Enameled wire manufacturing and processing technology

A processing technology, enameled wire technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, electrical components, etc., can solve the problems of impurities on the surface, affect the quality of enameled wires, and low quality of enameled wires, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

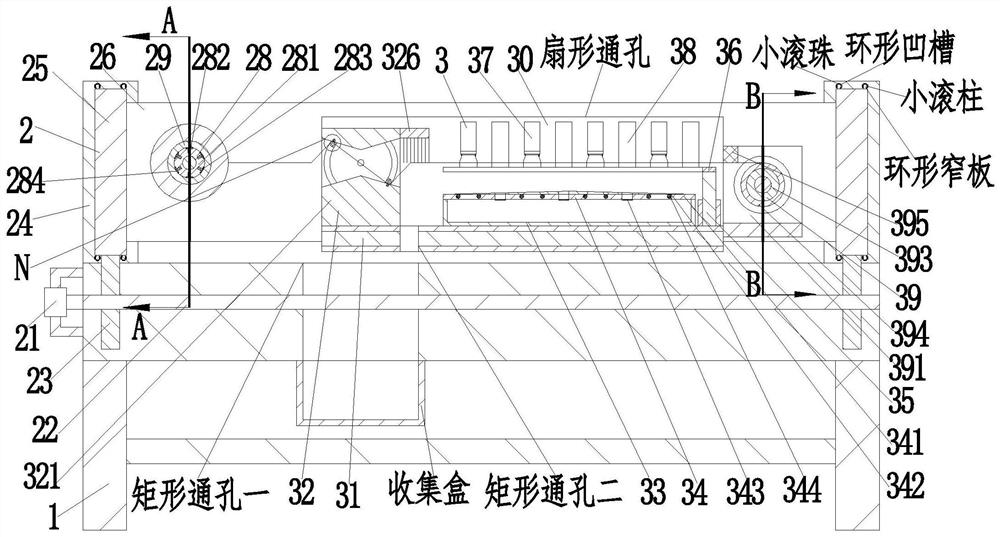

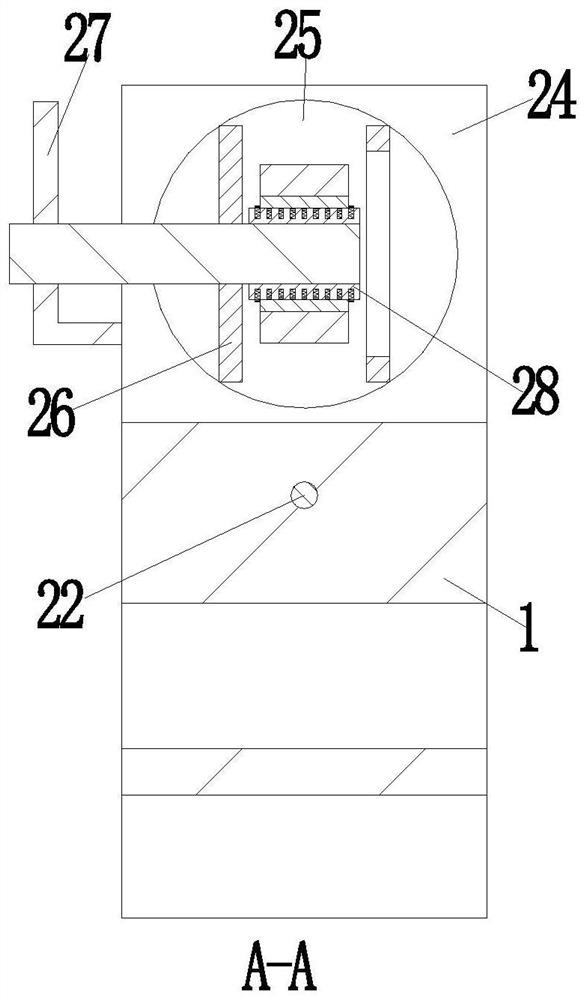

[0039] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0040] An enameled wire manufacturing process, which uses an enameled wire manufacturing and processing equipment, the enameled wire manufacturing and processing equipment includes a workbench 1, a moving device 2 and a painting device 3, and the enameled wire manufacturing and processing equipment is used to manufacture and process enameled wires. Methods as below:

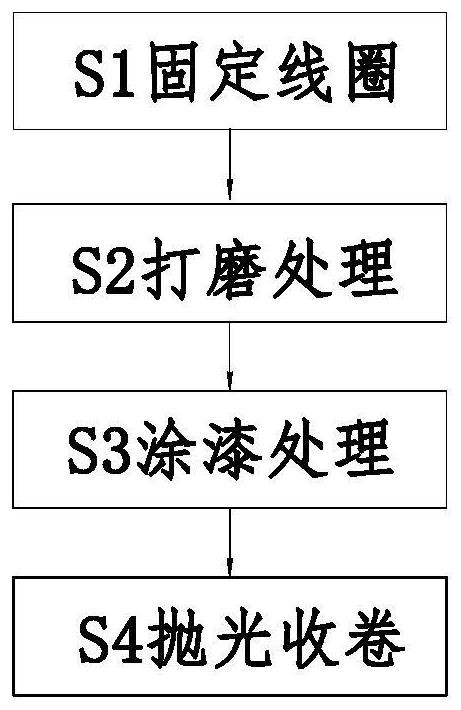

[0041] S1. Fixed coil: fix the coil on the moving device 2 of the equipment;

[0042] S2, grinding treatment: the surface of the metal wire is polished through the grinding frame 32, and the motor one 21 drives the metal wire to rotate at the same time, so that the surface of the metal wire is completely polished;

[0043] S3, painting treatment: the surface of the polished metal wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com