Patents

Literature

32results about How to "There will be no uneven thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

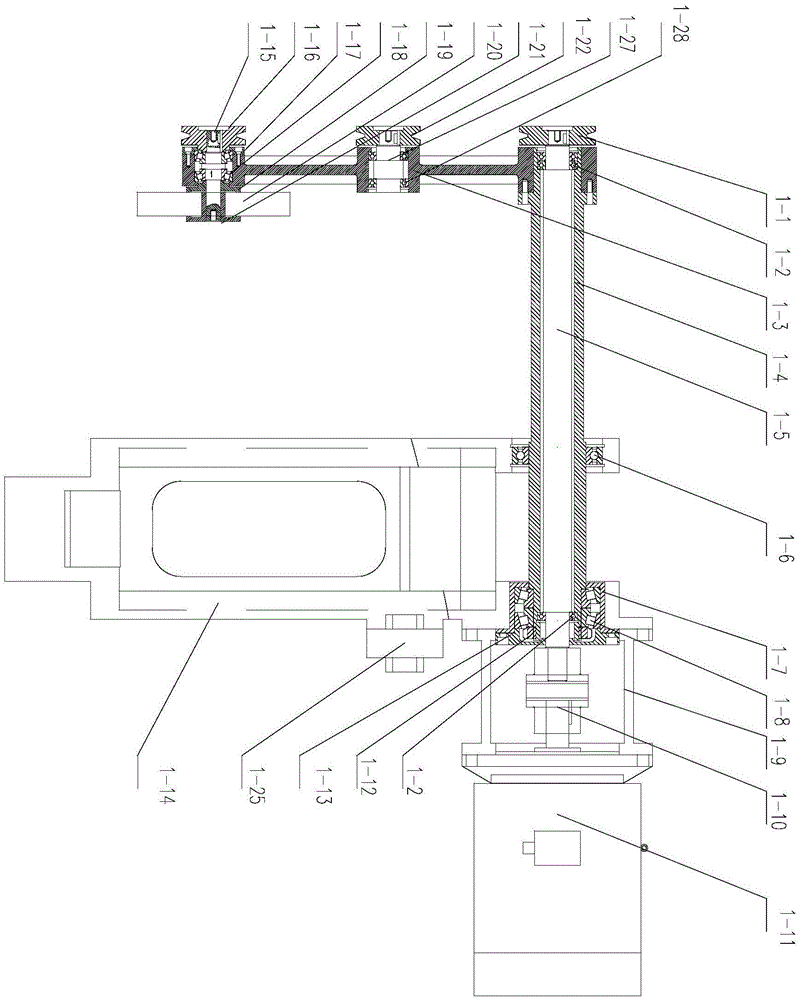

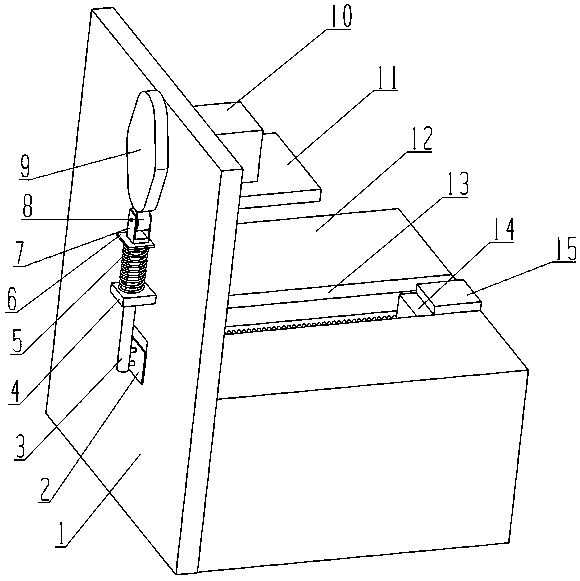

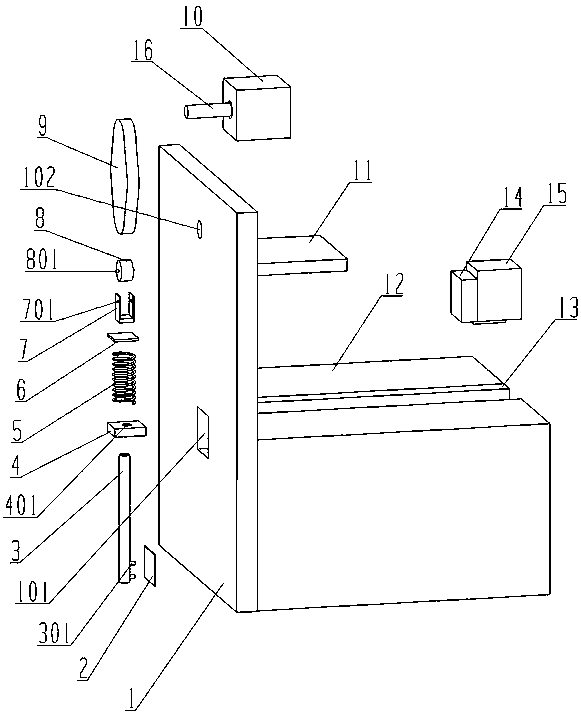

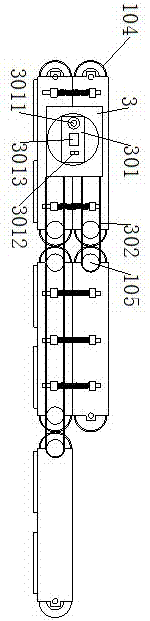

Semi-automatic derusting and paint spraying device for surface of metal tube and derusting and paint spraying method thereof

InactiveCN102151638AImprove work efficiencyGuaranteed cleanlinessCorrosion preventionPipe protection against corrosion/incrustationSemi automaticMetal

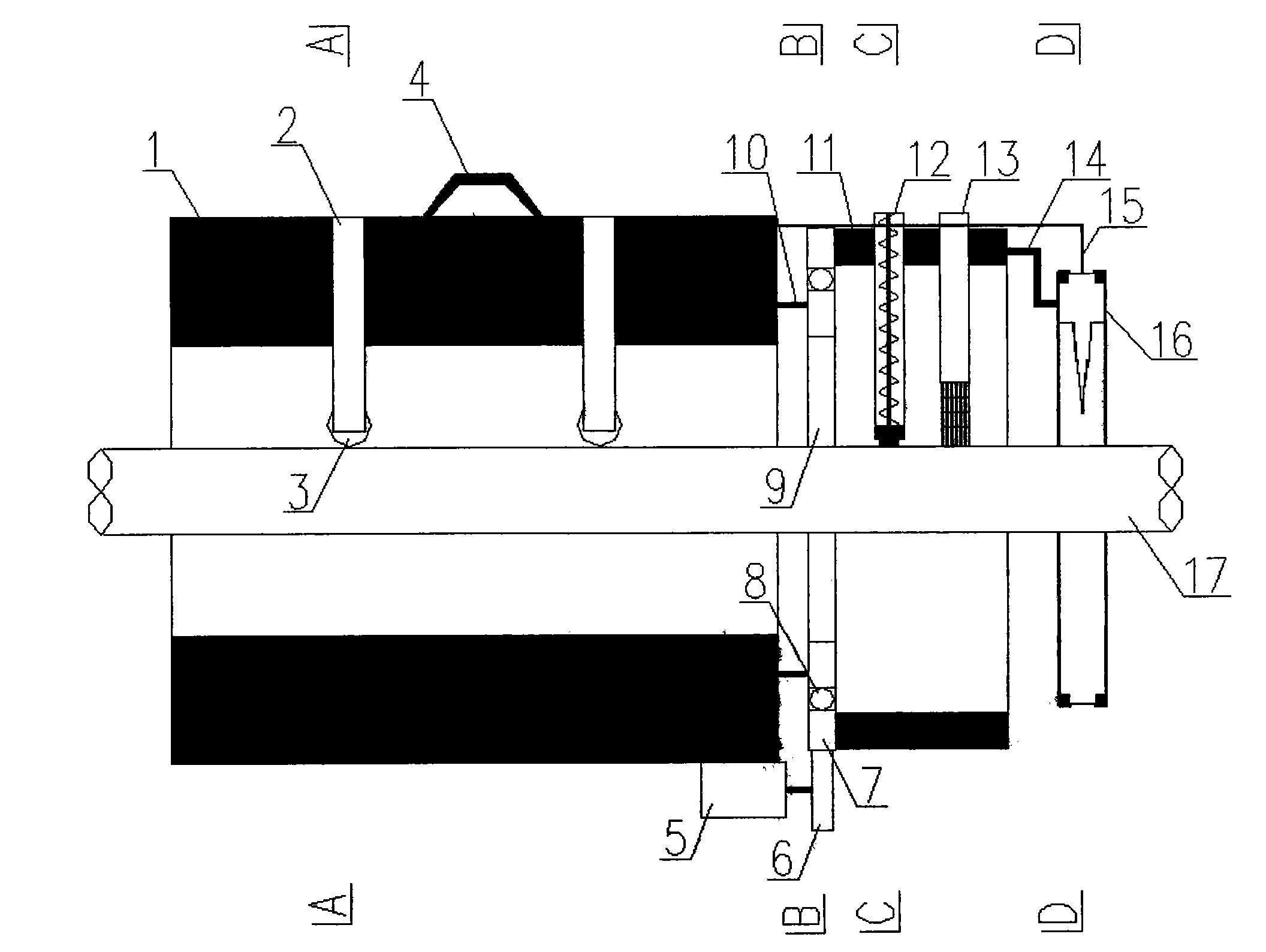

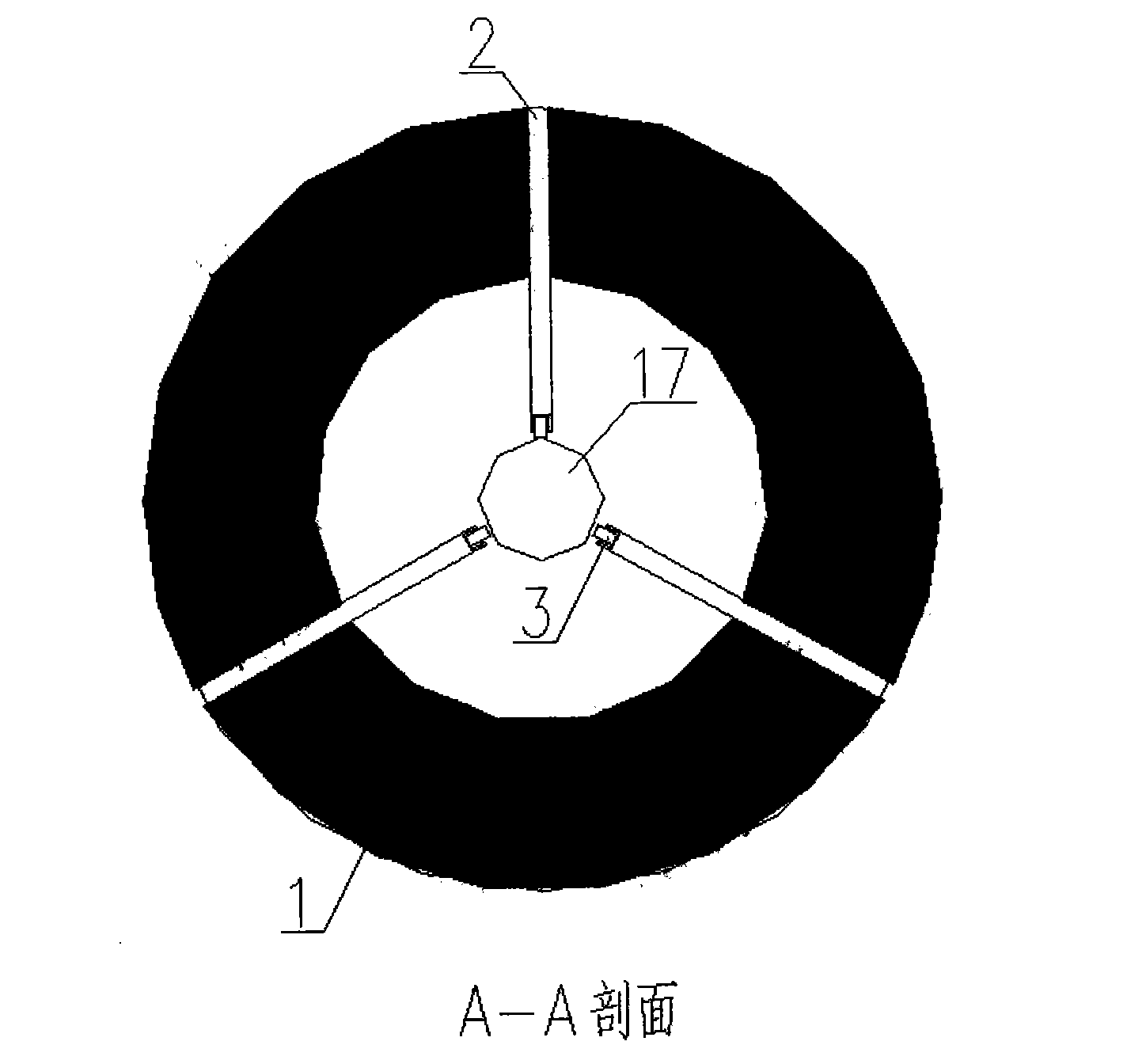

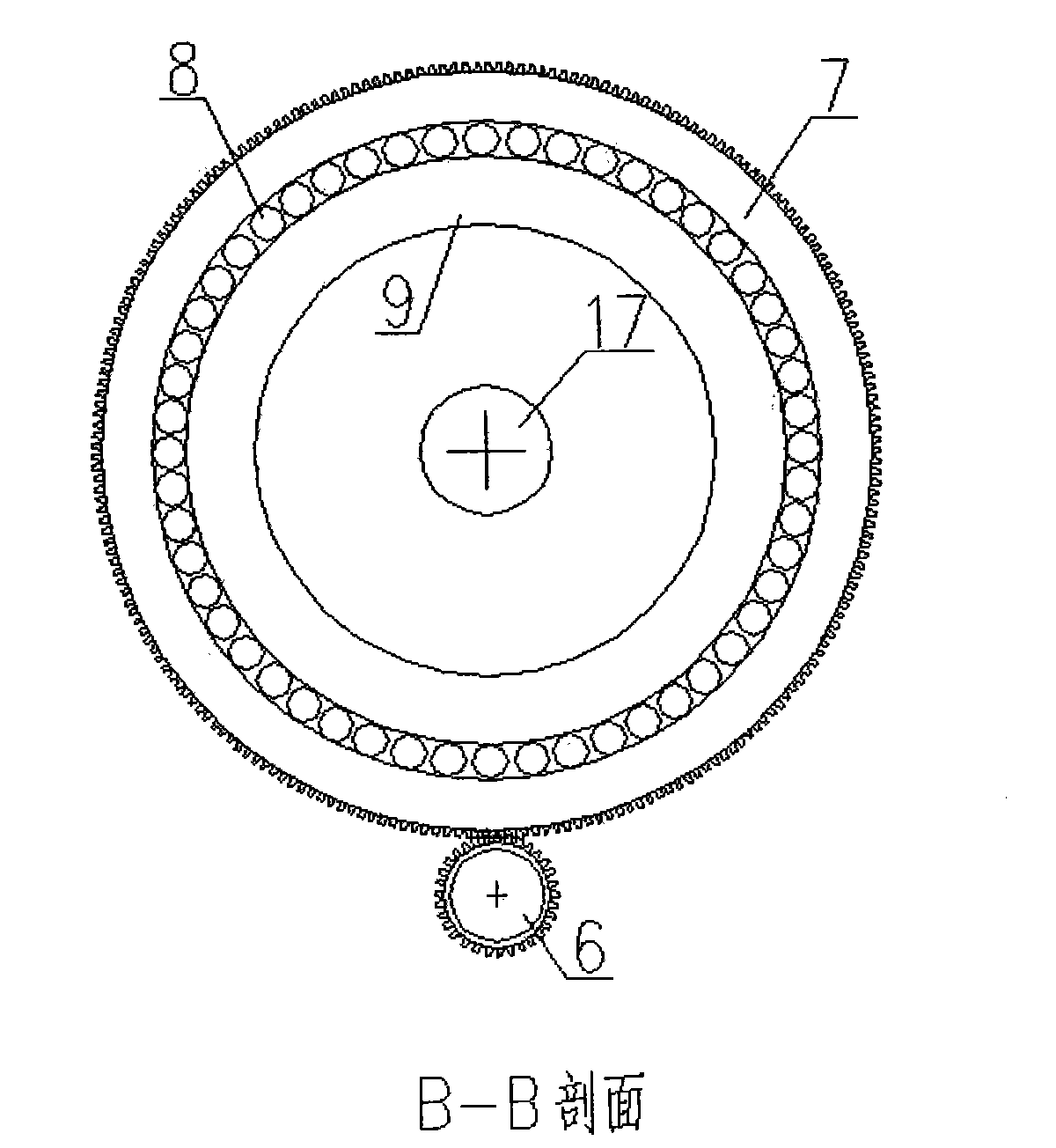

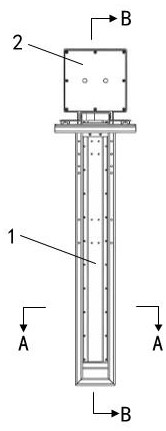

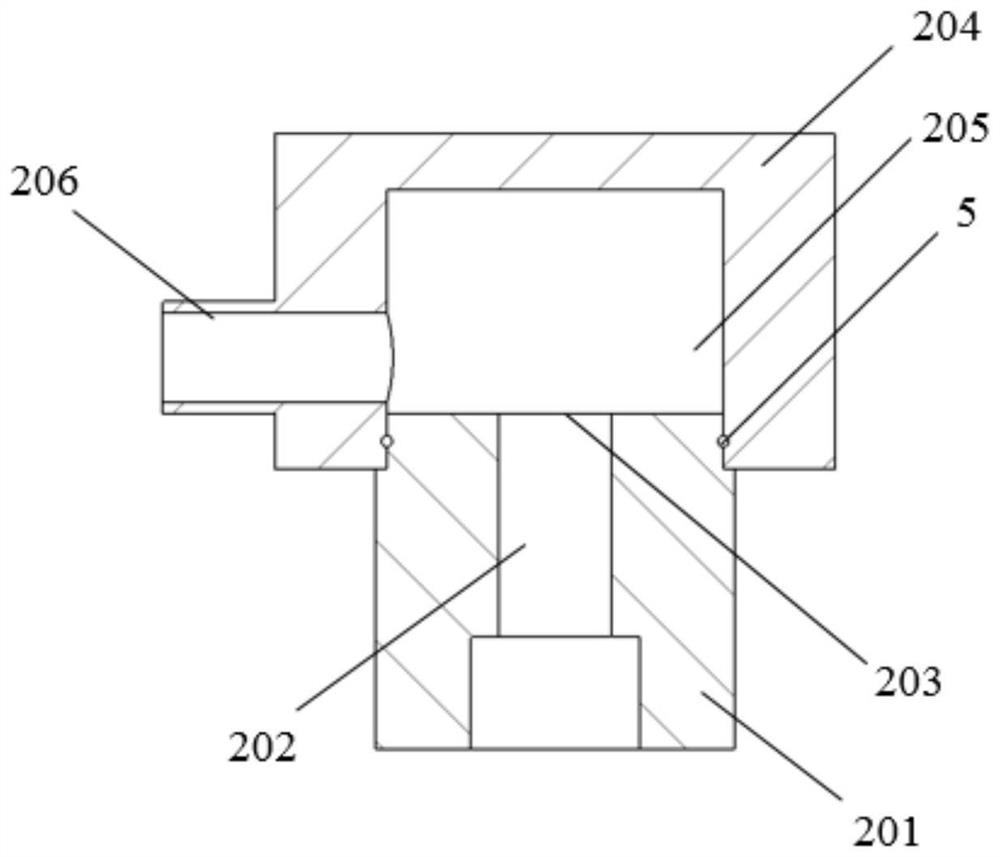

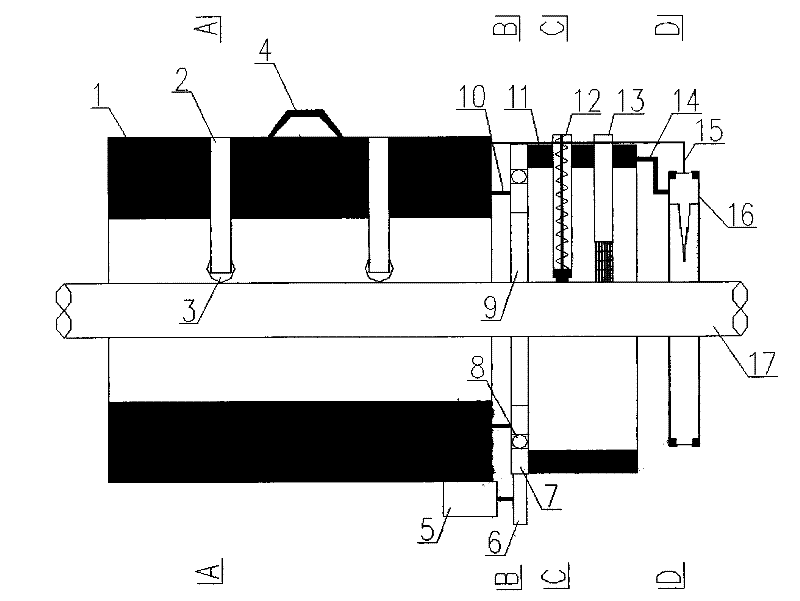

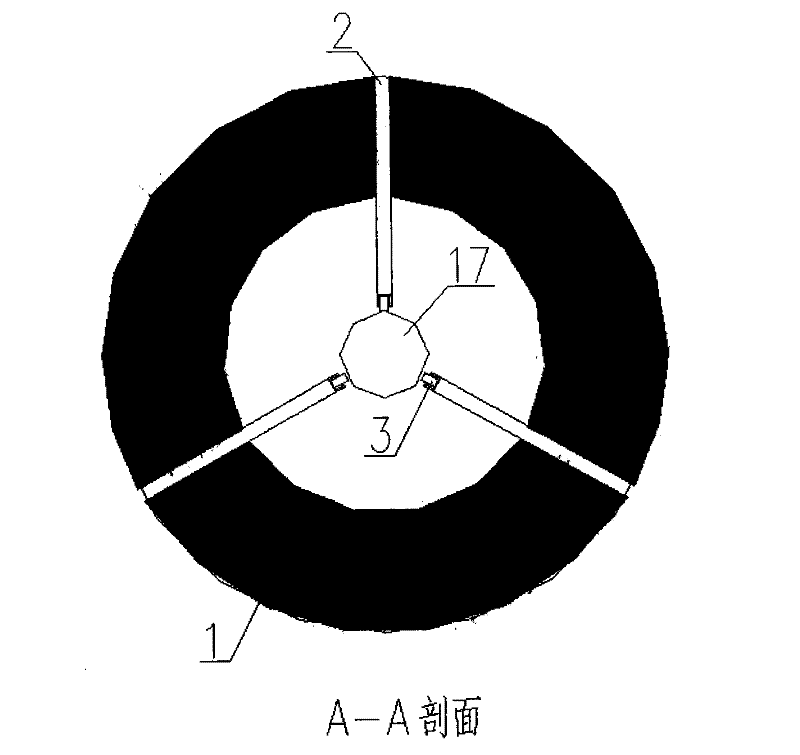

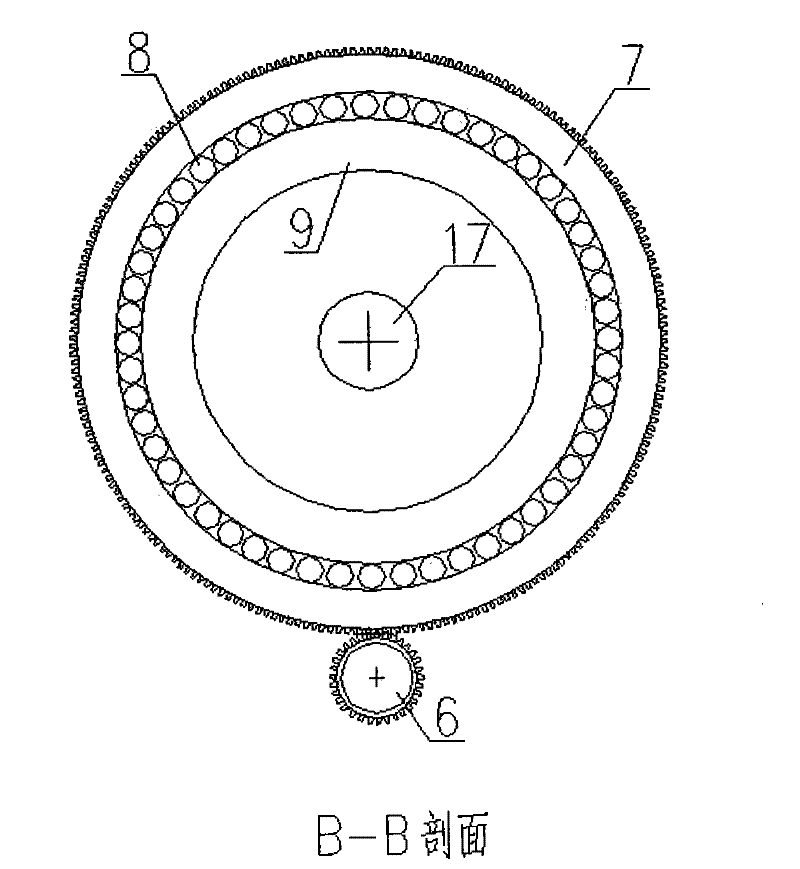

The invention relates to a semi-automatic portable derusting and paint spraying device for the surface of a metal tube, which comprises five parts, namely a movable hollow shaft system, a low-rotating speed transmission system, a derusting system, a cleaning system and a paint spraying system, wherein the movable hollow shaft system is used for fixing a metal tube on a central line of the movable hollow shaft system; the whole device moves forwards along a metal tube through the force applied on a handle; the circular motion of a motor self on the device is transferred to the derusting system, the cleaning system and the paint spraying system through the low-rotating speed transmission system, so that the derusting system, the cleaning system and the paint spraying system are driven to respectively carry out the circular motion around the metal tube, thereby performing procedures of derusting, cleaning and paint spraying on the metal tube; the whole device continuously moves forwards along the metal tube through the handle, and then the derusting and paint spraying work of the processed tube is finished.

