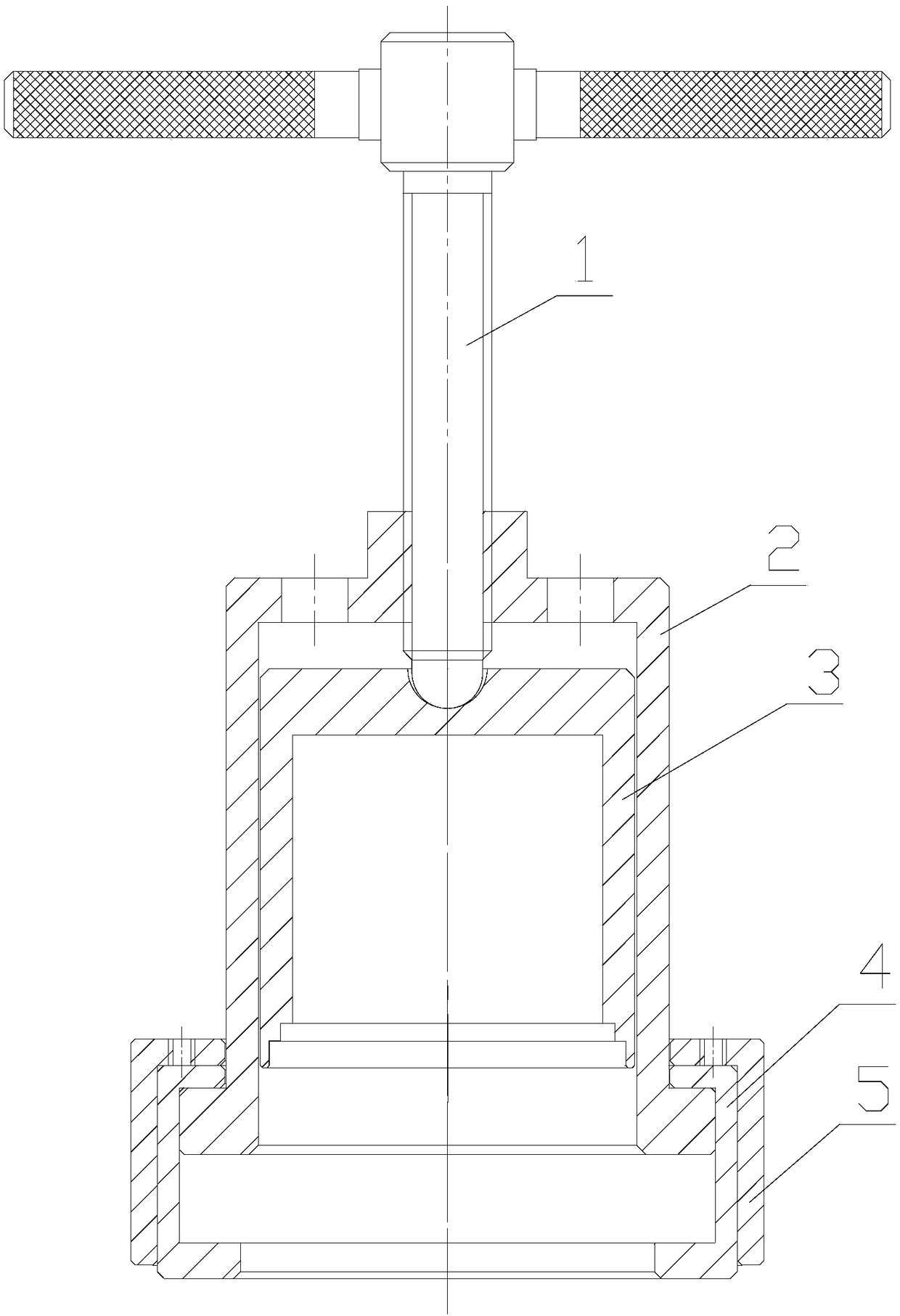

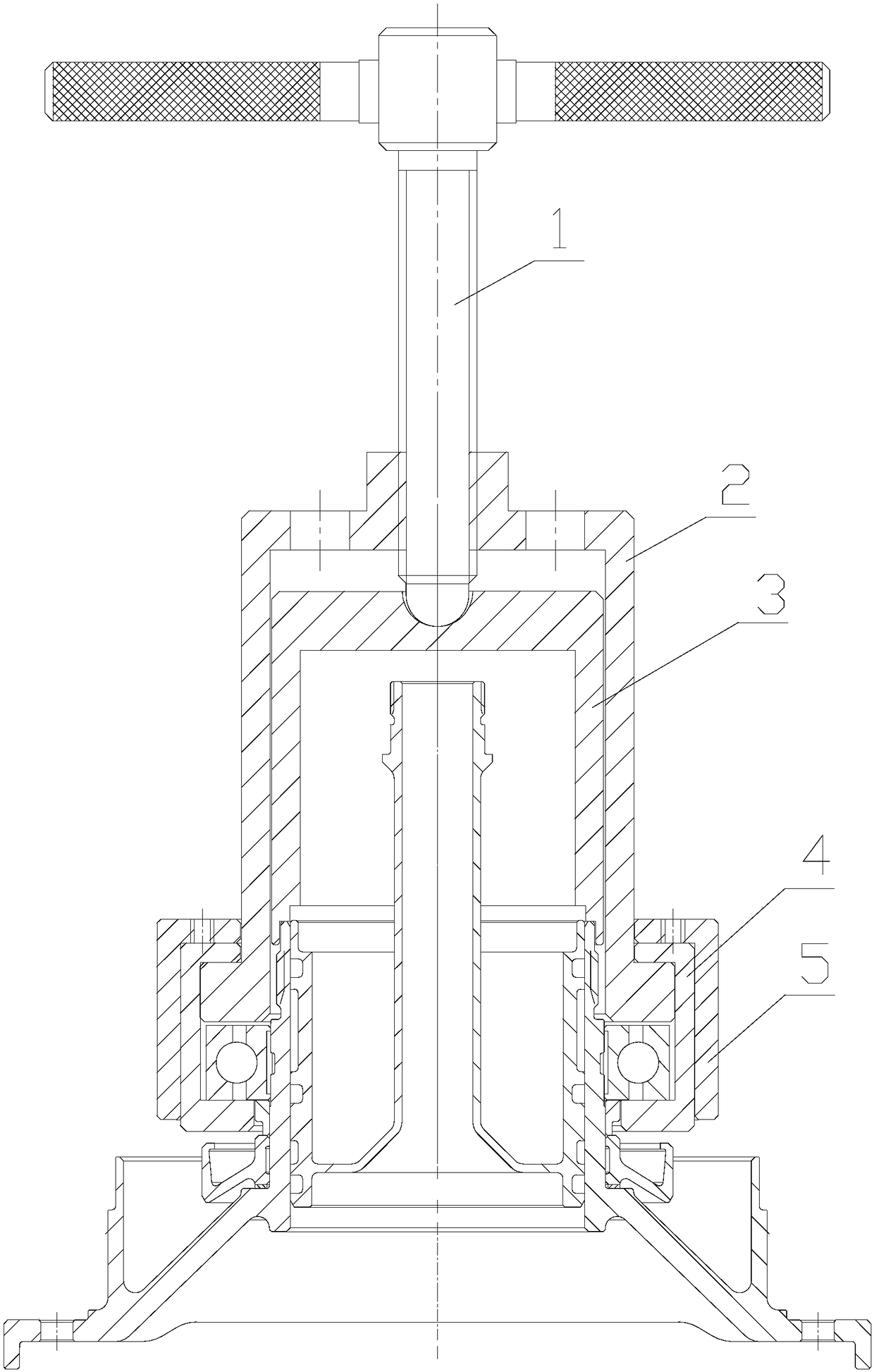

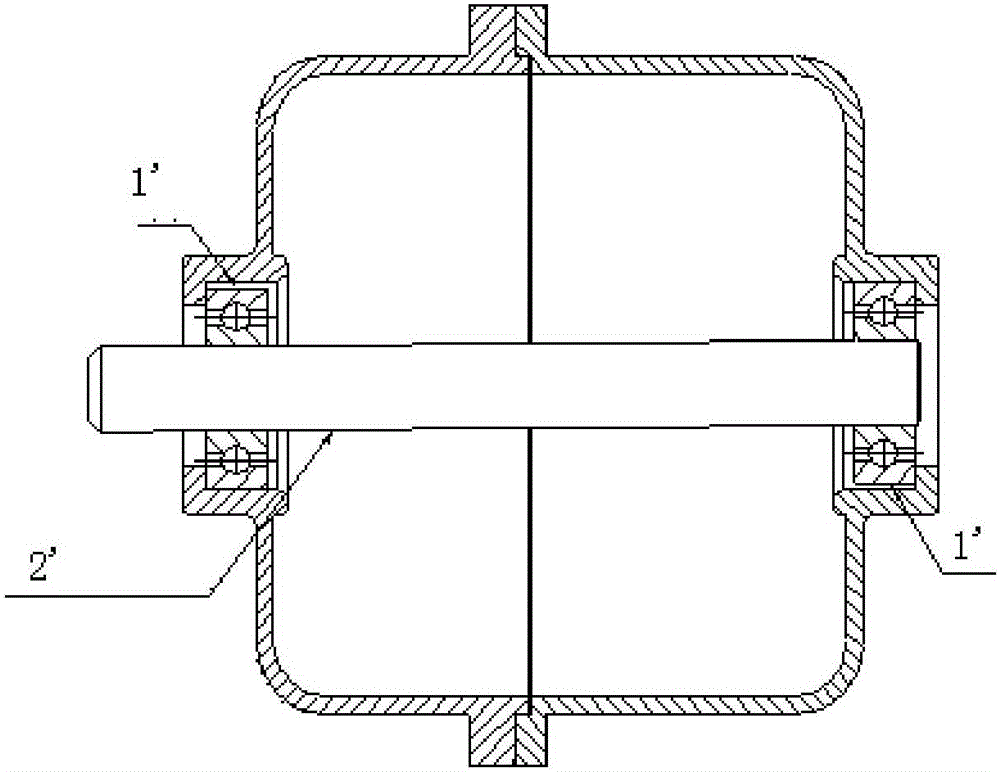

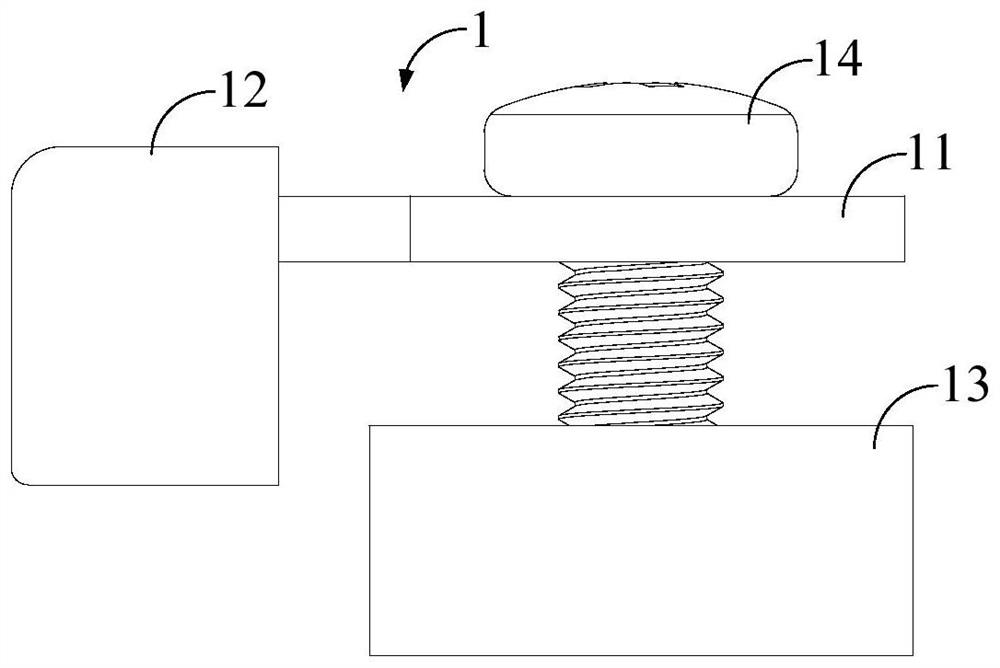

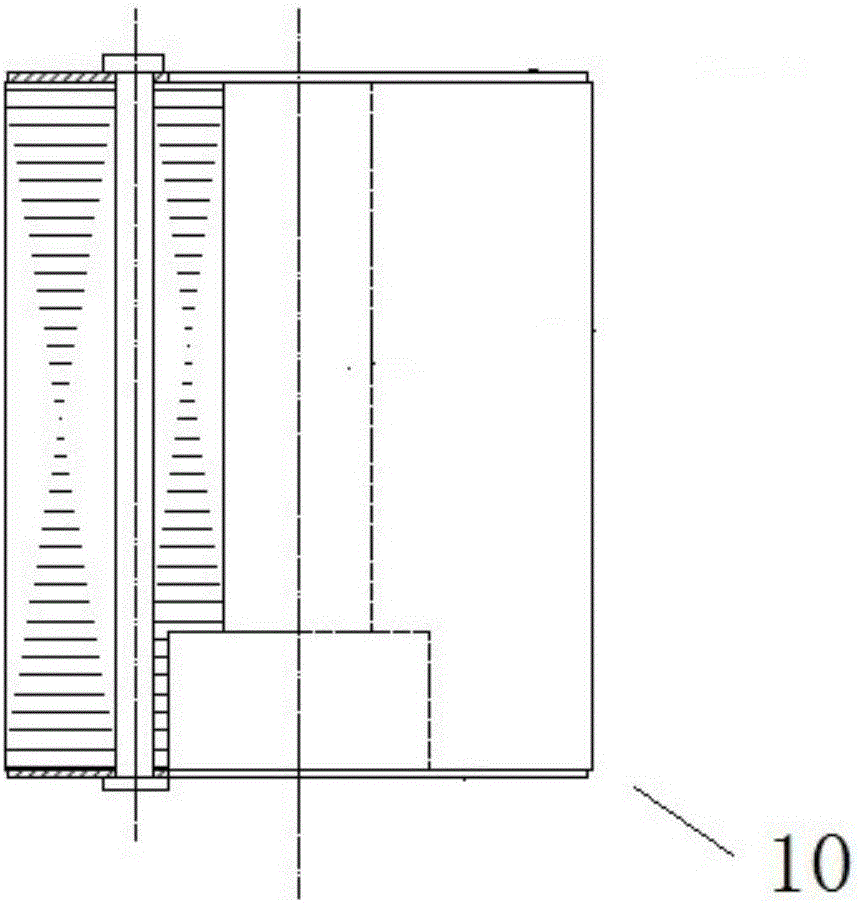

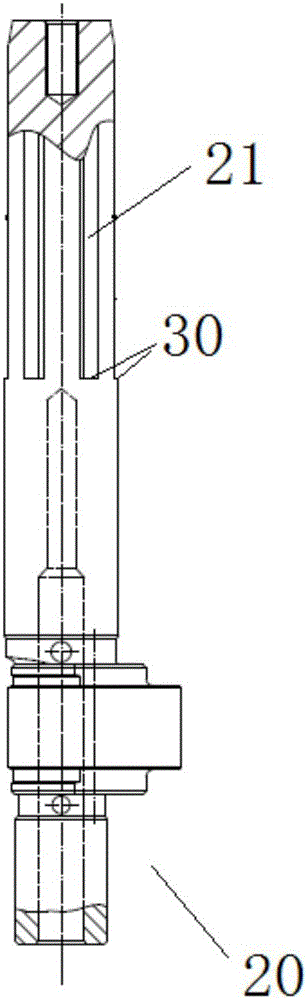

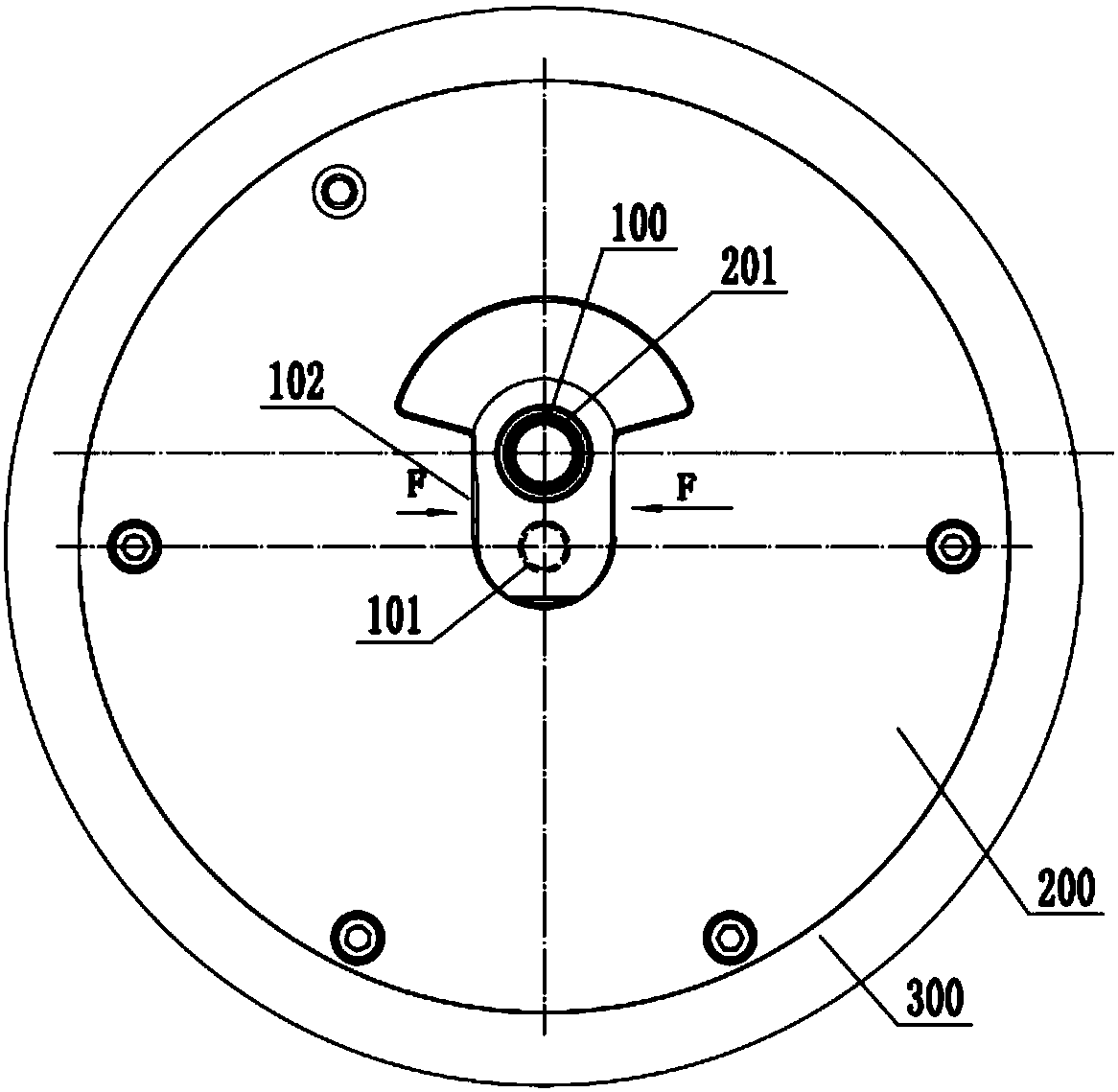

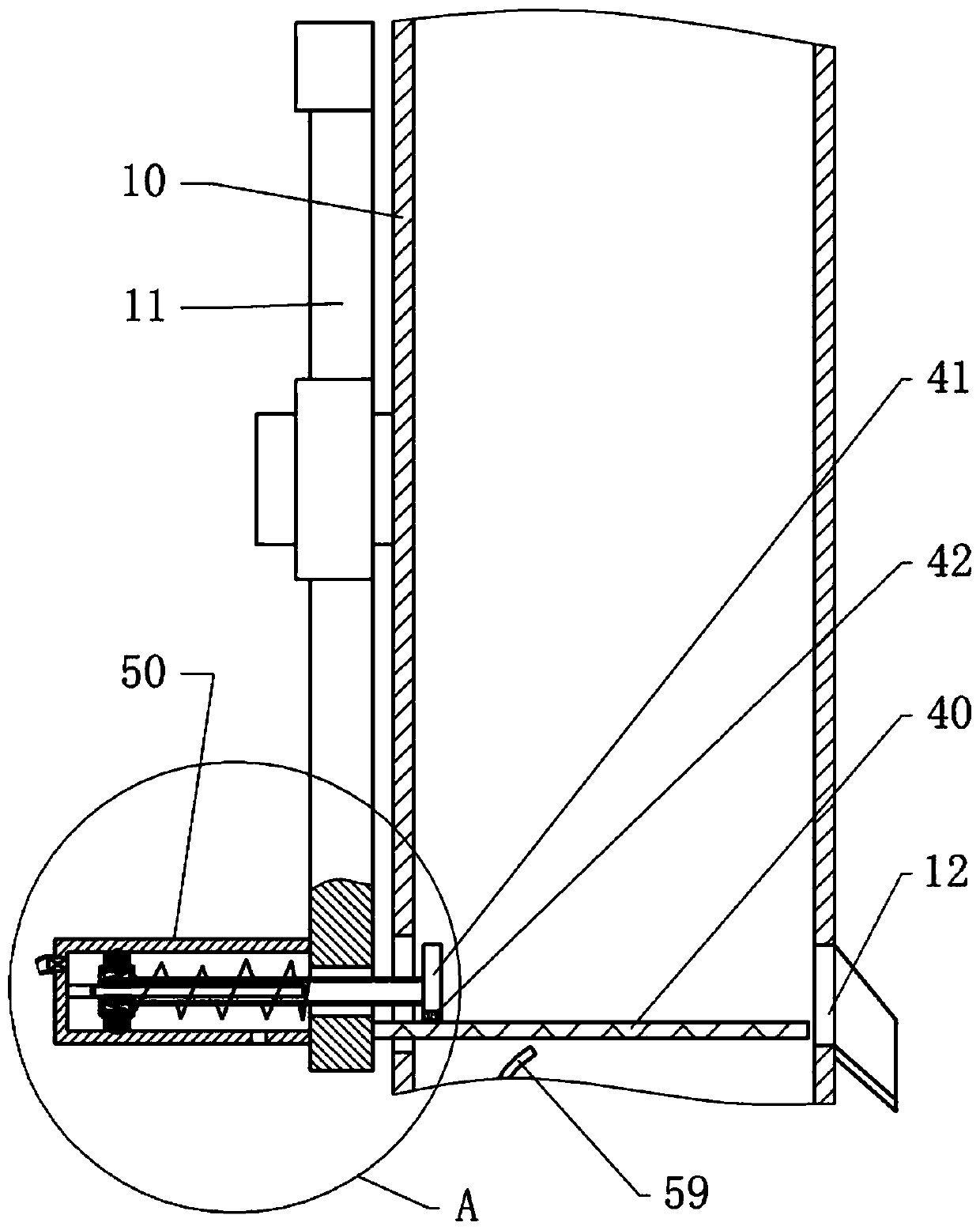

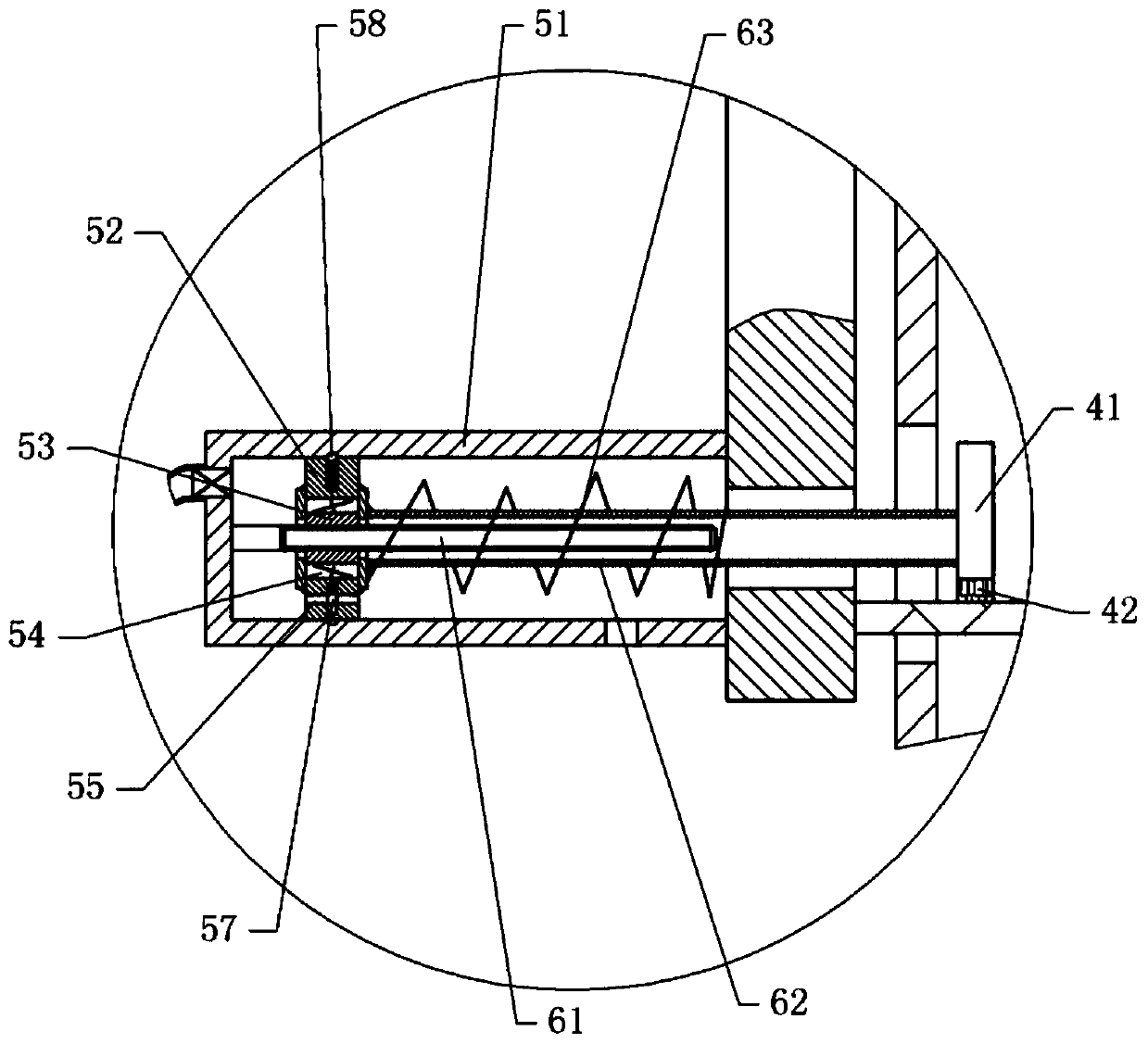

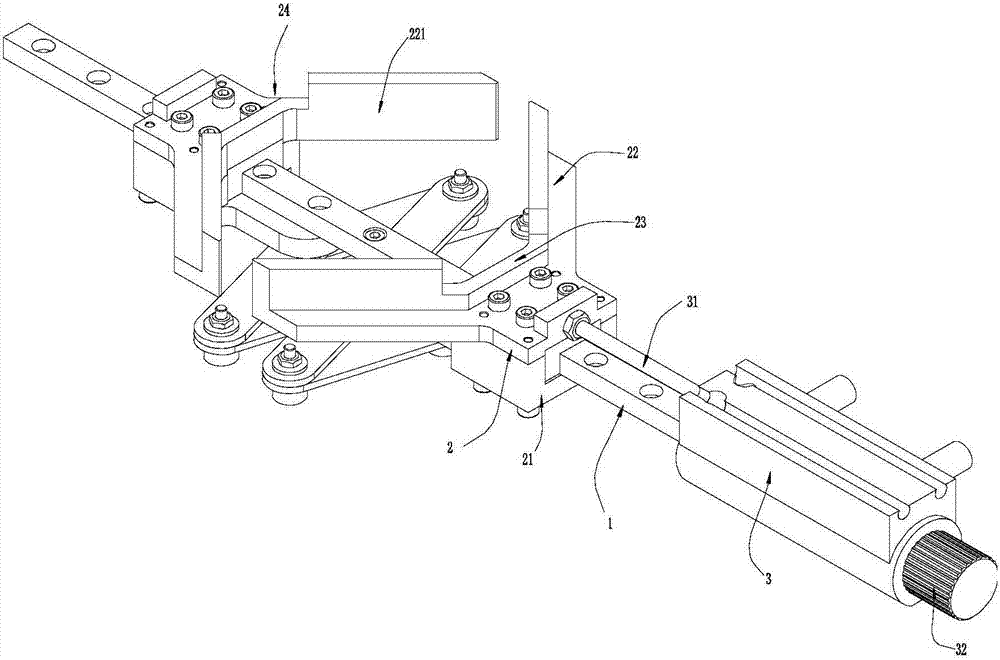

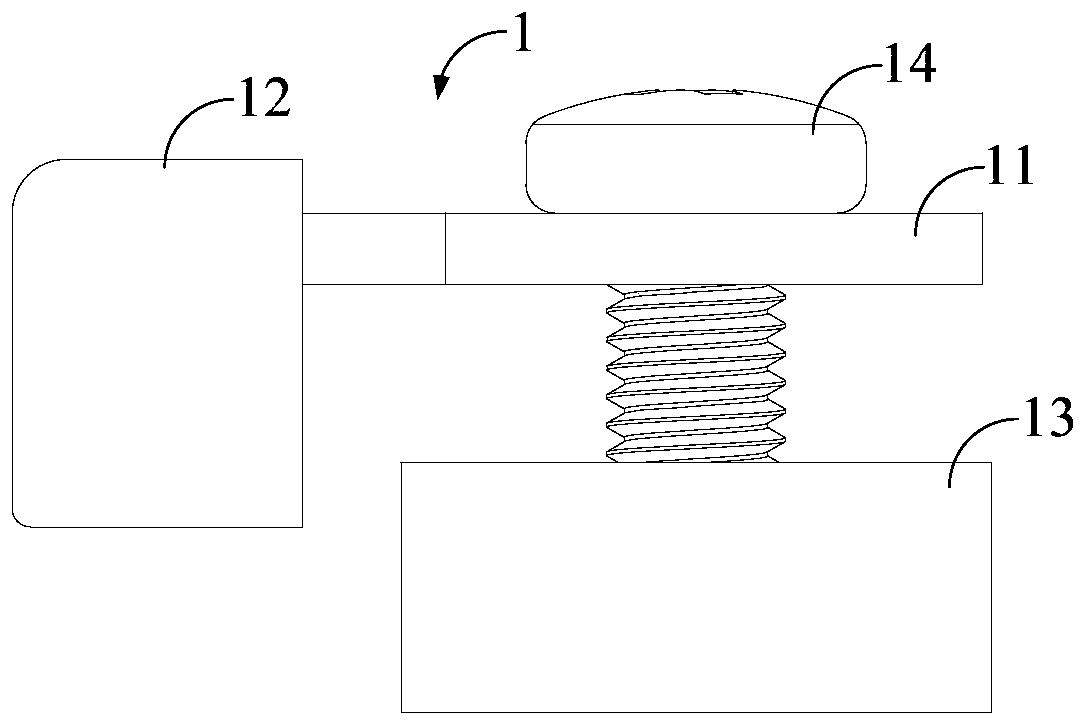

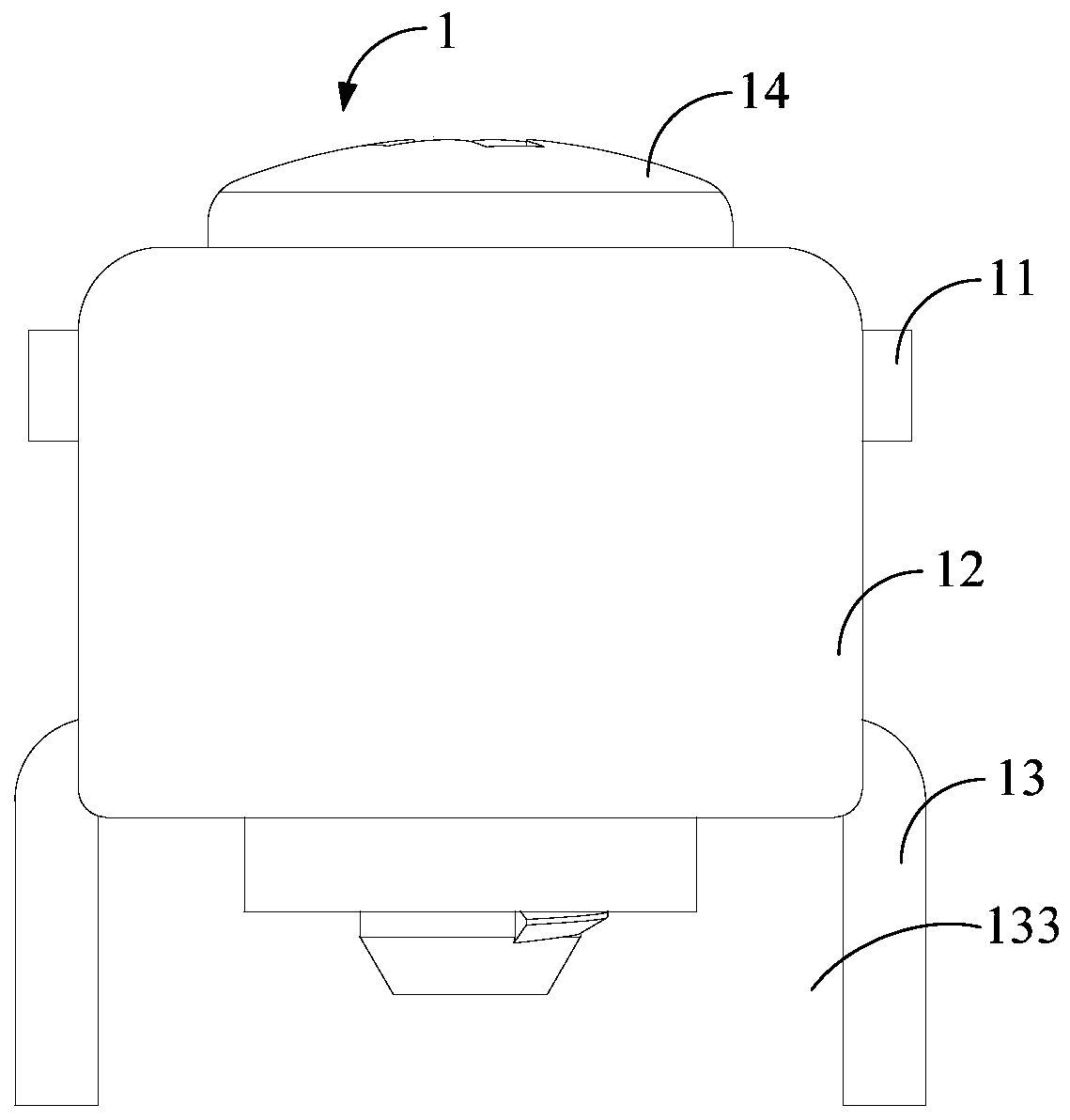

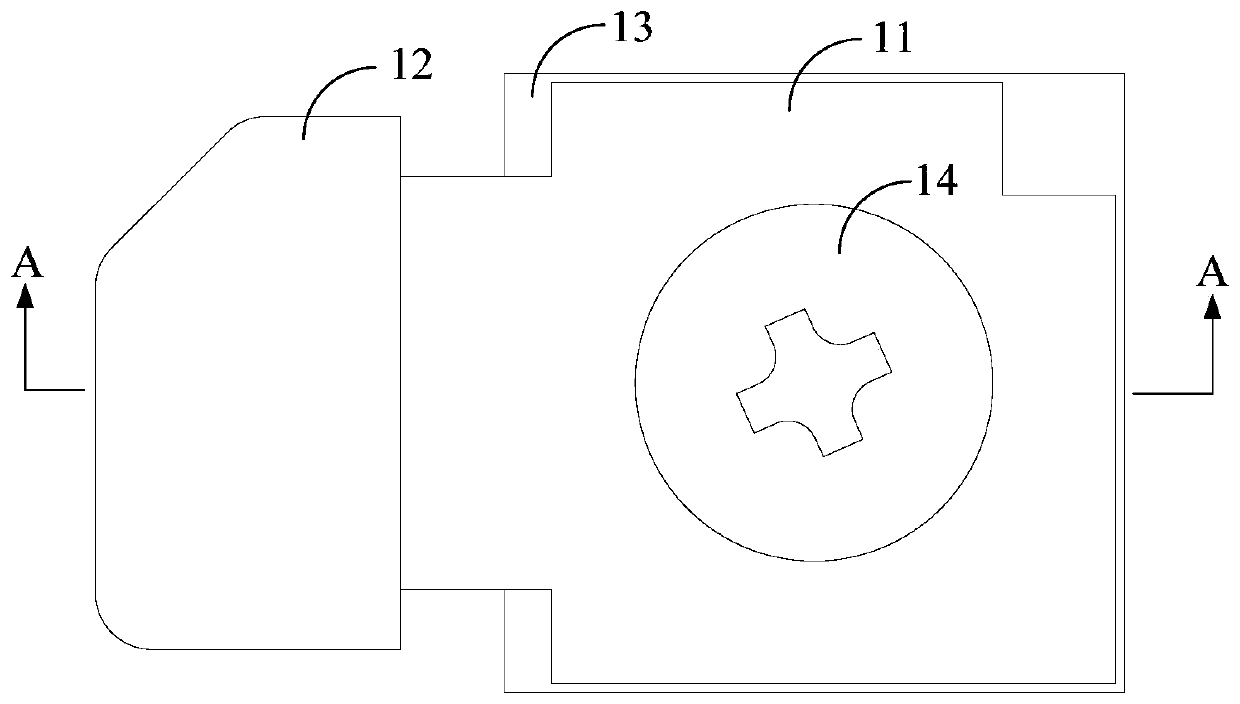

Quick bearing disassembly device

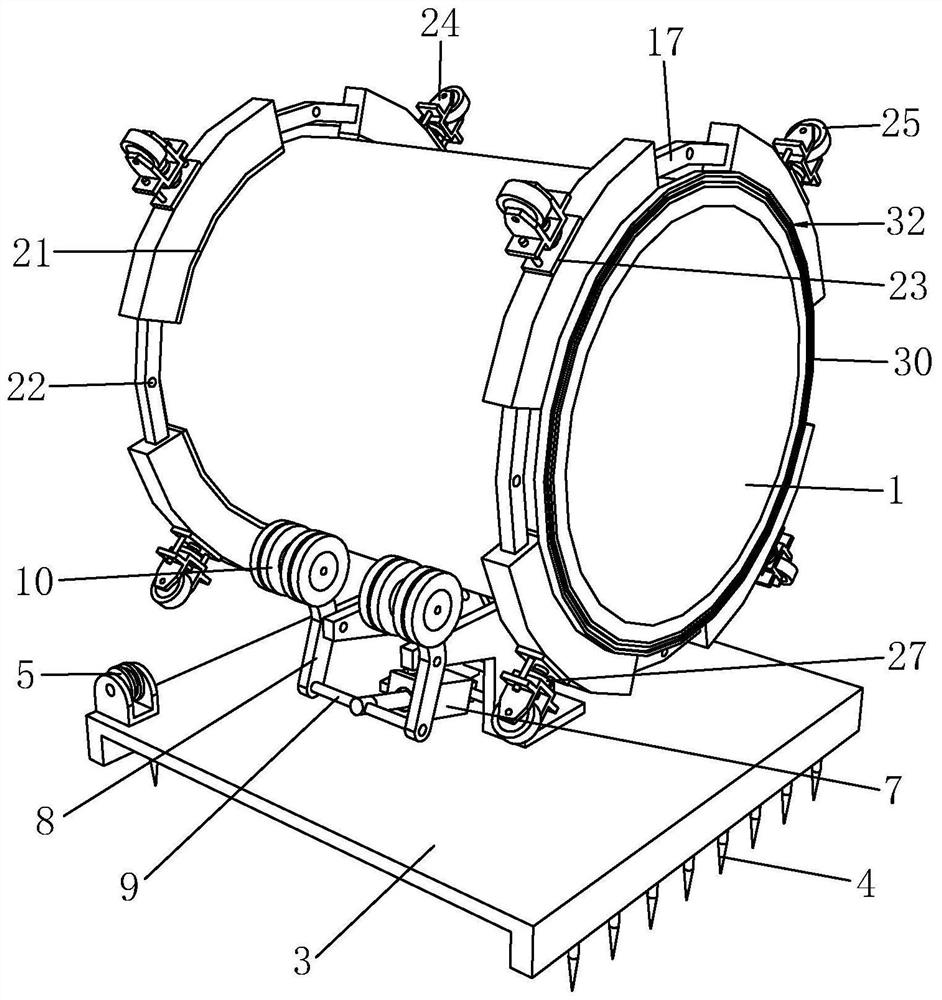

The invention belongs to the technical field of aeroengine assembly and particularly relates to a quick bearing disassembly device as shown in a drawing 1. The quick bearing disassembly device is simple in structure and convenient to operate. A bearing is pulled after being clamped by U-shaped open half pulling rings and is uniform in peripheral stress, and high contact stress is avoided due to surface-to-surface contact of contact end faces; the U-shaped open half pulling rings are tightly hooped by a pulling ring hoop and prevented from expanding outwards in a bearing pulling process, and slipping like pulling claws can be avoided. Therefore, the quick bearing disassembly device has advantages of high reliability, disassembly quality stability, high efficiency and high popularization andapplication value.

