A kind of non-woven fabric production device and using method for air filtration

A technology of air filtration and production equipment, which is applied in the direction of non-woven fabrics, textiles and papermaking, filament/thread forming, etc., which can solve the problems of spinning solution shaking, different thickness, restrictions, etc., and achieve good spinning stability and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

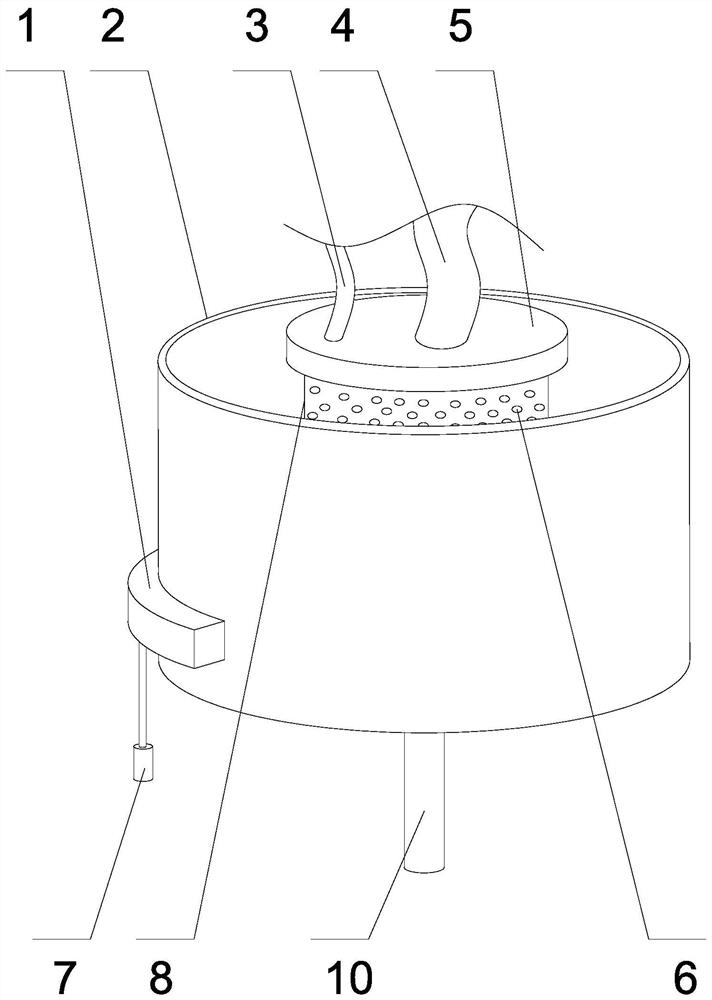

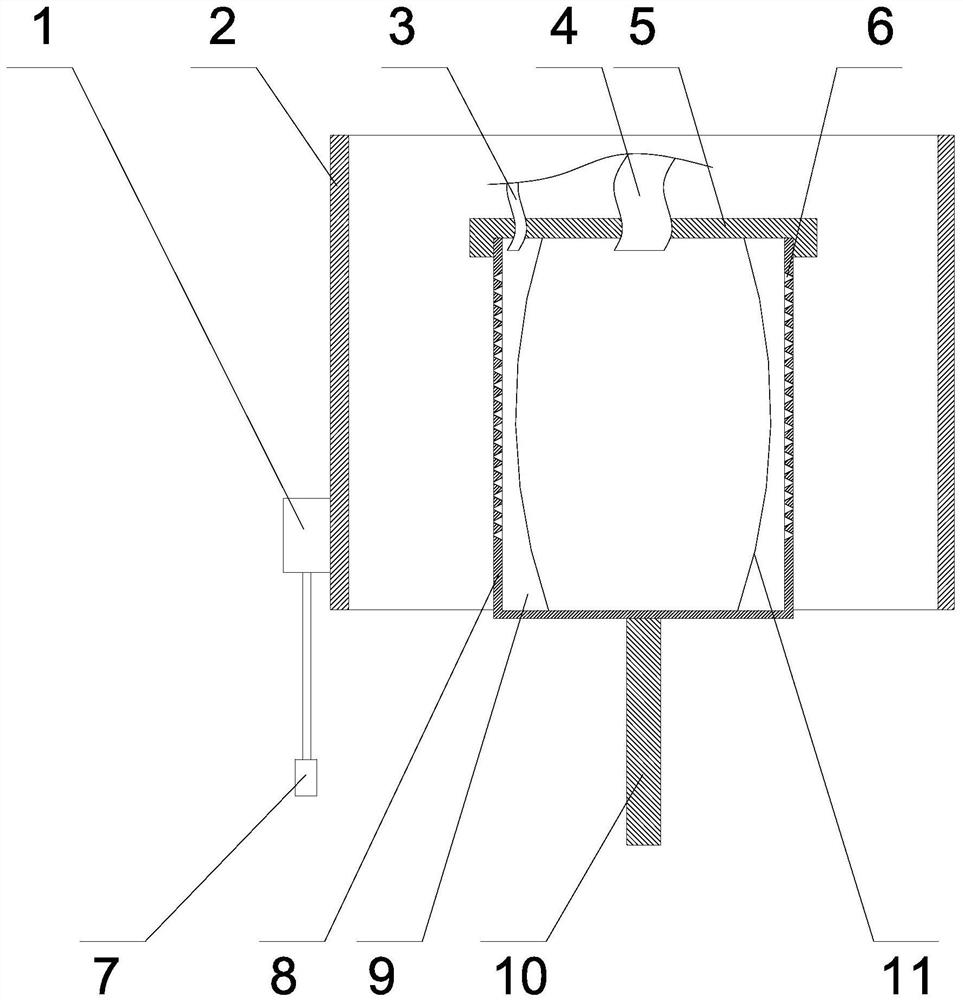

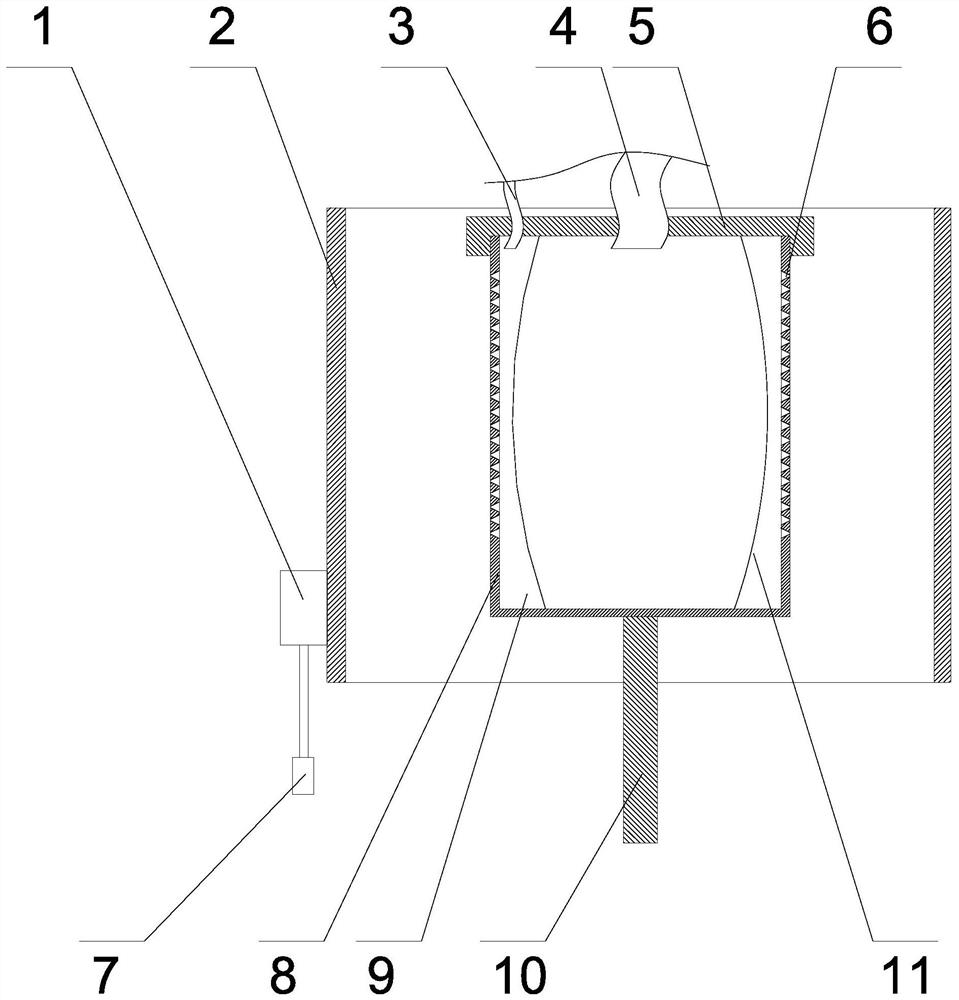

[0045] like Figure 1-4 As shown, the present embodiment provides a non-woven production device for air filtration, including an air bag 11, a cylindrical receiving device 2, a cover 5, a rotating shaft 10, a spinning drum 8, a driving device, an electronic air pump, a supply liquid device, reciprocating expansion device and high-voltage electrostatic generator; the spinning drum 8 has a cylindrical hollow structure, and an air bag 11 is arranged in the hollow structure, and a cover 5 is arranged on the top of the spinning drum 8, and the cover 5 is made of an insulating material. to make. The upper end and the lower end of the air bag 11 are respectively fixed at the middle part of the cover 5 and the middle part of the bottom surface of the spinning drum 8, so that the air bag 11 is concentric with the spinning drum 8 when inflated (see figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com