Owner:贾韶强

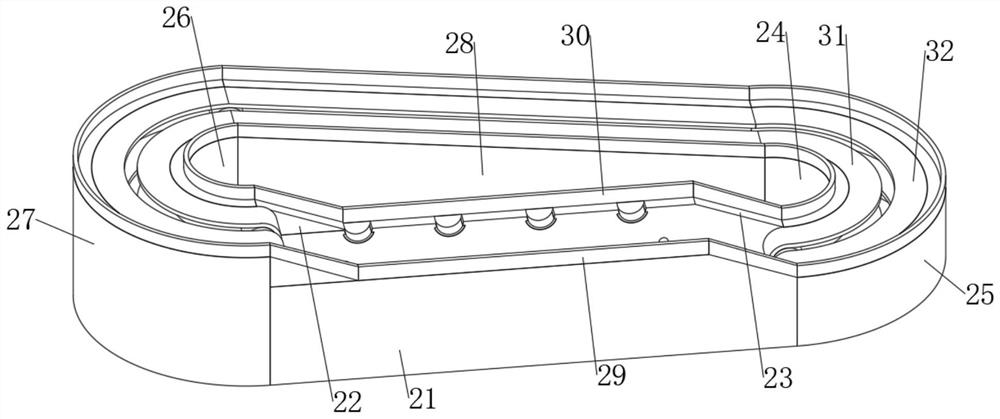

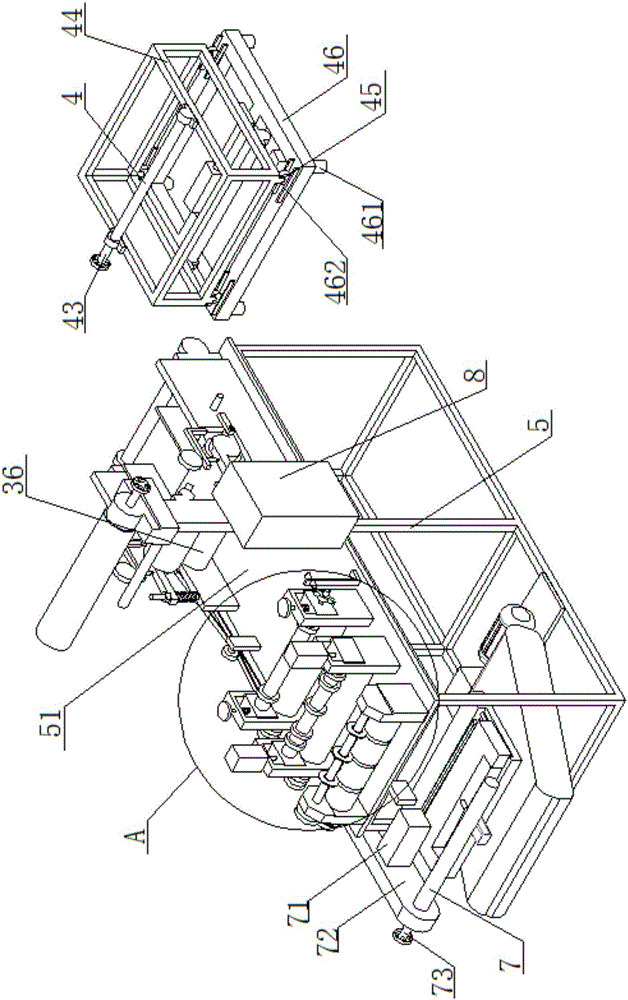

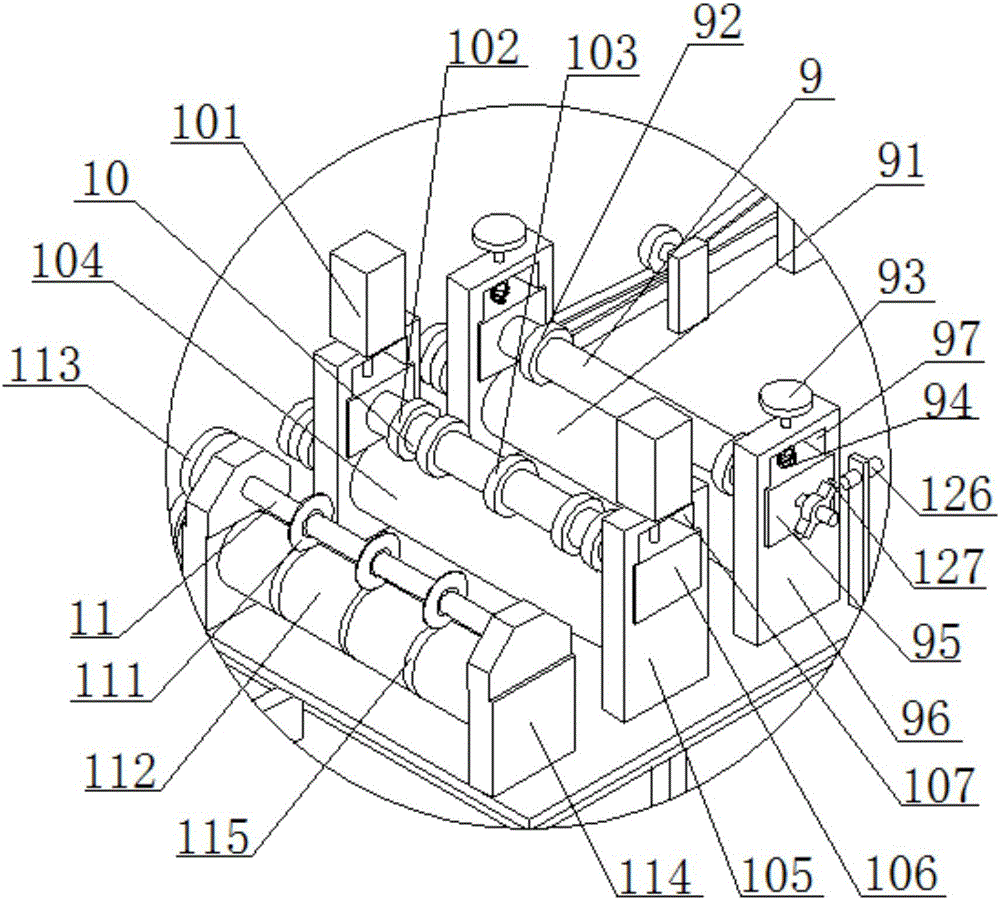

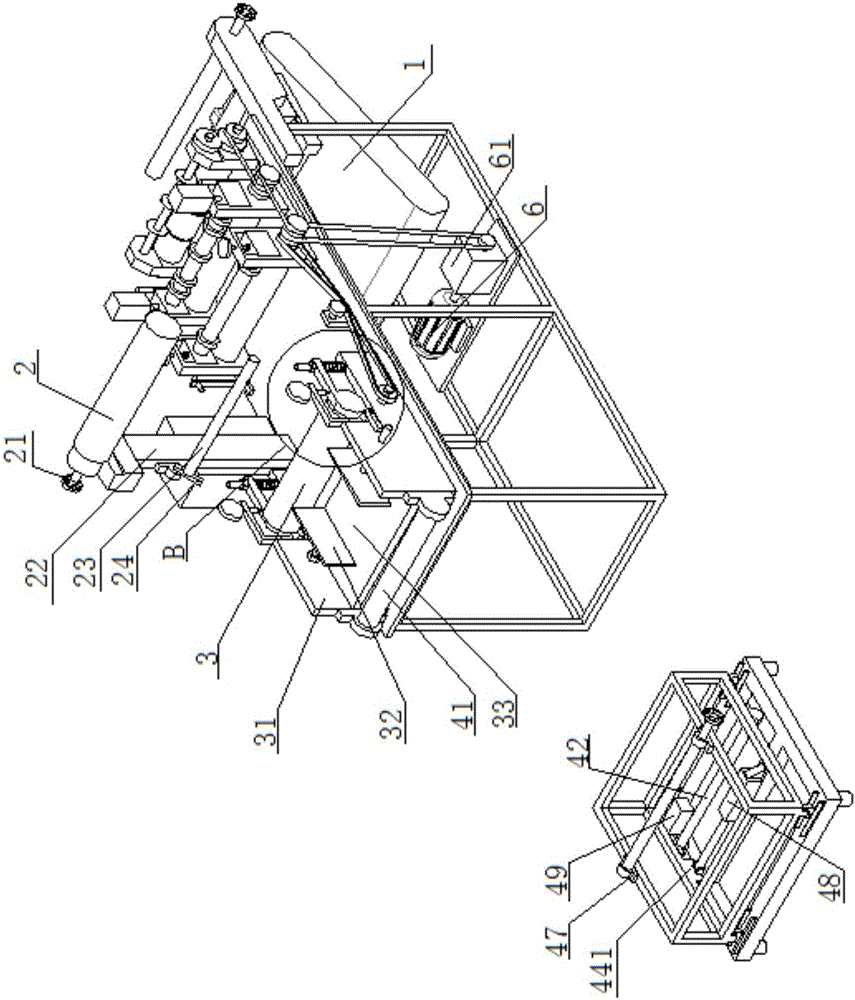

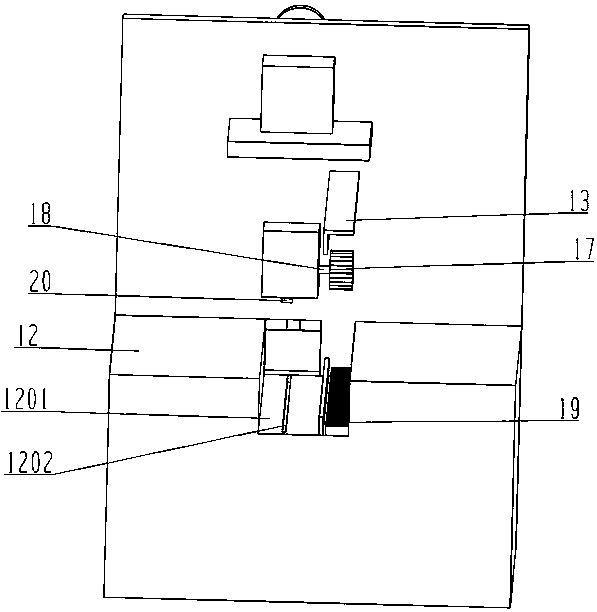

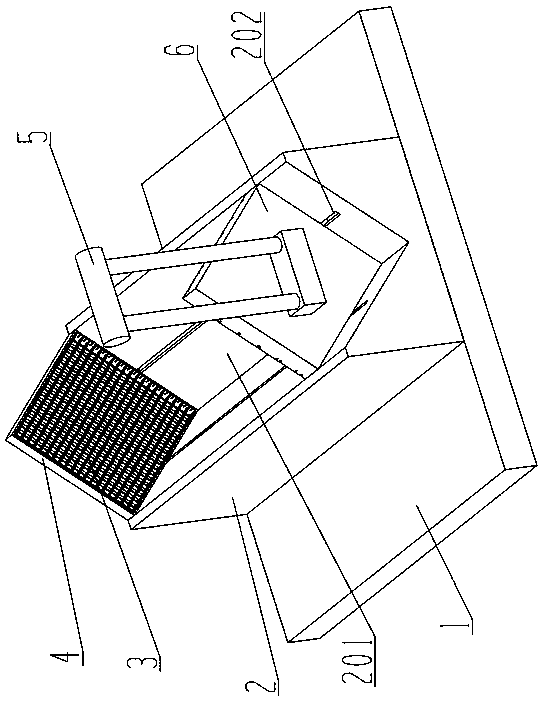

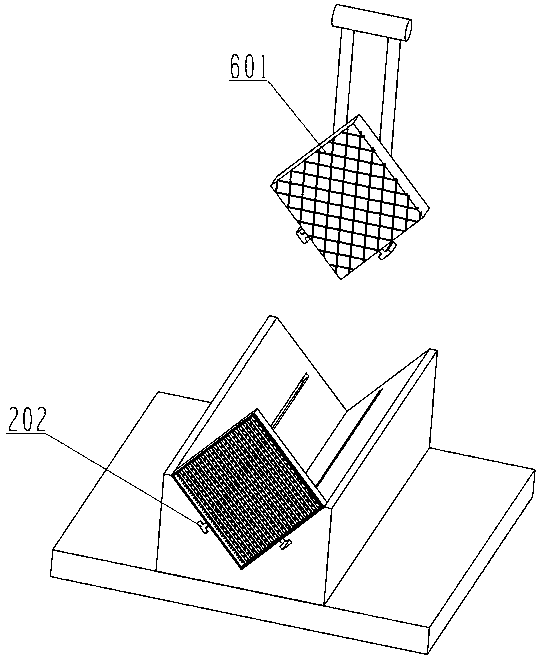

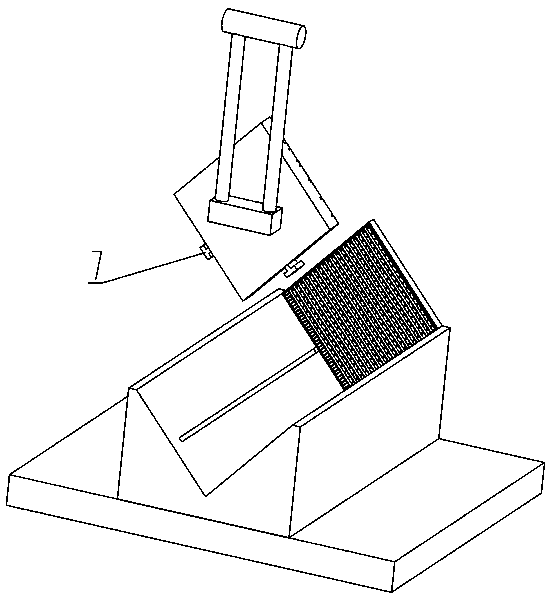

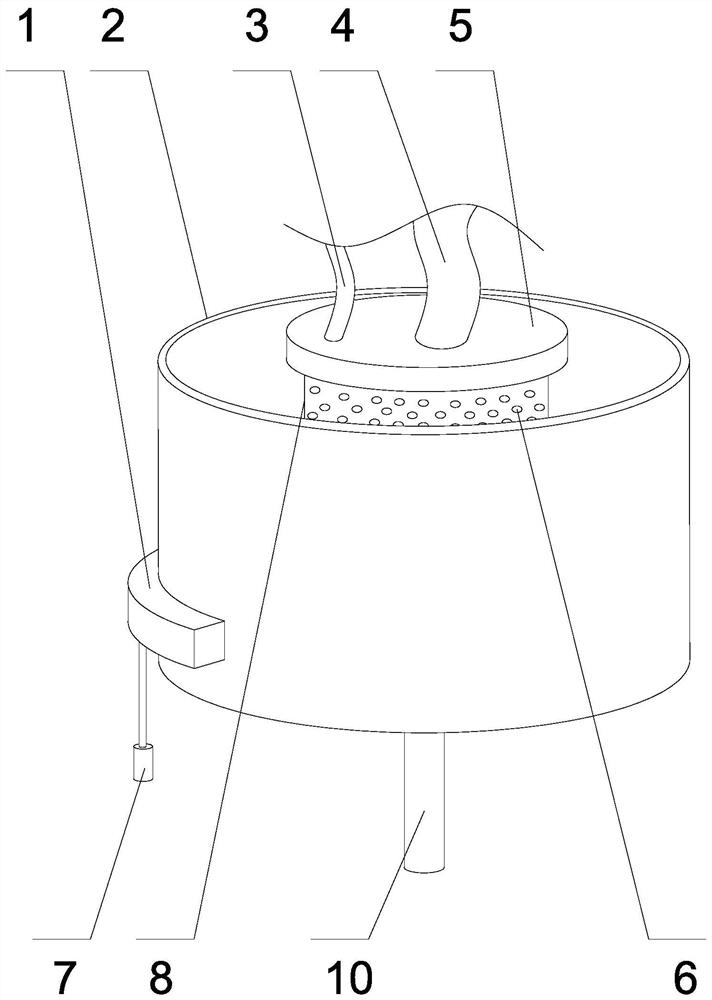

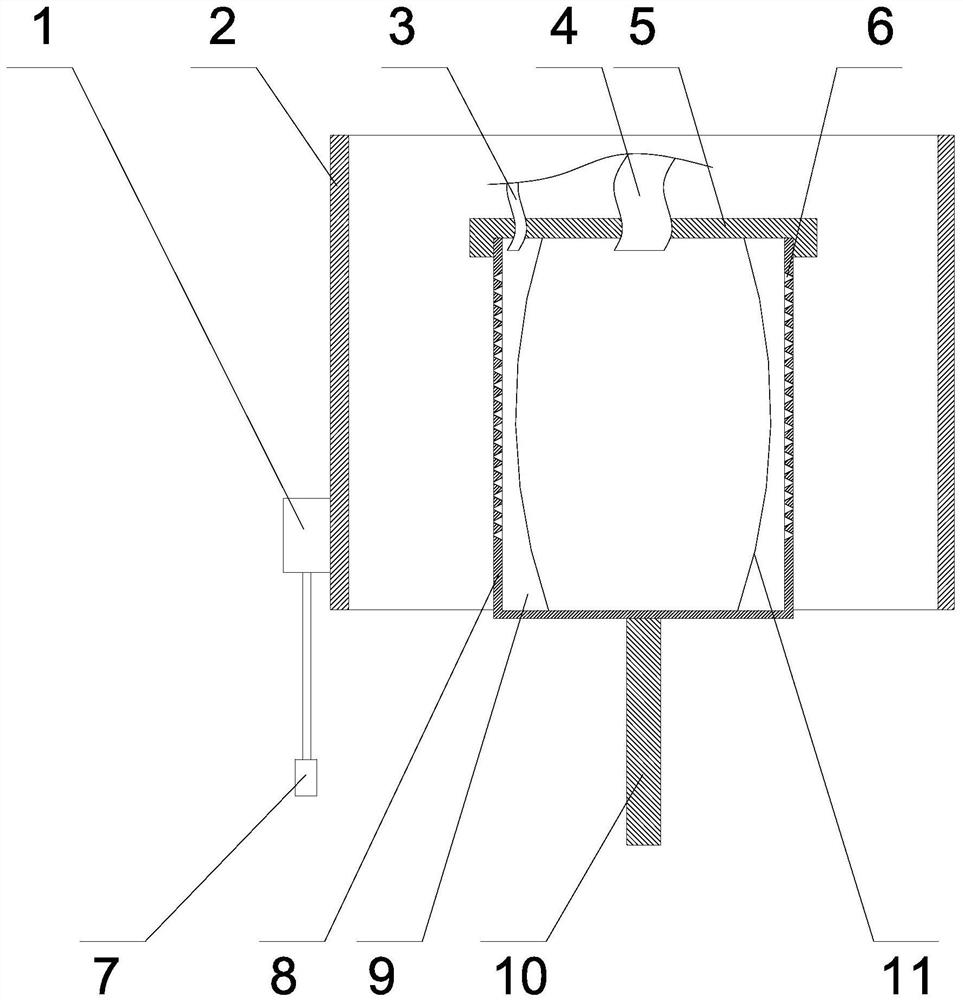

Rocker arm type automatic pot grinding machine

InactiveCN105150053AThere will be no uneven thicknessImprove product qualityGrinding machinesAutomatic grinding controlWorking environmentEngineering

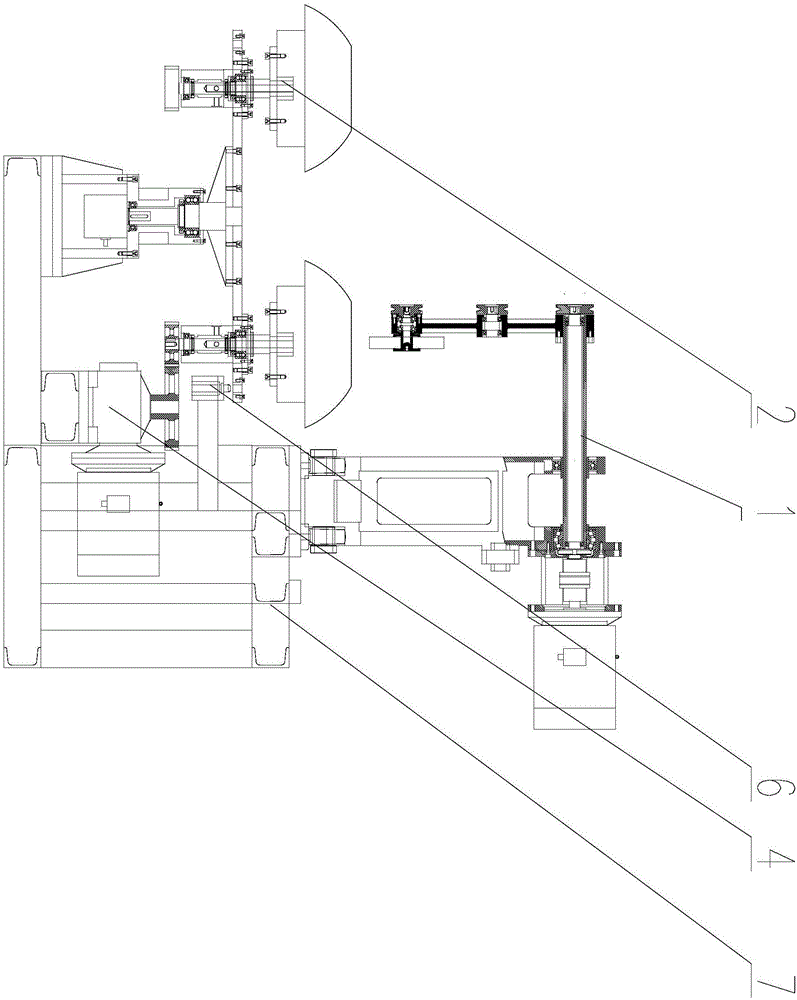

The invention discloses a rocker arm type automatic pot grinding machine. The rocker arm type automatic pot grinding machine comprises a rocker arm grinding wheel assembly and a rotary table mould assembly, wherein the rotary table mould assembly comprises a rotating shaft which is arranged in the center of a supporting base and is supported by a gear and rack swing air cylinder, wherein a rotary platform is connected above the rotating shaft; moulds are respectively arranged at the two sides of the rotary platform; mould rotary shafts are respectively connected below the moulds at two sides; the mould rotary shafts are driven by an electric motor via gear; the rock arm grinding wheel assembly is formed by connecting a rear rocker arm with a front rocker arm through the rotary shaft; the rear rocker arm is connected with a servo motor through a lead screw for driving; a connecting shaft is arranged outside the rotary shaft in a sleeving mode; and the front rocker arm consists of three belt wheels which are arranged on a connecting rod at intervals. According to the rocker arm type automatic pot grinding machine, all actions are controlled by program to complete a fully-automatic grinding process without an uneven thickness phenomenon, thereby greatly improving the product quality, reducing a rejection rate, increasing a yield, reducing labor power and also improving the working environment.