Owner:AECC SICHUAN GAS TURBINE RES INST

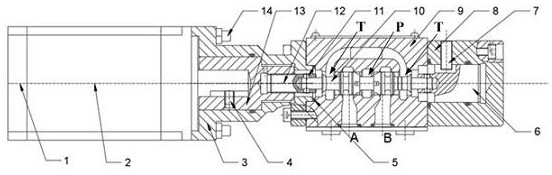

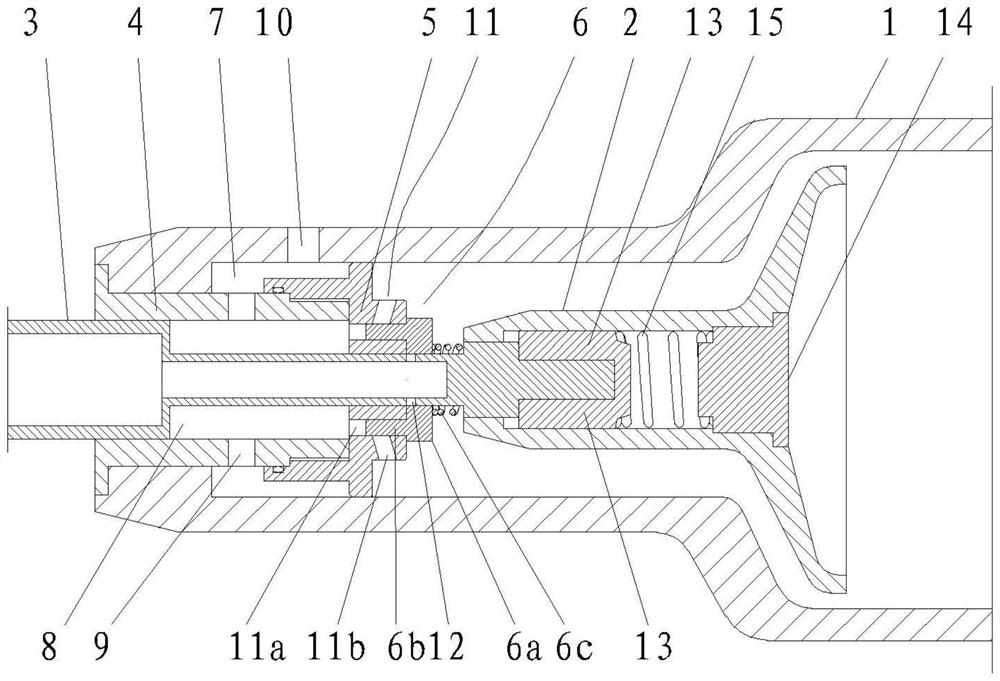

Digital reversing valve driven by servo motor

InactiveCN114658883AImprove performanceAvoid vibrationOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringControl valves

The invention discloses a digital reversing valve driven by a servo motor, and relates to the technical field of hydraulic and pneumatic transmission control valves. The problems of vibration, flow pulsation and uneven stress of a valve element of an existing digital reversing valve driven by a servo motor are solved, the valve element is sleeved with a valve body, the valve body is an O-shaped meso-position function three-position four-way valve body, and when the valve element is located at the meso-position of the valve body, the valve element is driven by the servo motor to rotate. A working cavity A, a working cavity B, an oil inlet P and an oil return opening T of the O-shaped meso-position function three-position four-way valve body are not communicated with one another, a servo motor rotates to drive a threaded sleeve to rotate, the threaded sleeve rotates to drive a threaded connecting rod to move leftwards or rightwards in the axial direction, when a valve element moves rightwards, the working cavity A of the O-shaped meso-position function three-position four-way valve body is communicated with the oil return opening T, the working cavity B is communicated with the oil inlet P, and the working cavity A is communicated with the oil return opening T; the working cavity B works; when the valve element moves leftwards, the working cavity A is communicated with the oil inlet P, the working cavity B is communicated with the oil return opening T, and the working cavity A works. The reversing valve is suitable for oil reversing.

