Automatic spraying equipment for suspension type assembly line

An automatic spraying and assembly line technology, applied in the direction of the spraying device, etc., can solve the problems of uneven thickness of the sprayed surface, high manufacturing cost, waste of spraying liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

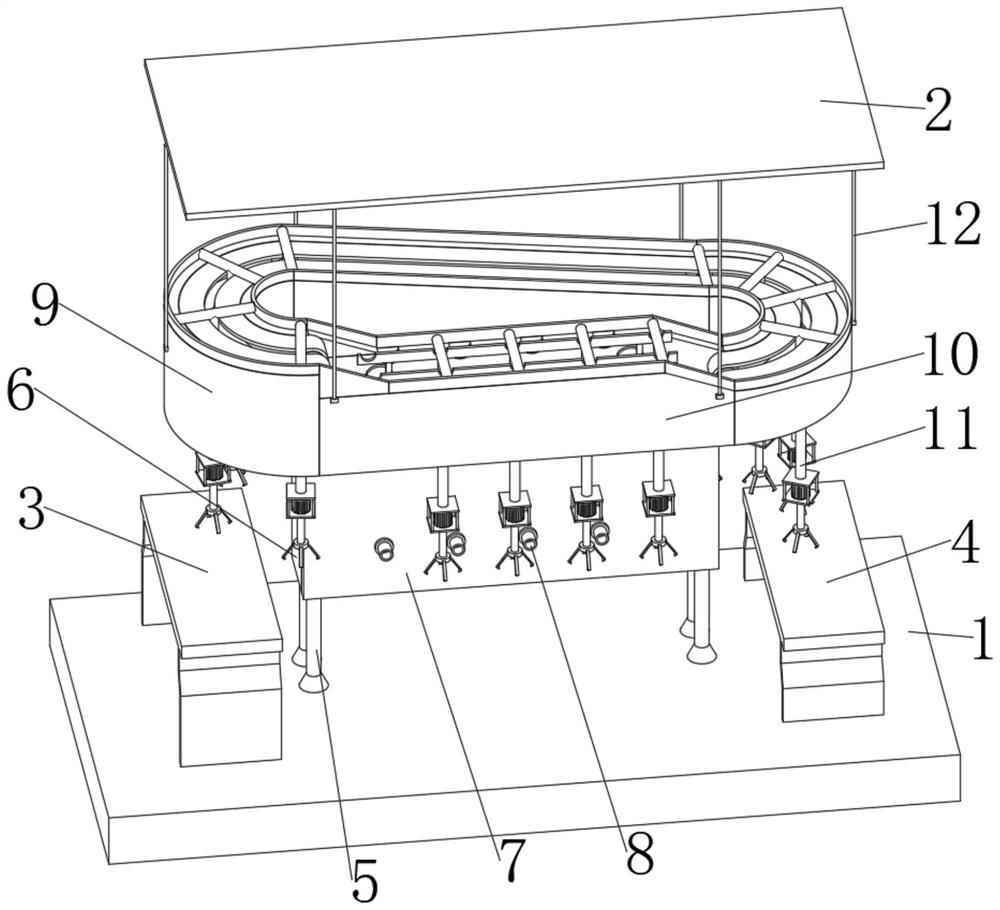

Embodiment 1

[0033] A hanging assembly line automatic spraying equipment, such as Figure 1-4 As shown, including the lower installation surface 1, the upper left part of the lower installation surface 1 is fixedly equipped with a loading platform 3, the upper right part of the lower installation surface 1 is fixedly installed with a feeding platform 4, and the upper middle part of the lower installation surface 1 is fixedly installed with two groups The supporting legs 5, and two sets of supporting legs 5 are symmetrically distributed left and right, the upper ends of the two sets of supporting legs 5 are jointly fixed with a liquid storage tank 6, the front end of the liquid storage tank 6 is fixedly installed with a first mounting plate 7, and the front end of the first mounting plate 7 A spraying assembly 8 is provided, and the spraying assembly 8 communicates with the liquid storage tank 6, and the upper end of the liquid storage tank 6 is provided with a transmission assembly 9, and a...