Owner:HANGZHOU FUYANGYIHUA TECH CO LTD

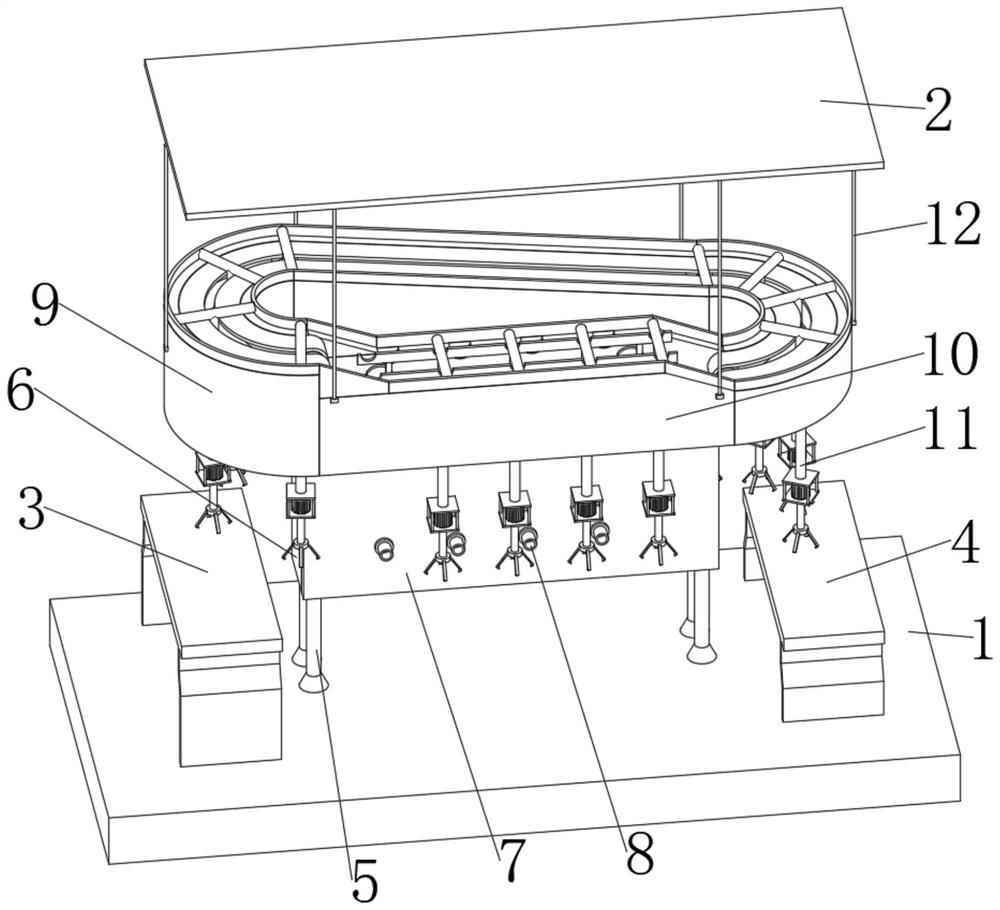

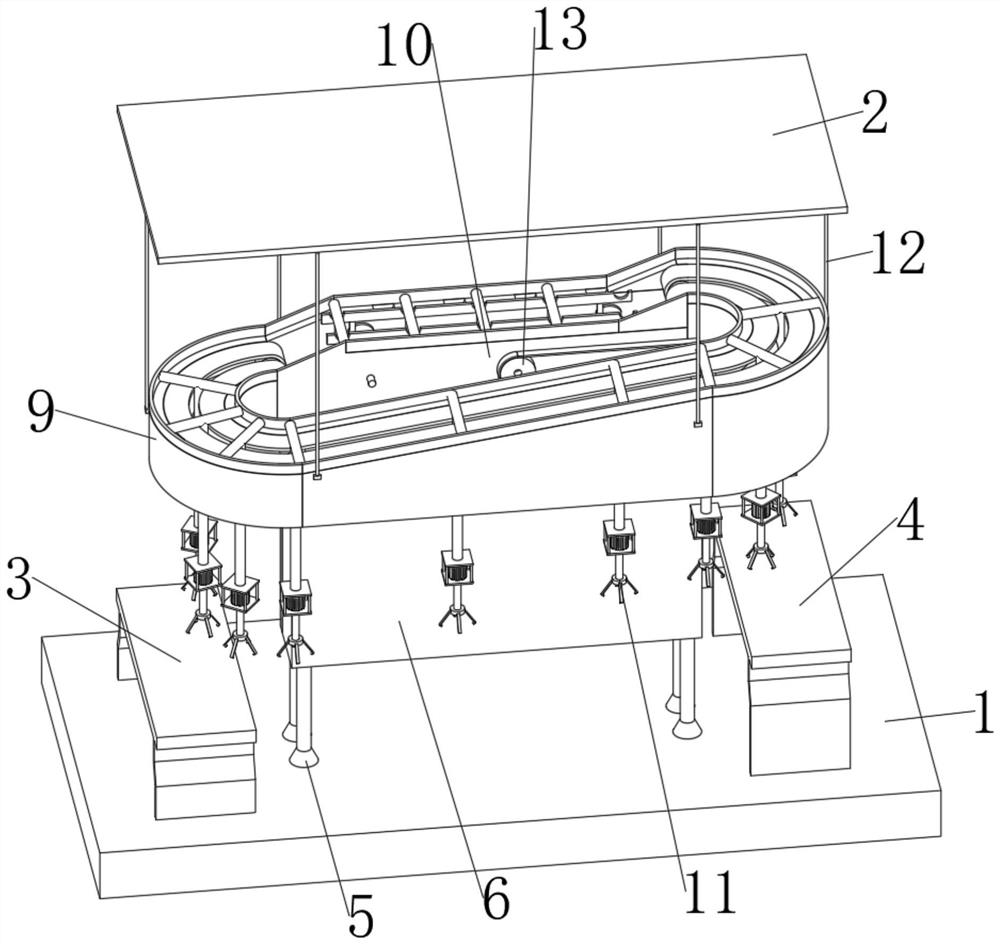

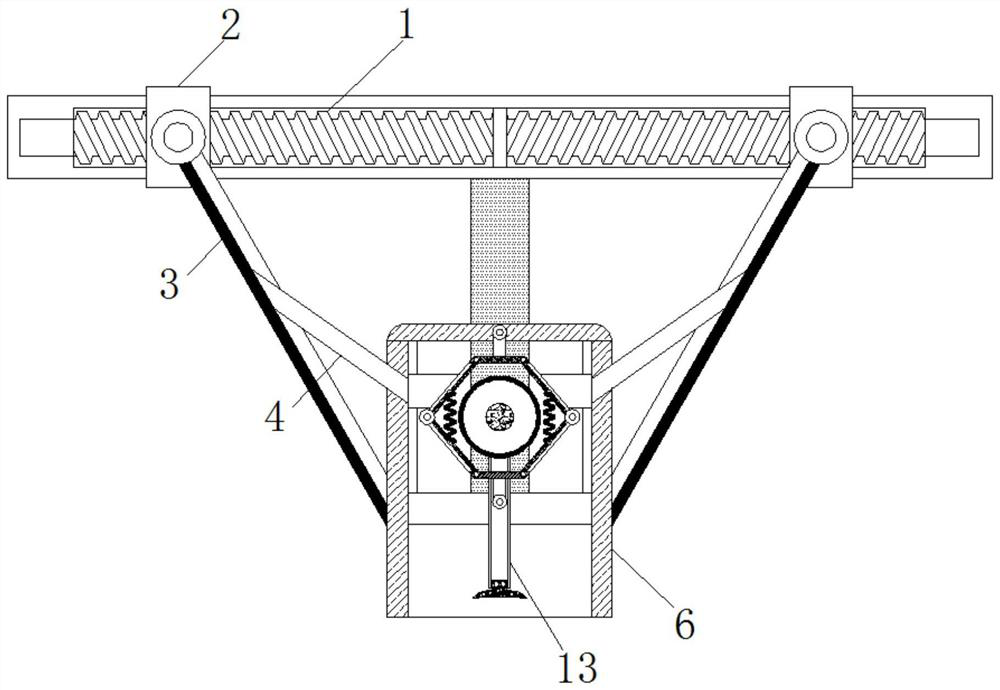

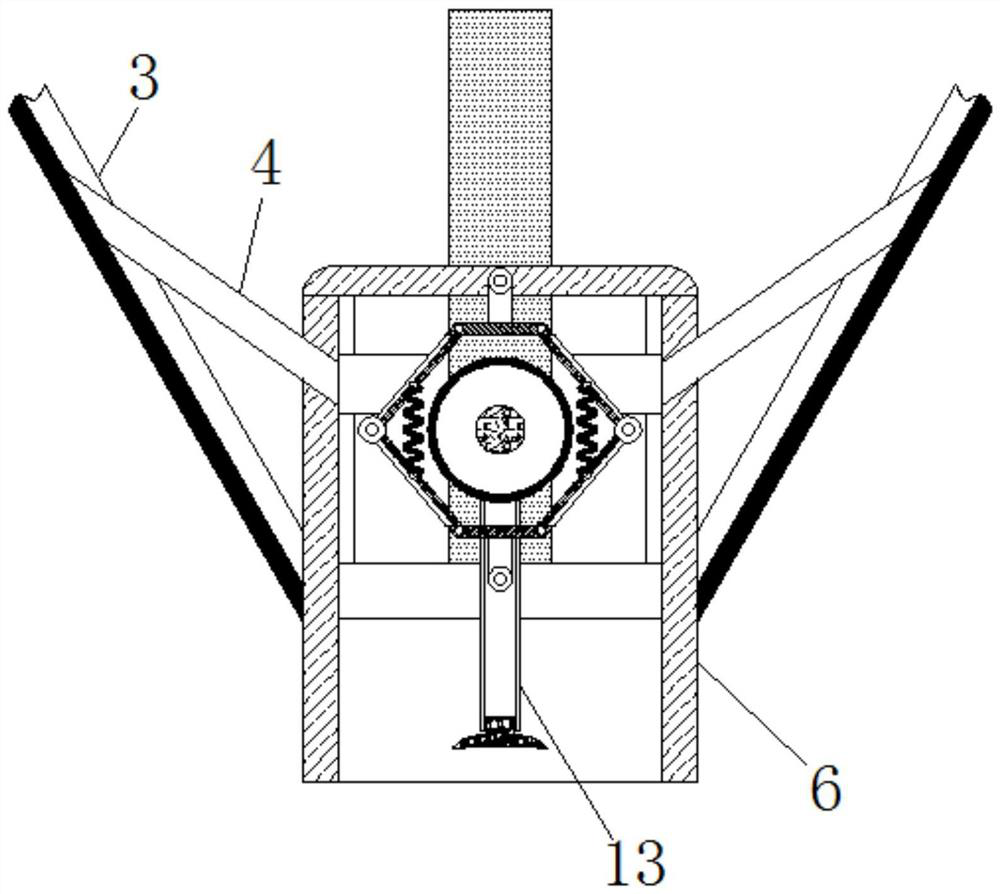

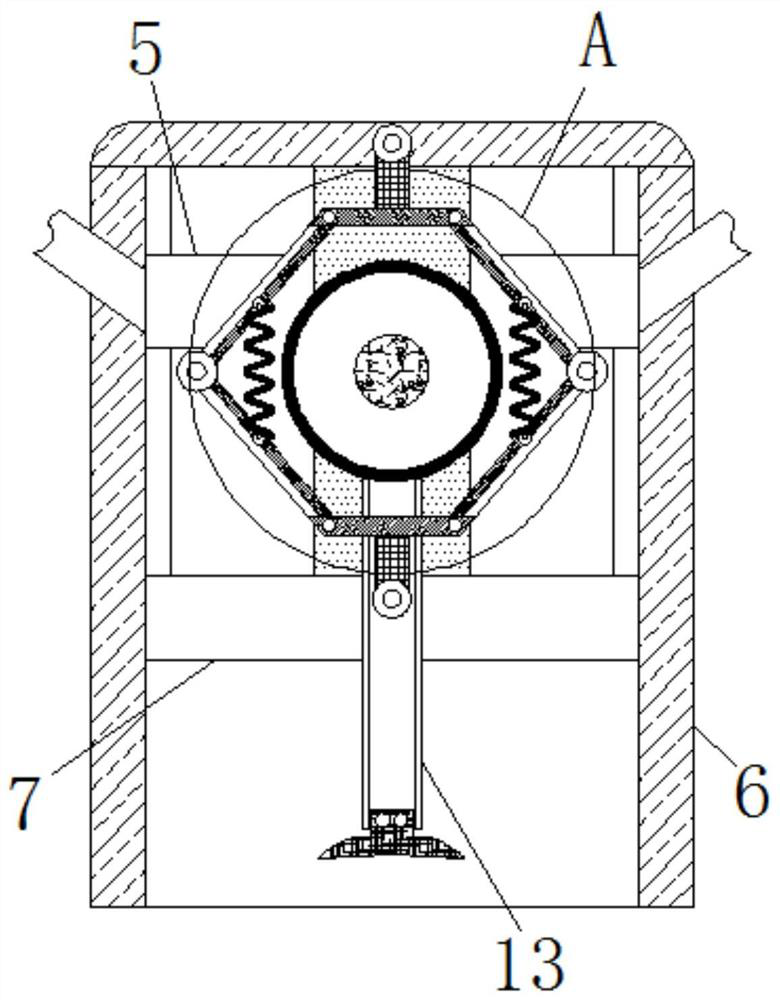

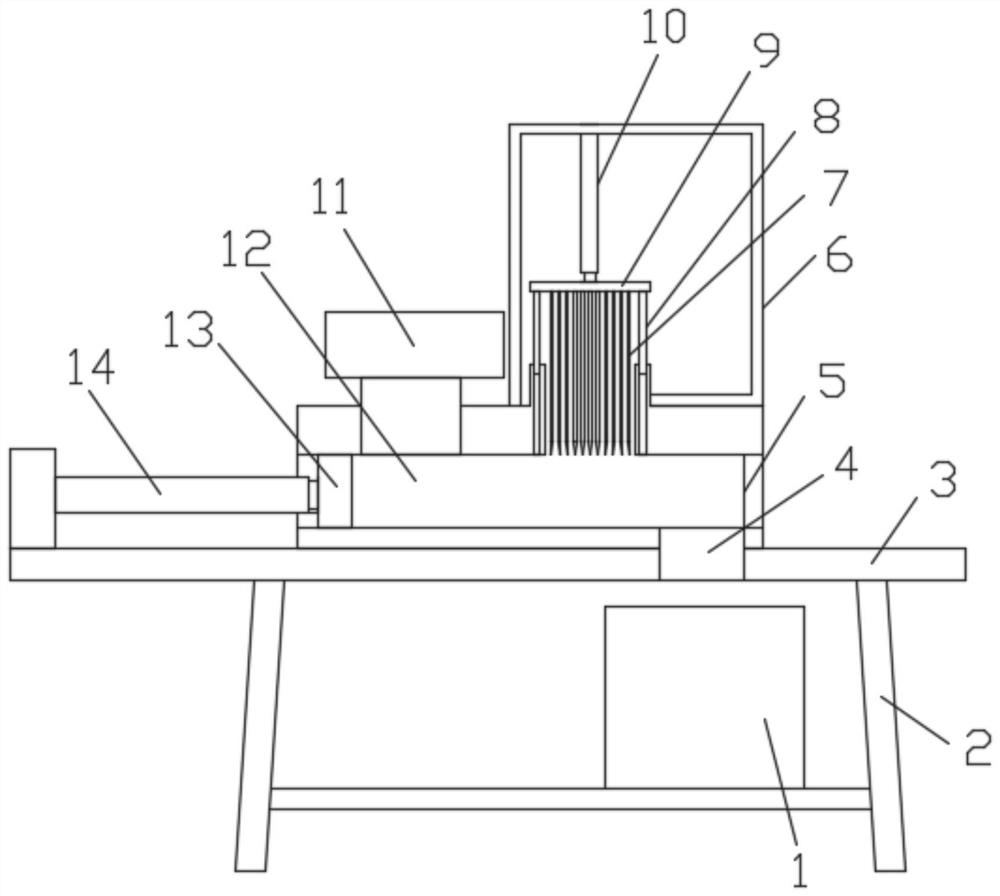

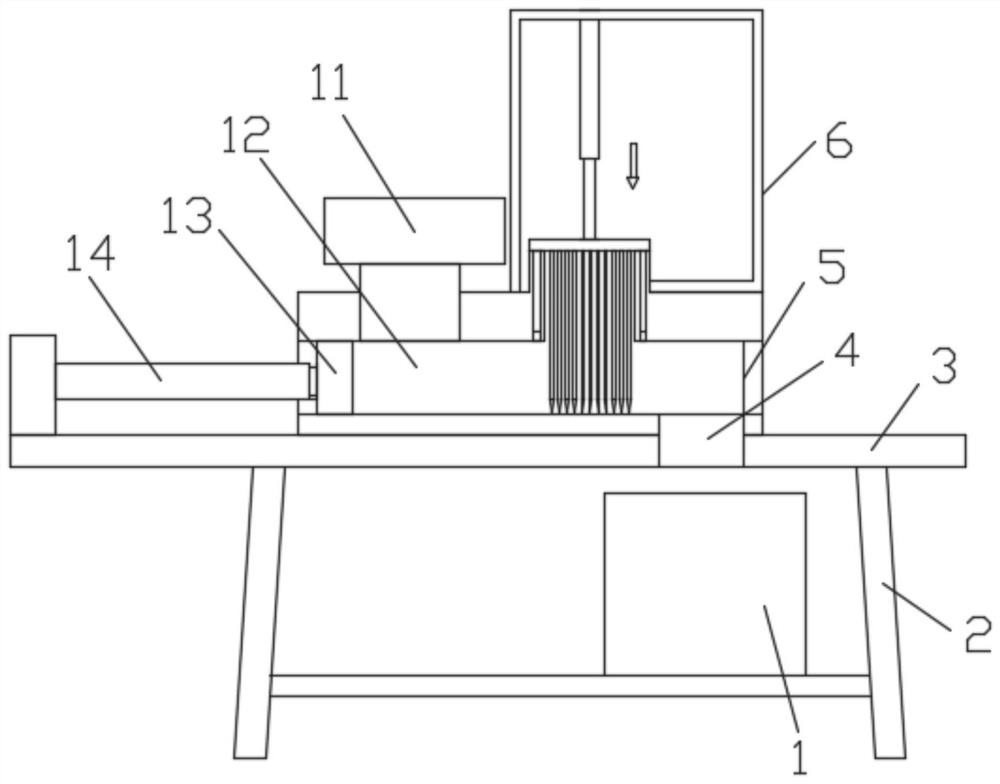

Automatic spraying equipment for suspension type assembly line

InactiveCN112642616AConsistent spraying timeThere will be no uneven thicknessSpraying apparatusLiquid storage tankEngineering

The invention discloses automatic spraying equipment for a suspension type assembly line. The automatic spraying equipment comprises a lower mounting surface, wherein a feeding platform is fixedly mounted on the left portion of the upper end of the lower mounting surface, a discharging platform is fixedly mounted on the right portion of the upper end of the lower mounting surface, and two sets of supporting legs are fixedly mounted in the middle of the upper end of the lower mounting surface and distributed in left-right symmetry. A liquid storage tank is fixedly installed at the upper ends of the two sets of supporting legs jointly, a first installation plate is fixedly installed at the front end of the liquid storage tank, a spraying assembly is arranged at the front end of the first installation plate and communicates with the liquid storage tank, a conveying assembly is arranged at the upper end of the liquid storage tank, a carrying mechanism is arranged in the conveying assembly, a plurality of grabbing mechanisms are arranged on the conveying assembly, and the number of the grabbing mechanisms is not less than four. According to the automatic spraying equipment for the suspension type assembly line, full-automatic spraying can be conducted on a workpiece, the spraying face is uniform in thickness, the intelligent degree is high, the equipment cost is low, and use is convenient.

Owner:陈庆森

Automatically adjusted cataplasm automatic production line

InactiveCN105853230ASimple structureEasy to use and maintainPharmaceutical product form changeAutomatic tuningCoating

The invention provides an automatically adjusted cataplasm automatic production line, which comprises an automatic skew adjustment device and a spunlaced fabric unwinding device, wherein the automatic skew adjustment device comprises a base and an adjusting vehicle which is arranged on the base; the adjusting vehicle is connected to the base in a sliding mode by virtue of a guide rail which is fixedly arranged at the upper end of the base; an adjusting cylinder is arranged on the base, and a piston rod of the adjusting cylinder is hinged with the vehicle body; an opposite-side sensor is additionally fixedly connected to the lower part of the base; the spunlaced fabric unwinding device is detachably connected to a bearing base which is fixedly arranged on the vehicle body by virtue of a bearing; and a lower spunlaced fabric rolling shaft is connected to the part, close to the opposite-side sensor, of the lower side of the vehicle body in a rotatable mode by virtue of a mounted bearing. The automatically adjusted cataplasm automatic production line disclosed by the invention is simple to operate and conducive to production and maintenance. The coating width and thickness of a cataplasm body can be controlled, so that uniform coating is guaranteed; and meanwhile, the sticking amount of the cataplasm body on a cutter head can be reduced when a finished product is cut in a longitudinal direction. In addition, the position of a spunlaced fabric can be also automatically adjusted, so that product quality is guaranteed.

Owner:TIANJIN ZHUOPU MEDICAL EQUIP CO LTD

Intermittent waste gas recovering device for paint spraying of hardware machinery parts

InactiveCN111974597AIncrease in sizeGuaranteed paint volumeSpraying apparatusToxic gasIndustrial engineering

The invention relates to the technical field of hardware machinery, and discloses an intermittent waste gas recovering device for paint spraying of hardware machinery parts. The waste gas recovering device comprises a screw; the left and right ends of the screw are in meshing connection with moving blocks; moving rods are fixedly mounted at the lower ends of the moving blocks; guiding rods are movably mounted on the opposite surfaces of the moving rods; sliding rods are fixedly mounted on the opposite surfaces of the guiding rods; and a paint storage pipe is movably mounted at the lower ends of the moving rods. According to the intermittent waste gas recovering device for paint spraying of the hardware machinery parts, a fixing plate is driven to move downwards through opposite movement ofthe moving rods and cooperates with a fixing rod to be fixedly mounted on the screw, the position of the paint storage pipe is unchanged, the fixing plate moves downwards, a moving frame can have theexpanding phenomenon, then the size of an inner air suction bag is increased, the air sucking state appears, and harmful and toxic gas produced during paint spraying can be absorbed and treated.