Owner:NORTHEAST FORESTRY UNIVERSITY

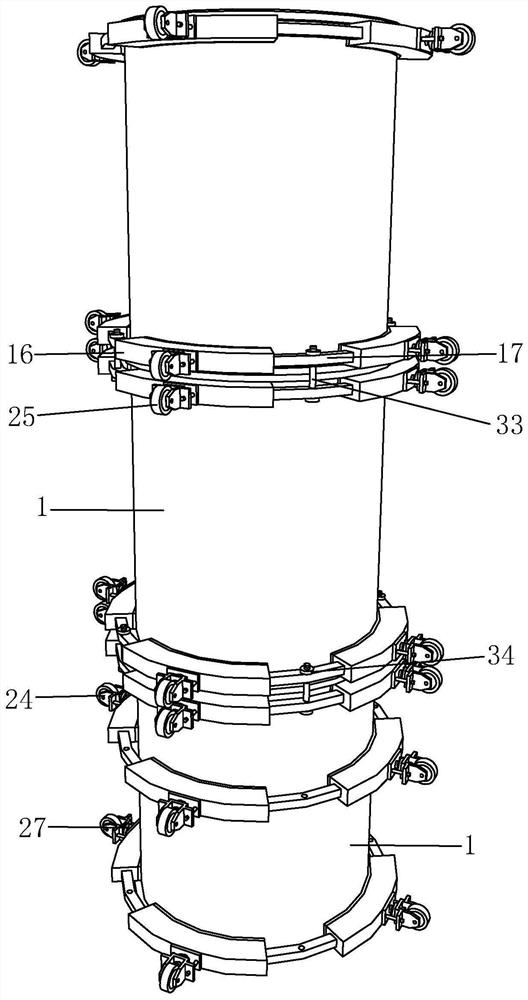

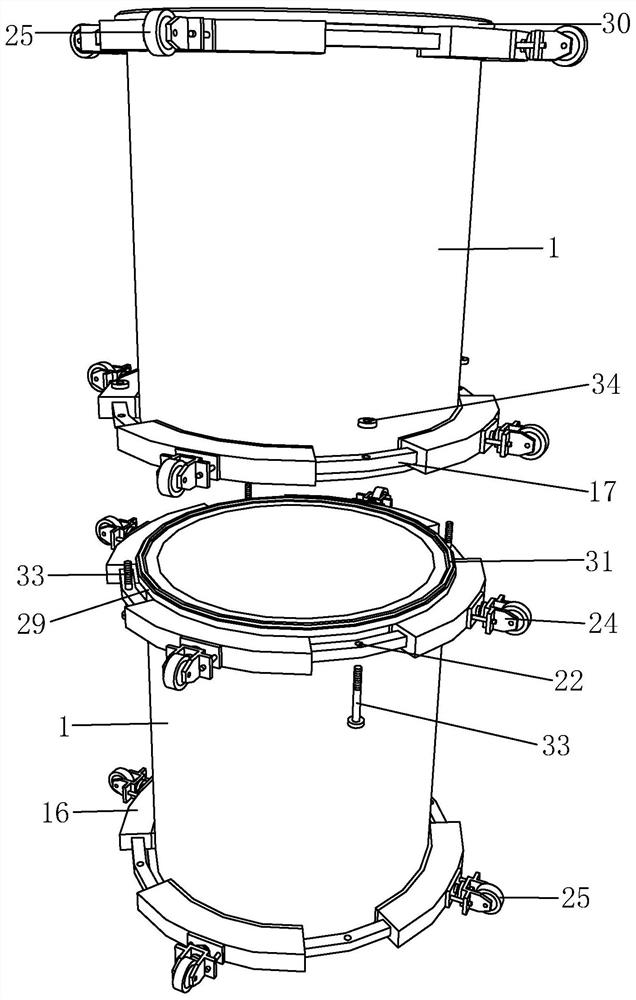

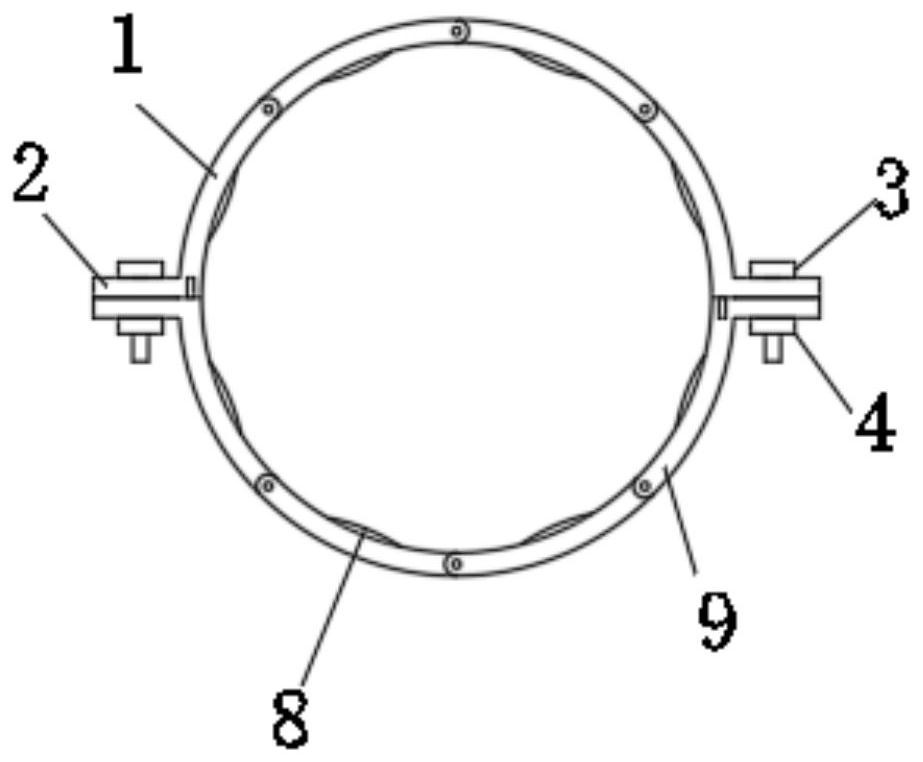

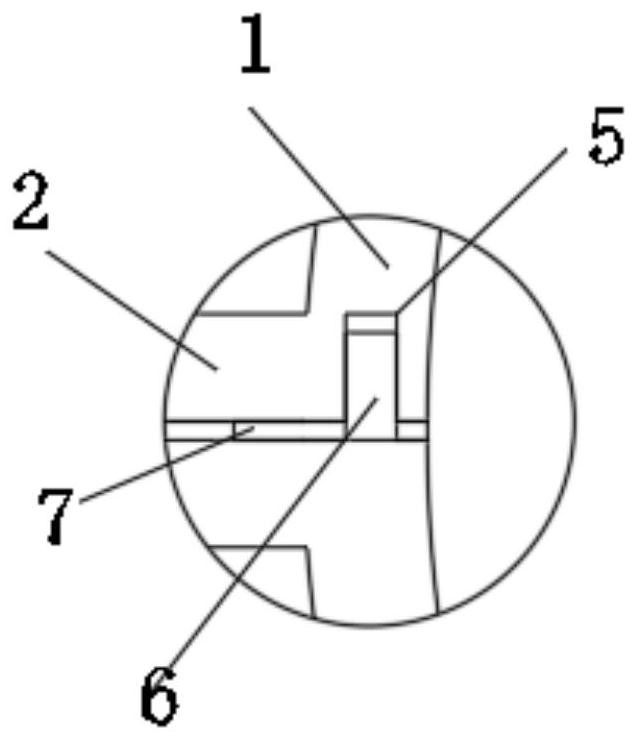

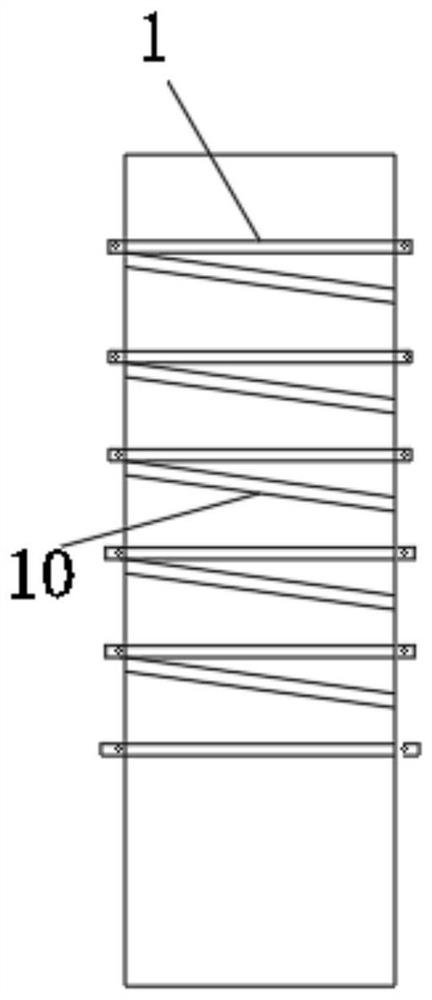

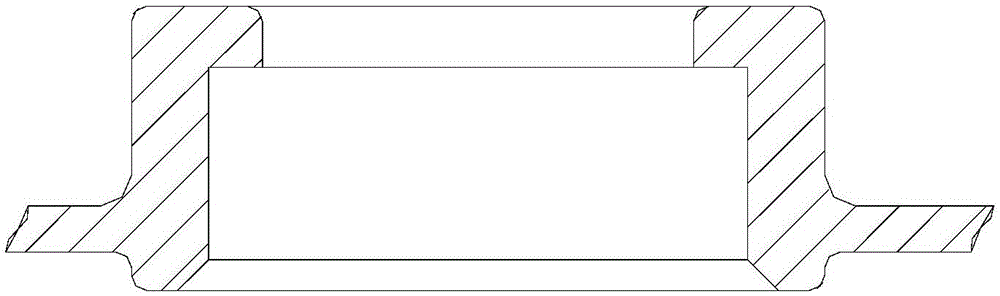

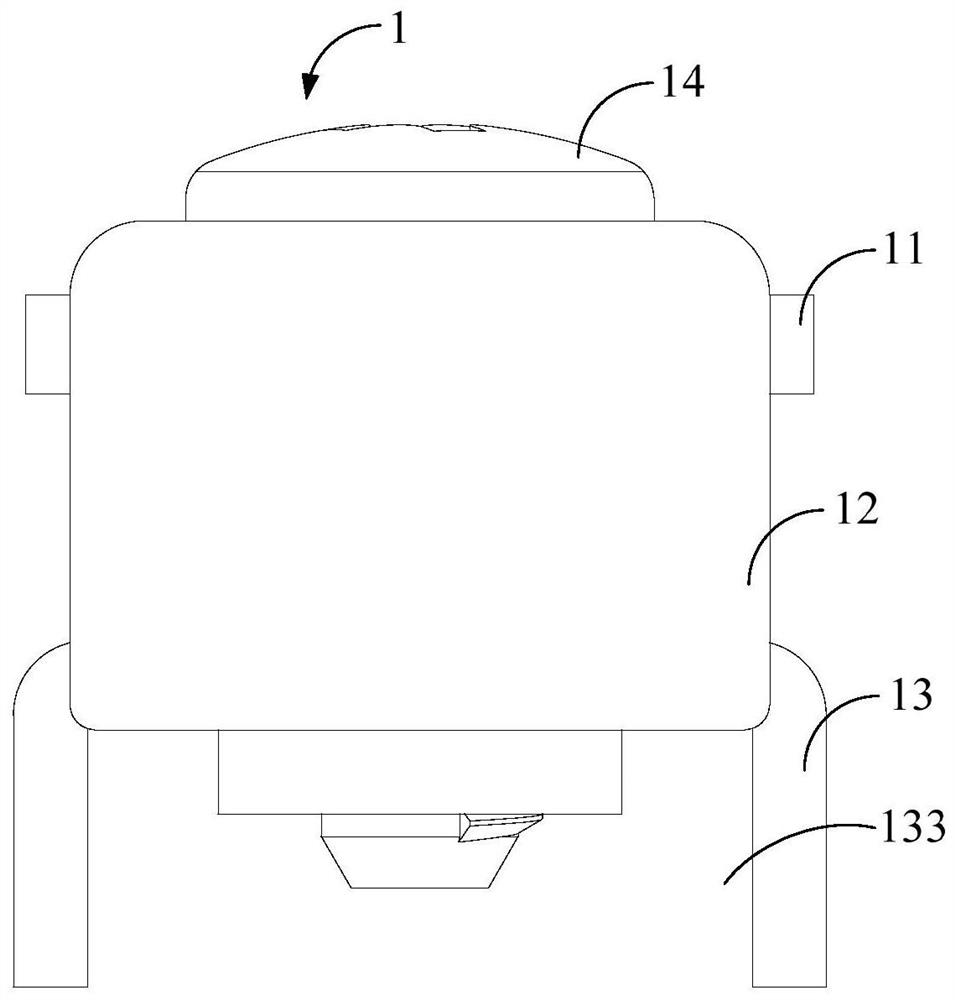

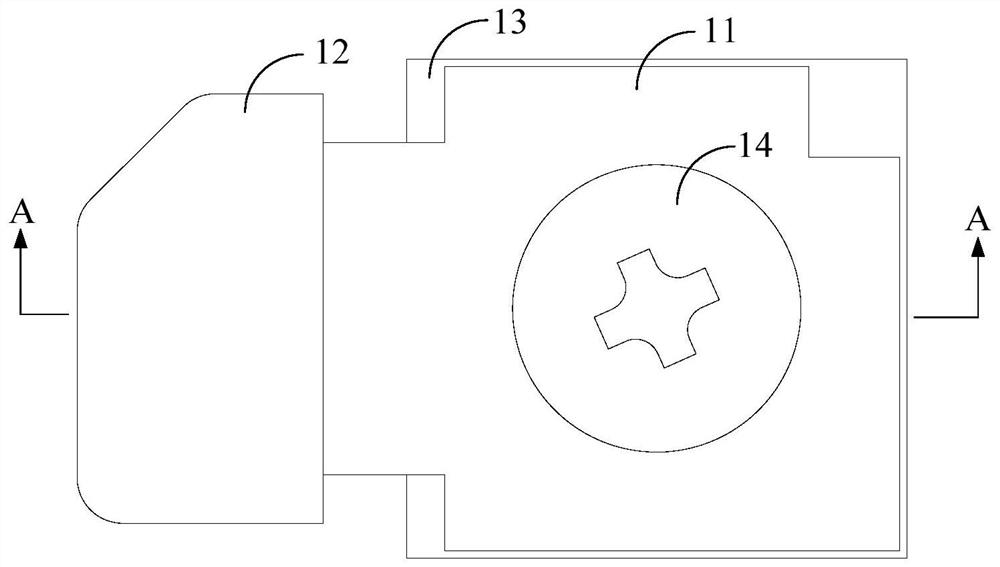

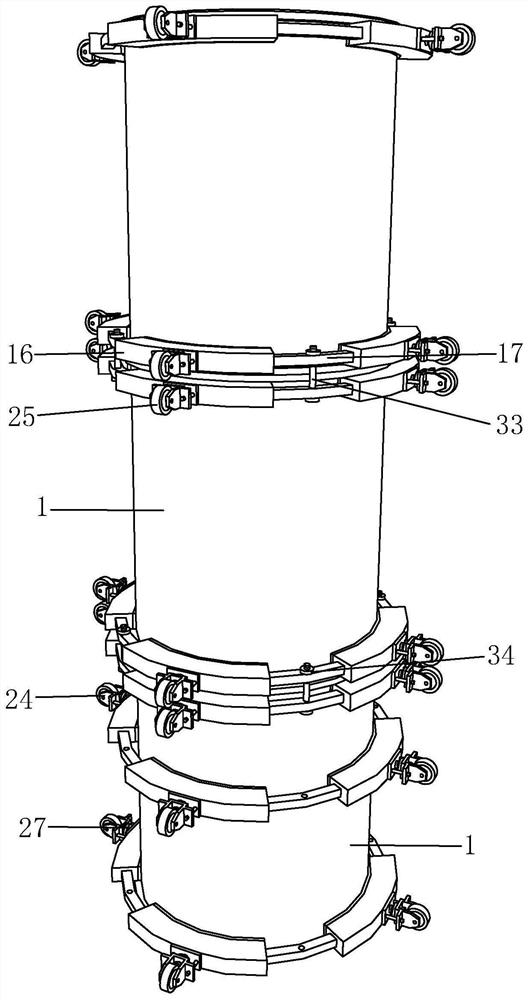

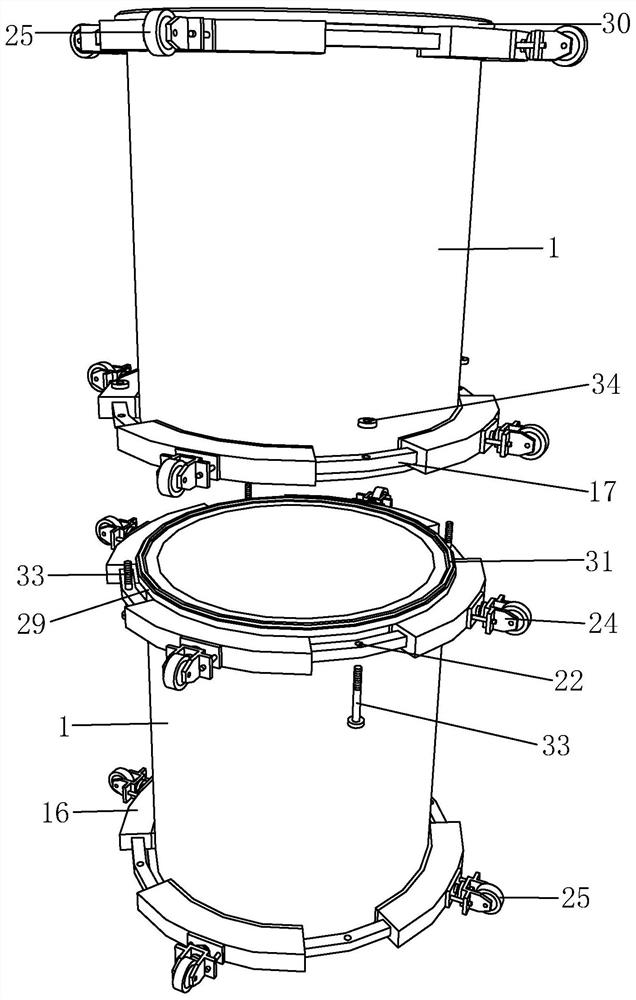

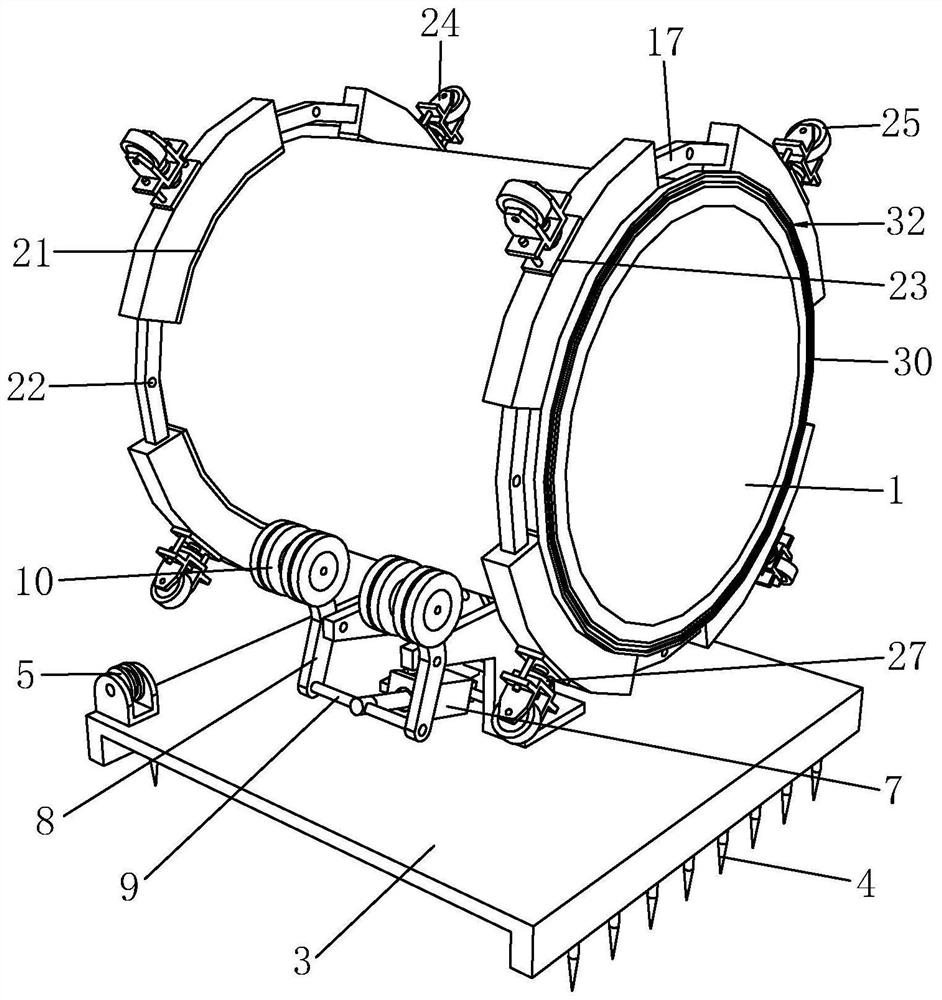

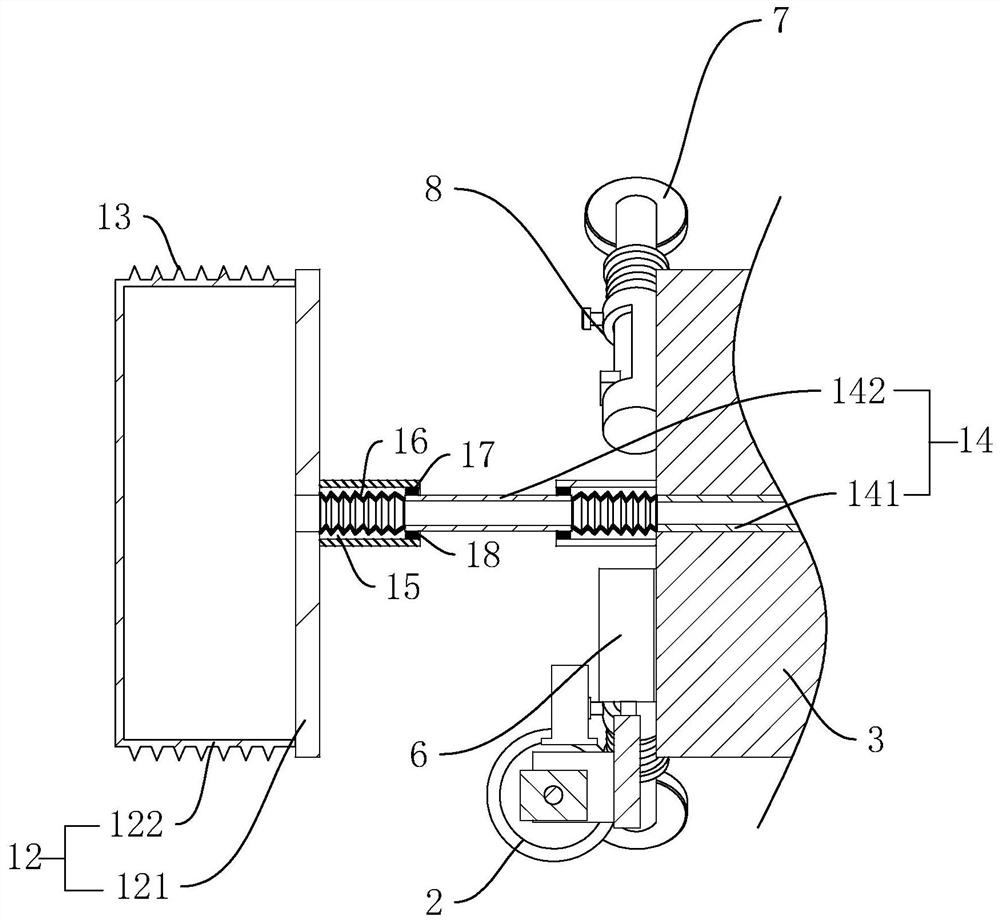

Cylindrical formwork fixing device and fixing method

PendingCN112780066ACircumferential force uniformHigh positioning accuracyForms/shuttering/falseworksAxis of symmetryClassical mechanics

The invention discloses a cylindrical formwork fixing device and a fixing method. The cylindrical formwork fixing device comprises two semicircular hoops and connecting plates arranged at the two ends of each hoop, connecting faces coplanar with the axis of the hoops are arranged on the connecting plates, a positioning hole is formed in one connecting face, a positioning shaft is arranged on the other connecting face, the axis of the positioning hole and the axis of the positioning shaft are symmetrically arranged with the axis of the hoops as the symmetry axis, and screw holes are formed in the connecting plate. The cylindrical formwork fixing devices and the fixing method have the beneficial effects that the hoops can bu utilized to apply inward pressure in the radial direction to a cylindrical formwork in the circumferential direction of the cylindrical formwork, the circumferential stress of the cylindrical formwork is uniform, the position precision of the cylindrical formwork can be advantageously kept, the impact resistance of the cylindrical formwork is improved, and deformation of the cylindrical formwork under the impact effect of concrete is avoided.

Owner:CHINA MCC5 GROUP CORP

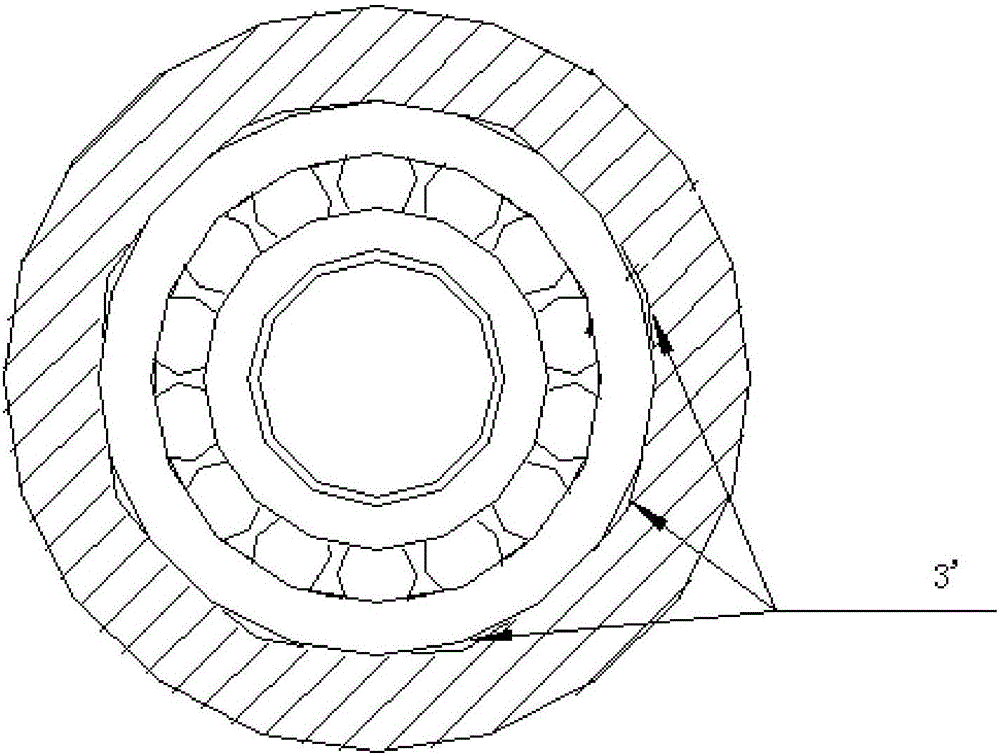

Bearing chamber, motor enclosure having same and motor

InactiveCN106357038AEasy to installSimplify the assembly processSupports/enclosures/casingsEngineeringElastomer

The invention discloses a bearing chamber, a motor enclosure having the same and a motor. A recess is formed on an inner wall surface of the bearing chamber, an elastomer is placed in the recess, and the elastomer protrudes out of the inner wall surface. As the inner wall surface of the bearing chamber is provided with the recess, the bearing chamber and a bearing can be designed with a clearance fit dimension according to a basic hole system, and when the bearing is to be installed in the bearing chamber, the bearing can be directly pressed into the bearing chamber without heating the bearing chamber. The installation way is convenient, the assembly technique is simple and the production efficiency is high. As the elastomer is made of a material easy to compress and the elastomer arranged in the recess radially protrudes out of the inner wall surface of the bearing chamber, even if the bearing chamber and the bearing are designed with a clearance fit dimension according to the basic hole system, after the bearing is installed in the bearing chamber, the bearing squeezes the elastomer and the bearing forms interference fit with the bearing chamber arranged at the elastomer, thus achieving the effect of preventing wriggle of the bearing.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

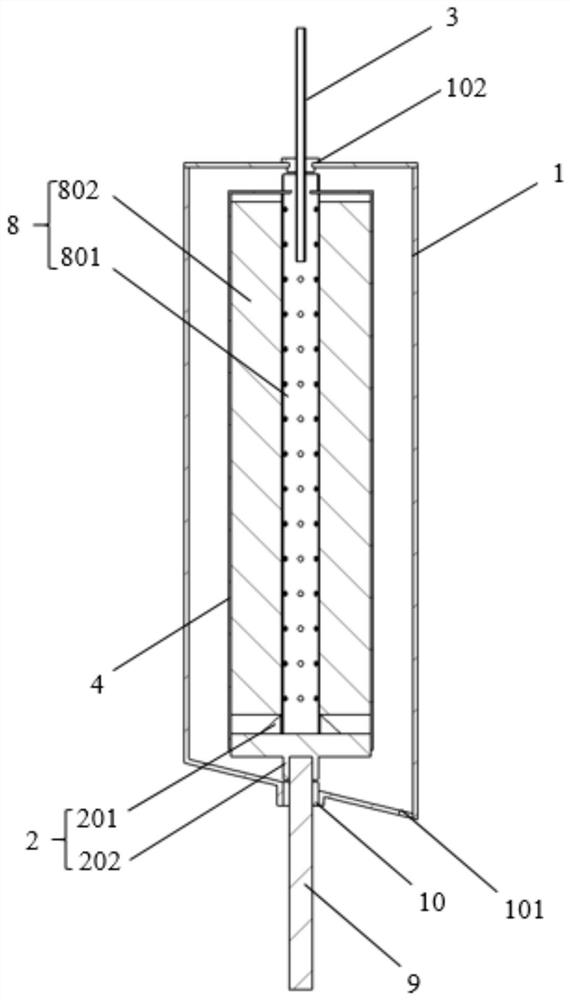

Device and method for spin-drying and infiltrating battery core of cylindrical battery

ActiveCN111786001ASpeed up the gasification processPromote infiltrationFinal product manufactureCylindrical casing cells/batteryElectric machineryBattery cell

The invention provides a spin-drying and infiltrating device for a battery core of a cylindrical battery. The spin-drying and infiltrating device is provided with a liquid collecting cylinder, an injection pipe and a roll core rotating device, wherein a battery core is arranged in the liquid collecting cylinder, the roll core of the battery core is connected with the roll core connecting part of the roll core rotating device, the driving connecting part of the roll core rotating device is directly or indirectly connected with the rotating shaft of a motor, and the injection pipe can extend into the hollow part of the roll core. When the rotating shaft of the motor drives the roll core rotating device to rotate, the whole battery core is driven to rotate, and under the action of centrifugalforce, a liquid in the winding part of the battery core can be thrown out or a liquid continuously injected into the roll core fully infiltrates the whole battery core. The invention also provides aspin-drying and infiltration method of the battery core of the cylindrical battery. Through the spin-drying and infiltrating device and the spin-drying and infiltrating method, the whole battery corecan be spin-dried and infiltrated, so that the production efficiency is improved, the spin-drying and infiltrating effects are guaranteed, and the energy consumption can be reduced.

