Device and method for spin-drying and infiltrating battery core of cylindrical battery

A technology of cylindrical battery and infiltration device, which is applied in the manufacture of cylindrical shell battery/battery, secondary battery, secondary battery, etc., can solve the problem of difficult solvent diffusion, accelerated solvent diffusion inside the battery, and the effect of infiltration cannot be obtained. security issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

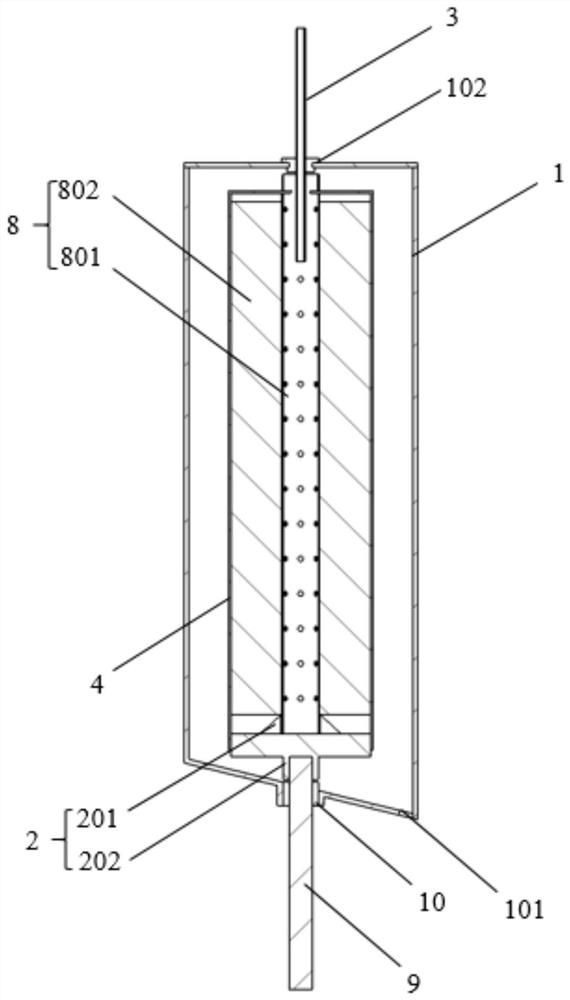

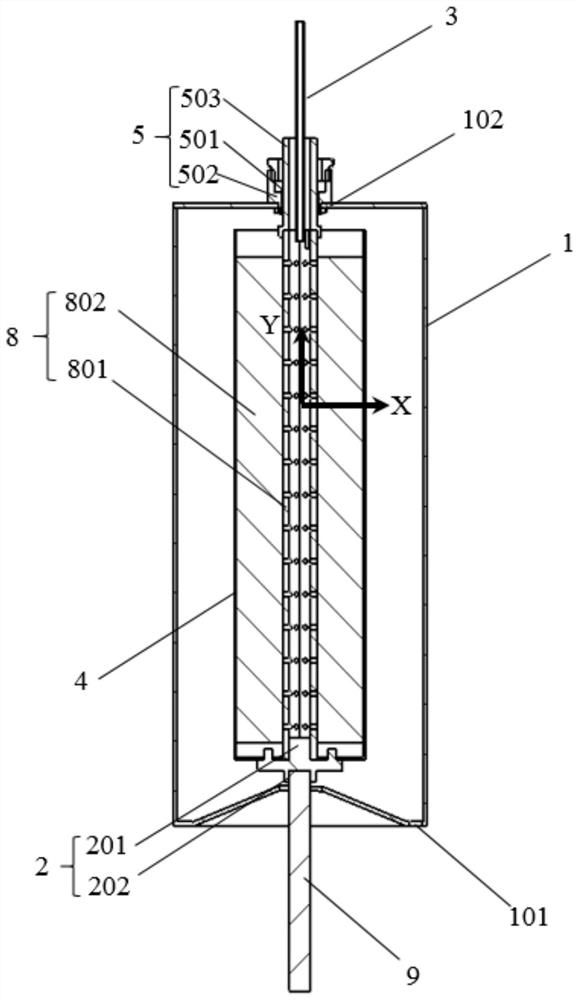

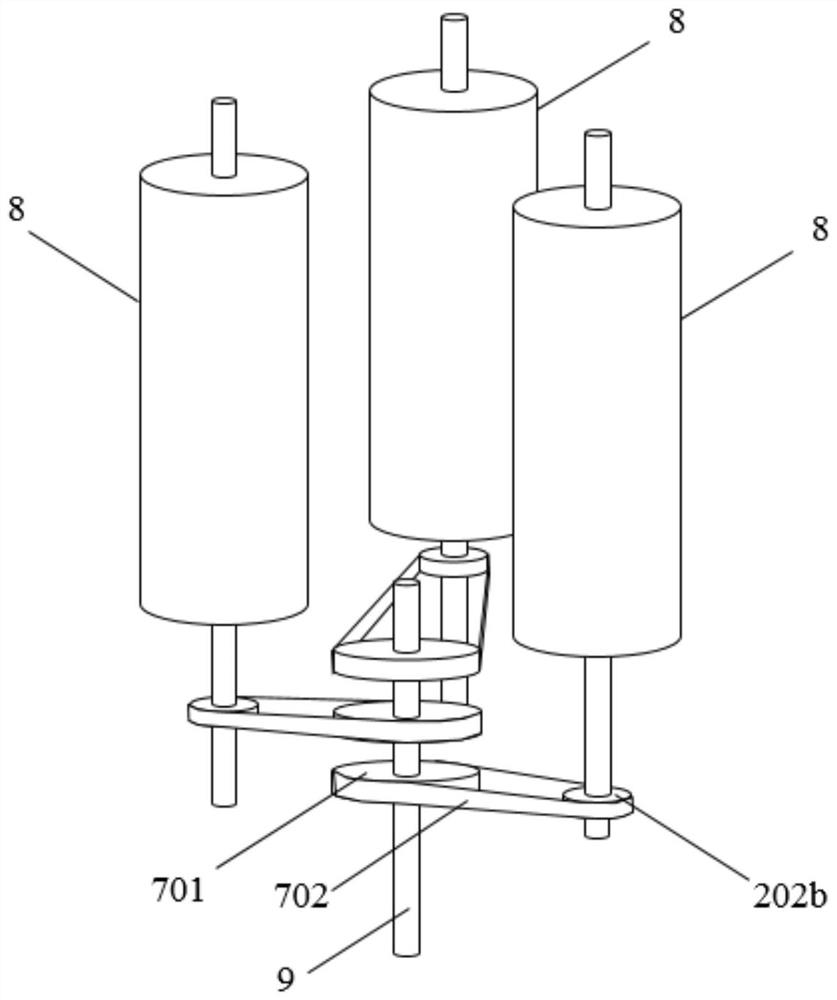

[0068] figure 1 It is a schematic cross-sectional view of a spin-drying and soaking device according to an embodiment of the present invention. exist figure 1 In the illustrated embodiment, the spin-drying and soaking device includes: a liquid collection cylinder 1 , a winding core rotating device 2 , an injection pipe 3 and a holding cylinder 4 . The liquid collection cylinder 1 comprises a liquid collection cylinder body and a liquid collection cylinder cover, a discharge port 101 is provided at the lowest point of the inclined bottom surface of the liquid collection cylinder body, and an injection port 102 is provided at the center of the liquid collection cylinder cover. The liquid collecting cylinder is cylindrical, the liquid collecting cylinder cover is located at the upper end of the liquid collecting cylinder, and the liquid collecting cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com