Owner:周亚东

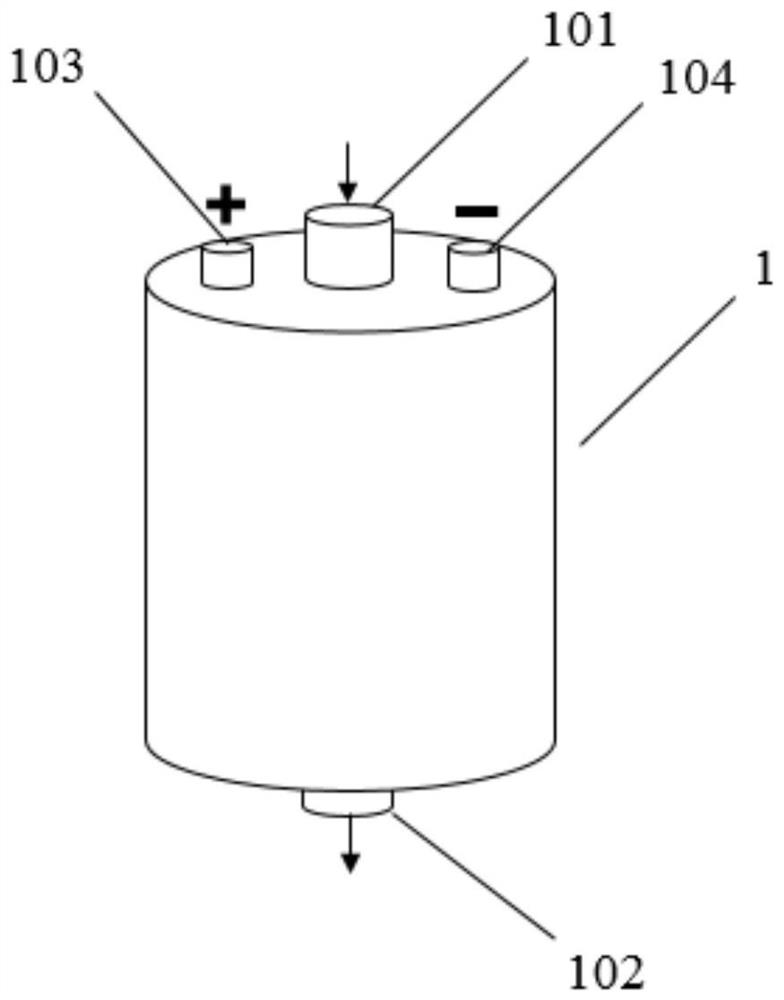

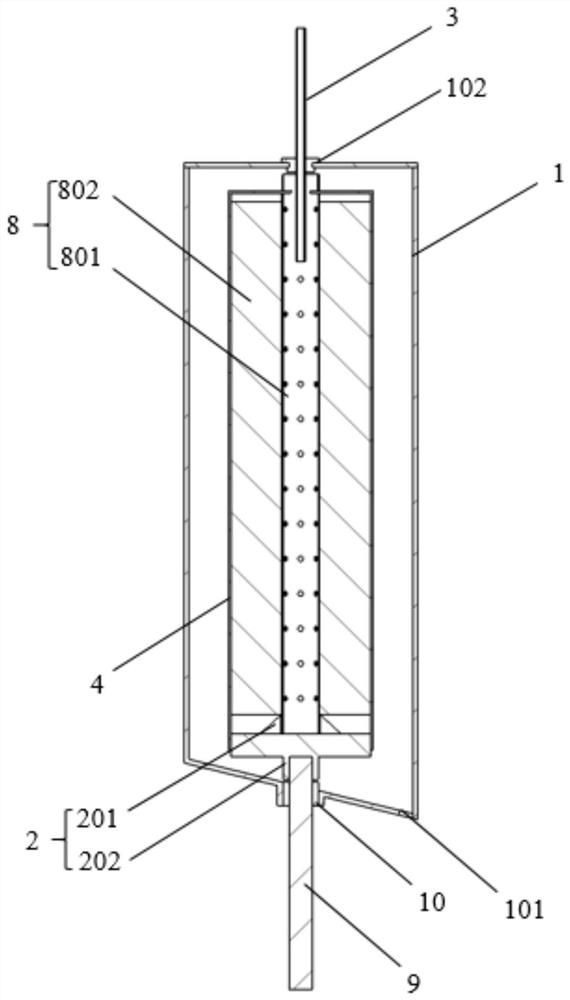

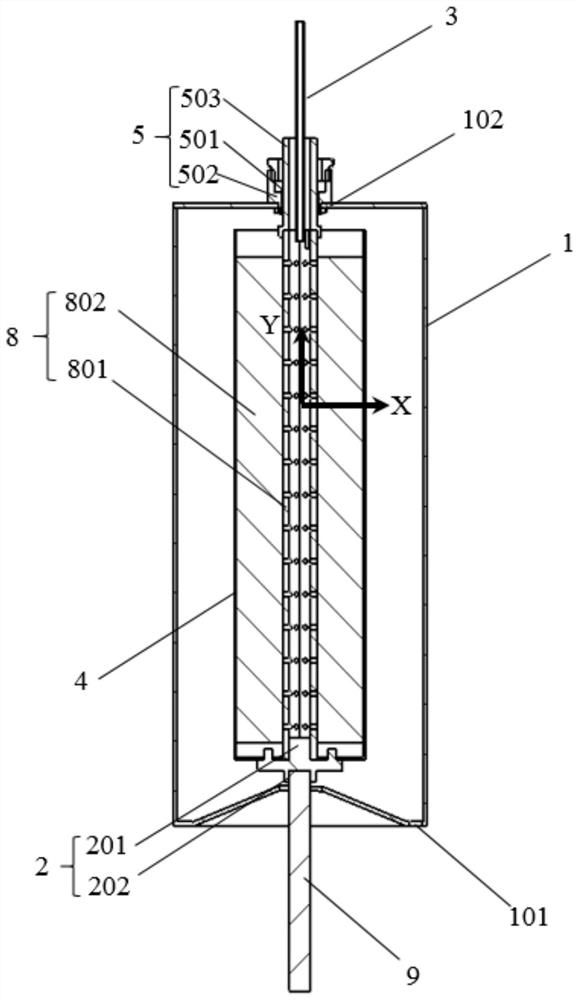

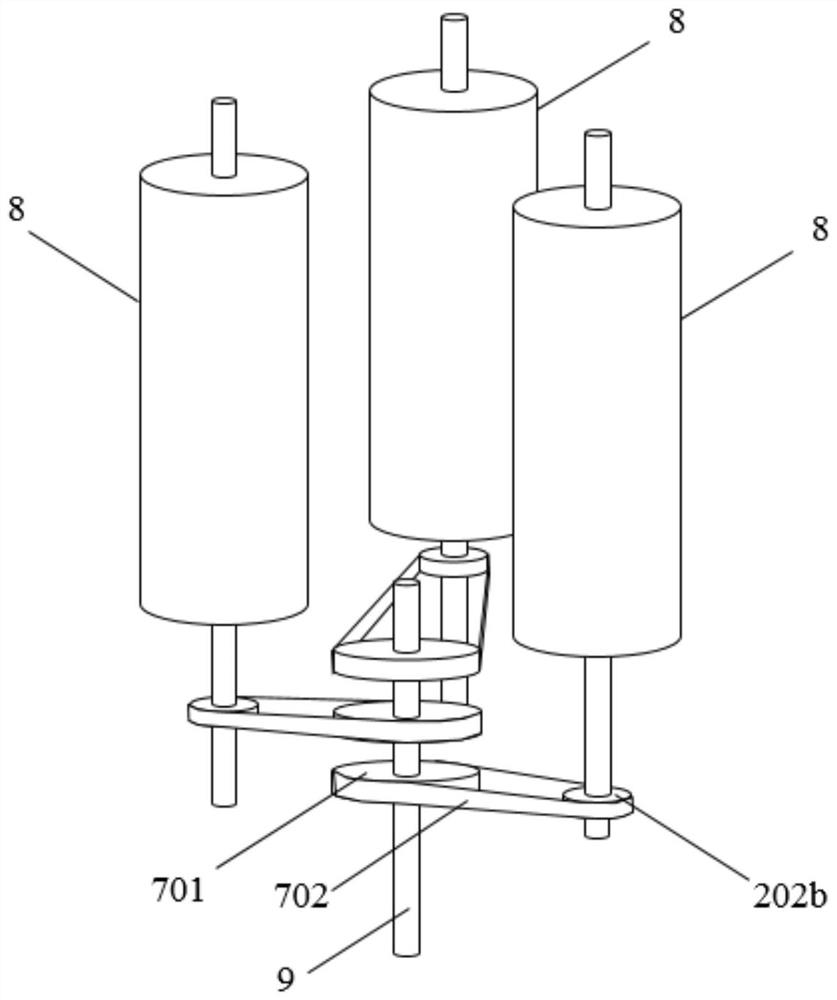

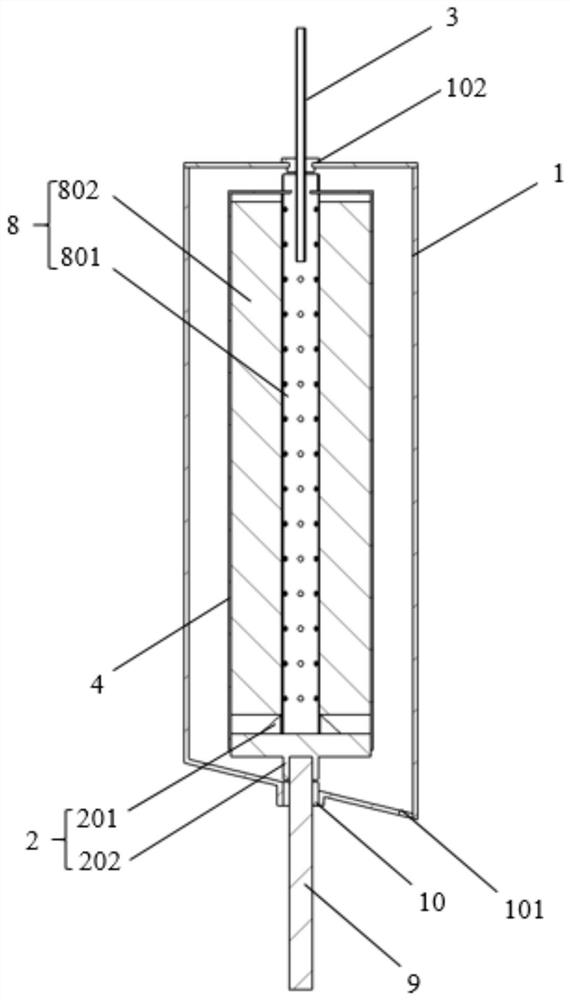

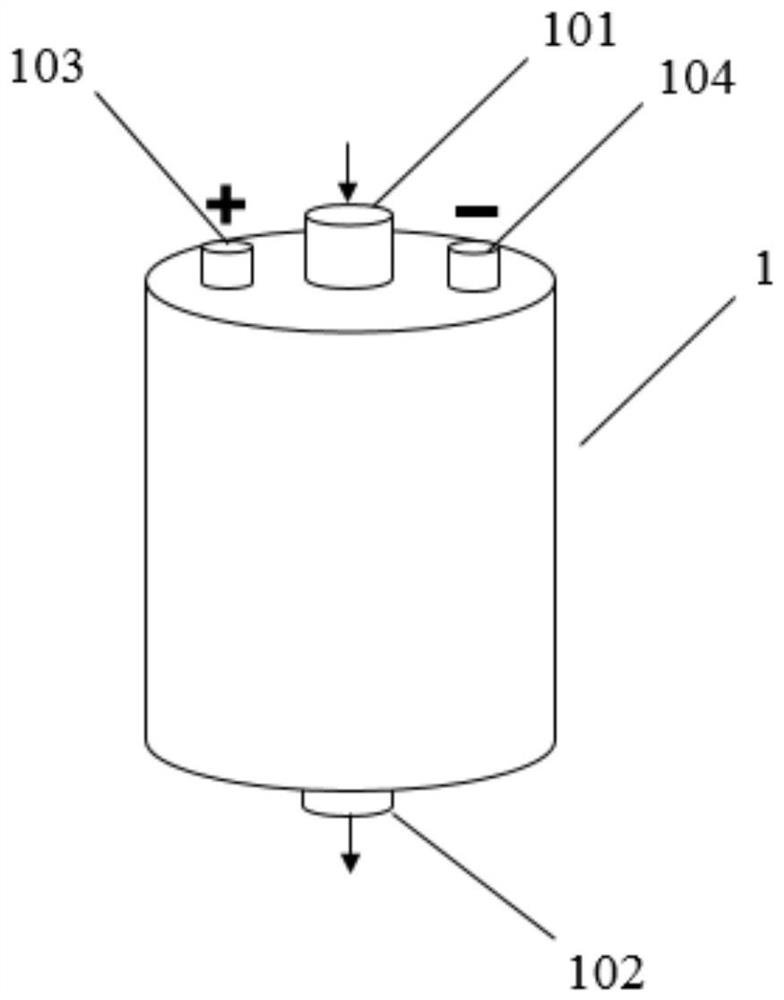

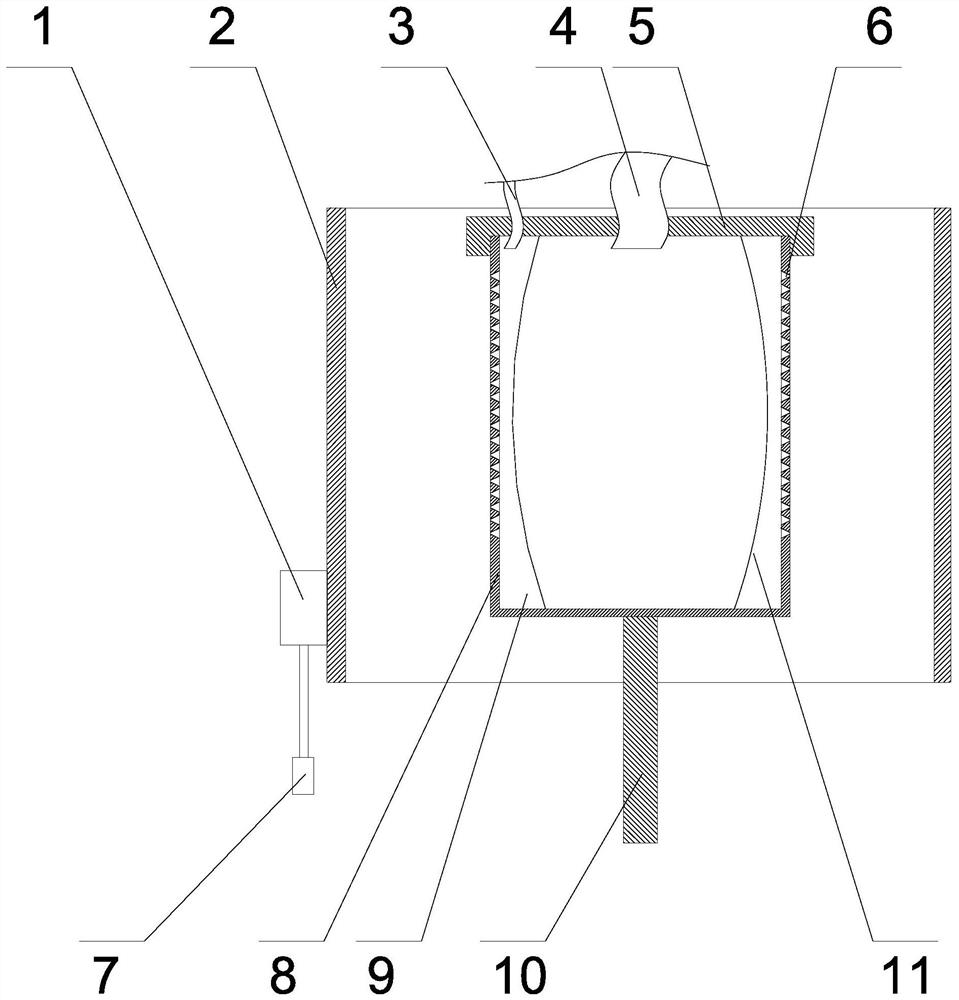

Device and method for liquid injection and liquid replacement of cylindrical battery

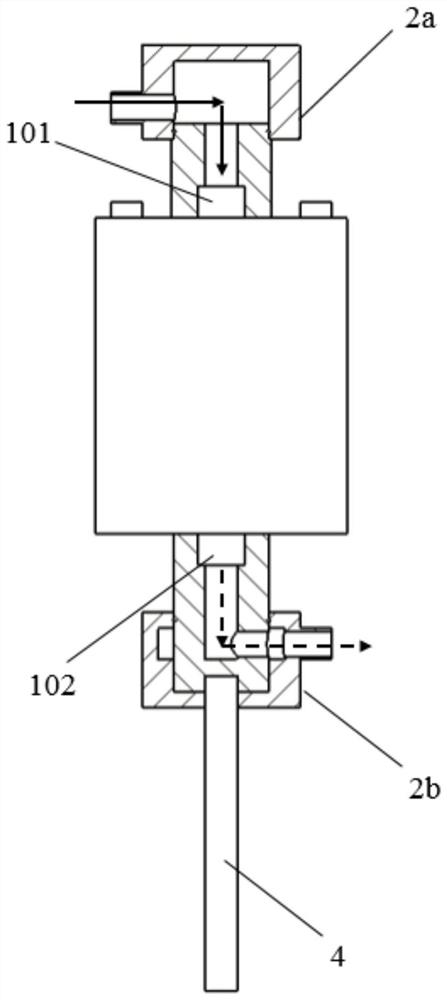

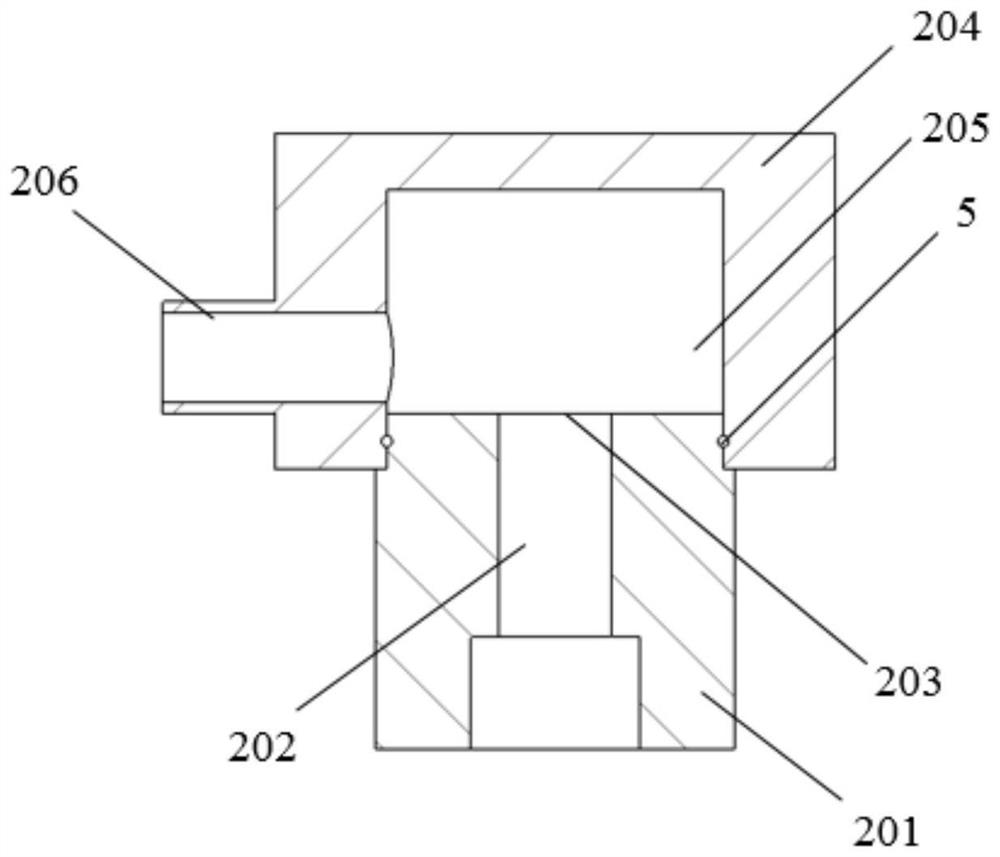

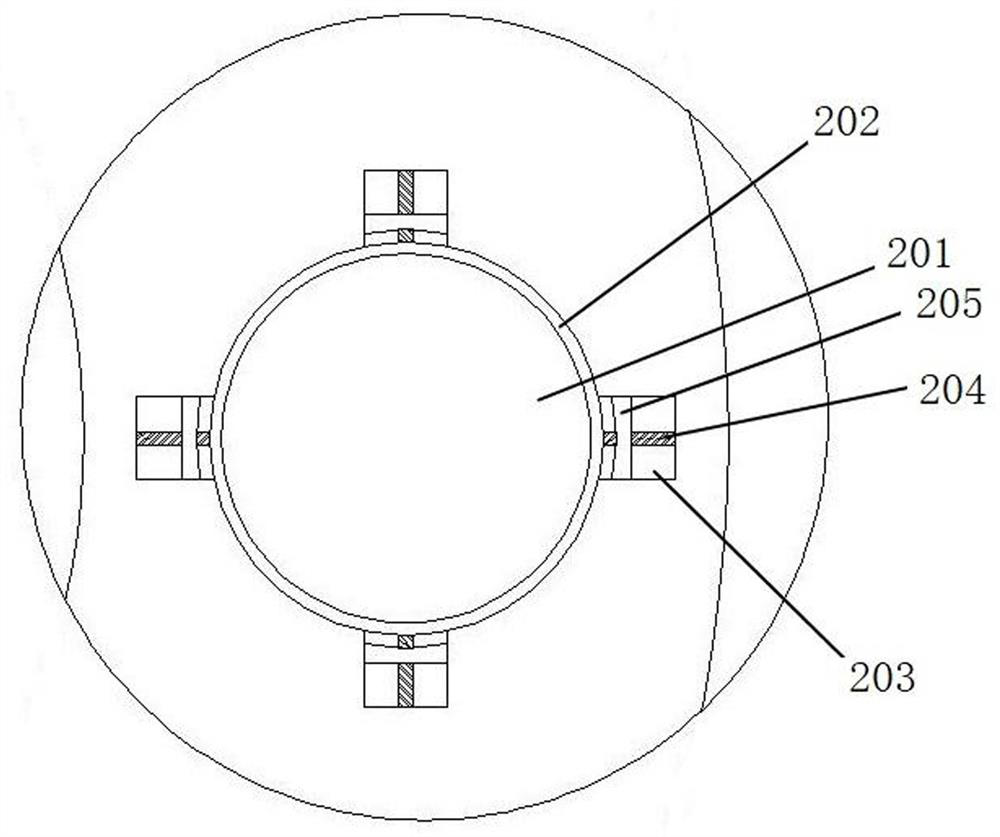

ActiveCN111785906AImprove infiltration efficiencyDrain fastCell component detailsPhysicsElectric machinery

The invention provides a liquid injecting and liquid replacing device for a cylindrical battery, wherein the liquid injecting and liquid replacing device is provided with a liquid injecting and discharging device and a battery rotating device. According to the invention, the battery rotating device can be fixedly connected with at least one part of a cylindrical battery, and the battery rotating device can be connected with the rotating shaft of a motor, so that the motor drives the battery rotating device to rotate so as to further drive the cylindrical battery to rotate; the liquid injectingand discharging device comprises a rotating part rotating together with the cylindrical battery and a fixing part used for being in butt joint with an external fluid storage device / fluid recovery device, wherein the fixing part is connected to the rotating part in a sleeving manner and is internally in fluid communication, so that the cylindrical battery can be in fluid communication with the external stationary fluid storage device / fluid recovery device while rotating; and under the action of centrifugal force, the liquid injected into the cylindrical battery can fully infiltrate the whole battery core, or the liquid in the battery core in the cylindrical battery can be thrown out and new liquid can be continuously injected to quickly replace the original liquid.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Slicer with uniform slicing effect

The invention discloses a slicer with a uniform slicing effect. The slicer comprises a base, motors, a push rod, a roller, a roller support a cam, an upper jacking plate, a lower jacking plate and a propulsion device; a partition plate is arranged on the left side of the base, a discharge port is formed in the middle of the partition plate, and a through hole is formed above the discharge port; the cam is arranged on the left side of the through hole in the partition plate, a support plate is arranged on the right side of the partition plate, the first motor is arranged on the support plate, and an output end of the first motor penetrates through the through hole to be connected with the cam; the roller support is disposed below the cam, the roller is rotatably arranged in the roller support, and the upper end of the roller fits the lower end of the cam; the upper jacking plate is disposed below the roller support, the push rod is disposed below the upper jacking plate, the upper jacking plate is fixed to the upper end of the push rod, and the lower jacking plate is arranged in the middle of the push rod; a lower jacking plate through hole is formed in the lower jacking plate, thepush rod penetrates through the lower jacking plate through hole, the lower jacking plate is fixed to the partition plate, and a spring is arranged between the upper jacking plate and the lower jacking plate. The slicer has the advantages that slicing is conducted quickly and sliced pieces are uniform in thickness.