Owner:BEIJING HAWAGA POWER STORAGE TECH

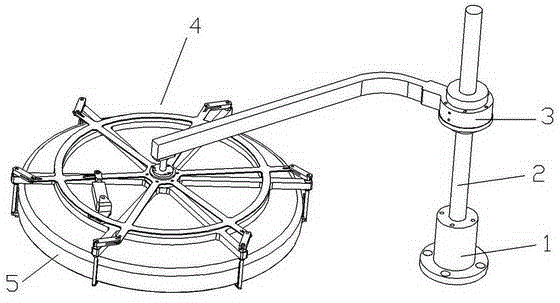

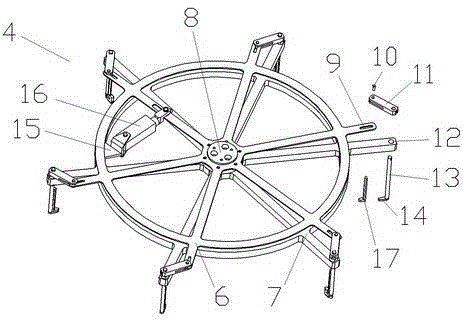

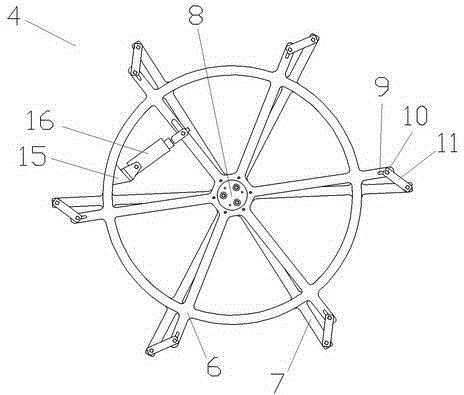

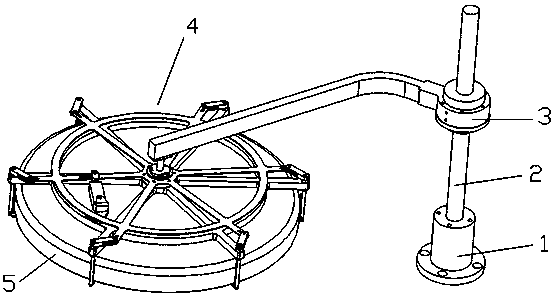

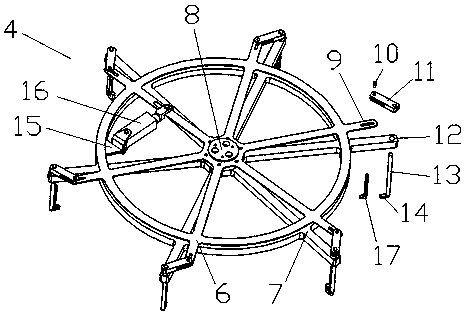

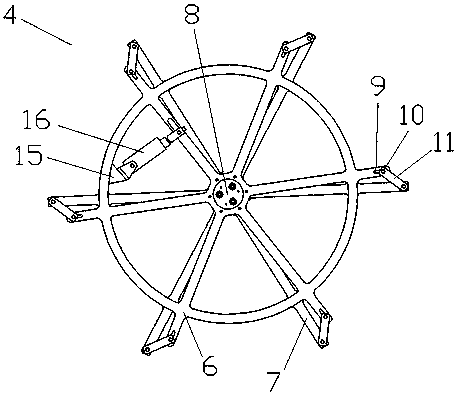

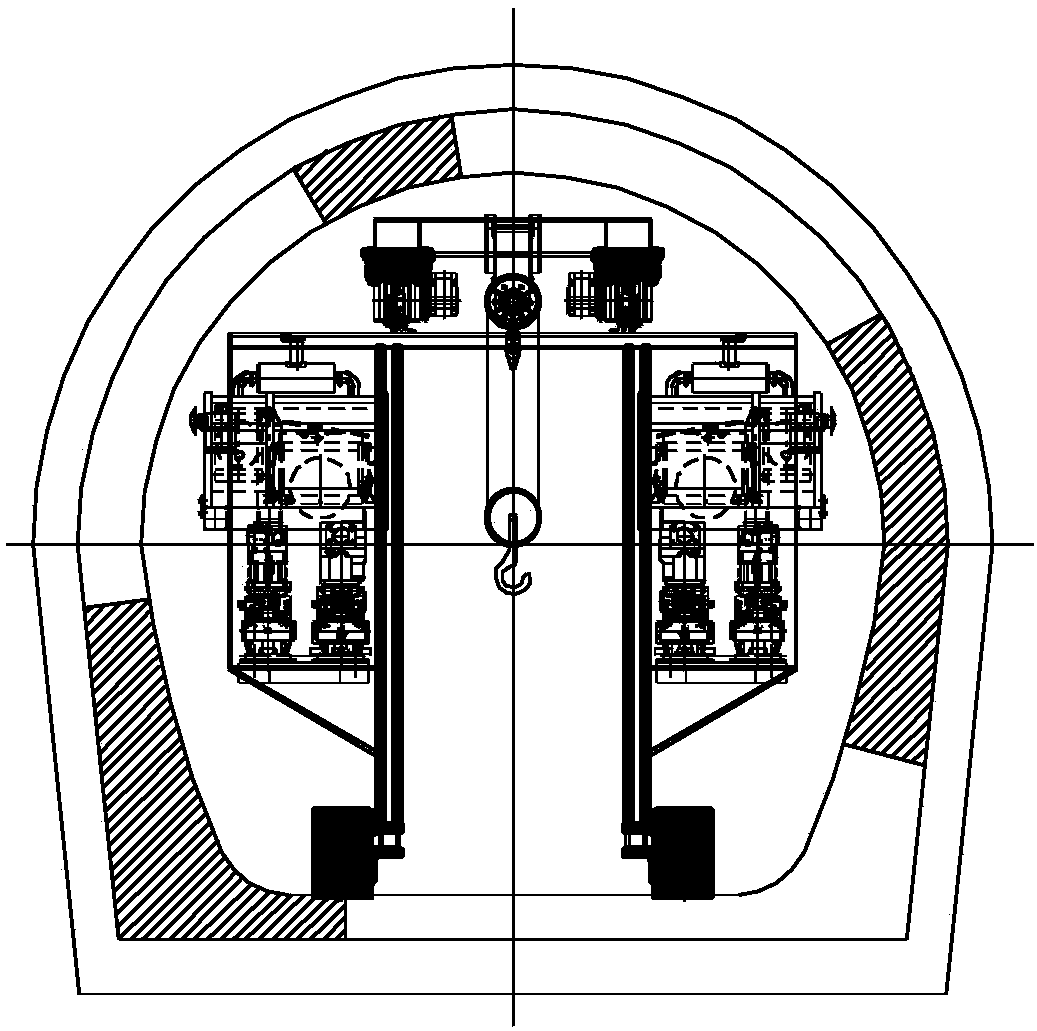

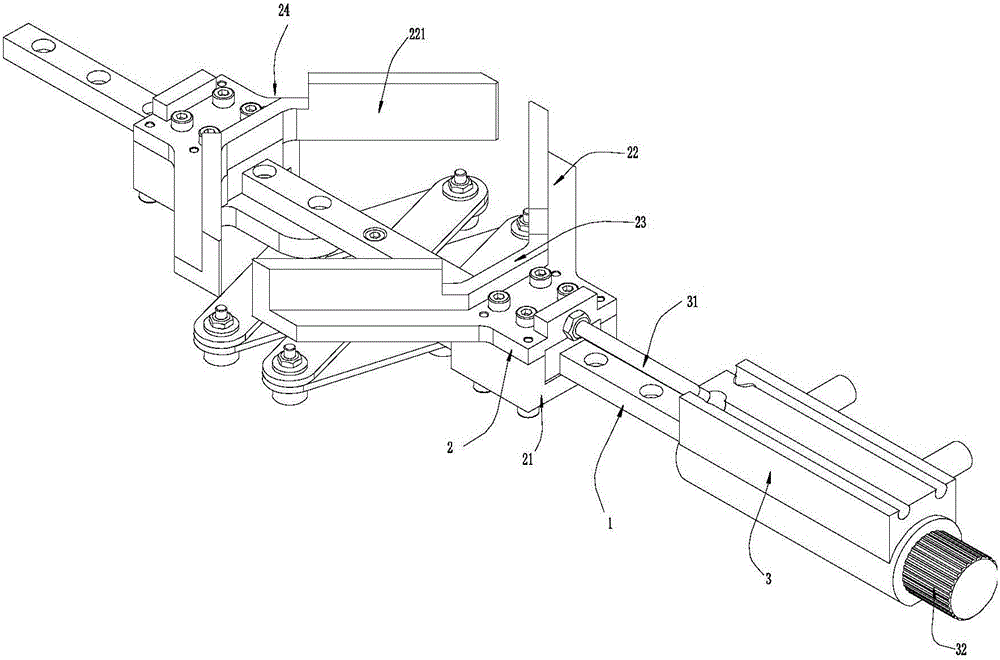

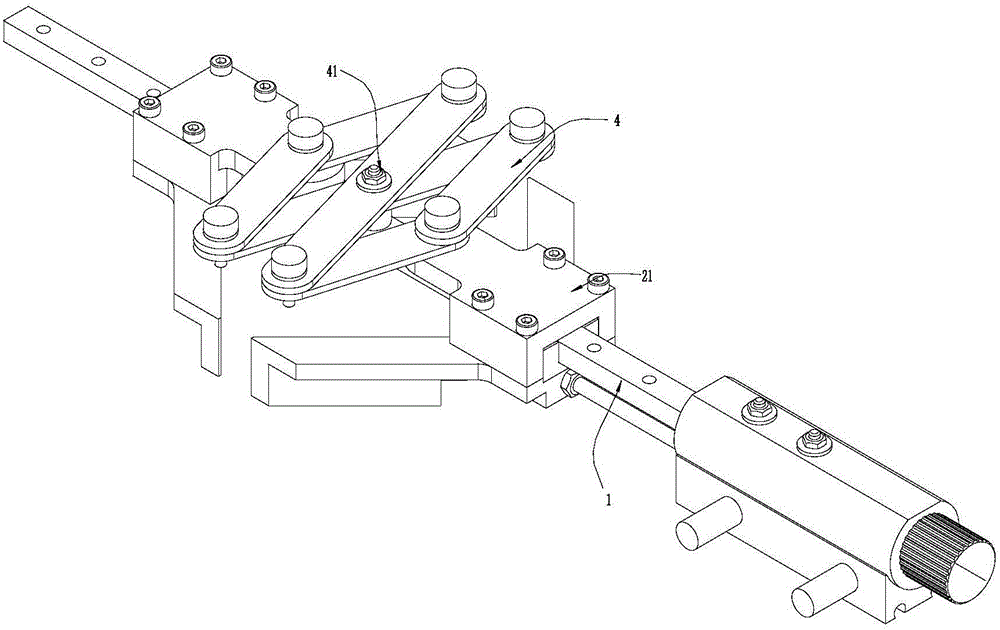

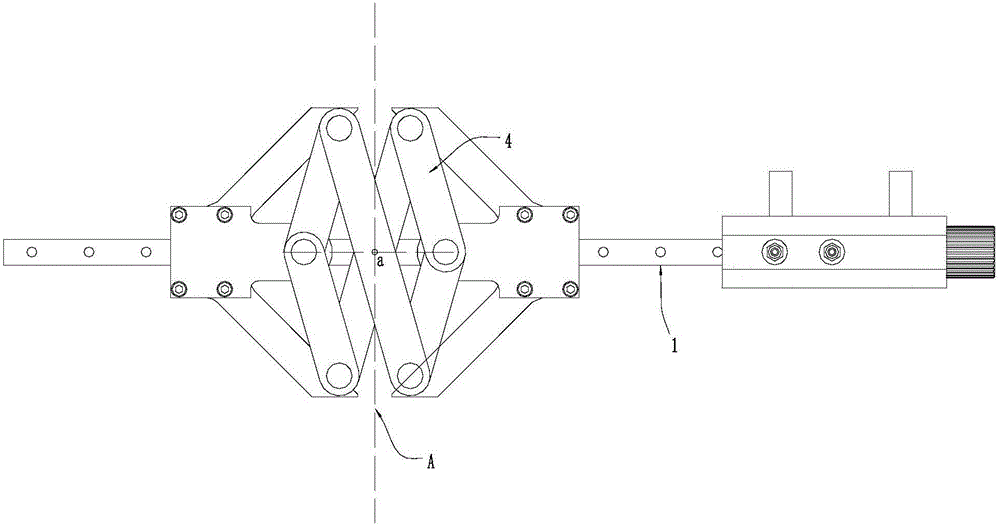

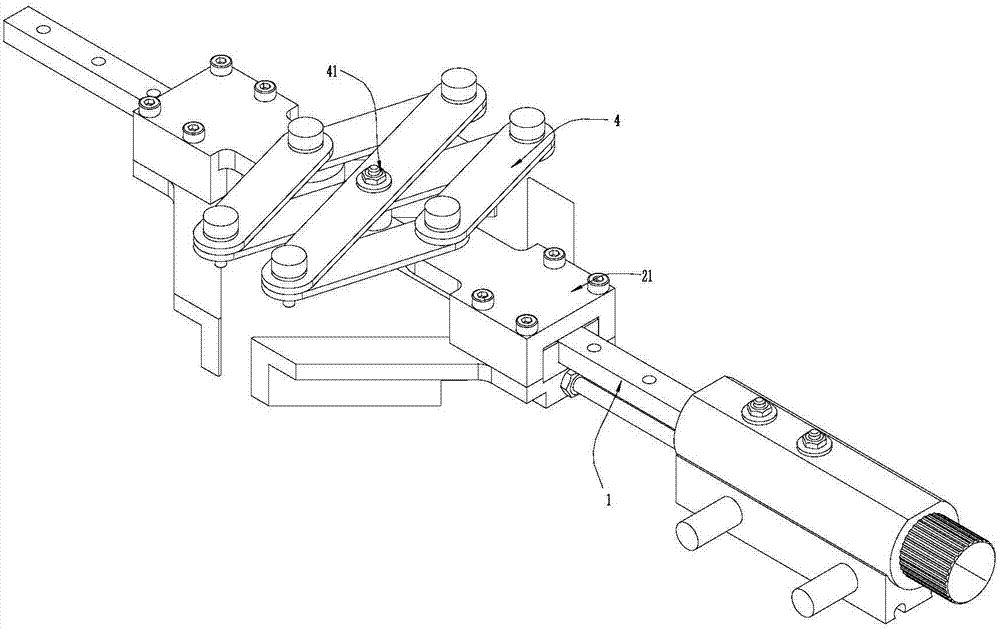

Gripping device for conveying wafer carrying discs

ActiveCN105624649ACircumferential force uniformSmooth manual operationChemical vapor deposition coatingPlacement actionEngineering

The invention discloses a gripping device for conveying wafer carrying discs of chemical vapor deposition equipment. The gripping device mainly comprises a base, a guide rod, a rotation arm and a mechanical arm. According to the gripping device for conveying the wafer carrying discs, the circumferential stress of the wafer carrying discs is more uniform in the manner that the wafer carrying discs are evenly hoisted in the circumferential direction, stable conveying of the wafer carrying discs and wafers in the wafer carrying discs is guaranteed, and in addition, by means of reverse application of a swinging guide rod mechanism, the gripping and placing actions of the mechanical arm are achieved. The structure is simple and reliable, operation is more stable and safer compared with manual operation, and the production efficiency is improved.

Owner:广东众元半导体科技有限公司

Press block assembly, door assembly and laundry treatment device

ActiveCN110656471BWell formedLess materialOther washing machinesTextiles and paperScrew threadThreaded fastener

The present invention provides a pressing block assembly, a door assembly and a clothes processing device. The pressing block assembly includes: a connecting piece; ; The fixing piece, one of the fixing piece and the connecting piece is provided with a through hole for the threaded fastener to pass through, and the other is a rigid component and is provided with a threaded hole corresponding to the through hole, and the through hole and the threaded hole are used for connecting with the through hole. The connecting holes on the inner ring of the door cooperate, so that the pressing block assembly is fixedly connected with the inner ring of the door through threaded fasteners. The pressing block assembly provided by the present invention can press the door glass onto the inner ring of the door, and realize the fixed connection between the pressing block assembly and the inner ring of the door by screwing common threaded fasteners and rigid parts. The connection method between the self-tapping screw and the plastic part significantly improves the connection strength, thereby reducing the risk of the door glass coming loose. Simultaneously, the briquetting block assembly has small structure and low cost, and is suitable for popularization.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Air inlet system of aero-engine and aero-engine

PendingCN114439657AGood for even distributionCircumferential force uniformValve arrangementsMachines/enginesSelf adaptiveCombustion chamber

The aero-engine air inlet system comprises an air inlet seat and an air valve, the air valve is installed on the right side of an air inlet channel in the air inlet seat in an elastic sliding mode, and the aero-engine air inlet system is characterized by further comprising an oil spraying pipe, a mixed air pipe sleeve, a mixed air spraying head and an opening and closing door; according to the gas inlet system, the gas inlet cavity is divided into multiple spaces, uniform distribution of mixed gas is facilitated, sufficient mixing of the mixed gas and fuel oil is guaranteed, meanwhile, the door is driven to be opened and closed through the gas pressure of the mixed gas, the response speed of the structure is high, gas spraying holes and oil spraying holes can be opened or closed in time, and the service life is prolonged. The oil injection hole and the air inlet can be rapidly opened and closed in a self-adaptive mode along with all strokes, waste gas in the combustion chamber can be effectively prevented from flowing back, the phenomenon of carbon deposition at the air inlet and the oil injection hole is avoided, and the combustion efficiency in the combustion chamber is comprehensively improved through the two aspects that fuel oil and mixed gas are evenly mixed and combined to prevent waste gas from flowing back.

Owner:重庆佳瑞斯科技有限公司

A device and method for drying and soaking cylindrical battery cells

ActiveCN111786001BSpeed up the gasification processPromote infiltrationFinal product manufactureCylindrical casing cells/batteryElectric machineCentrifugal force

The invention provides a spin-drying and soaking device for electric cores of cylindrical batteries, which is provided with a liquid collecting cylinder, an injection pipe and a winding core rotating device. The battery core is placed in the liquid collection cylinder, the winding core of the battery core is connected to the winding core connection part of the winding core rotating device, and the driving connection part of the winding core rotating device is directly or indirectly connected to the rotating shaft of the motor, and the injection pipe can be extended into the In the hollow part of the core. When the rotating shaft of the motor drives the winding core rotating device to rotate, it drives the entire battery core to rotate. Under the action of centrifugal force, the liquid in the winding part of the battery core can be thrown out or the liquid continuously injected into the winding core can fully soak the entire battery core. In addition, the invention also provides a drying and soaking method for the battery core of the cylindrical battery. Through the drying and soaking device and the drying and soaking method of the present invention, the whole battery cell can be dried and soaked, which is beneficial to improve production efficiency, ensure drying and soaking effects and save energy consumption.

Owner:BEIJING HAWAGA POWER STORAGE TECH

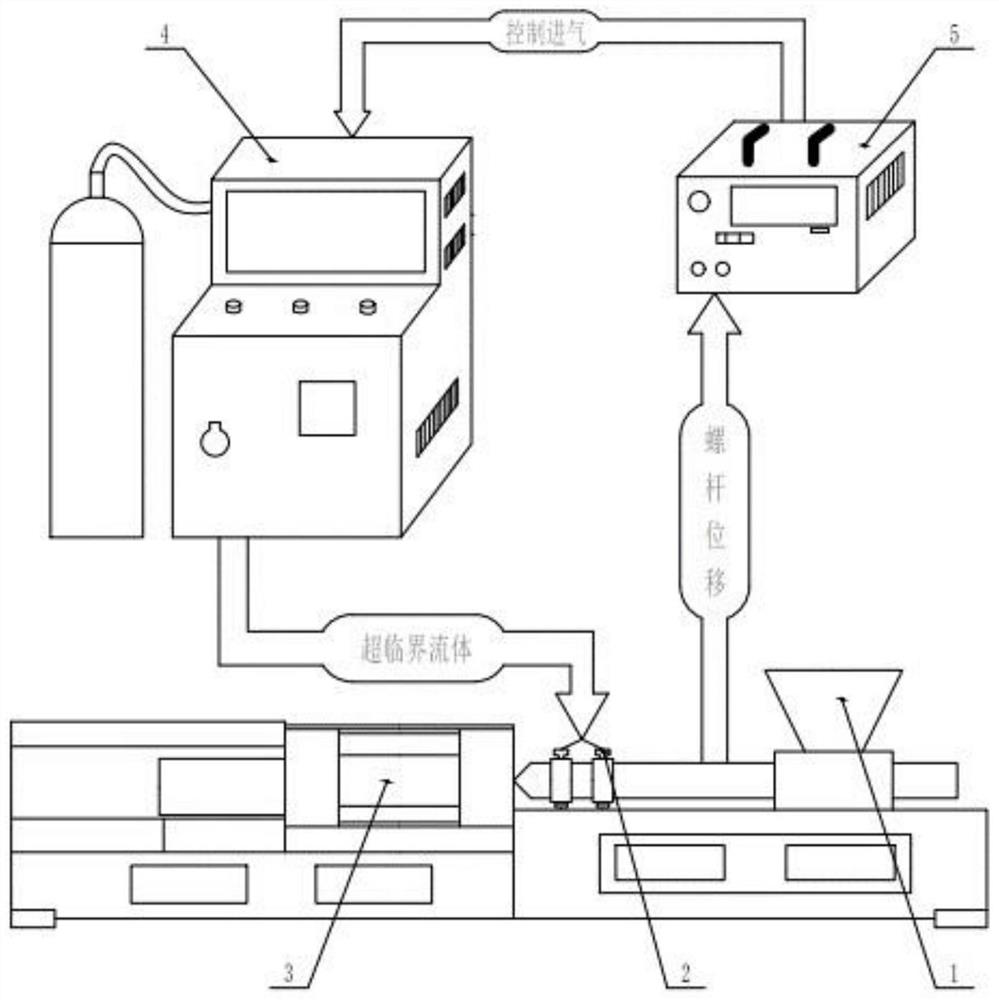

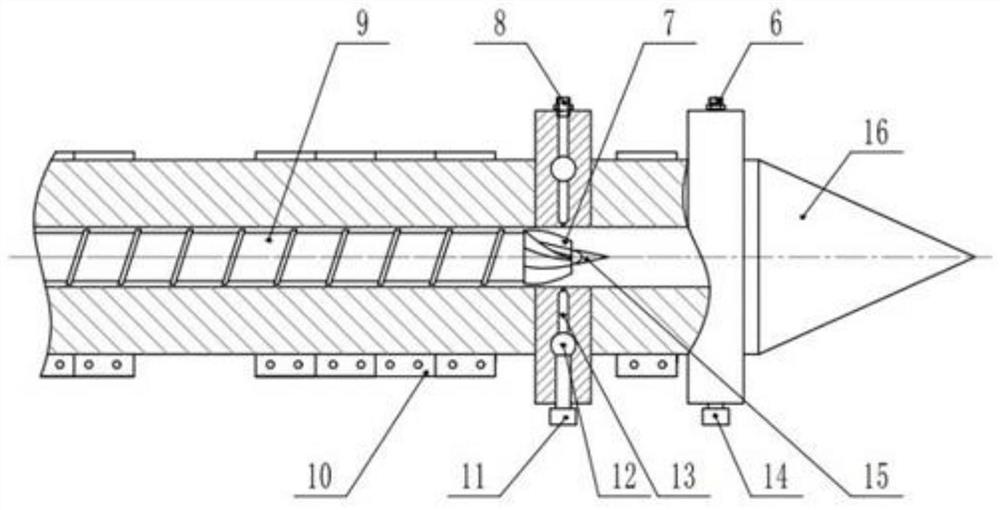

Decompression micro-foaming injection molding device and process thereof

PendingCN112959591AImprove dissolution efficiencyUniform air bubblesDomestic articlesInlet valveEngineering

The invention provides a decompression micro-foaming injection molding device and a process thereof, belongs to the field of injection molding, and solves the problems that existing supercritical fluid and polymers are poor in mixing, and a screw rod is uneven in stress. The decompression micro-foaming injection molding device comprises a high-pressure gradient mixing screw rod head, an injection molding screw rod, gas homogenizers, a machine head, a machine barrel, a supercritical fluid pressure control module and a screw rod displacement monitoring module, the plurality of gas homogenizers connected with an external gas supply unit are arranged on the machine barrel, and the high-pressure gradient mixing screw rod head is connected with the injection molding screw rod through nesting or threads. When a screw rod head is close to one of the gas homogenizers, an inlet valve at the part is opened, inlet valves at other parts are closed, and the pressure gradient generated by rotation of the screw rod head turns out core layer materials, so that supercritical fluid and the materials are fully dissolved, the supercritical fluid pressure control module controls the gas injection pressure and temperature, and the screw rod displacement monitoring module assists in positioning the position of the high-pressure gradient mixing screw rod head.

