An intelligent feeding device and method for electric motor silicon steel sheet stamping

A technology of silicon steel for motors and feeding devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of low intelligence, uneven thickness, and the same board difference, so as to achieve high intelligence and ensure normal work , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

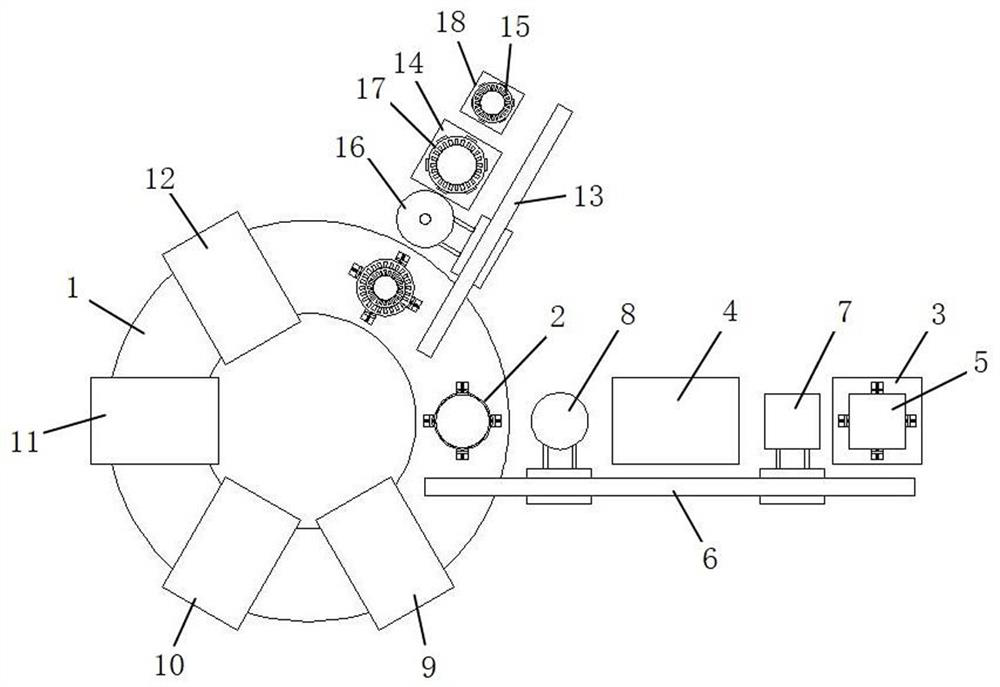

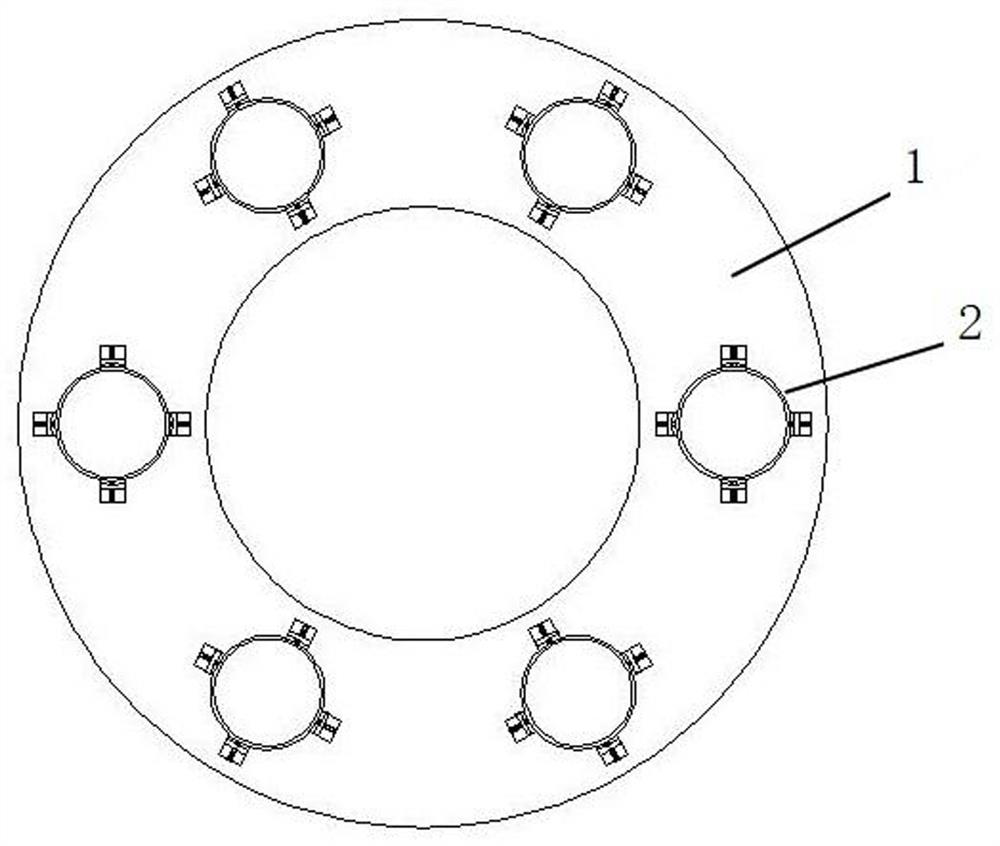

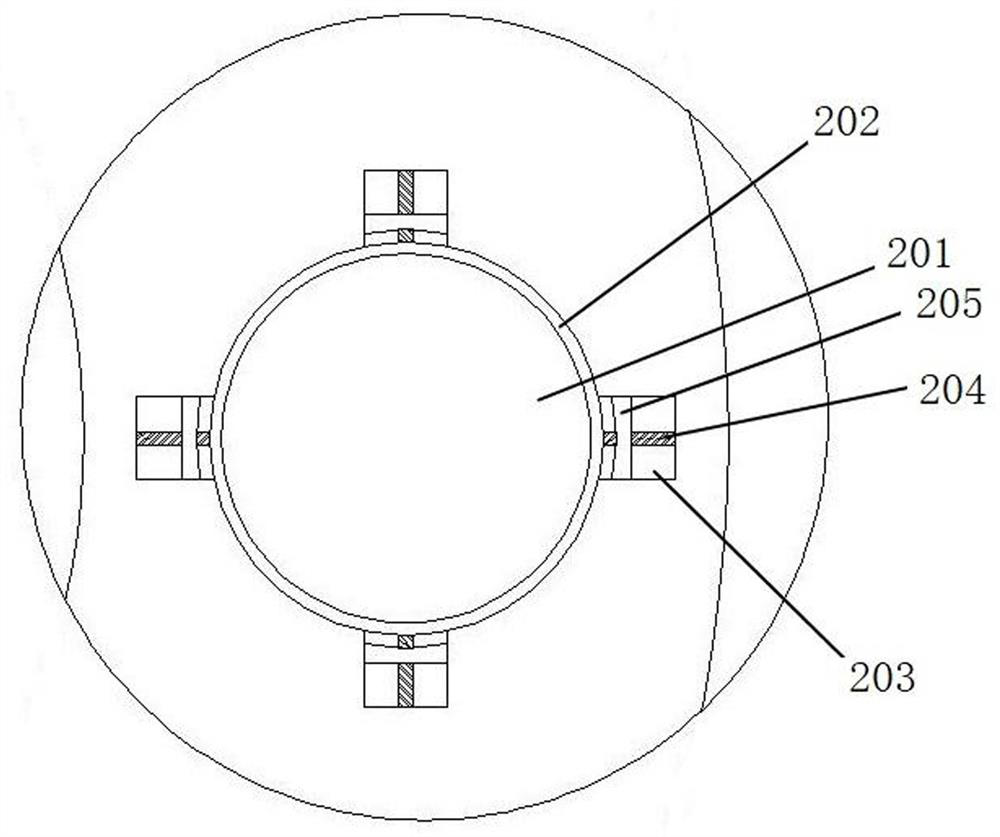

[0046] This embodiment is an intelligent feeding device for electric motor silicon steel sheet stamping, such as Figure 1-Figure 2 As shown, including the rotary table 1, there are six station areas 2 on the rotary table, and the six station areas are the feeding area, the first stamping area, the second stamping area, and the third stamping area. area, the fourth stamping area and the unloading area. Such as image 3 As shown, the working area 2 includes a through hole 201, a positioning ring 202 is formed on the periphery of the through hole 201, and the inner diameter of the positioning ring 202 is smaller than the outer diameter of the material. The periphery of the positioning ring 202 is provided with multiple groups of clamping mechanisms, the clamping mechanisms include a movable groove 203, a driving screw 204 and a clamping block 205, and the clamping blocks 205 of the same group are driven by the driving screw 204 to face each other along the movable groove 203. ...

Embodiment 2

[0055] This embodiment is an intelligent feeding method for electric motor silicon steel sheet stamping, including the following steps:

[0056] 1) Transfer the square material 5 in the square material storage rack 3 to the pre-punching machine 4 by using the first sucker handling manipulator 7 of the feeding component, and the pre-punching machine 4 works to stamp the square material 5 into a round material 501, and use the first part of the loading component The second sucker handling manipulator 8 transfers the round material 501 from the pre-punching machine 4 to the feeding area of the rotary table 1;

[0057] 2) The rotary table 1 is rotated, and the round material 501 in the feeding area is transferred to the first punching area, and the first punching machine 9 is used for the first punching to form the punching hole 502 of the outer ring winding plate;

[0058] 3) Rotate the rotary table 1 to transfer the round material in the first stamping area to the second stamp...

Embodiment 3

[0065] This embodiment is an intelligent feeding method for electric motor silicon steel sheet stamping, including the following steps:

[0066] 1) Transfer the square material 5 in the square material storage rack 3 to the pre-punching machine 4 by using the first sucker handling manipulator 7 of the feeding component, and the pre-punching machine 4 works to stamp the square material 5 into a round material 501, and use the first part of the loading component The second sucker handling manipulator 8 transfers the round material 501 from the pre-punching machine 4 to the feeding area of the rotary table 1;

[0067] 2) The rotary table 1 is rotated, and the round material 501 in the feeding area is transferred to the first punching area, and the first punching machine 9 is used for the first punching to form the punching hole 502 of the outer ring winding plate;

[0068] 3) The rotary table 1 is rotated, and the round material in the first punching area is transferred to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com