Owner:周楚楚

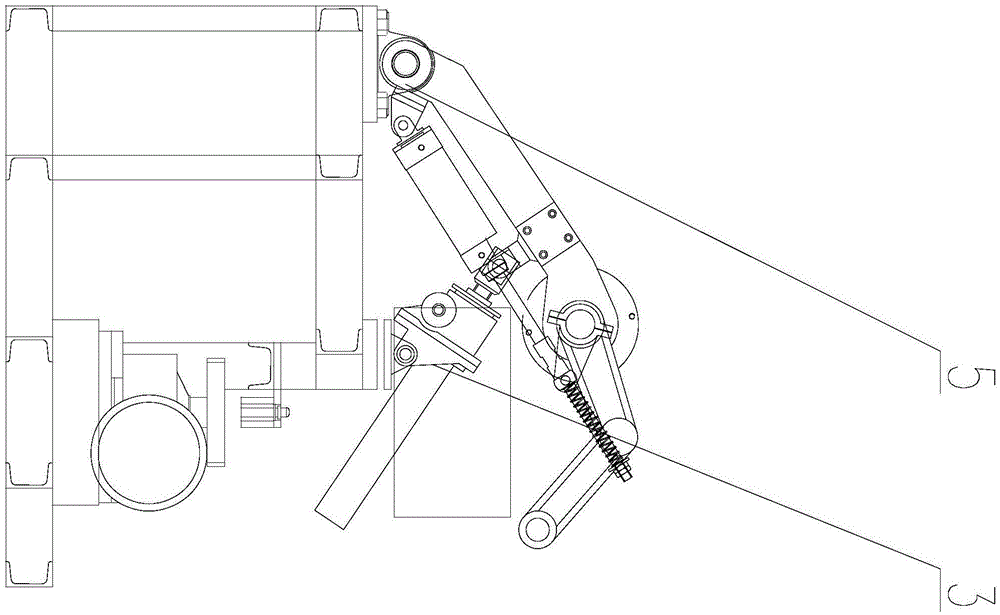

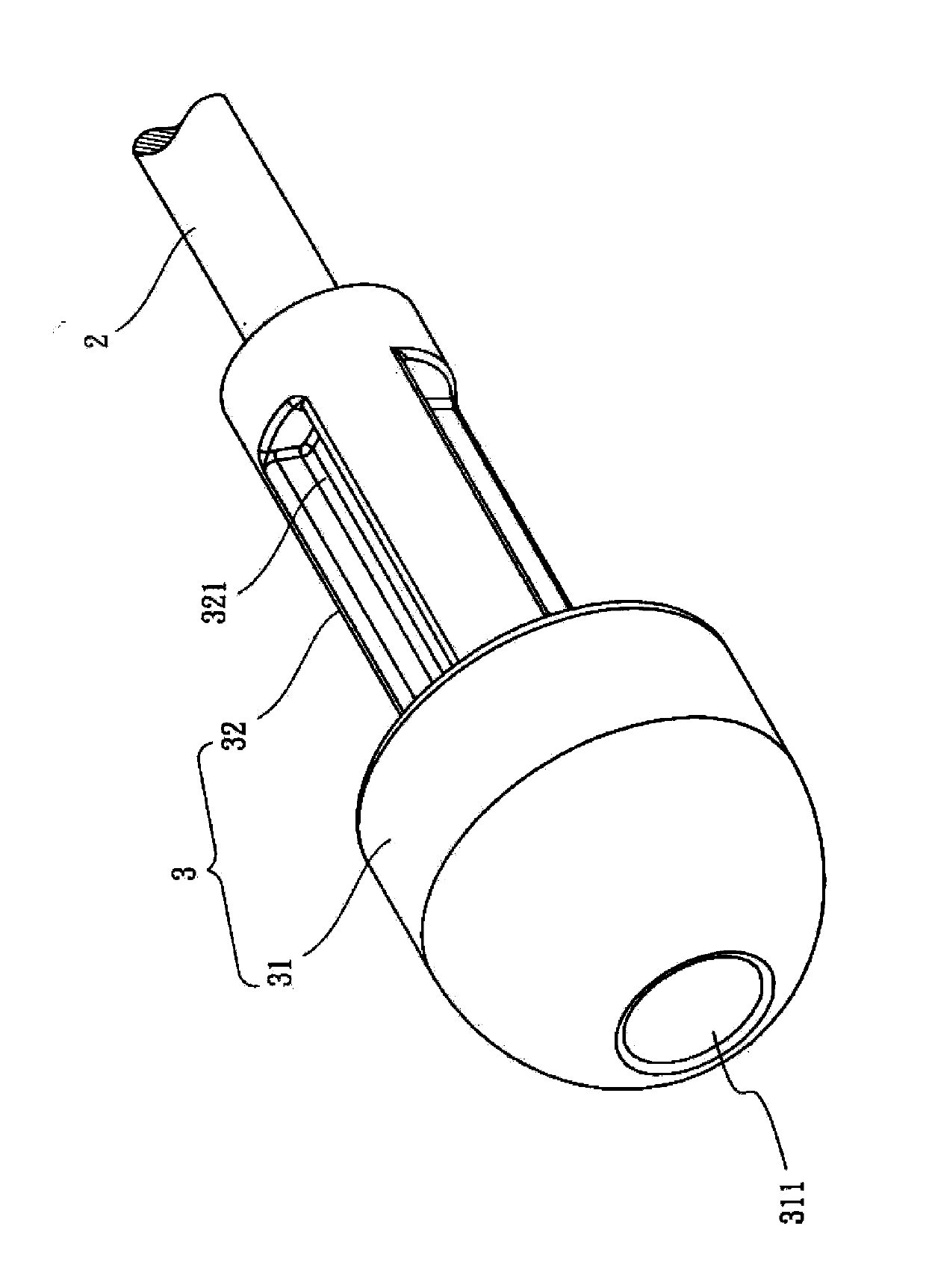

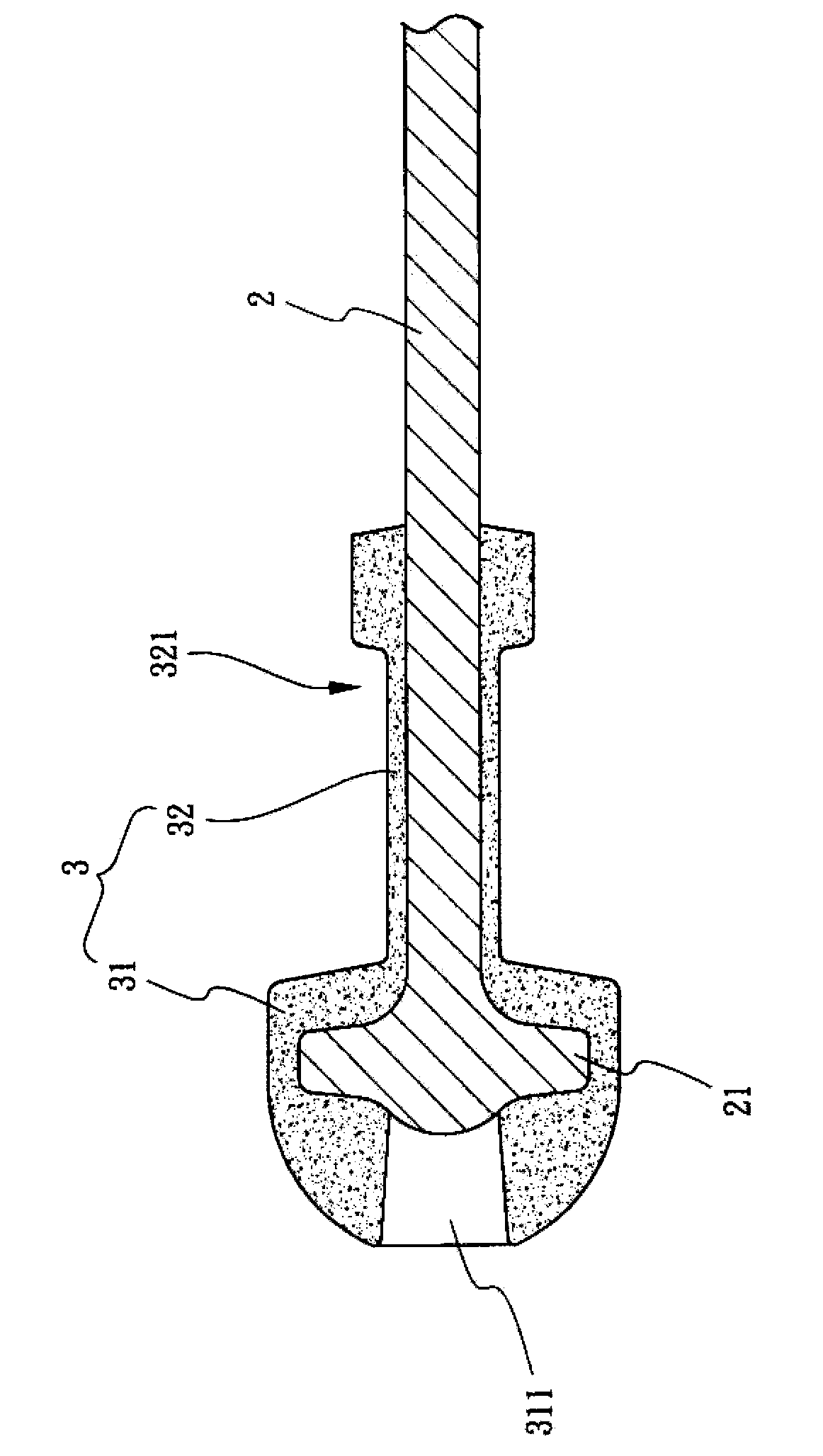

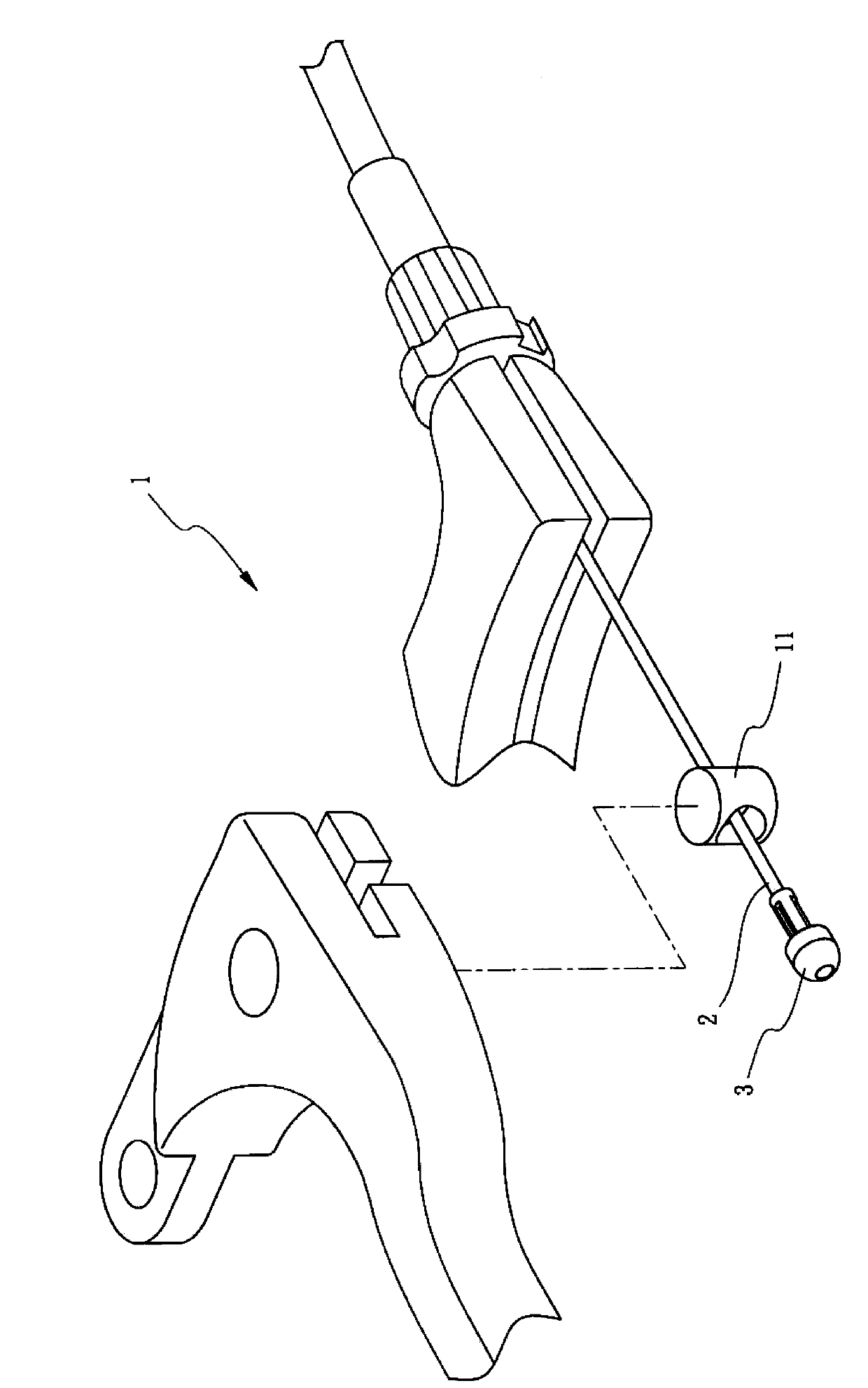

Brake thread head device and forming method

A brake thread head device is arranged on a bicycle brake device in an assembled mode so as to drive the brake device to act. The brake thread head device comprises a thread core and a casting block. One end of the thread head is provided with a knot; the end, provided with the knot, of the thread core is coated with the casting block, the casting block comprises a circular head portion and a body portion, the circular head portion sinks downward from the top end towards the end, provided with the knot, of the thread core to form a slot channel, and the circumferential side of the body portion is provided with a plurality of slot holes which are arranged at intervals in a concave mode. A forming method of the brake thread head device includes the following steps of preparing and taking of material pieces, mold closing and limiting, positioning and rectifying, molding and forming and processing modification. Therefore, the thread core is coated with the casting block, one end of the thread core can be connected to the brake device in an assembled mode and stably fixed to the brake device in a clamped mode, and motion of the brake device can be controlled smoothly. According to the brake thread head device, when a user places the brake device into a mold, a brake thread can be accurately placed at an appropriate position of the mold, and thus finished molded products will not be uneven in thickness.

Owner:ASHIMA LTD

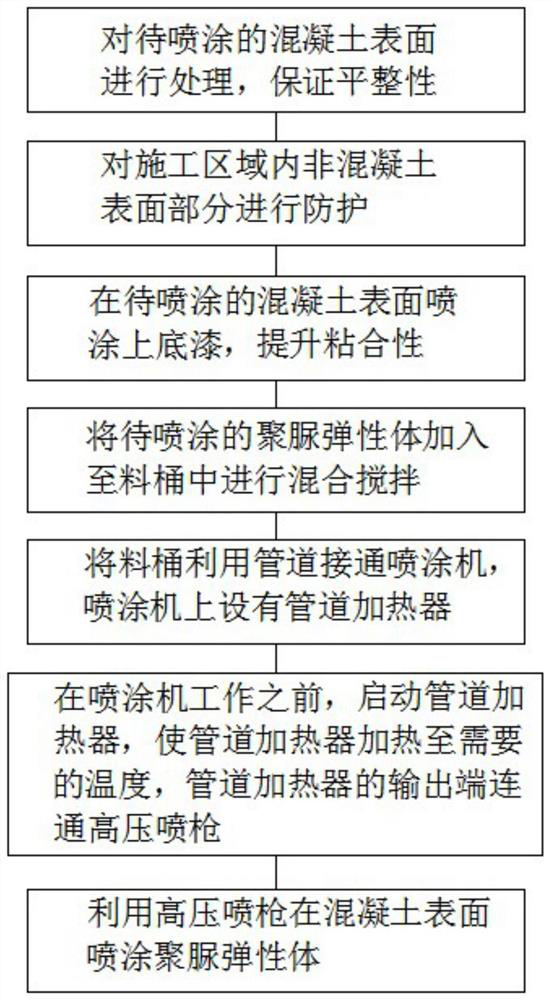

Method for spraying polyurea elastomer on concrete surface

InactiveCN114433456AImprove uniformityImprove aestheticsLiquid surface applicatorsCoatingsElastomerPolymer science

The invention belongs to the technical field of spraying of polyurea elastomers, particularly relates to a method for spraying a polyurea elastomer on the surface of concrete and application of the method, and aims to solve the problems that in the existing polyurea elastomer spraying process, due to nonstandard construction operation, a coating is prone to being uneven, the overall attractiveness is affected, and popularization and application are not facilitated. According to the scheme, the method comprises the following steps that S1, the surface of concrete to be sprayed is treated; s2, safety maintenance is conducted on the non-concrete surface part in the construction area; s3, primer is sprayed on the surface of the concrete to be sprayed; and S4, the polyurea elastomer to be sprayed is added into the material barrel to be mixed and stirred. The spraying direction and the spraying speed of the polyurea elastomer are strictly controlled, the uniformity of the polyurea elastomer sprayed on the concrete surface can be improved, the situation that the thickness is not uniform is avoided, the attractiveness of the sprayed polyurea elastomer is improved, and the spraying device is worthy of wide application and popularization.

Owner:江苏朗科建材科技有限公司

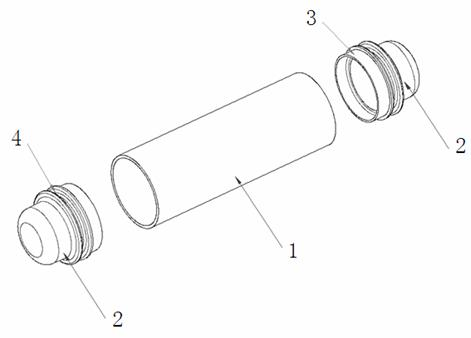

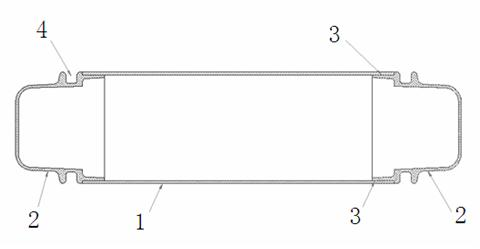

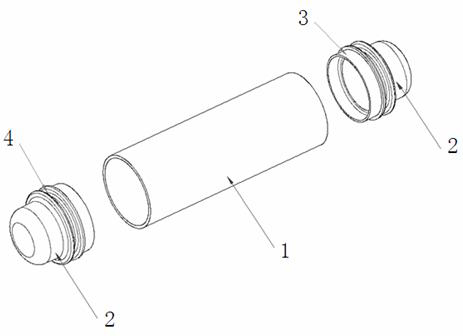

Welding seal type waterborne floating ball and manufacturing process thereof

The invention relates to a welding seal type waterborne floating ball and a manufacturing process thereof. The waterborne floating ball comprises a floating ball pipe body and floating ball end covers, wherein the floating ball end covers are arranged on two ports of the floating ball pipe body respectively; steps which are subjected to hot-melt welding together with the floating ball pipe body are arranged on the edges of the opening parts of the floating ball end covers; and rope binding grooves for binding ropes are formed on the floating ball end covers. The manufacturing process for the waterborne floating ball comprises the following steps of: (1) molding the floating ball pipe body and the floating ball end covers on a pull pipe mold and an injection mold respectively by using a polyurethane (PE) material; and (2) sleeving the two floating ball end covers on the two ports of the floating ball pipe body respectively, and welding by using a hot melting machine to ensure that the two floating ball end covers and the floating ball pipe body are enclosed to form a sealed floating ball. The waterborne floating ball has a reasonable design and a simple structure and production process, reduction in production cost is facilitated, production periods are shortened, and production efficiency is improved.

Owner:福建五友模具科技有限公司

Preparation process of vertical polypropylene infusion bag capable of avoiding shrinkage and cracking

PendingCN112592532AFusion smoothlyHigh strengthPharmaceutical containersMedical packagingPolypropyleneInfusion solution

The invention relates to the technical field of medical supplies, and discloses a preparation process of a vertical polypropylene infusion bag capable of avoiding shrinkage and cracking, which comprises the following preparation steps of: (1) preparing a polypropylene raw material; (2) preparing a bag blank; and (3) preparing an infusion bag. According to the preparation process of the vertical polypropylene infusion bag capable of avoiding injection molding shrinkage and cracking, infusion bag preparation raw materials are compounded and prepared again, long carbon fibers and alkali-free glass fibers are added, the raw materials are fused more smoothly through a compatilizer and a coupling agent, the overall strength of the raw materials is enhanced, the toughness is improved, the shrinkage probability is reduced, the error-tolerant rate is high, and the yield is increased; and the raw materials are heated to 180-220 DEG C in an injection molding machine, so that the raw materials aremelted, moisture in the raw materials is evaporated, it is guaranteed that the raw materials cannot be uneven in thickness during forming in the mold through repeated short-time pressure maintaining,it is guaranteed that the raw materials cannot crack due to sudden temperature change by checking the temperature of the mold, and the rejection rate is reduced.

Owner:ANHUI DOUBLE CRANE PHARMA

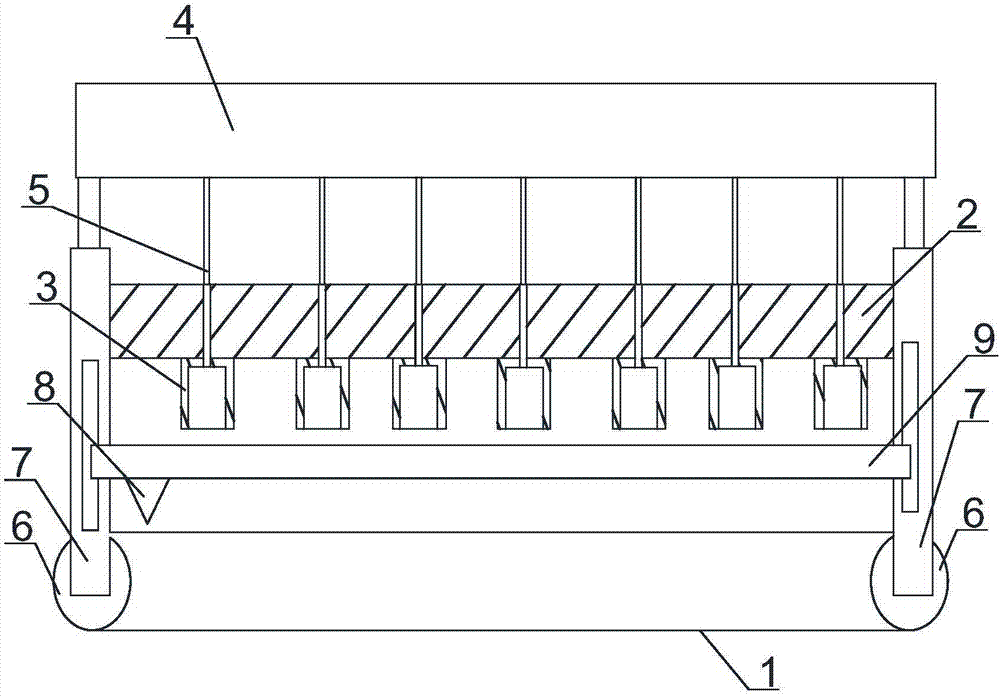

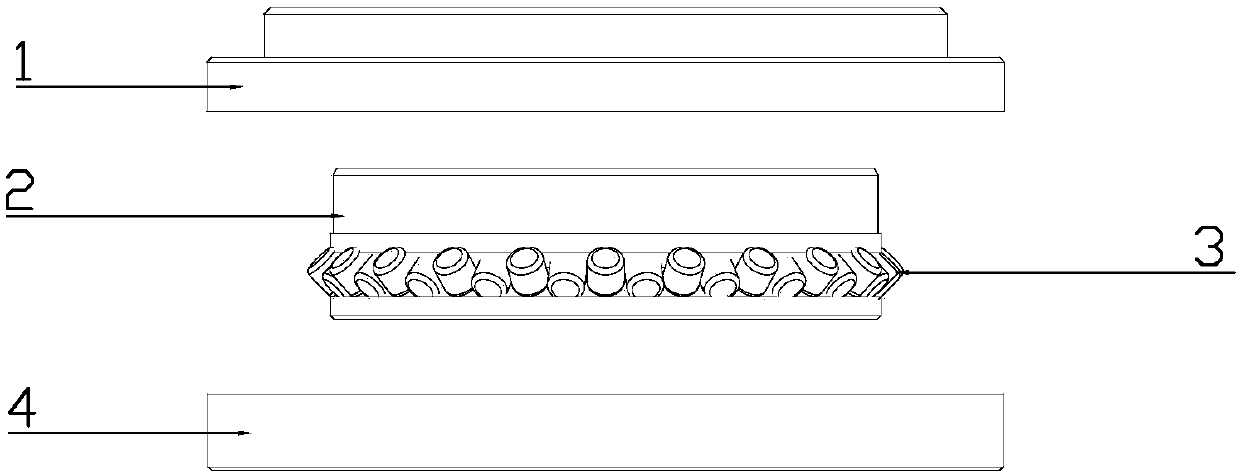

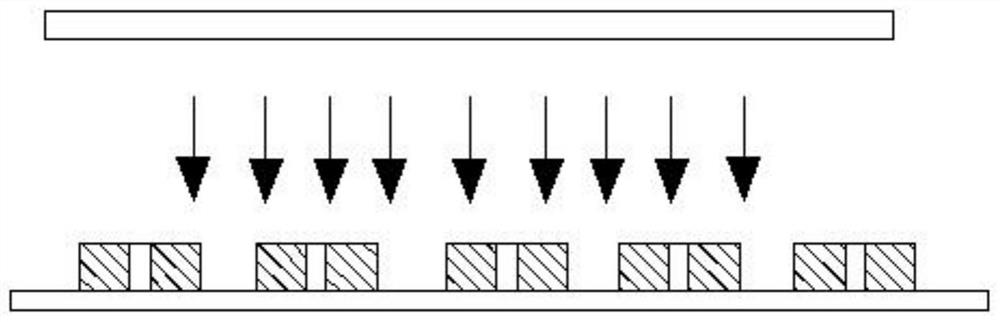

Glue coating machine with troweling equipment

InactiveCN107398390AEvenly distributedThere will be no uneven thicknessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a glue coating machine with troweling equipment. The glue coating machine with the troweling equipment comprises a rolling wheel conveying belt used for conveying glue coating workpieces, wherein a fixing plate parallel to the rolling wheel conveying belt is arranged right above the rolling wheel conveying belt; a plurality of cylinder tubes with openings at the lower ends are arranged under the fixing plate; the cylinder tubes are positioned on a positive projection line of a long center shaft of the rolling wheel conveying belt on the lower plate surface of the fixing plate; the cylinder tubes are distributed at equal intervals on the positive projection line; a container for containing glue coating slurry is arranged above the fixing plate; glue discharging pipes communicating with the cylinder tubes in one-to-one corresponding way are arranged under the container; a telescopic post fixedly connected with the fixing plate is arranged on each of two rolling wheels of the rolling wheel conveying belt; telescopic posts are arranged at the two sides of each rolling wheel; a scraper for flatly scraping the glue layer on a glue coating workpiece is also arranged above the rolling wheel conveying belt. The cylinder tube form is used; before the glue slurry is flatly scraped by the scraper, the glue slurry can be uniformly distributed on the workpiece; the thickness of the glue slurry is uniform.