Owner:管继莲 +2

Connecting structure of main shaft and rotor and integrated rolling rotor compressor

InactiveCN106368950APrevent mutual disengagementRealize linkageRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Gripping device for transporting slide trays

ActiveCN105624649BCircumferential force uniformSmooth manual operationChemical vapor deposition coatingPlacement actionEngineering

The invention discloses a gripping device for conveying wafer carrying discs of chemical vapor deposition equipment. The gripping device mainly comprises a base, a guide rod, a rotation arm and a mechanical arm. According to the gripping device for conveying the wafer carrying discs, the circumferential stress of the wafer carrying discs is more uniform in the manner that the wafer carrying discs are evenly hoisted in the circumferential direction, stable conveying of the wafer carrying discs and wafers in the wafer carrying discs is guaranteed, and in addition, by means of reverse application of a swinging guide rod mechanism, the gripping and placing actions of the mechanical arm are achieved. The structure is simple and reliable, operation is more stable and safer compared with manual operation, and the production efficiency is improved.

Owner:广东众元半导体科技有限公司

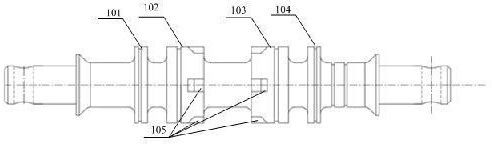

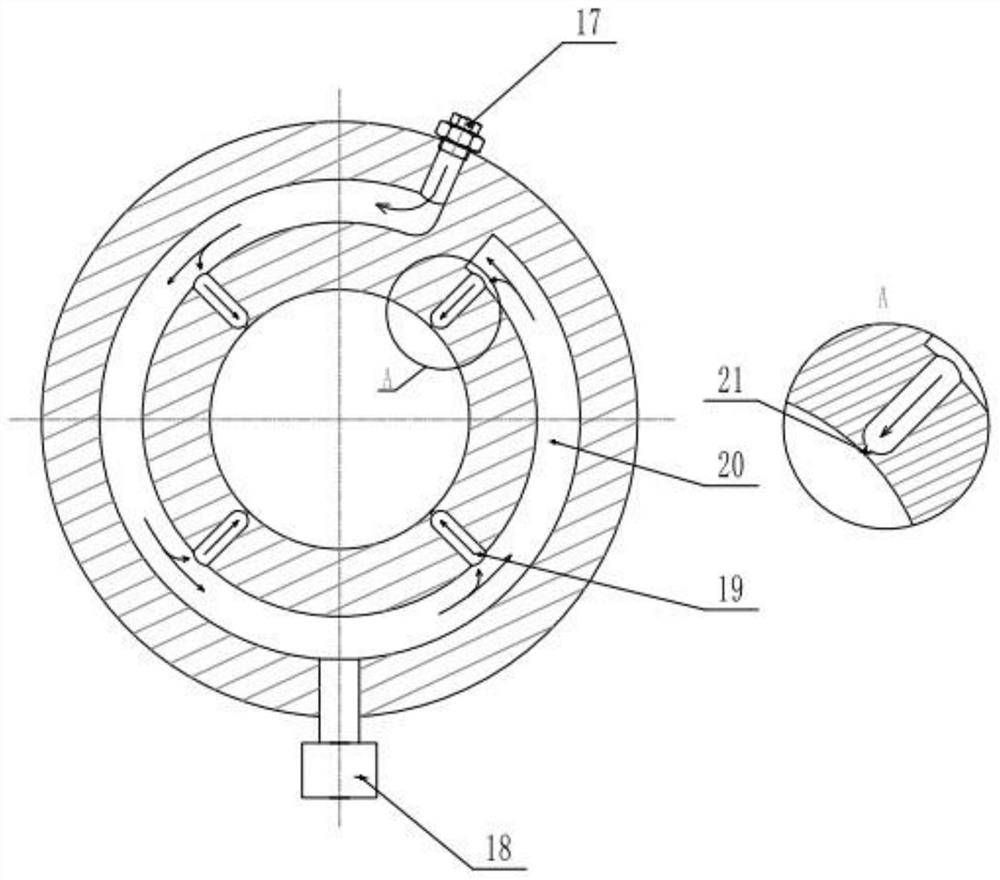

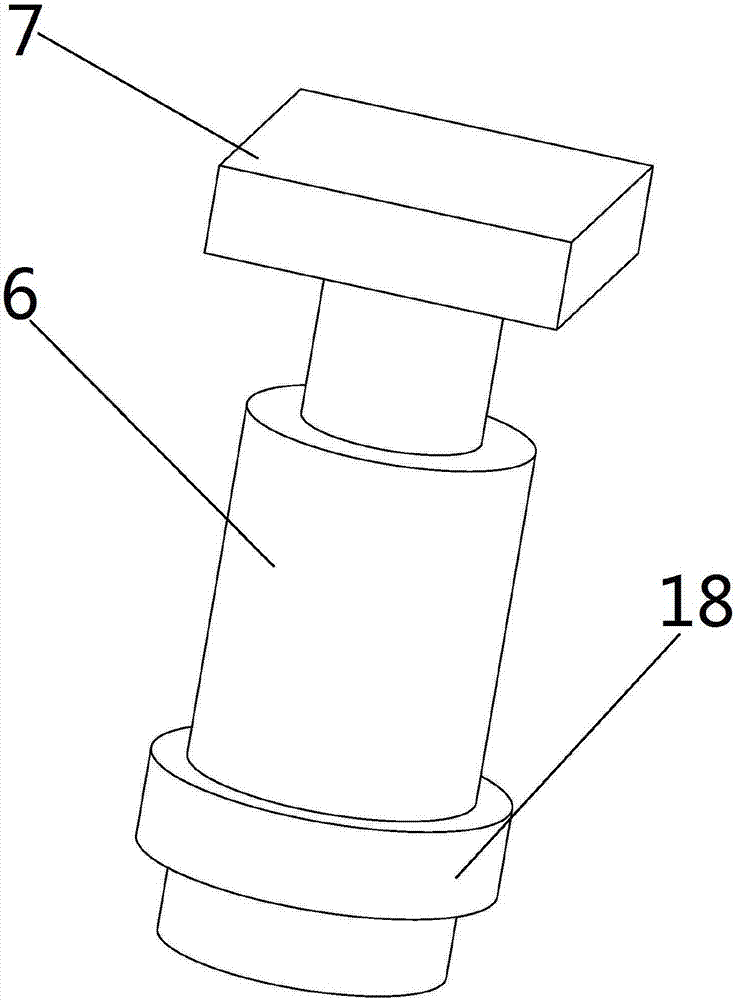

Radial multi-row vertical piston pump

PendingCN110360075ASmall sizeCompact structurePositive displacement pump componentsPositive-displacement liquid enginesDrive shaftEngineering

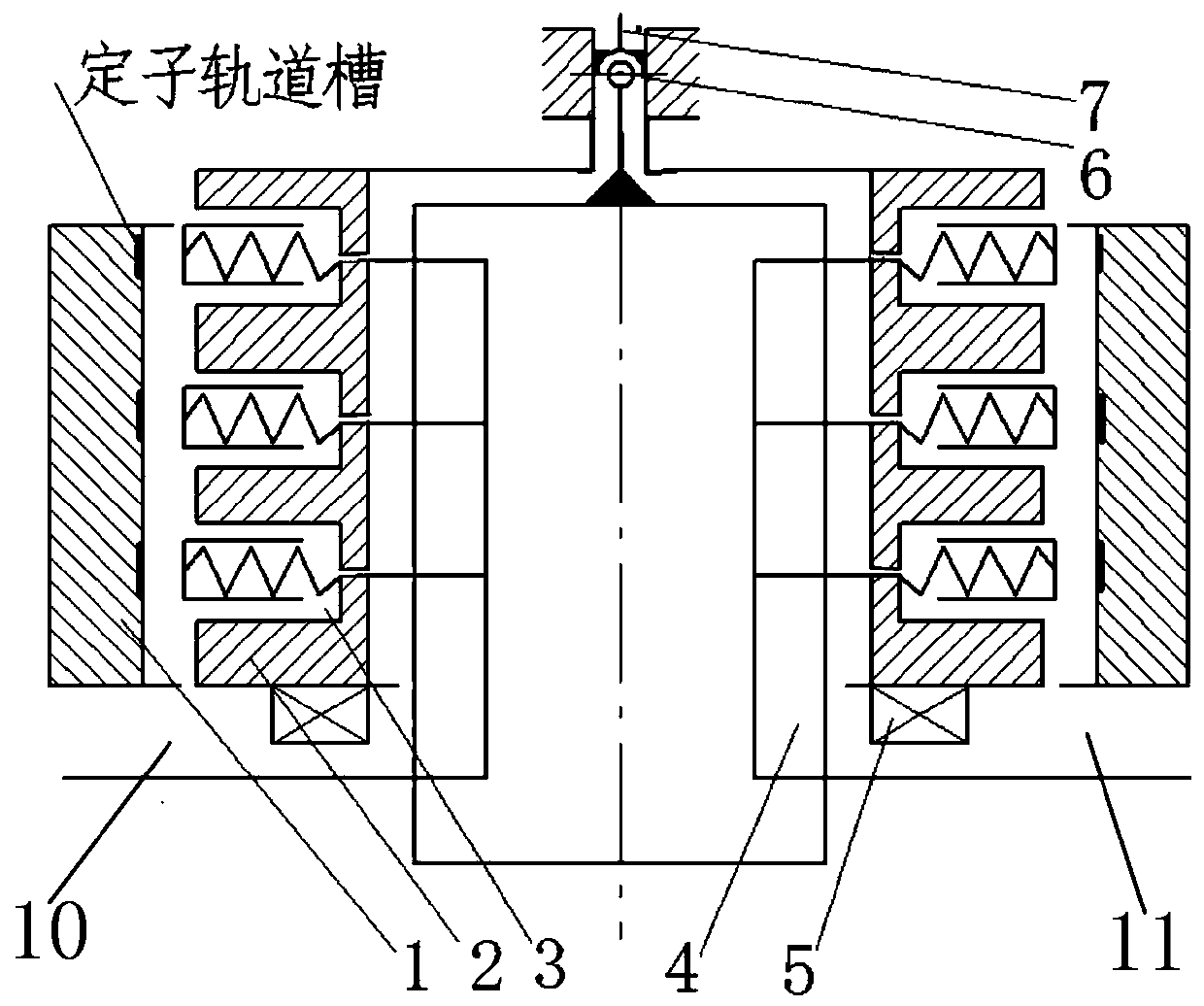

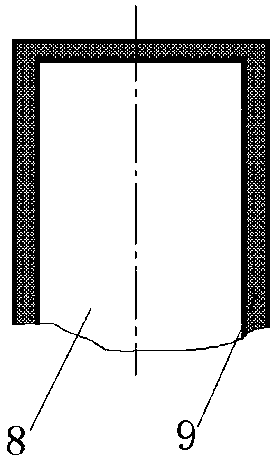

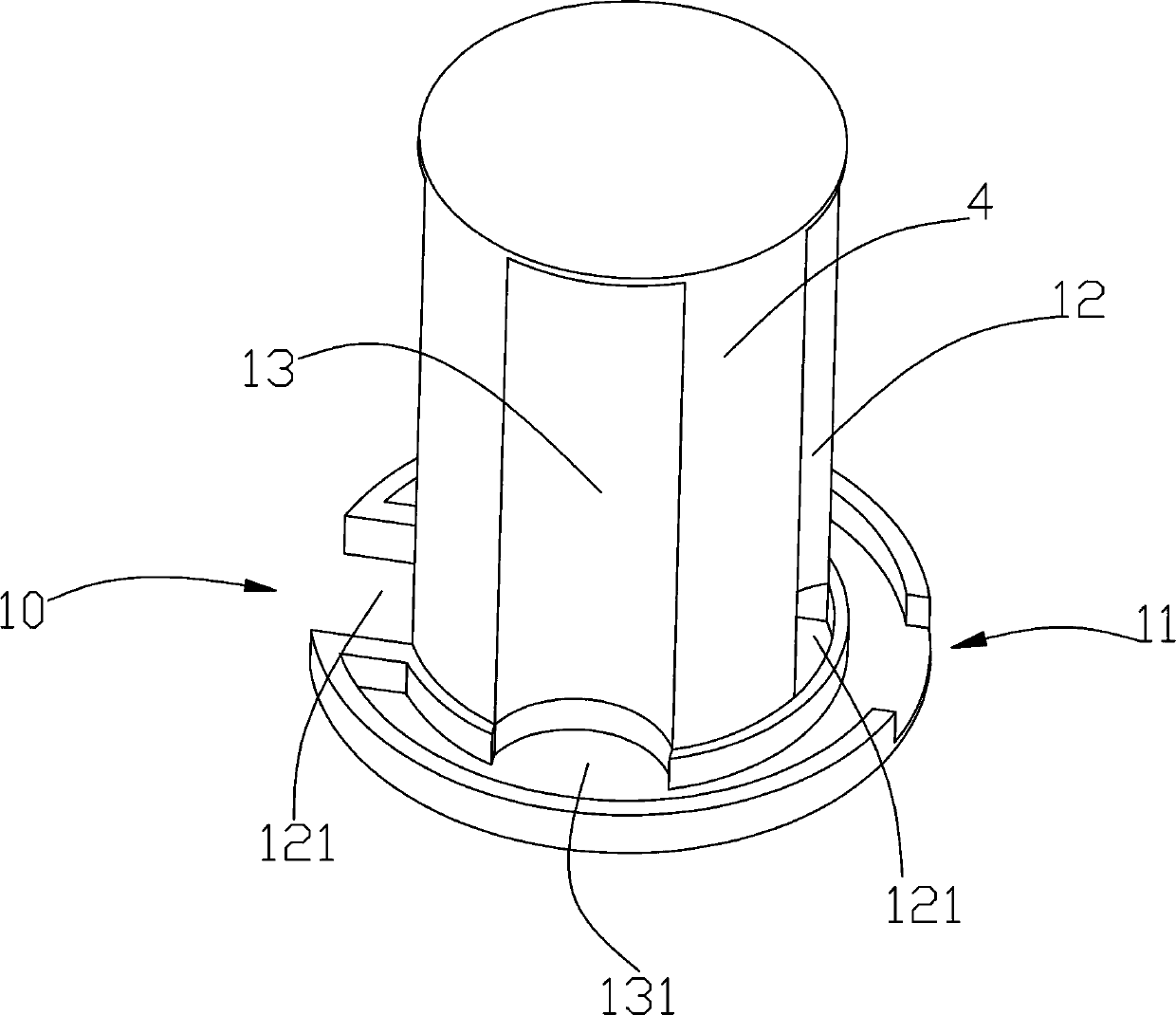

The invention relates to the field of sea water pumps, in particular to a radial multi-row vertical piston pump. The radial multi-row vertical piston pump comprises a stator 1, a rotor 2, a pluralityof piston 3 and a flow distribution shaft 4, wherein the stator 1 is of a cylindrical cavity structure with end covers arranged on the upper part and the lower part; the cross section of a cavity of the stator 1 is oval; the flow distribution shaft 4 is arranged in the stator 1, and the flow distribution shaft 4 is coaxial with the stator 1; the rotor 2 capable of rotating is arranged between theflow distribution shaft 4 and the cavity of the stator 1 in a sleeving mode; the upper end of the rotor 2 passes through a ball pair 6 and a transmission shaft 7 to be connected with a motor; the rotor 2 is vertically provided with a plurality of groups of plug groove groups, each plug groove group consists of a plurality of plug grooves in a circular array mode, and each plug groove is internallyprovided with a piston 3; the extending end of each piston 3 is attached to the cavity wall of the stator 1 through external force; and the two ends of the bottom of the stator 1 are separately provided with a water inlet 10 and a water outlet 11.

