Circular plastic impeller fixture

A technology of plastics and impellers, applied in the direction of clamps, manufacturing tools, etc., can solve problems such as product extrusion deformation, product processing quality problems, and affecting the company's product image, and achieve the effect of consistent working frequency and uniform circumferential force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

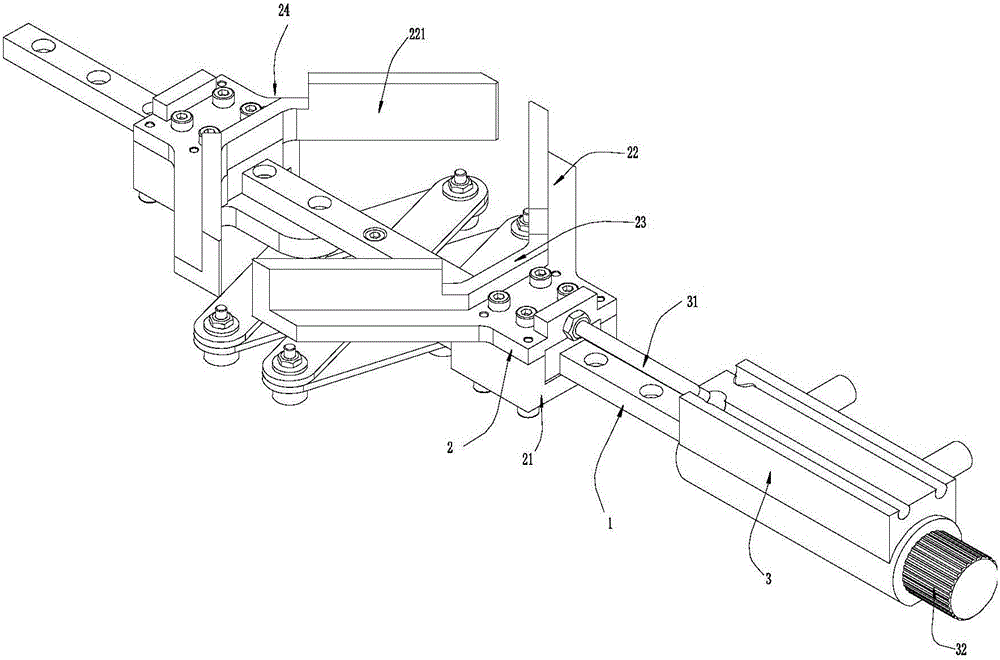

[0022] Such as Figure 1~Figure 3 The shown circular plastic impeller fixture includes a linear guide rail 1 and a clamping assembly slidably arranged on the linear guide rail 1 . The clamping assembly includes two sets of clamping parts 2 facing each other. The two sets of clamping parts 2 are linked together. There is one and only one set of clamping parts 2 connected to the output end of the driving part. The driving part drives the clamping part 2 Move along the track direction of the linear guide 1. Since the two sets of clamping components 2 are linked together, only one set of clamping components 2 needs to be driven by a driving component to realize the synchronous movement of the two sets of clamping components 2 . As shown in the figure, conventionally used driving components are cylinders 3, which are arranged at one end of the linear guide rail 1, and the output shaft 31 of the cylinder 3 is parallel to the linear guide rail 1 and connected to the clamping part 2....