Owner:四川省新康意新材料科技有限公司

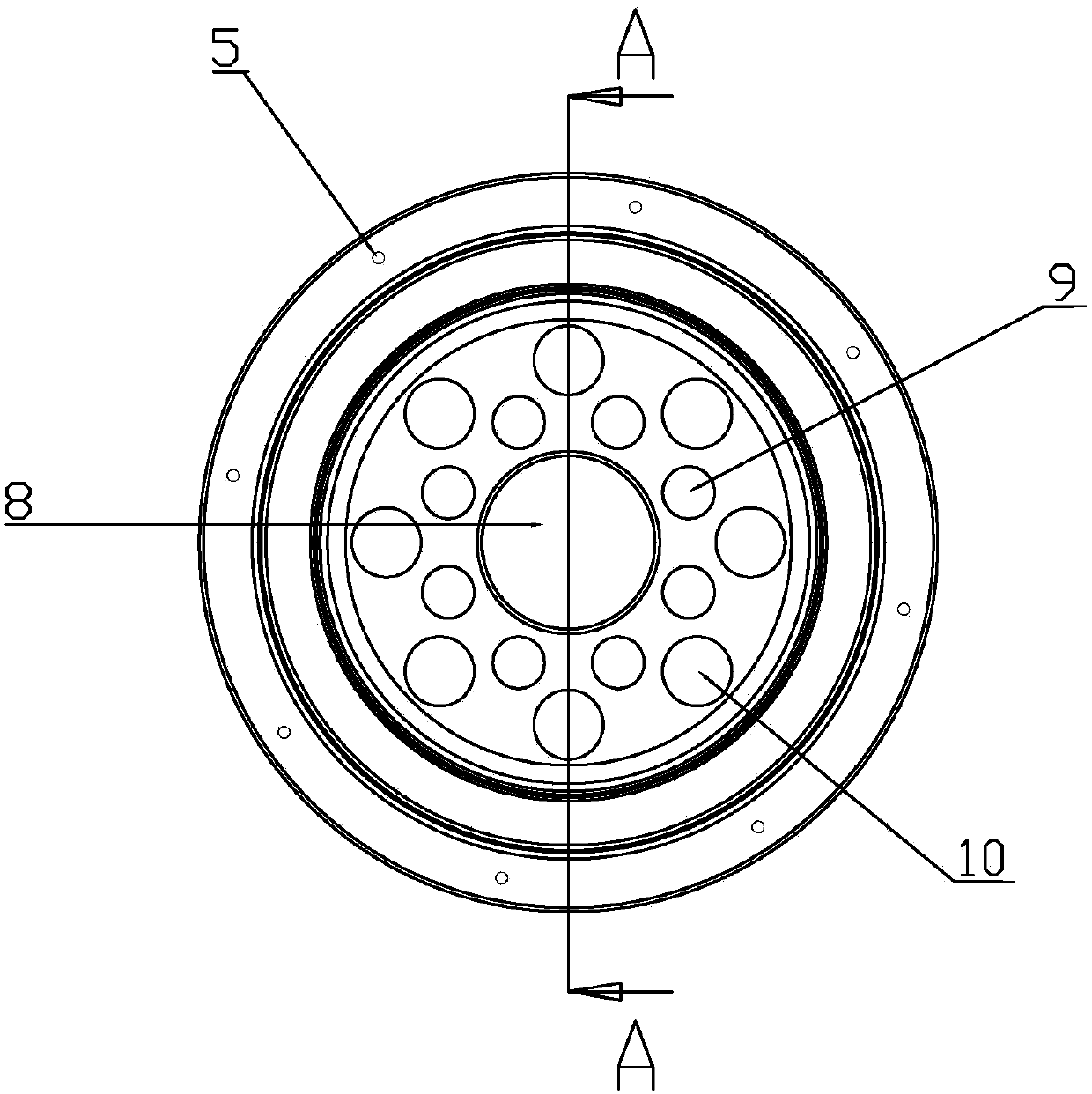

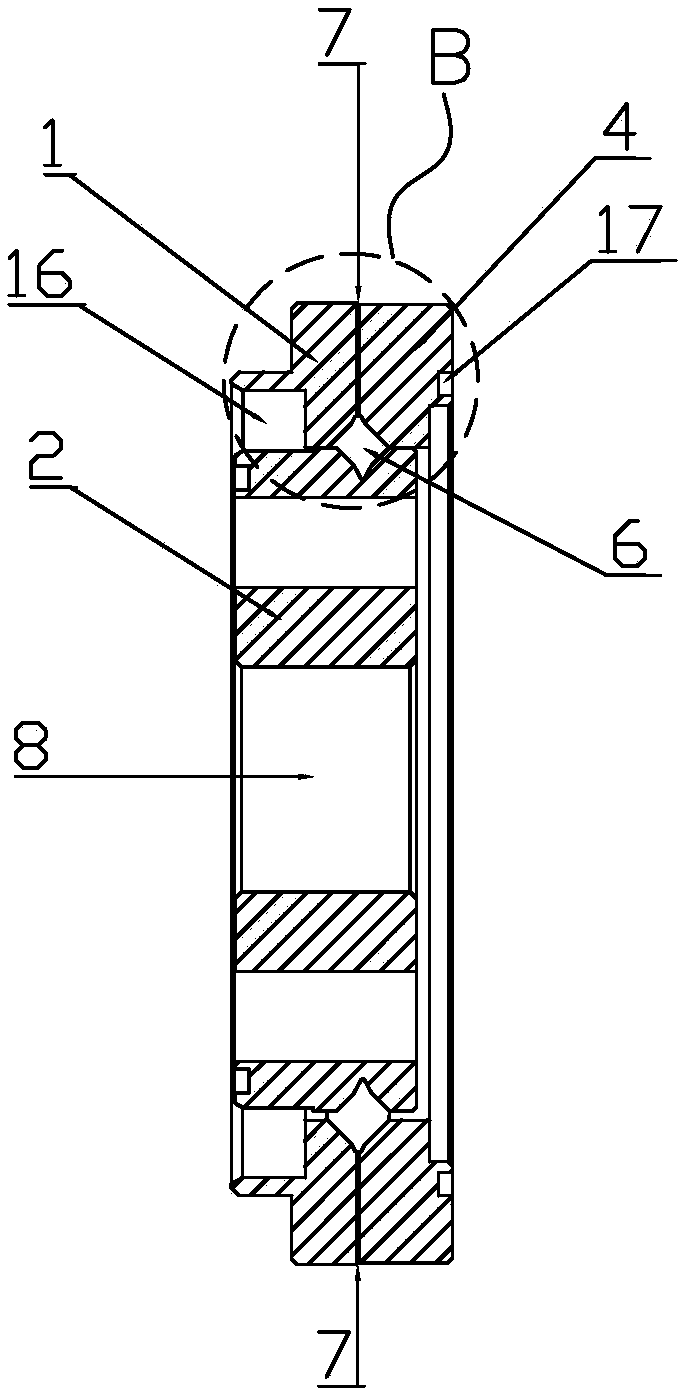

Two-piece bearing outer ring crossed rolling bearing

PendingCN107917139AAvoid uneven thicknessEffective grindingRoller bearingsBearing componentsEngineeringOuter space

The invention discloses a two-piece bearing outer ring crossed rolling bearing. The two-piece bearing outer ring crossed rolling bearing comprises upper and lower outer rings, a bearing inner ring, aroller, a rivet hole, a ball slide way, a reserved gap, upper and lower groove surfaces, and an inner ring groove; the inner ring groove is arranged on the outer peripheral surface of the bearing inner ring; the upper ring groove surface is arranged on the inner side of the upper outer ring; the lower ring groove surface is arranged on the inner side of the lower outer ring; the upper and lower ring groove surfaces and the inner ring groove form the ball slide way; crossed rollers are fully distributed in the ball slide way; and the reserved gap is formed between butt joint surfaces of the upper and lower outer rings, enables the upper and lower outer rings to separate from each other, and keeps non-contact configuration of the upper and lower outer rings. A bearing outer ring adopts a two-piece non-contact separation structure, and is fixed by adopting glue and rivets during grinding without generating the phenomenon of nonuniform groove wall thickness; and the reserved gap is formedbetween two halves of the outer ring, so that the outer ring can be recycled after being worn through repair.

Owner:苏州普拉米精密机械有限公司

Melon and fruit slicing device

InactiveCN113492426AQuick sliceThere will be no uneven thicknessMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses a melon and fruit slicing device. The melon and fruit slicing device comprises a rack, a panel is arranged at the upper end of the rack, a slicing seat is arranged on the panel, a transverse channel is arranged in the slicing seat, a feeding hopper is arranged at the position, located at the left upper end of the transverse channel, at the top of the slicing seat, a material pushing mechanism is arranged on the left side of the transverse channel, a cover plate is arranged on the right side of the transverse channel, a material falling hole is formed in the position, located on the side close to the cover plate, at the bottom of the transverse channel, a material storage box is arranged under the material falling hole, and a cutter assembly for slicing melons and fruits through downward pressing is arranged in the transverse channel in a matched manner. According to the melon and fruit slicing device, melons and fruits are conveyed to the position under a slicing assembly through the material pushing mechanism, the slicing assembly achieves downwards pressing to quickly slice the melons and fruits, the cut effect is uniform in thickness, the phenomenon of uneven thickness cannot happen, meanwhile, production has the characteristics of continuity, high efficiency and the like, and the requirement for large-scale production is met.

Owner:东安县众创农业设备有限公司

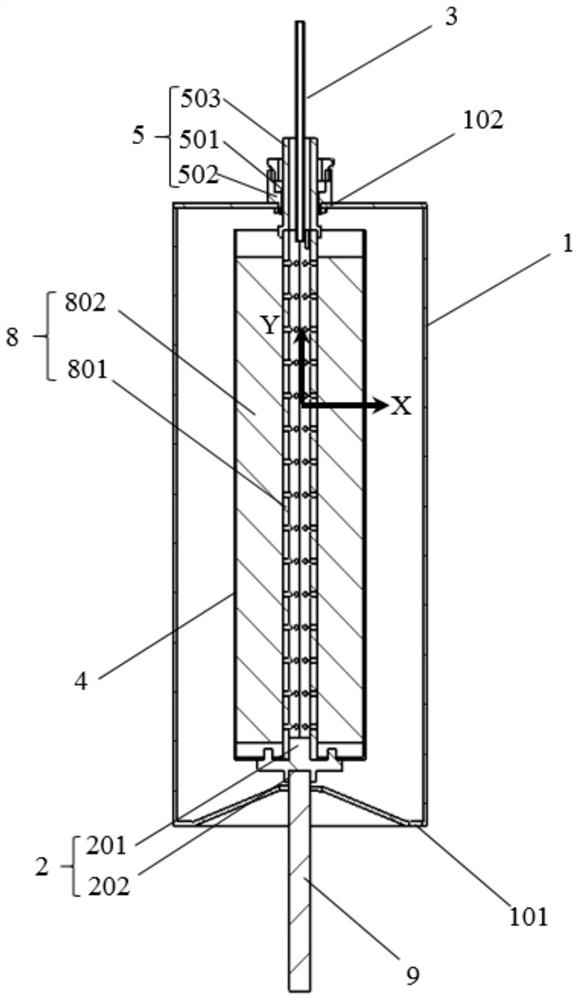

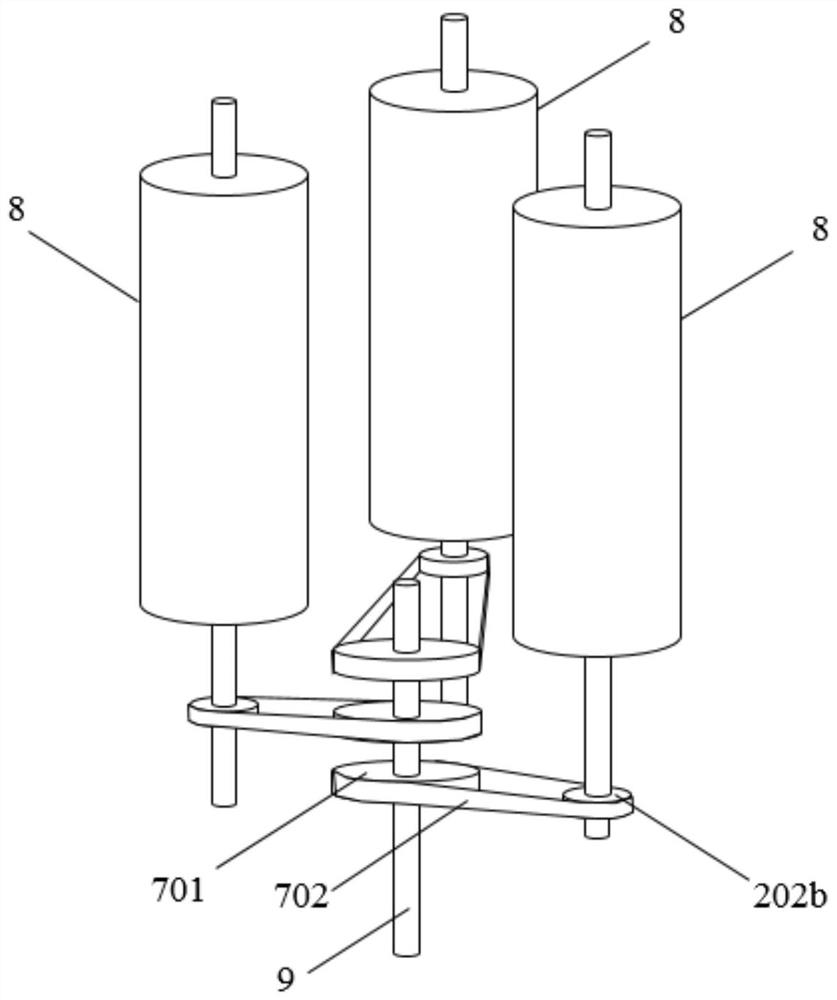

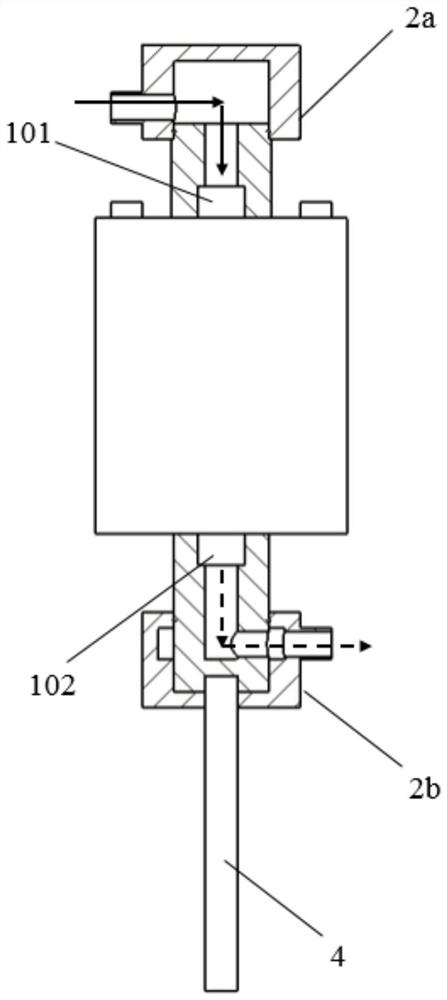

Device and method for spin-drying and infiltrating battery core of cylindrical battery

ActiveCN111786001ASpeed up the gasification processPromote infiltrationFinal product manufactureCylindrical casing cells/batteryElectric machineryBattery cell

The invention provides a spin-drying and infiltrating device for a battery core of a cylindrical battery. The spin-drying and infiltrating device is provided with a liquid collecting cylinder, an injection pipe and a roll core rotating device, wherein a battery core is arranged in the liquid collecting cylinder, the roll core of the battery core is connected with the roll core connecting part of the roll core rotating device, the driving connecting part of the roll core rotating device is directly or indirectly connected with the rotating shaft of a motor, and the injection pipe can extend into the hollow part of the roll core. When the rotating shaft of the motor drives the roll core rotating device to rotate, the whole battery core is driven to rotate, and under the action of centrifugalforce, a liquid in the winding part of the battery core can be thrown out or a liquid continuously injected into the roll core fully infiltrates the whole battery core. The invention also provides aspin-drying and infiltration method of the battery core of the cylindrical battery. Through the spin-drying and infiltrating device and the spin-drying and infiltrating method, the whole battery corecan be spin-dried and infiltrated, so that the production efficiency is improved, the spin-drying and infiltrating effects are guaranteed, and the energy consumption can be reduced.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Food material cutting device

InactiveCN109571568AUniform thicknessEasy to cleanKitchen equipmentMetal working apparatusEngineeringMultiple function

The invention discloses a food material cutting device. The food material cutting device comprises a bottom plate, a base, a push plate, a push handle, blades, an outer frame and a detachable shredding plate. The base is arranged on the bottom plate. The base is provided with a groove. The left and right ends of the groove penetrate through the base. The outer frame is arranged at the left end ofthe groove. The blades and the detachable shredding plate are detachably arranged in the outer frame. The push plate is located on the right side of the outer frame and movably arranged on the groove.The push handle is arranged on the right side of the push plate. Compared with the defects existing during manual operation, the food material cutting device can cut food materials into segments quickly in the using process and is also safe in the cutting process. Besides, the thickness of the cut food materials can be controlled by adjusting the distance between the blades in the using process,and using is quite convenient. Moreover, the shredding plate arranged in the food material cutting device can conduct shredding on radishes and other solid substances, and the food material cutting device has multiple functions.

Owner:杨鹏

A device and method for drying and soaking cylindrical battery cells

ActiveCN111786001BSpeed up the gasification processPromote infiltrationFinal product manufactureCylindrical casing cells/batteryElectric machineCentrifugal force

The invention provides a spin-drying and soaking device for electric cores of cylindrical batteries, which is provided with a liquid collecting cylinder, an injection pipe and a winding core rotating device. The battery core is placed in the liquid collection cylinder, the winding core of the battery core is connected to the winding core connection part of the winding core rotating device, and the driving connection part of the winding core rotating device is directly or indirectly connected to the rotating shaft of the motor, and the injection pipe can be extended into the In the hollow part of the core. When the rotating shaft of the motor drives the winding core rotating device to rotate, it drives the entire battery core to rotate. Under the action of centrifugal force, the liquid in the winding part of the battery core can be thrown out or the liquid continuously injected into the winding core can fully soak the entire battery core. In addition, the invention also provides a drying and soaking method for the battery core of the cylindrical battery. Through the drying and soaking device and the drying and soaking method of the present invention, the whole battery cell can be dried and soaked, which is beneficial to improve production efficiency, ensure drying and soaking effects and save energy consumption.

Owner:BEIJING HAWAGA POWER STORAGE TECH

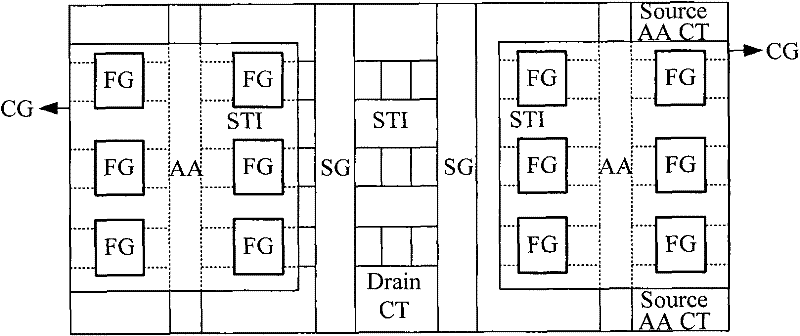

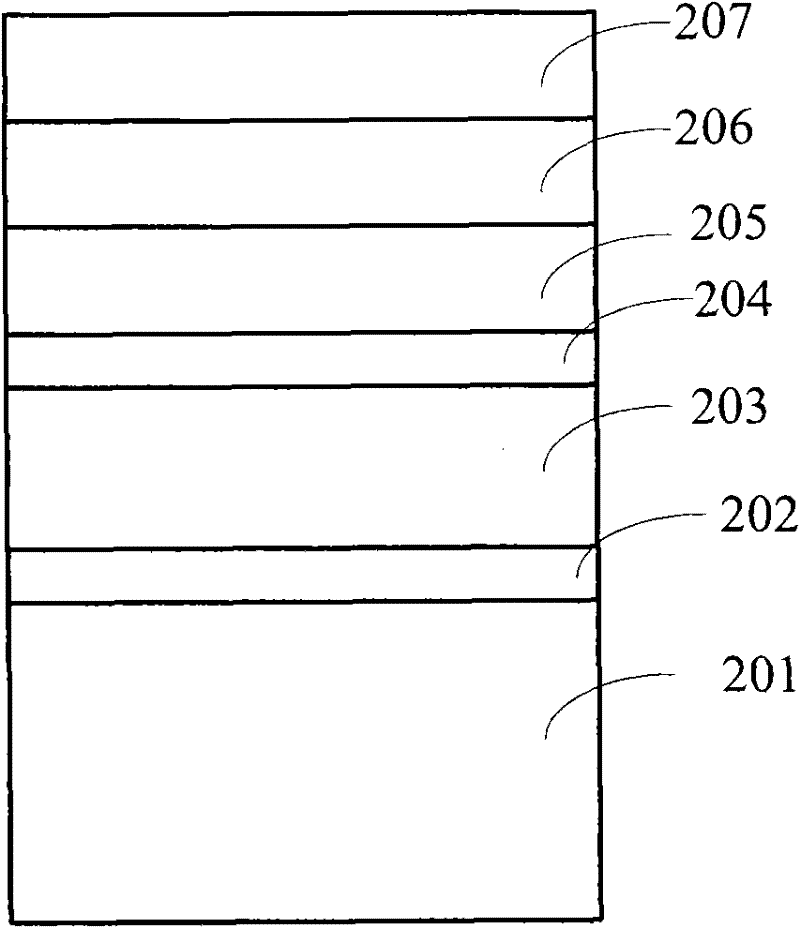

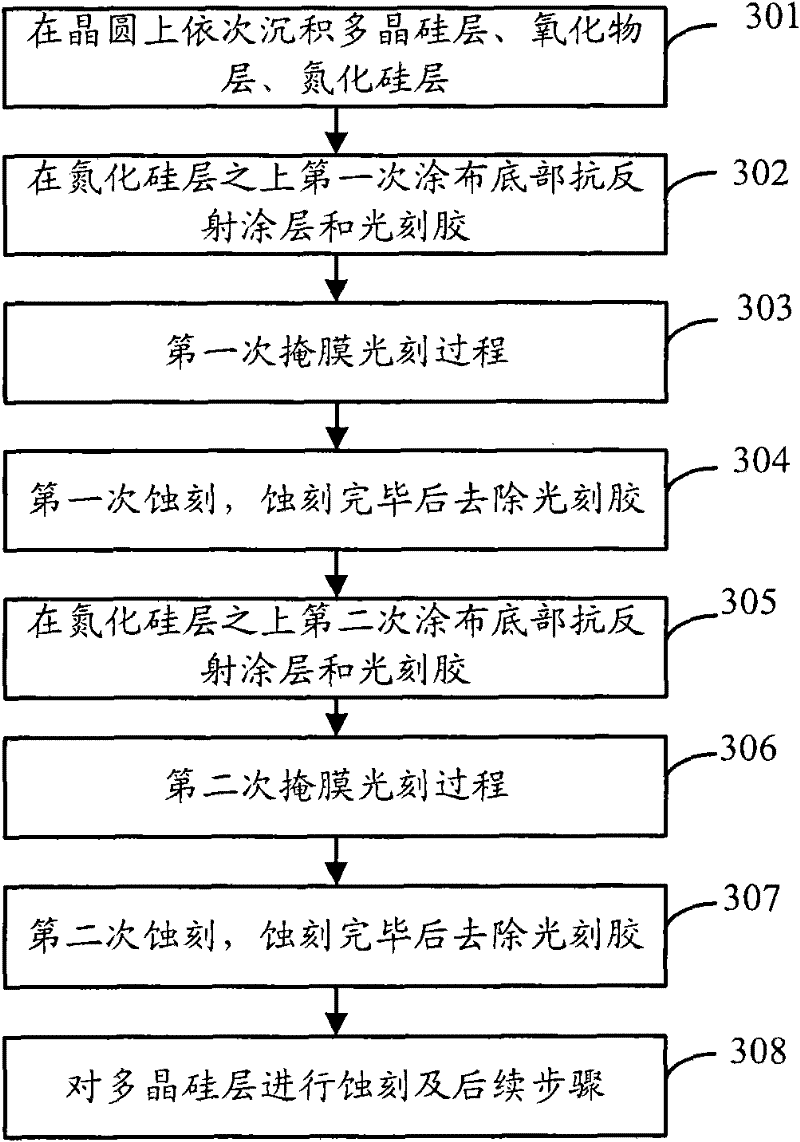

Method for constructing floating gate

ActiveCN102005374BSimple processThere will be no uneven thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsOxygen

The invention discloses a method for constructing a floating gate. The method comprises the following steps: depositing a gate oxygen layer, a polycrystalline silicon layer, an oxide layer and a silicon nitride layer in turn on the upper surface of a wafer; coating photoresist on the silicon nitride layer; performing the first exposure on the photoresist by using a photomask with an x-direction strip pattern; performing the second exposure on the photoresist by using a photomask with a y-direction strip pattern and developing, and defining an x-direction strip pattern and a y-direction strip pattern on the photoresist, wherein the y direction is vertical to the x direction; and etching the silicon nitride layer of the wafer by taking the photoresist as a mask, and then removing the photoresist on the surface of the wafer. In the scheme of the invention, as only once etching is performed on the silicon nitride layer, the thickness unevenness of the polycrystalline silicon layer is avoided. Moreover, due to two photomasks, the outer corner of floating gate(FG) is kept as a right angle, and the performance loss of a grid is prevented.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Ceramic glazing system and control method

ActiveCN114654573APrevent leakageThere will be no uneven thicknessAuxillary shaping apparatusEngineeringMechanical engineering

The invention relates to the field of ceramic glazing, in particular to a ceramic glazing system and a control method.The ceramic glazing system comprises a glazing mechanism, a pressure reduction mechanism and a pressurization mechanism, the glazing mechanism comprises a spray head and a first glaze storage container, the spray head comprises a spray head body and a partition plate, a glaze cavity is formed in the spray head body, and the partition plate is arranged in the glaze cavity; the glaze cavity is divided into a glaze inlet cavity and a glaze outlet cavity; a glaze passing channel is formed between the partition plate and the bottom of the glaze cavity; when the pressure in the first glaze storage container is adjusted to be first preset pressure by the pressure reducing mechanism and the pressure increasing mechanism, glaze in the first glaze storage container sequentially flows through the glaze inlet cavity, the glaze passing channel, the glaze outlet cavity and the first glaze storage container to form an outer circulation loop; and when the pressure in the first glaze storage container is adjusted to be second preset pressure by the pressure reducing mechanism and the pressure increasing mechanism, the glaze in the outer circulation loop is sprayed outwards along the glaze spraying hole. According to the invention, glaze spraying is uniform, glaze spraying is carried out according to needs, and large-particle glaze can be adopted.

