A kind of preparation method of bamboo winding composite elbow

An elbow and composite material technology, which is applied in elbows, manufacturing tools, mechanical equipment, etc., can solve the problems of inability to apply bamboo winding composite elbows, poor dimensional accuracy of elbows, uneven thickness of elbows, etc., to achieve material utilization. The effect of high rate, uniform thickness and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a kind of preparation method of bamboo winding composite elbow, and this method comprises the following steps:

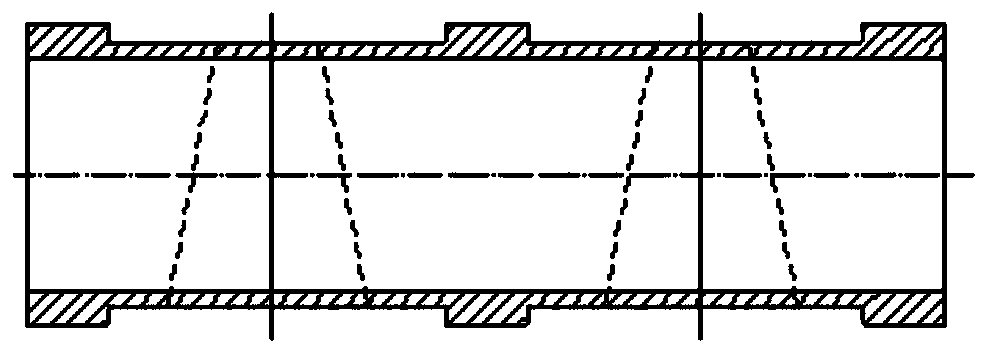

[0023] (1) Elbow master pipe is prepared by winding at first, and the elbow master pipe is a bamboo winding composite pipe, which includes an inner lining layer, a structural layer and an outer protective layer in the radial direction from the inside to the outside;

[0024] (2) Unfold the sample, draw and cut on the elbow main pipe prepared by winding, and obtain multiple branch pipes, for example, draw a cutting line on the outer surface of the elbow main pipe prepared by winding, and cut the longitudinal section along the cutting line. Multiple trapezoidal pipes, the angle between the plane where the cutting line is located and the axial direction of the elbow main pipe is an acute angle, and two adjacent cutting lines are symmetrically distributed about the radial direction of the elbow main pipe, and the tr...

Embodiment 1

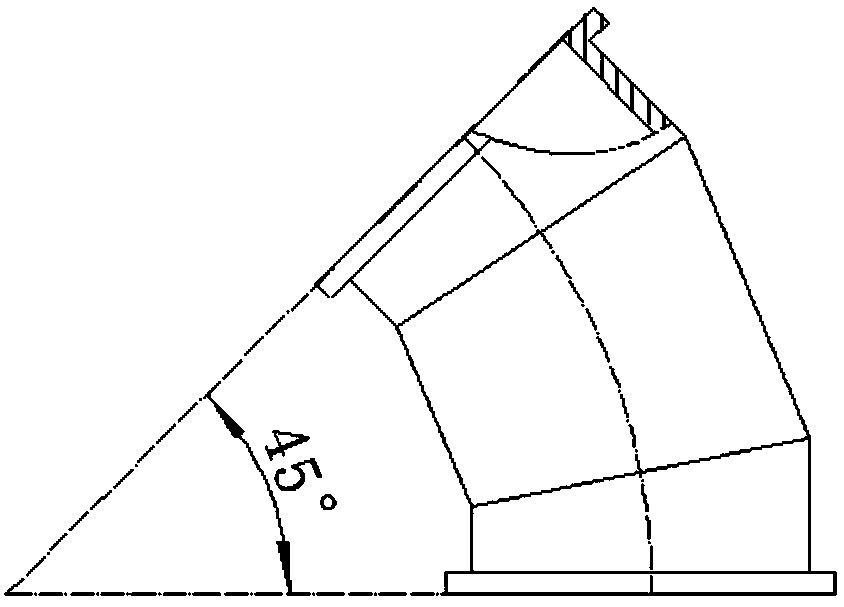

[0032] Such as Figure 1-Figure 3 As shown, this embodiment takes a 45° elbow as an example to illustrate the present invention, and its two ends are connected to the pipeline to be connected by flanges. The following are the specific preparation steps:

[0033] (1) Elbow master pipe prepared by winding (same as the process of preparing bamboo winding composite pipe)

[0034] (1.1) Bamboo fiber pretreatment: cut fresh bamboo into bamboo slices, remove green and yellow from the bamboo slices, and cut them into 1.5m long, 1mm thick, 5mm wide bamboo strips, dry the bamboo strips, and then cut 10 bamboo strips The bamboo strips are arranged in a row in parallel, and the back of the whole row of bamboo strips is lined with mesh cloth, which is stitched with a sewing machine to form a bamboo curtain. The uninterrupted bamboo curtain belt of more than tens of meters is rolled up to obtain bamboo rolls for use;

[0035] (1.2) Prepare the lining layer: coat a layer of 0.03mm thick pol...

Embodiment 2

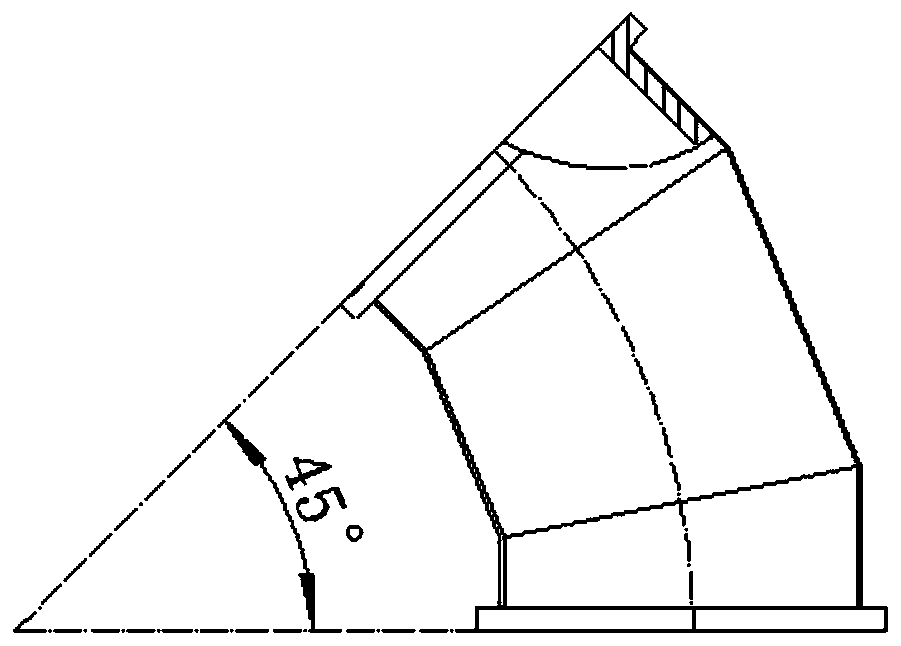

[0042] Such as Figure 4-6 As shown, this embodiment takes a 90° elbow as an example to illustrate the present invention, and its two ends are connected to the pipeline to be connected by a socket connection method. The following are the specific preparation steps:

[0043] (1) Elbow master pipe prepared by winding (same as the process of preparing bamboo winding composite pipe)

[0044](1.1) Bamboo fiber pretreatment: cut fresh bamboo into bamboo slices, remove green and yellow from the bamboo slices, cut them into bamboo slivers with a length of 2m, a thickness of 1.2mm, and a width of 4mm, dry the bamboo strips, and then cut 12 The bamboo strips are arranged in a row in parallel, and the back of the whole row of bamboo strips is lined with mesh cloth, which is stitched with a sewing machine to form a bamboo curtain. Uninterrupted bamboo curtain belts over tens of meters are rolled up to obtain bamboo rolls for use.

[0045] (1.2) Prepare inner liner: coat a layer of 0.02m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com