Embodiment 2

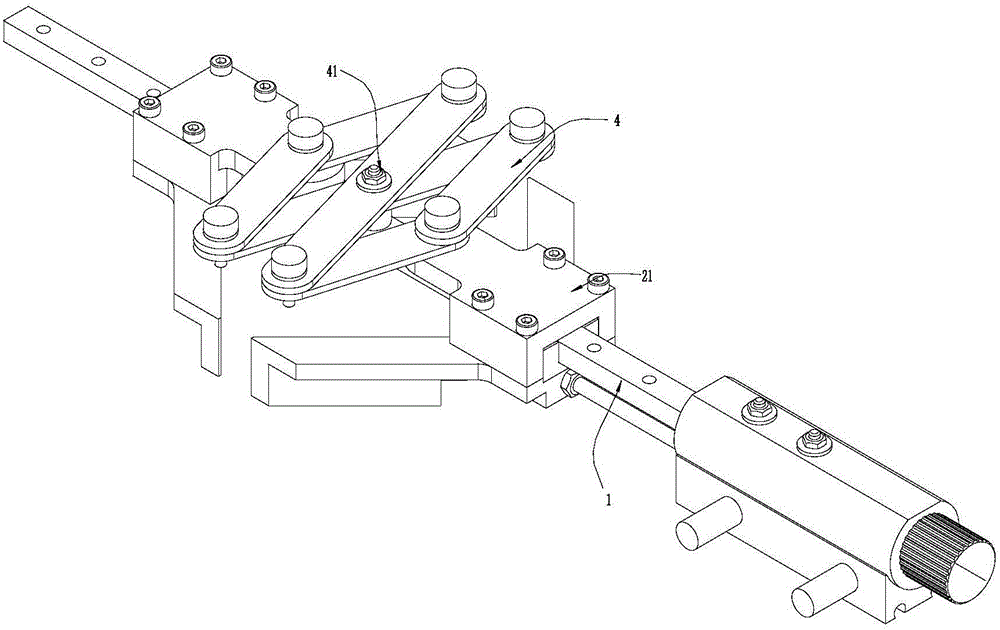

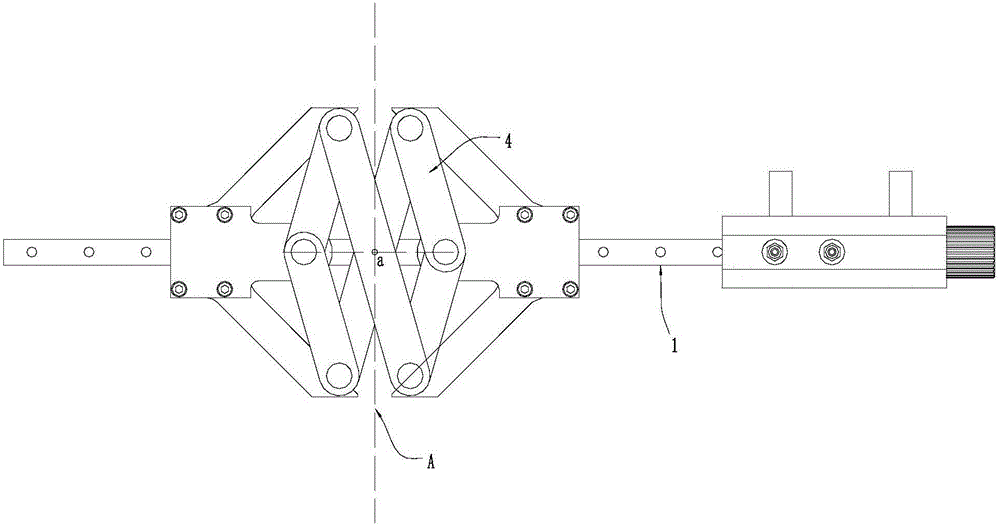

[0027] Such as Figure 4~Figure 6 Shown is the second embodiment of the circular plastic impeller clamp, which adopts the same inventive concept as the impeller clamp in Example 1, solves the same technical problem, and achieves the same invention purpose. The difference between this solution and Embodiment 1 is that in this solution, there are two linear guide rails 1, and the two linear guide rails 1 are arranged on the base plate 5 along the same axis, and a passage is opened on the base plate 5 between the two linear guide rails 1. Hole 51. The linkage assembly also adopts an X-shaped telescopic part 4, and the two ends of the X-shaped telescopic part 4 along the track direction of the linear guide rail 1 are respectively connected to two sets of clamping parts 2; There are two hinge points 41 on the top, and the two hinge points 41 are symmetrical to each other with the linkage pivot point a as the center. The two hinge points 41 are both slidably positioned on the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com