Owner:FOSHAN ARES CERAMIC TECH CO LTD

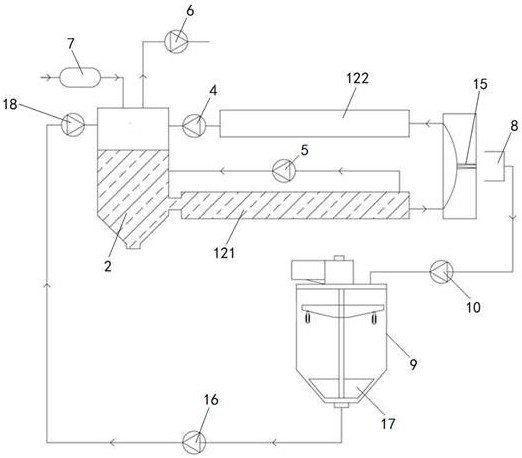

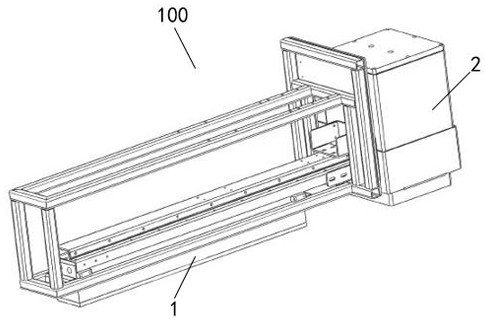

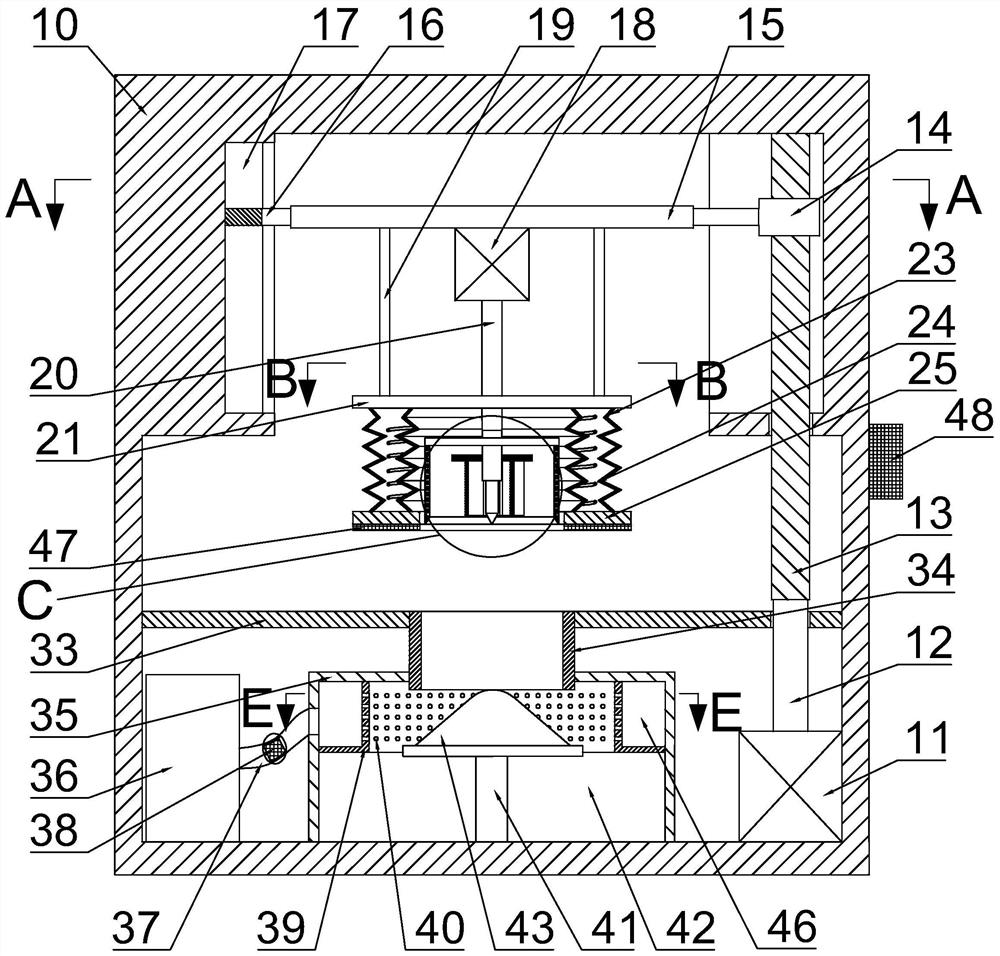

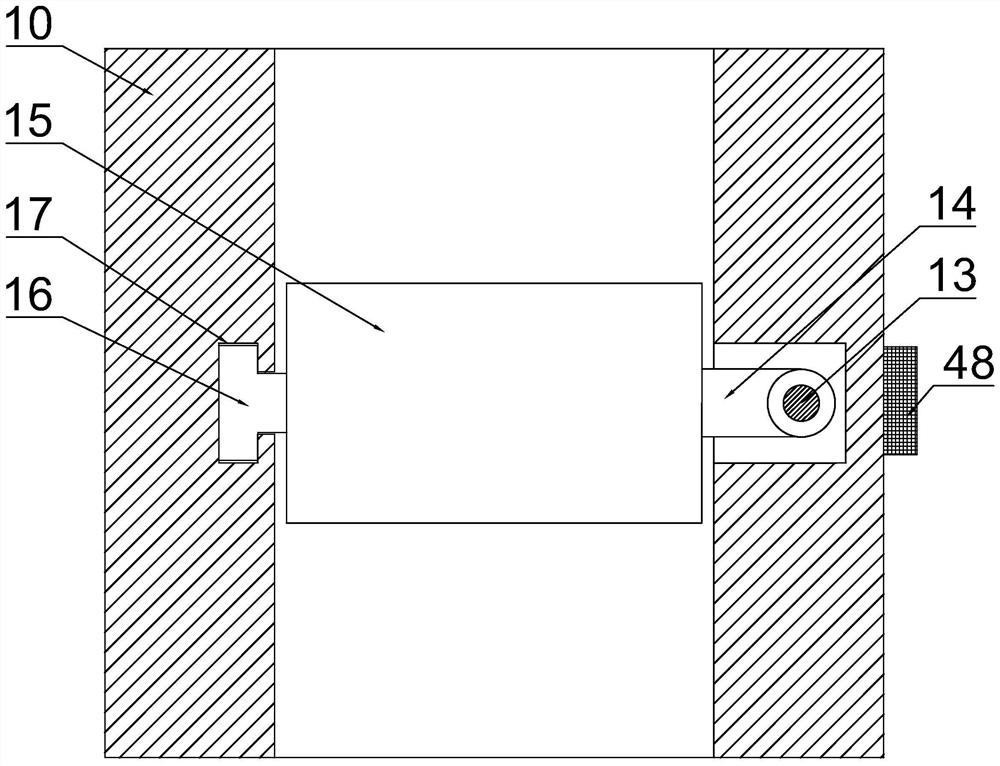

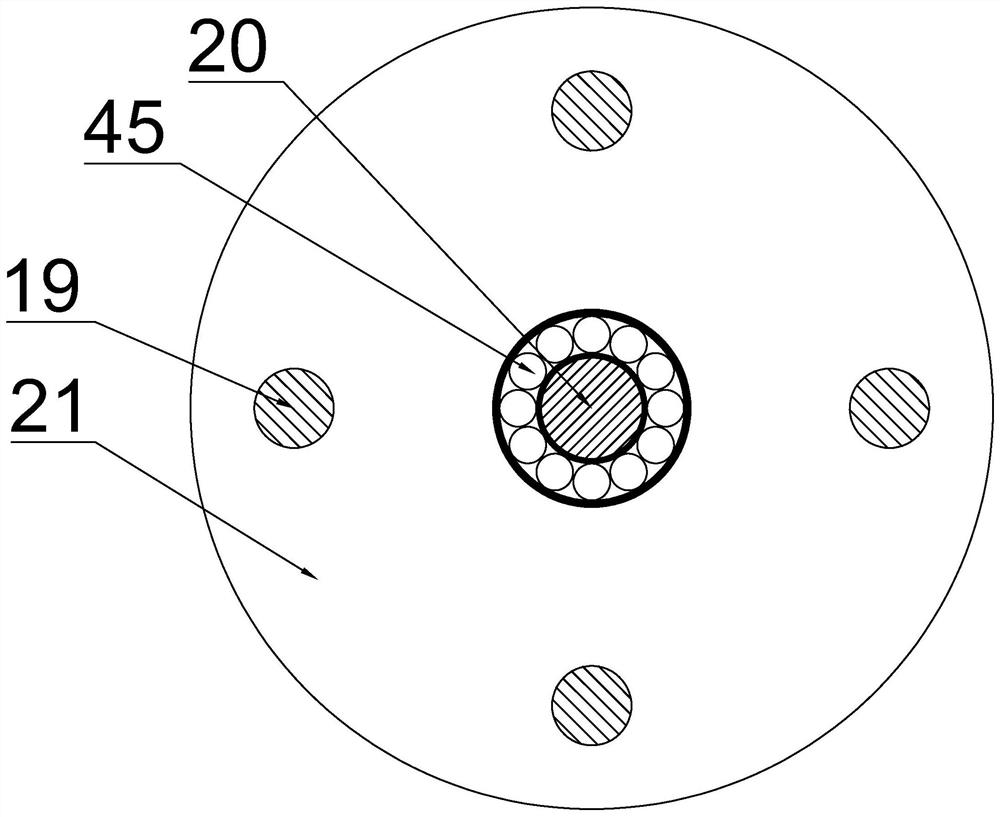

Large shock-proof spring paint spraying system

InactiveCN113798101ASpray evenlyThere will be no uneven thicknessSpray boothsShock avoidanceMachining

The invention belongs to the spring paint spraying technology, and relates to a large shock-proof spring paint spraying system which comprises a shell. A machining cavity is formed in the shell, a spring paint spraying device is arranged in the machining cavity, the paint spraying device is used for surface paint spraying machining of a large shock-proof spring, a transmission device is arranged in the machining cavity, and the transmission device is used for transmitting the displacement path of the spring paint spraying device and clamping the spring. When the spring needs to be subjected to paint spraying treatment, stretching and retracting are conducted according to the size of the shock-proof spring, a magnet in the paint spraying device makes a second one-way valve more attached to the surface of the shock-proof spring through magnetism, paint is sprayed out of a nozzle, and due to the fact that the paint is sprayed through an internal device, paint loss is greatly reduced; and a telescopic plate can adapt to machining of shock-proof springs of more sizes and types, meanwhile, the device is more attached to the surface so that paint can be more uniform in the spraying process, the situation that the thickness of paint is uneven cannot occur, and finally one-time paint spraying machining of the shock-proof springs is completed.

Owner:史桂生

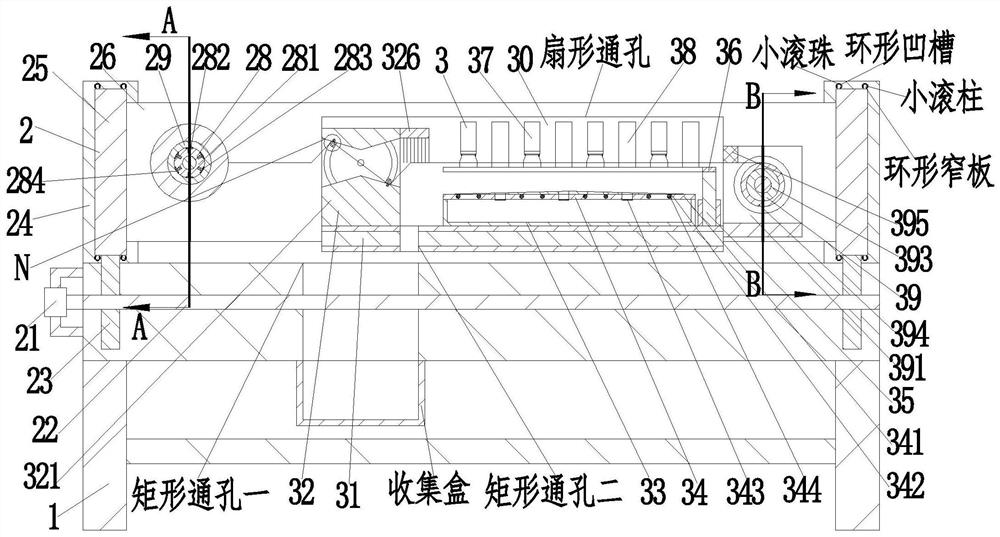

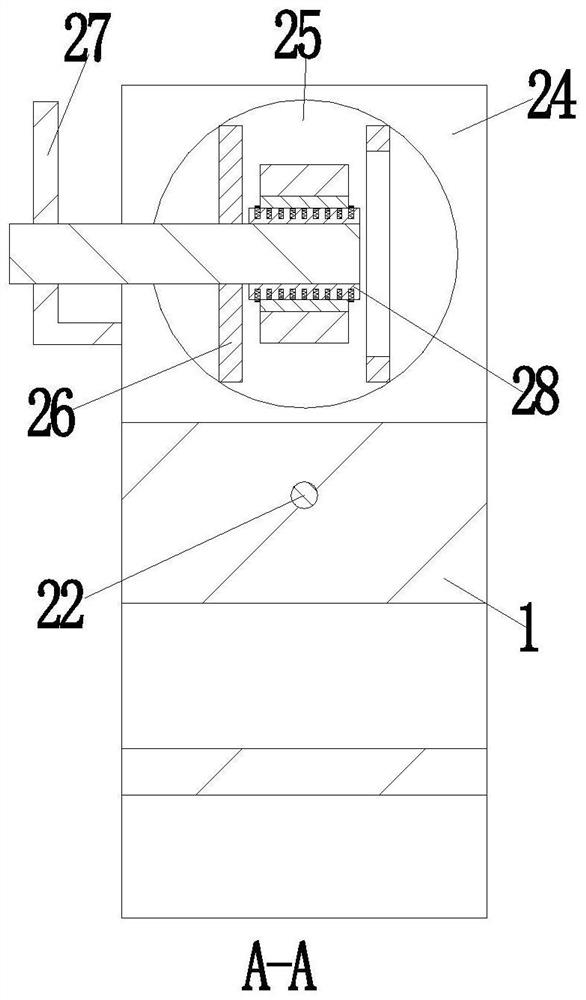

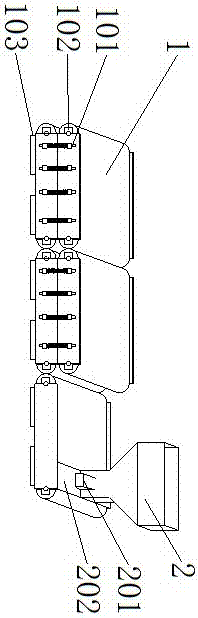

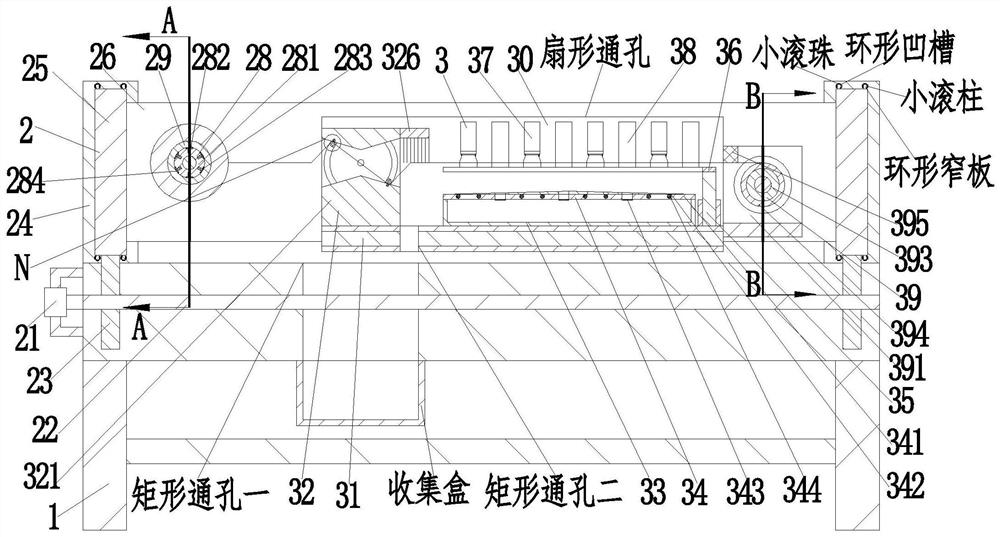

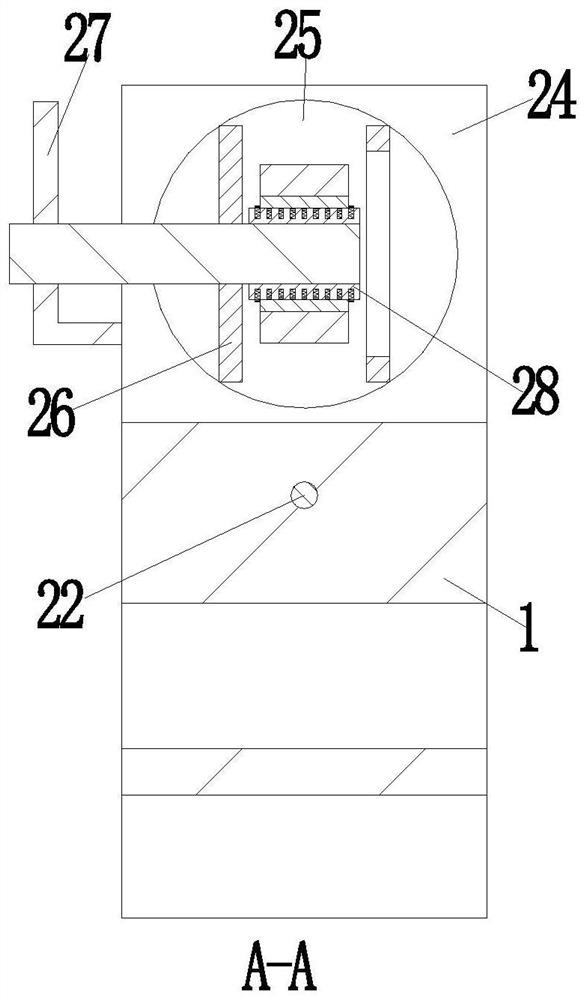

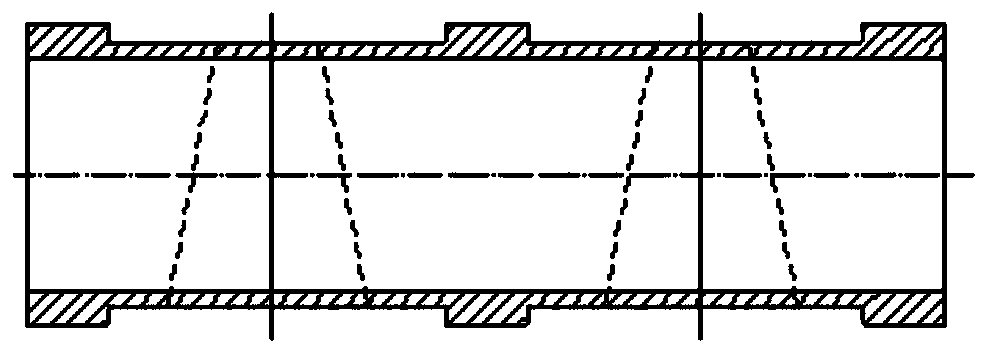

A kind of enameled wire manufacturing and processing equipment

ActiveCN112562920BEven by forceThere will be no uneven thicknessApparatus for feeding conductors/cablesInsulating conductors/cablesGear wheelEngineering

Owner:XIANGYANG NUOLIXIN WIRE & CABLE CO LTD

Variable-frequency speed-regulating type automatic bamboo shoot slice flattening machine

PendingCN107981394AThere will be no uneven thicknessUniform transmission of forceFood shapingPressesElectric machineTransmitted power

The invention discloses a variable-frequency speed-regulating type automatic bamboo shoot slice flattening machine, comprising flattening plates; fixed gaskets are arranged at the fronts of the flattening plates and are closely welded with the fronts of the flattening plates; support bases are arranged at the bottoms of the flattening plates and are fixedly connected with the bottoms of the flattening plates by means of screws; each flattening plate is internally provided with a roller, and the rollers are embedded in the flattening plates. The variable-frequency speed-regulating type automatic bamboo shoot slice flattening machine is provided with the flattening plates, and the flattening plates which are respectively arranged at the upper part and the lower part can be used for flattening a bamboo shoot slice passing through a gap between the flattening plates; the flattening plates of the bamboo shoot slice flattening machine are separately and internally provided with the roller, amotor is used for transmitting power to the rollers by means of transmission belts, flattening belts are then driven to rotate by means of the rollers, and the flattening belts can averagely distribute the received force onto the flattening plates so as to enable surfaces of all bamboo shoot slices to be subjected to uniform pressure, so that the phenomenon that the bamboo shoot slices are not uniform in thicknesses after being flattened can be avoided, and the bamboo shoot slices are also enabled to be more attractive.