Owner:南昌谱瑞斯天泵业有限公司

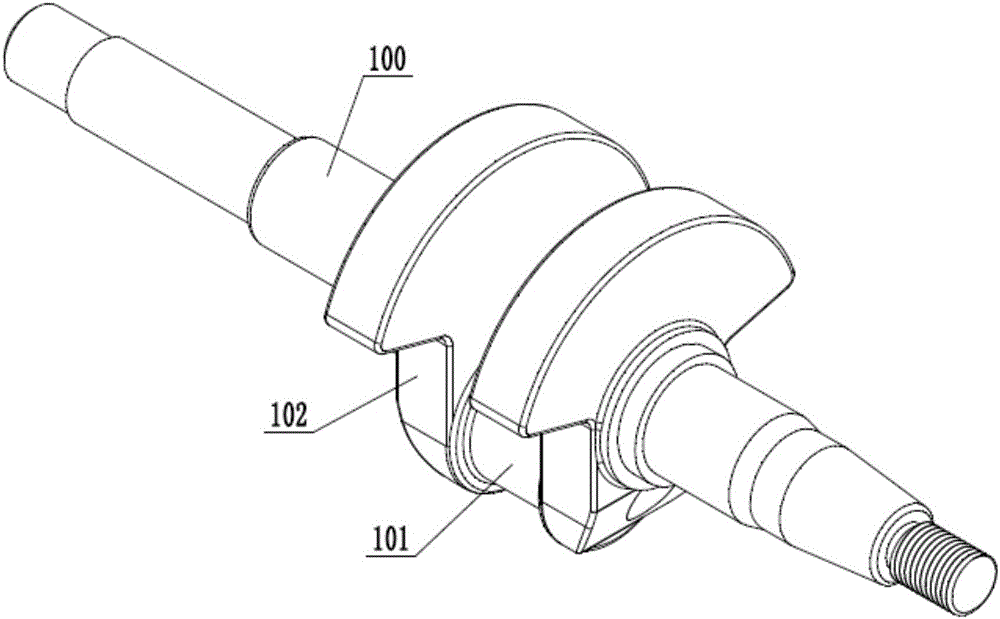

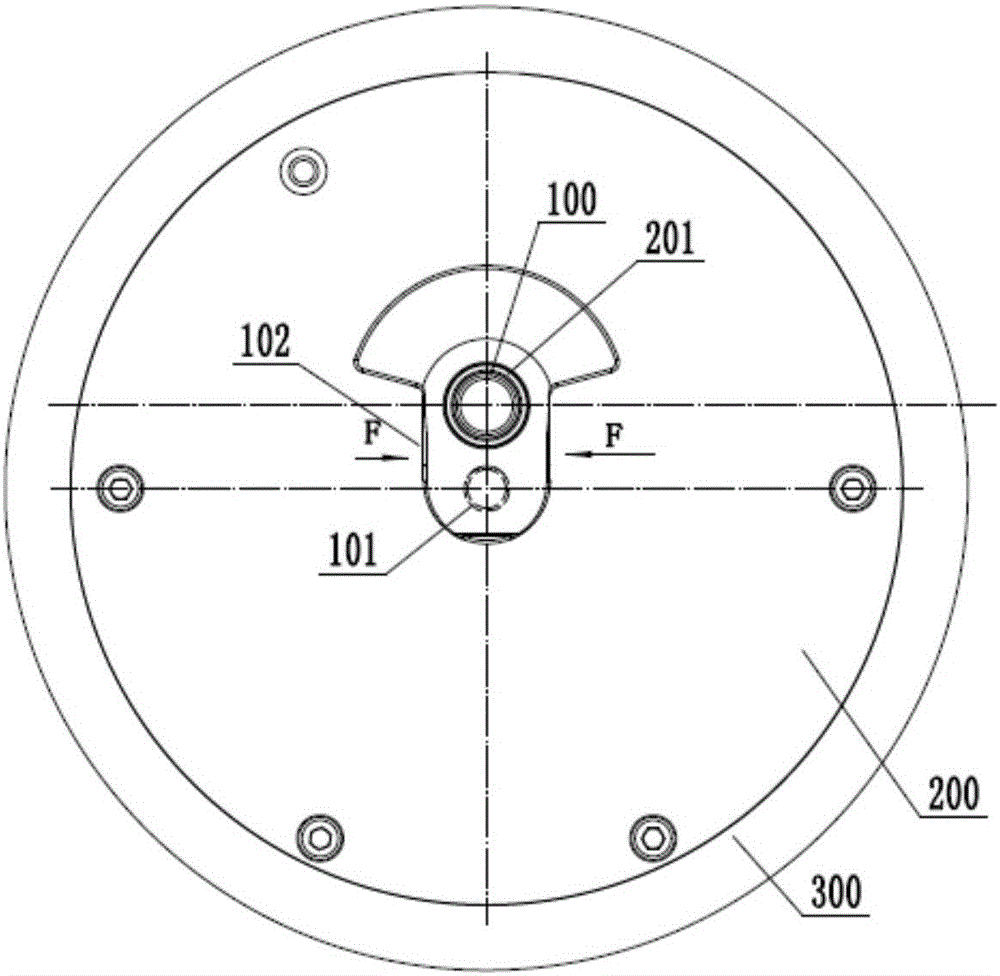

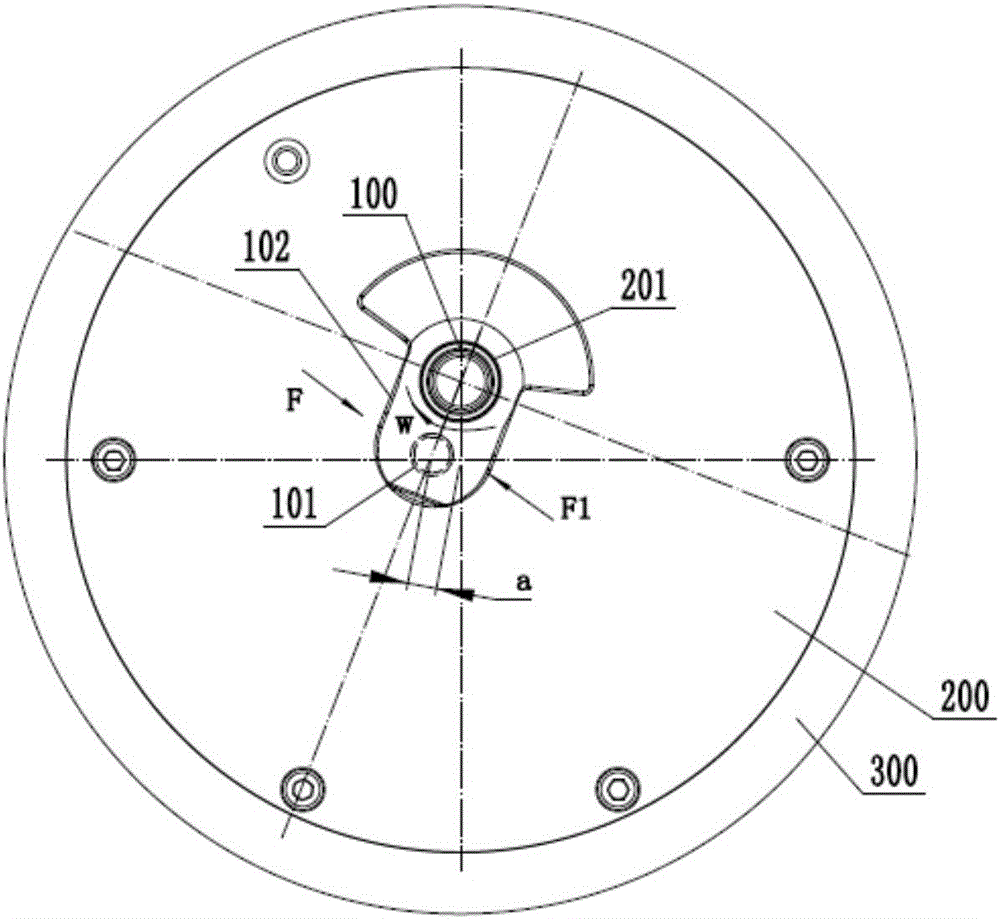

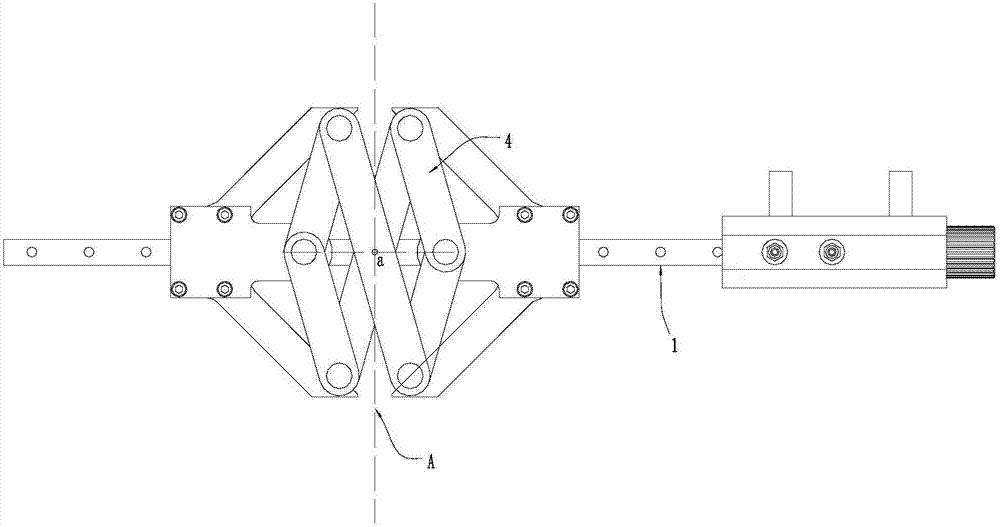

A crank positioning fixture

ActiveCN106112042BCircumferential force uniformForce balanceExpansion mandrelsEngineeringMechanical engineering

Owner:CHONGQING MEIXIN YINGSHEN MACHINERY CO LTD

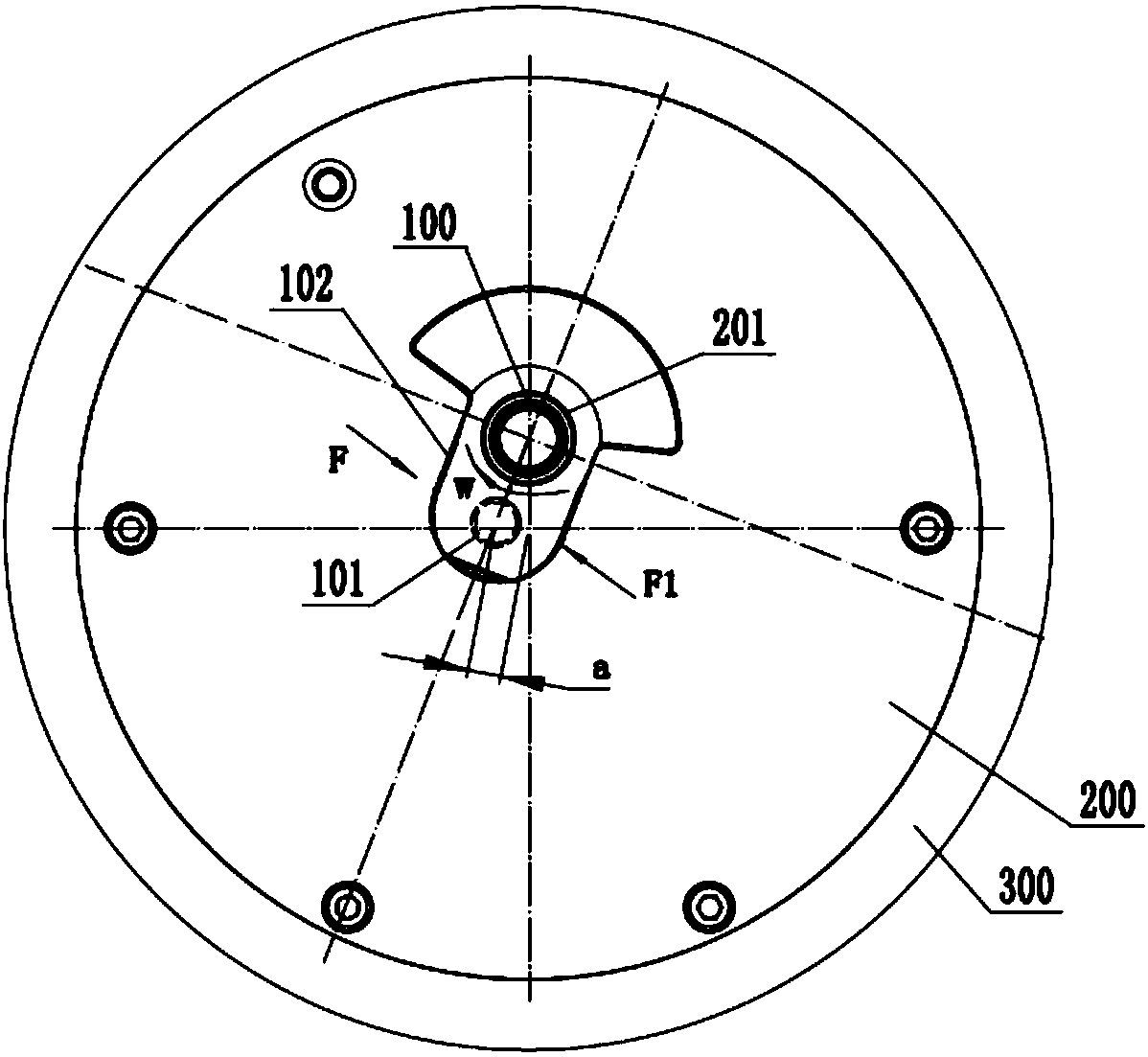

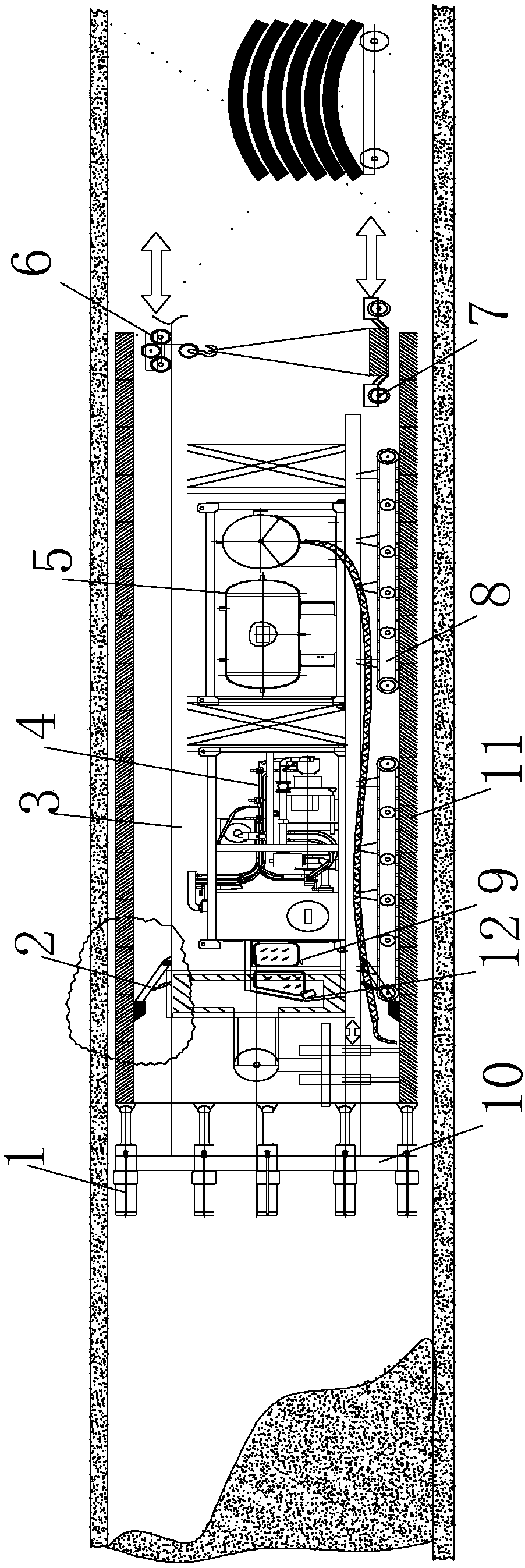

A crawler type segment secondary lining equipment

ActiveCN105221169BQuality assuranceCircumferential force uniformUnderground chambersTunnel liningVehicle frameEngineering

Owner:CHINA RAILWAY SCI & IND GRP RAIL TRANSPORTATION EQUIP LIMITED

Circular plastic impeller fixture

ActiveCN105818011AMove preciselyCircumferential force uniformClampsMirror imageMechanical engineering

The invention relates to the field of mechanical fixtures, and discloses a circular plastic impeller fixture. The circular plastic impeller fixture comprises a linear guide rail, and a clamping module slidingly arranged on the linear guide rail; the clamping module includes two sets of opposite clamping parts; a clamping station is formed between the two sets of clamping parts; two clamping arms are arranged on the clamping parts; clamping end surfaces of the two clamping arms are perpendicular; two adjacent clamping end surfaces on the two sets of clamping parts are also perpendicular; the two sets of clamping parts are linked, and can make mirror image movement along a linkage axis surface; the linkage axis surface is a plane passing through a linkage axis point and being perpendicular to the direction of the linear guide rail; and the linkage axis point is a center point of the moving direction of the two sets of clamping parts. The impeller fixture clamps workpieces or products through two sets of clamping parts linked on the same linear rail; and the two sets of clamping parts are consistent in working frequency, so that the clamping station accuracy is guaranteed, and the product machining quality is guaranteed.

Owner:NINGBO LANGDI IMPELLER MACHINERY

Device and method for liquid injection and liquid replacement of cylindrical batteries

ActiveCN111785906BImprove infiltration efficiencyDrain fastCell component detailsElectric machineMechanical engineering

The invention provides a liquid injection and liquid replacement device for a cylindrical battery, which is provided with an injection and discharge device and a battery rotation device. The battery rotating device can be connected and fixed with at least a part of the cylindrical battery, and the battery rotating device can be connected with the rotating shaft of the motor, so that the motor drives the battery rotating device to rotate and then drives the cylindrical battery to rotate. The drainage device includes a rotating part that rotates together with the cylindrical battery and a fixed part for docking with the external fluid storage device / fluid recovery device. The fixed part is sleeved on the rotating part and communicated with the internal fluid, so that the cylindrical battery rotates while enabling fluid communication with an external stationary fluid storage / fluid recovery device. Under the action of centrifugal force, the liquid injected into the cylindrical battery can fully soak the entire cell, or the liquid in the cell in the cylindrical battery can be thrown out and new liquid can be continuously injected to quickly replace the original liquid .

Owner:BEIJING HAWAGA POWER STORAGE TECH

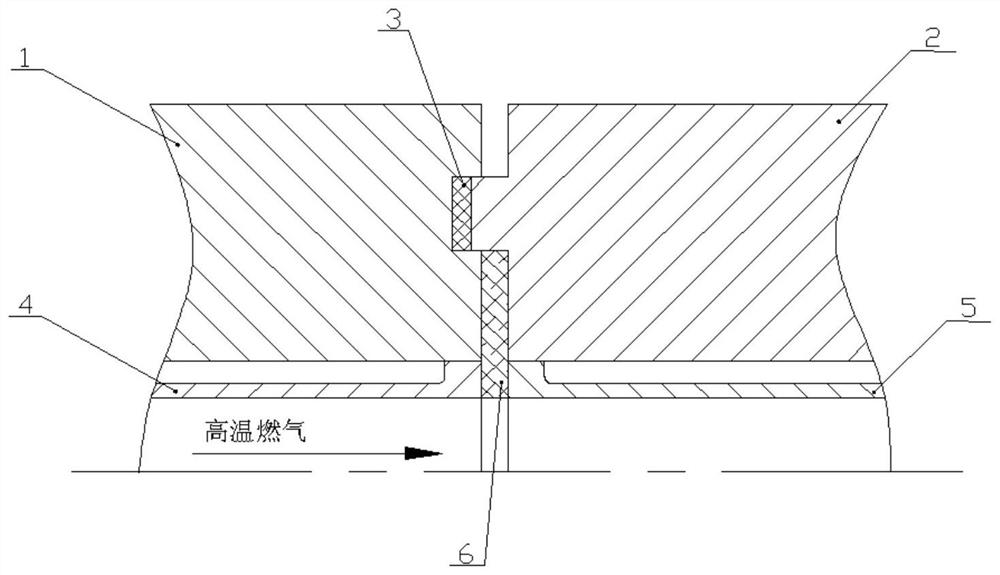

A flange sealing structure suitable for high temperature and large heat flow environment and its installation method

The invention provides a flange sealing structure suitable for a high temperature and large heat flow environment and an installation method thereof, which solves the problems of inconvenient maintenance, high production and maintenance costs, and difficult reuse after damage of the existing integrated high temperature and large heat flow equipment. The sealing structure includes two inner cylinders, and matching groove flanges and tenon flanges; the groove and the tenon respectively separate the butt end faces of the two flanges into an inner end face and an outer end face; the two inner cylinders are welded on the two flanges respectively. On the inner side of each flange, there is a gap between the two inner cylinders and the two flanges, the end faces of the two inner cylinders are flush with the inner end faces of the two flanges respectively, and the wall surfaces of the two inner cylinders are flush or formed Steps along the airflow direction; gaskets are arranged in the groove, inorganic high temperature glue is arranged between the inner end faces of the two flanges and between the butt end faces of the two inner cylinders; An anti-adhesive layer that is easy to vaporize at high temperature is provided, and the thickness is not more than 0.1mm; the outer sides of the two flanges are fastened by fasteners.