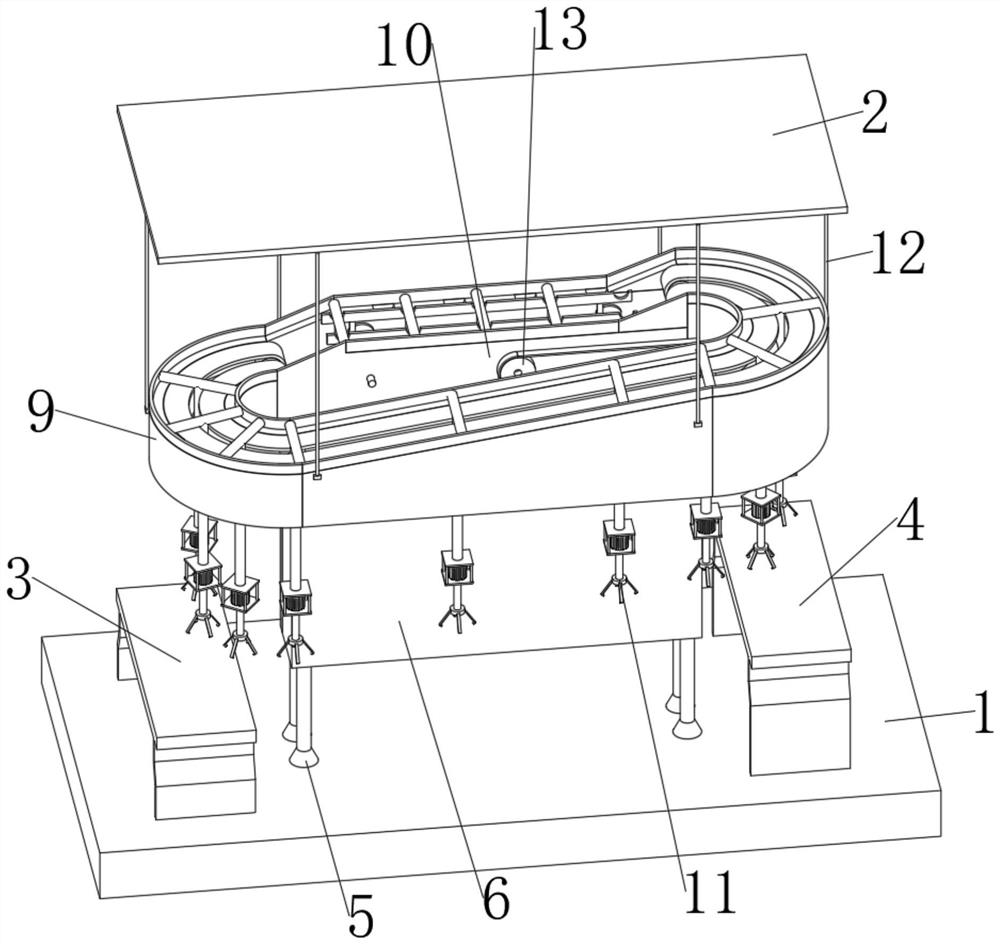

Embodiment 2

[0036] On the basis of Example 1, as Figure 5-7 As shown, a suspended assembly line automatic spraying equipment includes a lower installation surface 1, a loading platform 3 is fixedly installed on the left side of the upper end of the lower installation surface 1, and a feeding platform 4 is fixedly installed on the upper right side of the lower installation surface 1, and the lower installation surface 1 is fixedly installed on the upper left side. Two sets of support legs 5 are fixedly installed in the middle of the upper end of surface 1, and the two sets of support legs 5 are distributed symmetrically from left to right. plate 7, the front end of the first mounting plate 7 is provided with a spraying assembly 8, and the spraying assembly 8 communicates with the liquid storage tank 6, the upper end of the liquid storage tank 6 is provided with a transmission assembly 9, and a transport mechanism 10 is arranged inside the transmission assembly 9, and the transmission assem...

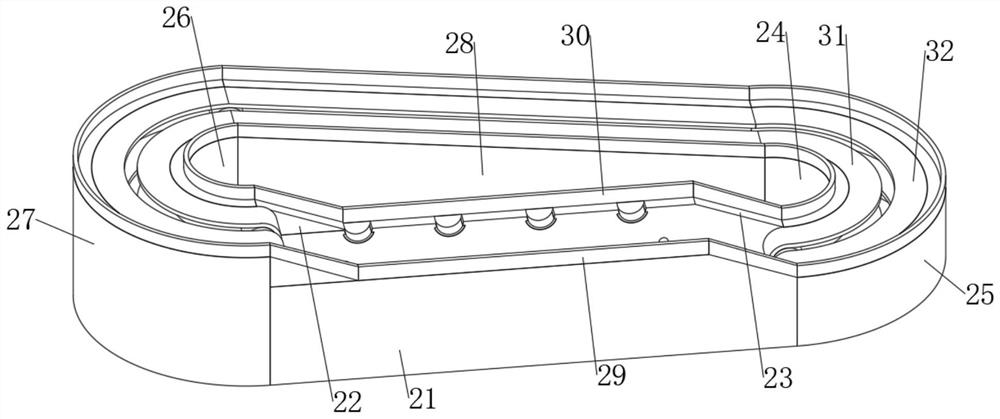

Embodiment 3

[0039] On the basis of Example 1, as Figure 8-9 As shown, a suspended assembly line automatic spraying equipment includes a lower installation surface 1, a loading platform 3 is fixedly installed on the left side of the upper end of the lower installation surface 1, and a feeding platform 4 is fixedly installed on the upper right side of the lower installation surface 1, and the lower installation surface 1 is fixedly installed on the upper left side. Two sets of support legs 5 are fixedly installed in the middle of the upper end of surface 1, and the two sets of support legs 5 are distributed symmetrically from left to right. plate 7, the front end of the first mounting plate 7 is provided with a spraying assembly 8, and the spraying assembly 8 communicates with the liquid storage tank 6, the upper end of the liquid storage tank 6 is provided with a transmission assembly 9, and a transport mechanism 10 is arranged inside the transmission assembly 9, and the transmission assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com