Owner:广西华竹生物科技有限公司

Device and method for liquid injection and liquid replacement of cylindrical batteries

ActiveCN111785906BImprove infiltration efficiencyDrain fastCell component detailsElectric machineMechanical engineering

The invention provides a liquid injection and liquid replacement device for a cylindrical battery, which is provided with an injection and discharge device and a battery rotation device. The battery rotating device can be connected and fixed with at least a part of the cylindrical battery, and the battery rotating device can be connected with the rotating shaft of the motor, so that the motor drives the battery rotating device to rotate and then drives the cylindrical battery to rotate. The drainage device includes a rotating part that rotates together with the cylindrical battery and a fixed part for docking with the external fluid storage device / fluid recovery device. The fixed part is sleeved on the rotating part and communicated with the internal fluid, so that the cylindrical battery rotates while enabling fluid communication with an external stationary fluid storage / fluid recovery device. Under the action of centrifugal force, the liquid injected into the cylindrical battery can fully soak the entire cell, or the liquid in the cell in the cylindrical battery can be thrown out and new liquid can be continuously injected to quickly replace the original liquid .

Owner:BEIJING HAWAGA POWER STORAGE TECH

Semi-automatic derusting and paint spraying device for surface of metal tube, and derusting and paint spraying method thereof

InactiveCN102151638BImprove work efficiencyGuaranteed cleanlinessCorrosion preventionPipe protection against corrosion/incrustationSemi automaticEngineering

The invention relates to a semi-automatic portable derusting and paint spraying device for the surface of a metal tube, which comprises five parts, namely a movable hollow shaft system, a low-rotating speed transmission system, a derusting system, a cleaning system and a paint spraying system, wherein the movable hollow shaft system is used for fixing a metal tube on a central line of the movablehollow shaft system; the whole device moves forwards along a metal tube through the force applied on a handle; the circular motion of a motor self on the device is transferred to the derusting system, the cleaning system and the paint spraying system through the low-rotating speed transmission system, so that the derusting system, the cleaning system and the paint spraying system are driven to respectively carry out the circular motion around the metal tube, thereby performing procedures of derusting, cleaning and paint spraying on the metal tube; the whole device continuously moves forwards along the metal tube through the handle, and then the derusting and paint spraying work of the processed tube is finished.

Owner:贾韶强

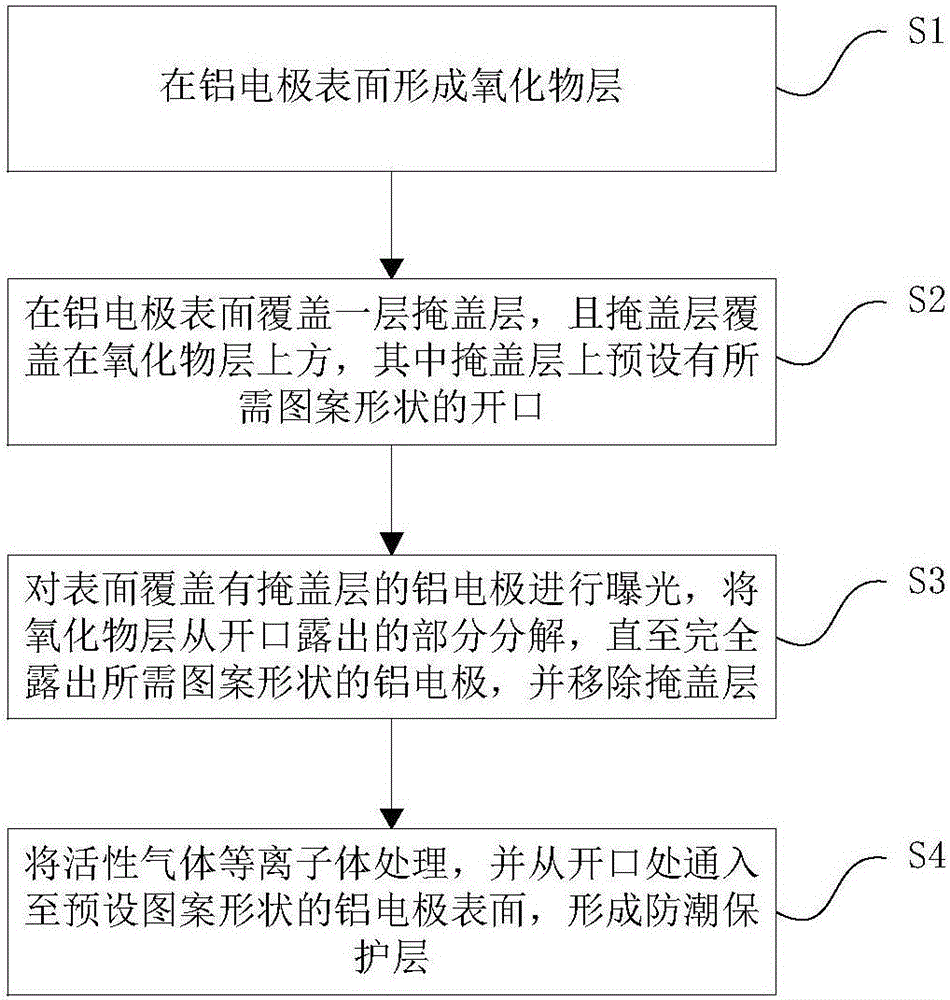

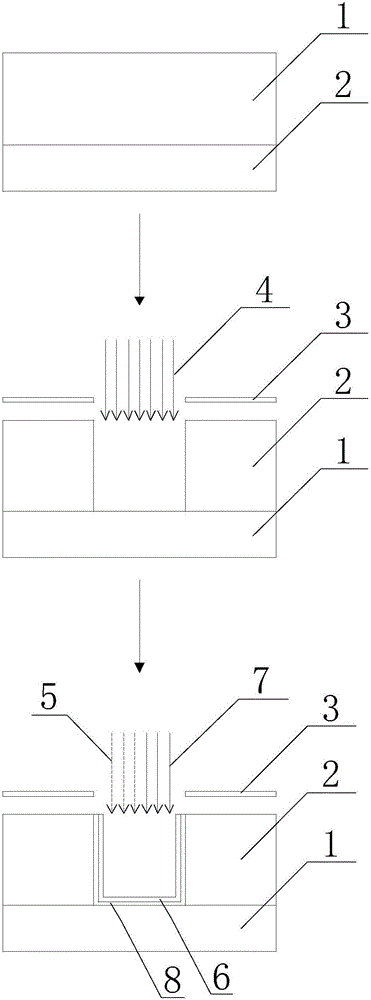

Manufacturing process for eliminating crystal defects of aluminium electrode

ActiveCN105810571ASimple preparation processQuality improvementSemiconductor/solid-state device manufacturingPlasma treatmentOxide

The invention relates to a manufacturing process for eliminating crystal defects of an aluminium electrode. The manufacturing process comprises the following steps of: forming an oxide layer on the surface of the aluminium electrode; covering a covering layer on the surface of the aluminium electrode, wherein the covering layer covers the oxide layer; and an opening having a required pattern shape is preset on the covering layer; exposing the aluminium electrode, the surface of which is covered by the covering layer, decomposing the oxide layer from a part exposed from the opening till the aluminium electrode having the required pattern shape is exposed, and removing the covering layer; and performing plasma treatment of first active gas, and introducing the first active gas onto the surface of the aluminium electrode having the preset pattern shape from the opening, so that a moisture-proof protective layer is formed. According to the manufacturing process for eliminating the crystal defects of the aluminium electrode disclosed by the invention, oxides on the surface of the aluminium electrode are decomposed by utilizing illumination; a high-molecular compound including fluorine is prevented from being introduced; therefore, formation of the crystal defects is eliminated from the source; the quality of the aluminium electrode is improved; and the manufacturing process of the aluminium electrode in the prior art is optimized.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

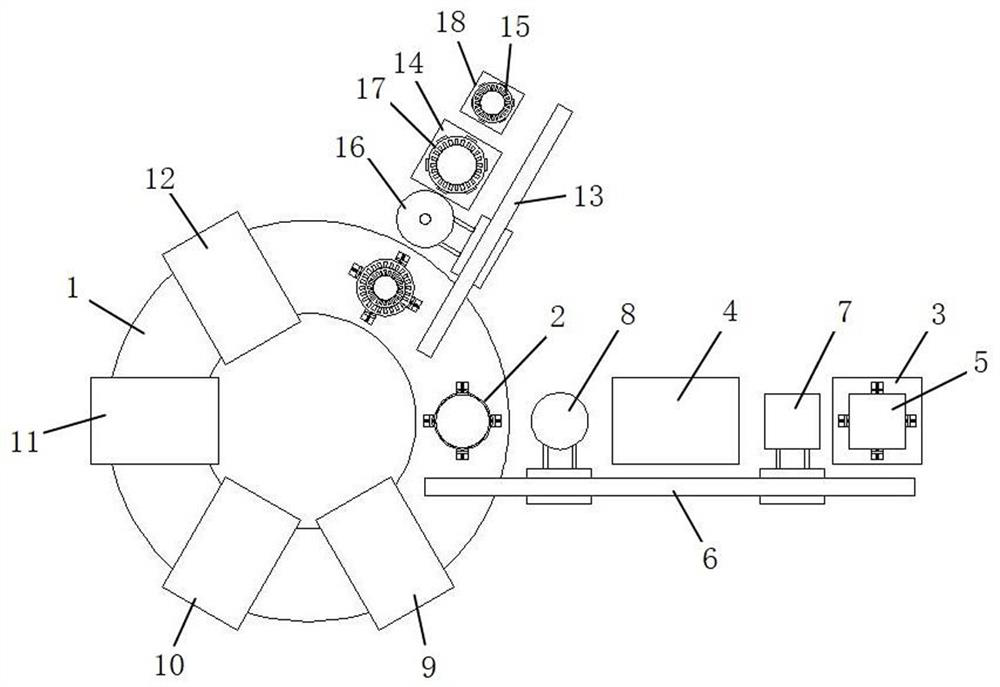

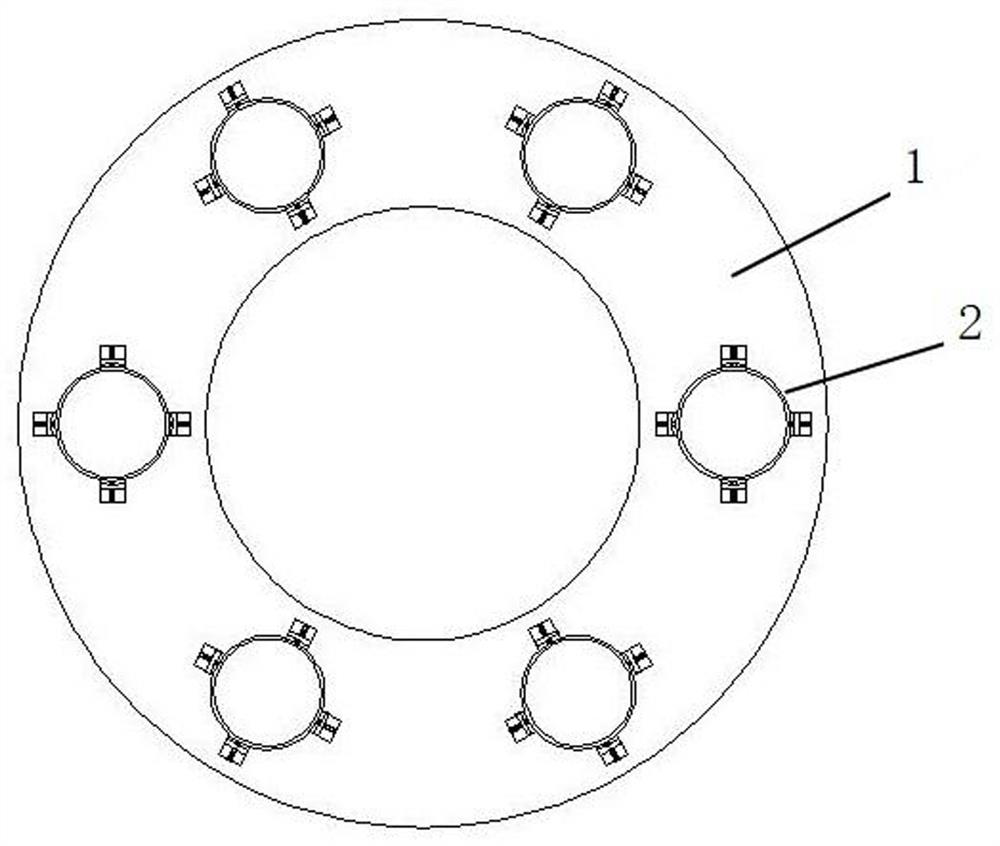

An intelligent feeding device and method for electric motor silicon steel sheet stamping

ActiveCN114101513BReasonable structural designReduce cost ratioMetal-working feeding devicesManufacturing stator/rotor bodiesElectric machineryManufactured material

The invention belongs to the technical field of wind power generator production, and in particular relates to a stamping intelligent feeding device and method for silicon steel sheets of electric motors. There are square material storage racks, pre-punching machines and feeding components on the outside. The first stamping area, the second stamping area, the third stamping area, and the fourth stamping area are respectively equipped with the first stamping machine and the second stamping area. For the secondary punching machine, the third punching machine, and the fourth punching machine, the outer side of the unloading area is equipped with an outer ring silicon steel sheet storage rack, an inner ring silicon steel sheet storage rack and an unloading assembly. The device of the invention has a reasonable structural design and a high degree of intelligence. It can use the same square material to produce two specifications of silicon steel sheets. The cost of waste materials is relatively low. It can continuously and automatically load raw materials and unload products according to classification, and the production efficiency is high. , and at the same time solve the problem of the difference between the same board, and meet the feeding requirements of the stator laminated sheet.

Owner:CHANGZHOU SHENLI MOTOR

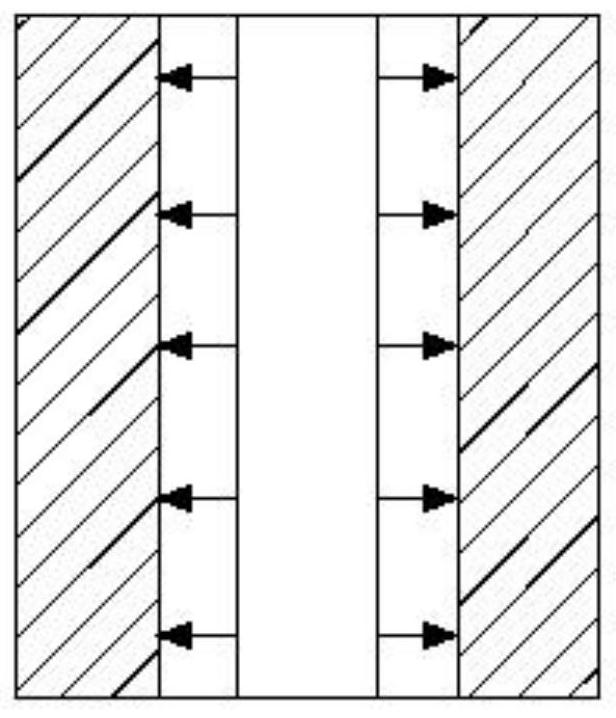

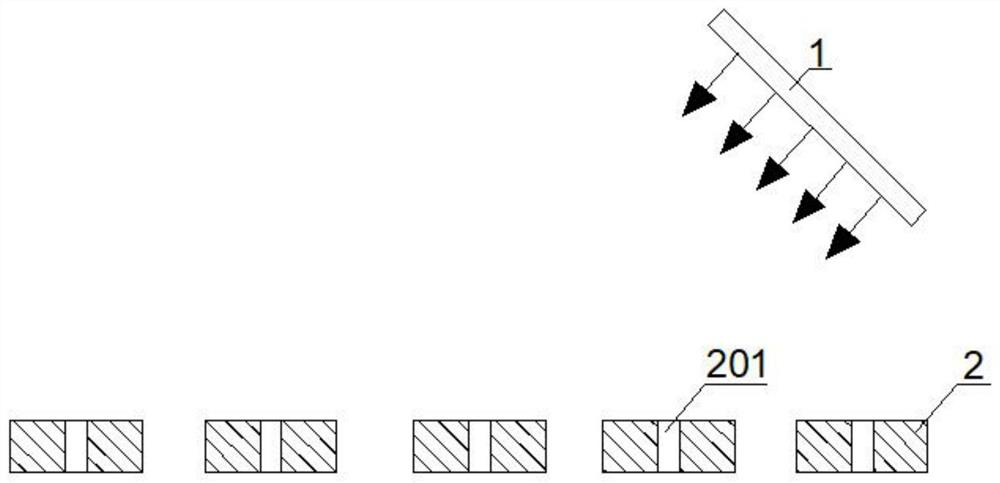

Method and device for depositing thin film on inner wall of small hole

ActiveCN111235539BReduce lossUniform depositionVacuum evaporation coatingSputtering coatingThin membraneSmall hole

The invention provides a method and a device for depositing a thin film on the inner wall of a small hole, belonging to the technical field of thin film deposition. On the inner wall of the small hole of the material to be sputtered, the target material is a cylindrical target material, and the diameter of the target material is 100-200 mm; during the sputtering process, the material to be sputtered is controlled to rotate at a uniform speed, so as to achieve the target ions in the small Uniform deposition on the inner wall of the hole. In the present invention, the target material is inclined, on the one hand, a small diameter target material can be used to achieve uniform deposition in a large area, which improves the deposition efficiency, reduces the loss of the target material, and saves costs; on the other hand, the deposition of the inclined target magnetron sputtering The method can make the target ions shoot at a certain angle to the material to be sputtered, so that the target ions shoot at a certain angle to the inner wall of the small hole, instead of the direct sputtering, the deposition direction is parallel to the inner wall of the small hole, and the deposition efficiency and combination Strength is better.

Owner:摩科斯电子科技(苏州)有限公司

Enameled wire manufacturing and processing technology

ActiveCN112562920AEven by forceThere will be no uneven thicknessApparatus for feeding conductors/cablesInsulating conductors/cablesElectric machineGear wheel

The invention relates to an enameled wire manufacturing and processing technology which comprises a workbench, a moving device and a painting device. The moving device is fixedly installed on the upper side of the workbench, and the painting device is connected to the upper end of the middle of the moving device in a sliding fit mode. The moving device comprises a first motor, a fixing rod, a first gear, a first rectangular plate, a circular plate, a fixing plate, a right-angle plate, a positioning roller and a coil barrel. The moving device drives the whole metal wire to rotate while positioning and conveying the metal wire, and therefore the metal wire is stressed evenly in a grinding and painting process, and meanwhile, the surface of the metal wire is completely ground, and paint flowsaround the metal wire under the action of gravity so that a phenomenon that the thickness of a paint layer is not uniform is avoided; and the surface of the metal wire is ground and painted through the painting device, and meanwhile the surface of the enameled wire obtained after painting is completed is polished and rolled.

Owner:XIANGYANG NUOLIXIN WIRE & CABLE CO LTD

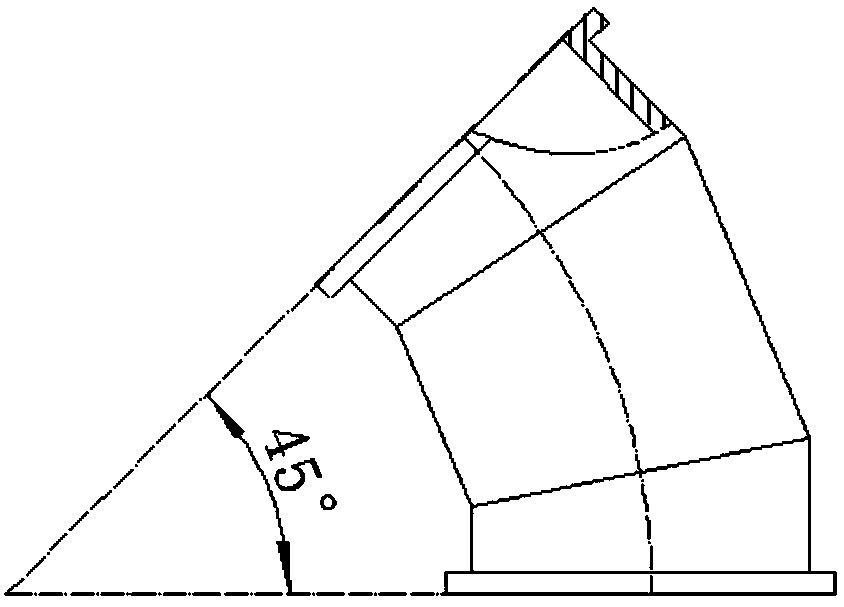

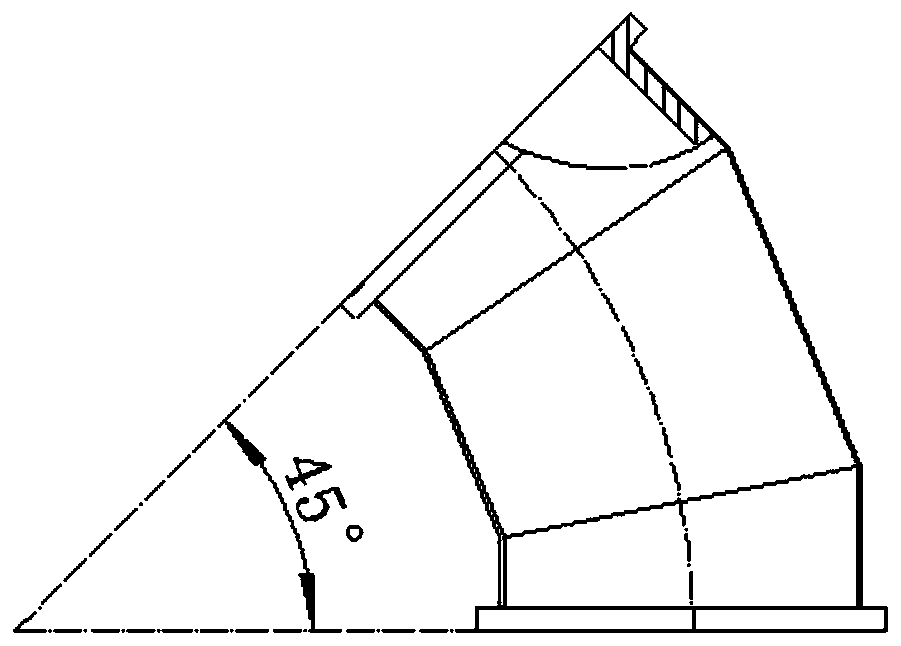

A kind of preparation method of bamboo winding composite elbow

ActiveCN108119719BHigh dimensional accuracyHigh strengthCane mechanical workingWood working apparatusButt jointFiber-reinforced composite

The invention discloses a preparation method for a composite elbow wrapped with bamboo. The preparation method comprises the following steps that (1) an elbow mother pipe is prepared through wrapping,and the elbow mother pipe is a composite pipe wrapped with the bamboo, sequentially comprises an inner lining layer, a structure layer and an outer protection layer from inside to outside in the radial direction; (2) the elbow mother pipe prepared through winding is marked with a line and cut, and a plurality of branched pipes are obtained; (3) the cut edges of the branched pipes are polished till the inner lining layers are exposed; (4) the branched pipes are in butt joint in sequence, the portions, at the butt joint, of the inner lining layers are pasted, and then solidification is conducted; and (5) after the inner lining layers are solidified, a fiber reinforced composite material structure layer is pasted onto the butt joint position and then solidified, after solidification, outer surface anti-corrosion treatment is conducted, and the needed elbow is prepared and obtained. According to the preparation method, operation is easy, the efficiency is high, and the elbow obtained through preparation has the advantages of being high in size precision, good in strength performance and the like.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

A kind of non-woven fabric production device and using method for air filtration

ActiveCN112680801BPromote formationImprove spinning stabilitySpinnerette packsFilament/thread formingAir filtrationPolymer science

The invention relates to the technical field of nanofiber non-woven fabrics, in particular to a non-woven fabric production device and use method for air filtration. The production device includes an air bag, a cylindrical receiving device, a cover, a rotating shaft, a spinning drum, a driving device, an electronic air pump, a liquid supply device, a reciprocating telescopic device and a high-voltage electrostatic generator, and an air bag is arranged inside the spinning drum, and A volume-variable annular cavity is formed by cooperating with the air bag; several spinning micro-holes are evenly arranged on the wall of the upper part of the spinning drum, and there are no spinning holes on the wall of the lower part of the spinning drum. Spinning microholes are set; the reciprocating telescopic device is set on the outer wall of the cylindrical receiving device. Compared with the prior art, the production device of the present invention can provide the spinning solution with air bag extrusion force to assist spinning, and the spinning solution is always filled with the annular cavity, which improves the spinning efficiency and the continuous stability of spinning, and The resulting non-woven fabric has a larger area and higher strength.

Owner:江苏臻中滤料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com