Owner:XIAN AEROSPACE PROPULSION INST

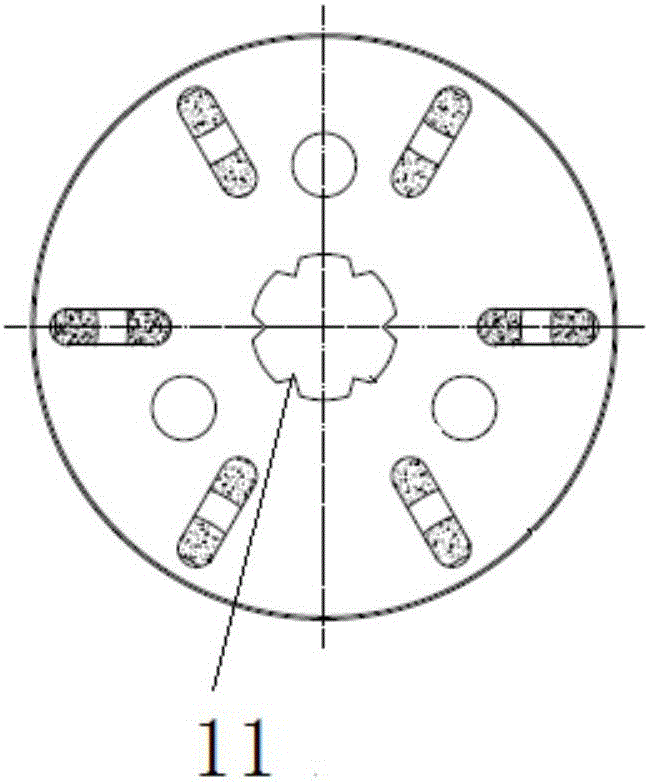

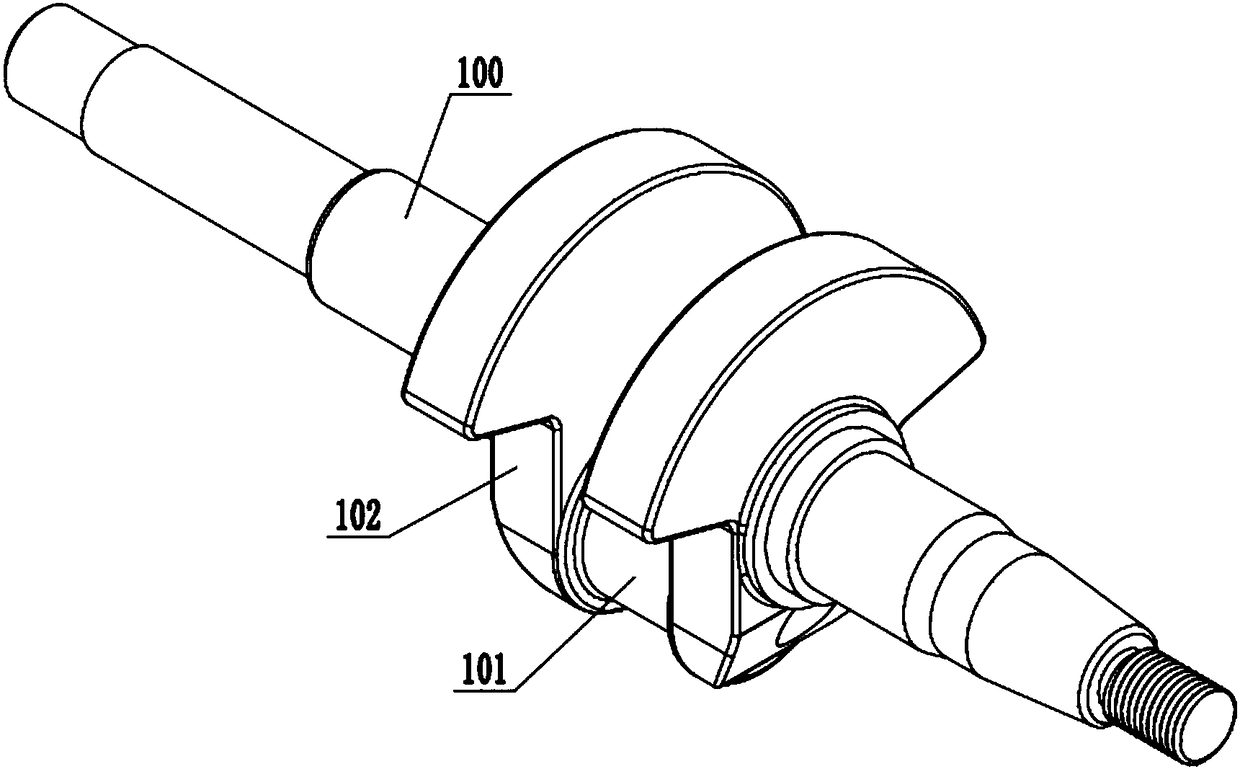

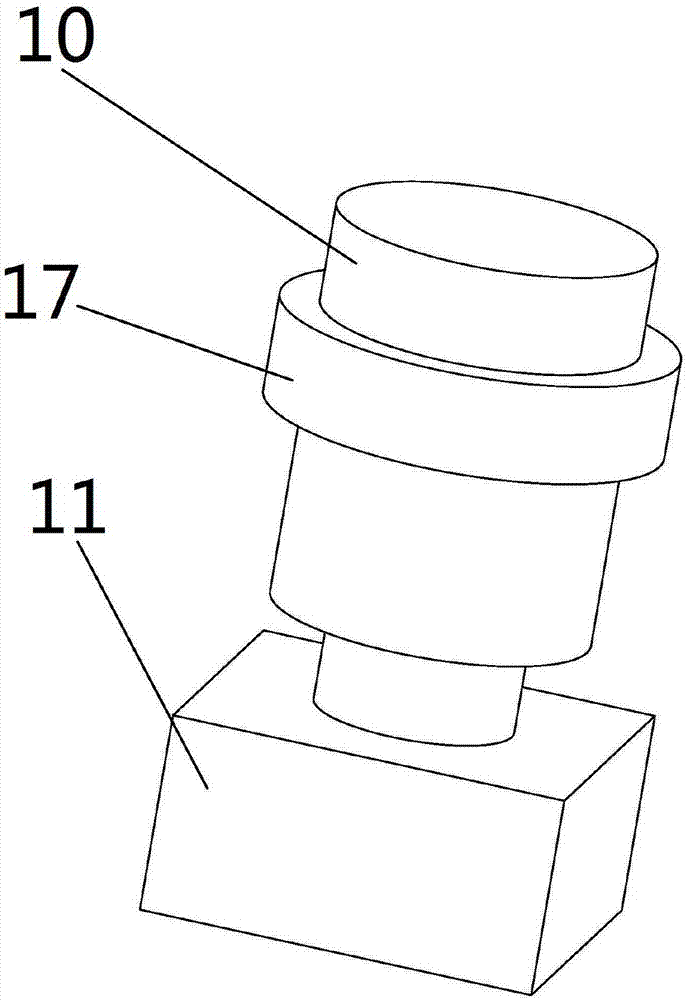

Crank throw positioning clamp

ActiveCN106112042AEven by forceReduce impact damageExpansion mandrelsEngineeringMechanical engineering

The invention discloses a crank throw positioning clamp. The crank throw positioning clamp is characterized by comprising a positioning plate, an ejection rod, a taper sleeve, a spring clamping sleeve and a pair of positioning rotary arms. The positioning plate is provided with a first positioning hole and a second positioning hole in parallel; the taper sleeve is installed in the first positioning hole; the ejection rod is installed in the second positioning hole; the spring clamping sleeve is installed in the taper sleeve, and the outer taper face of the spring clamping sleeve is matched with an inner taper hole of the taper sleeve; a stopping ring is arranged on the outer side of the spring clamping sleeve; the positioning rotary arms are symmetrically arranged along the center connecting line of the first positioning hole and the second positioning hole, and the middle portions of the positioning rotary arms are both hinged to the outer side face of the positioning plate; the outer end of the ejection rod is provided with a taper part, a gap exists between the first ends of the pair of positioning rotary arms, and the second ends of the pair of positioning rotary arms are located on the two sides of the spring clamping sleeve. By means of the crank throw positioning clamp, accurate positioning can be achieved, and eccentricity is not prone to occurrence.

Owner:CHONGQING MEIXIN YINGSHEN MACHINERY CO LTD

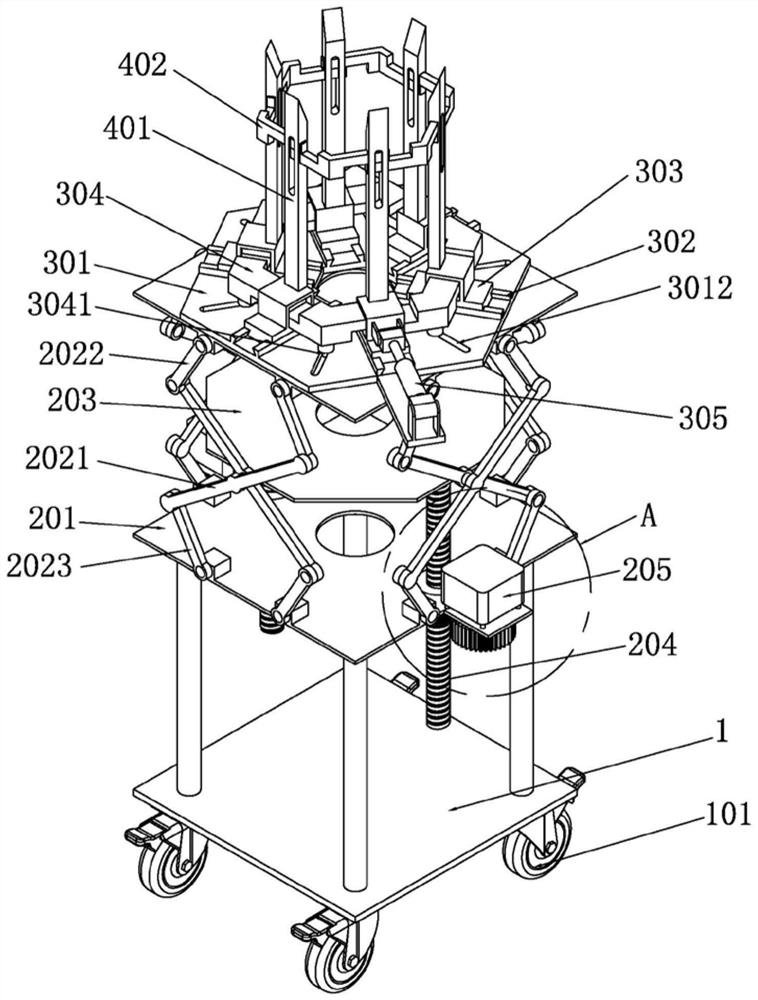

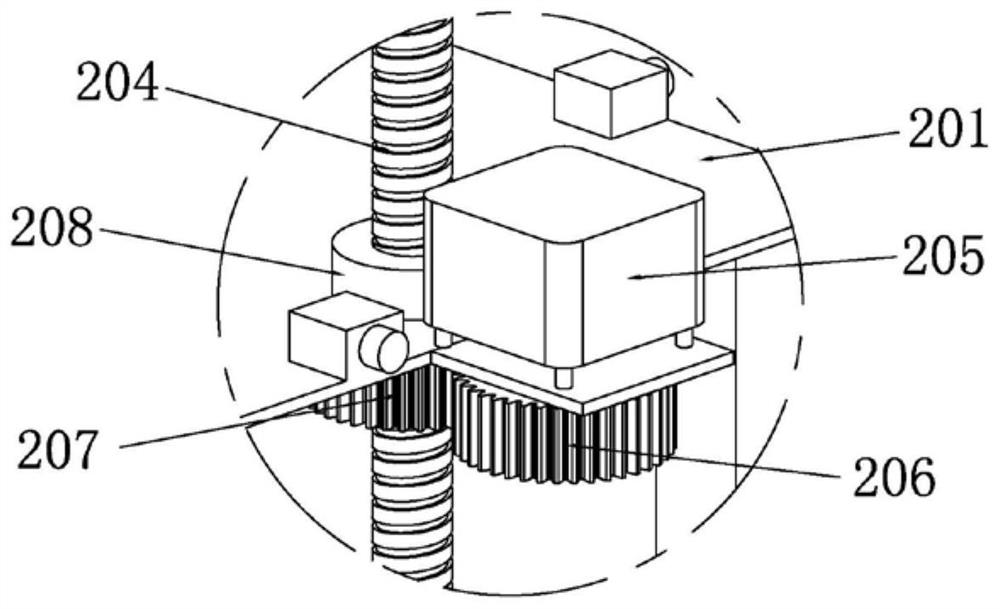

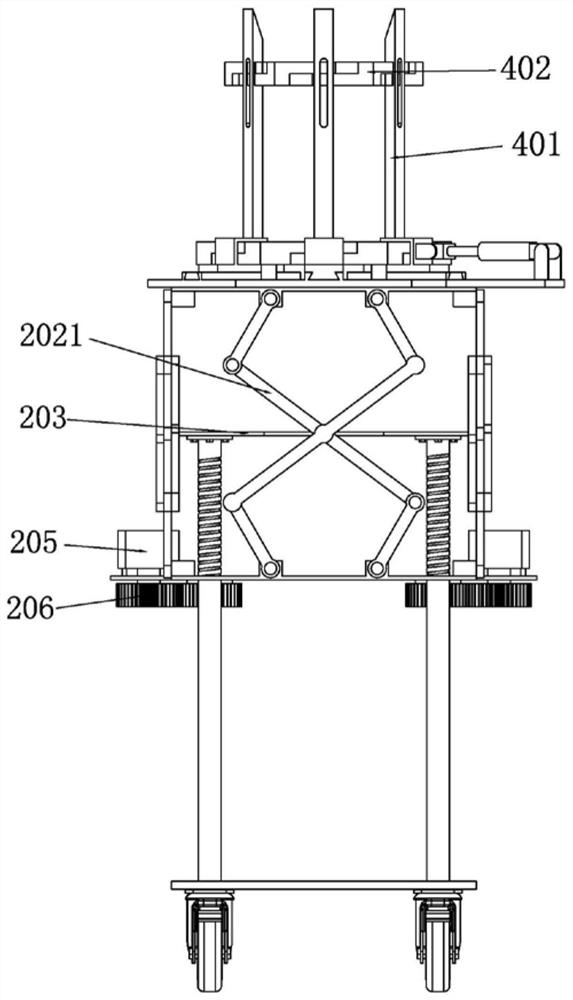

A synchronous self-centering liftable linear cutting banana drop-comb device

The invention discloses a synchronous self-centering lifting linear cutting type banana combing device, which comprises a frame, a lifting mechanism, a synchronous self-centering variable diameter mechanism and a cutting tool set; the lifting mechanism is installed on the frame, and It can move up and down under the drive of its lifting power source; the synchronous self-centering diameter-reducing mechanism is installed on the lifting mechanism and can move up and down synchronously with the lifting mechanism, and the synchronous self-centering diameter-reducing mechanism can Driven by the source, it is unfolded or folded; the cutting tool is assembled on the synchronous self-centering diameter-reducing mechanism, and can be unfolded or retracted synchronously with the synchronous self-centering diameter-reducing mechanism, so as to adapt to the change of the diameter of the banana fruit cob. The invention can effectively solve the problems of low combing efficiency of continuous combing in the combing operation process of bananas, easy damage of banana combs in the combing cutting process, poor adaptability to banana cobs, and easy omission of comb handles during combing cutting.

Owner:SOUTH CHINA AGRI UNIV

Roll Crusher

The invention relates to a crushing device, and particularly discloses a pair roller crushing machine. The pair roller crushing machine is provided with a driving roller assembly and a driven roller assembly, wherein when too hard materials pass through a position between the driving roller assembly and the driven roller assembly, the driven roller assembly can realize the active avoiding. A sievescreen is arranged under the driving roller assembly and the driven roller assembly; the sieve screen is driven to swing by a crank rocker mechanism; a material pushing plate is arranged on the sievescreen and is driven by an air cylinder; gas is supplied to the air cylinder by a gas generating mechanism; the material pushing plate is driven to do clearance reciprocating movement, so that wastematerials on the sieve screen can be discharged. Through the sieve screen arranged under the driving roller assembly and the driven roller assembly, after the retreating avoidance of the driven roller, uncrushed raw materials can be mixed into the crushed raw materials; through the sieve screen, unqualified waste materials are screened out.

Owner:重庆市南川区王小平机械制造有限公司

A construction method of inner piercing steel pipe for pipe jacking in water diversion project

ActiveCN113339585BFlexible height changeStrong penetrating powerPipe laying and repairArchitectural engineeringPipe

The invention discloses a construction method for internally piercing steel pipes for pipe jacking in water diversion projects, which comprises the following steps: (a) construction preparation; (b) placing the first steel pipe in place; (c) positioning the first steel pipe; (d) step by step Root piercing tube. The invention has low construction difficulty, high efficiency, flexible application, orderly step-by-step, convenient control, guaranteed construction quality, convenient steel pipe advancement, low equipment investment cost, firm connection of the front and rear steel pipes, stable structure, strong sealing performance, and long service life long.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

A circular plastic impeller fixture

The invention relates to the field of mechanical fixtures, and discloses a circular plastic impeller fixture. The circular plastic impeller fixture comprises a linear guide rail, and a clamping module slidingly arranged on the linear guide rail; the clamping module includes two sets of opposite clamping parts; a clamping station is formed between the two sets of clamping parts; two clamping arms are arranged on the clamping parts; clamping end surfaces of the two clamping arms are perpendicular; two adjacent clamping end surfaces on the two sets of clamping parts are also perpendicular; the two sets of clamping parts are linked, and can make mirror image movement along a linkage axis surface; the linkage axis surface is a plane passing through a linkage axis point and being perpendicular to the direction of the linear guide rail; and the linkage axis point is a center point of the moving direction of the two sets of clamping parts. The impeller fixture clamps workpieces or products through two sets of clamping parts linked on the same linear rail; and the two sets of clamping parts are consistent in working frequency, so that the clamping station accuracy is guaranteed, and the product machining quality is guaranteed.

Owner:NINGBO LANGDI IMPELLER MACHINERY

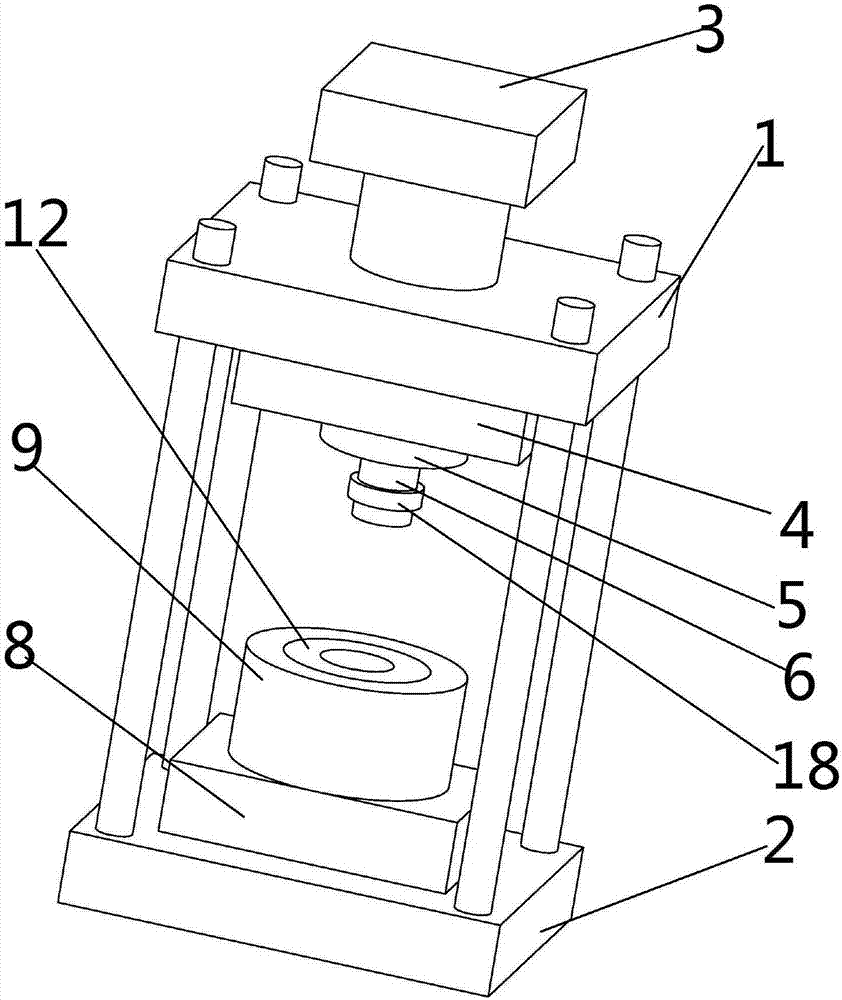

Forming die for tooth shape of spiral gear and forming method of forming die

PendingCN107999685AImprove forming effectReduce process stepsExtrusion diesWheelsEngineeringSpur gear

The invention discloses a forming die for the tooth shape of a spiral gear and a forming method of the forming die. The forming die comprises a hydraulic mechanism, an upper die mechanism and a lowerdie mechanism. The upper die mechanism comprises an upper die base, an upper die body and a pressing rod mechanism. A first through hole is formed in the center of the upper die body. The pressing rodmechanism comprises a pressing rod and a second power device. The lower die mechanism comprises a lower die base, a lower die body and an ejector rod mechanism. A containing cavity is formed in the center of the lower die body and used for storing a workpiece to be formed. The inner wall of the containing cavity is provided with a spiral tooth groove. A second through hole is formed in the centerof the bottom of the containing cavity. The ejector rod mechanism comprises an ejector rod and a third power device. The ejector rod penetrates the second through hole. According to the forming die,the manner of arranging the spiral tooth groove in the lower die body is adopted, the tooth shape of the workpiece to be formed is formed in the cold pressing forming process, in the tooth shape forming process, excessive metal moves to the middle portion of the workpiece to be formed, the problem that in the prior art, the spiral tooth groove is formed in the upper die body, and as a result, remaining materials accumulate on one end face of the workpiece is avoided, and the forming effect is improved.

Owner:SHANDONG WENLING PRECISION FORGING TECH

Pressing block assembly, door assembly and clothes treating apparatus

ActiveCN110656471ACompact structureLow costOther washing machinesTextiles and paperScrew threadThreaded fastener

The invention provides a pressing block assembly, a door assembly and a clothes treating apparatus. The pressing block assembly comprises a connector, a press-fit part, a fixing part, the press-fit part is connected with the connector and used for press-fitting door glass of the clothes treating apparatus onto a door inner ring, one of the fixing part and the connector is provided with a through hole, the other one of the fixing part and the connector is a rigid component and provided with a threaded hole corresponding to the through hole, a threaded fastener penetrates the through hole, and the through hole and the threaded hole are matched with connecting holes in the door inner ring, so that the pressing block assembly is fixedly connected with the door inner ring through the threaded fastener. According to the pressing block assembly, the door glass can be press-fitted onto the door inner ring, and the common threaded fastener is engaged with a thread of the rigid component to fixedly connect the pressing block assembly and the door inner ring. Compared with a connecting mode of self-tapping screws and plastic parts, connecting strength is remarkably improved, so that the riskof looseness of the door glass is reduced. Besides, the pressing block assembly is small in structure, low in cost and suitable for popularization.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Robots for repairing the inner walls of pipes

Owner:浙江越歌科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com