Digital reversing valve driven by servo motor

A servo motor and reversing valve technology, applied in valve details, valve devices, multi-port valves, etc., can solve problems such as flow pulsation and uneven force on the valve core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

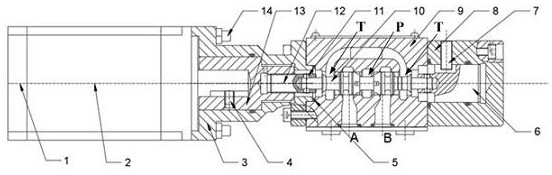

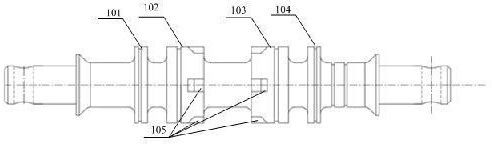

[0024] Specific embodiment one: the following combination figure 1 Describing this embodiment, a servo motor-driven digital directional valve described in this embodiment includes: an absolute encoder 1, a servo motor 2, a limit block 6, a valve body 9, a valve core 10, a threaded connecting rod 12, Screw sleeve 13 and servo motor controller;

[0025] The absolute encoder 1 is used to detect the rotational displacement of the output shaft of the servo motor 2, and send the detected rotational displacement signal of the output shaft to the servo motor controller, and the servo motor controller is used to control the servo according to the rotational displacement signal of the output shaft. Rotational displacement of motor 2;

[0026] One end of the screw sleeve 13 is sleeved on the output shaft of the servo motor 2, the screw sleeve 13 rotates with the output shaft of the servo motor 2, the other end of the screw sleeve 13 is internally threaded with a threaded connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com