Patents

Literature

199results about How to "Meet delivery needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shuttle vehicle dispatching management system and dispatching method for cold storage

InactiveCN109190840AImprove logistics efficiencyReal-time monitoring statusForecastingResourcesLogistics managementManagement system

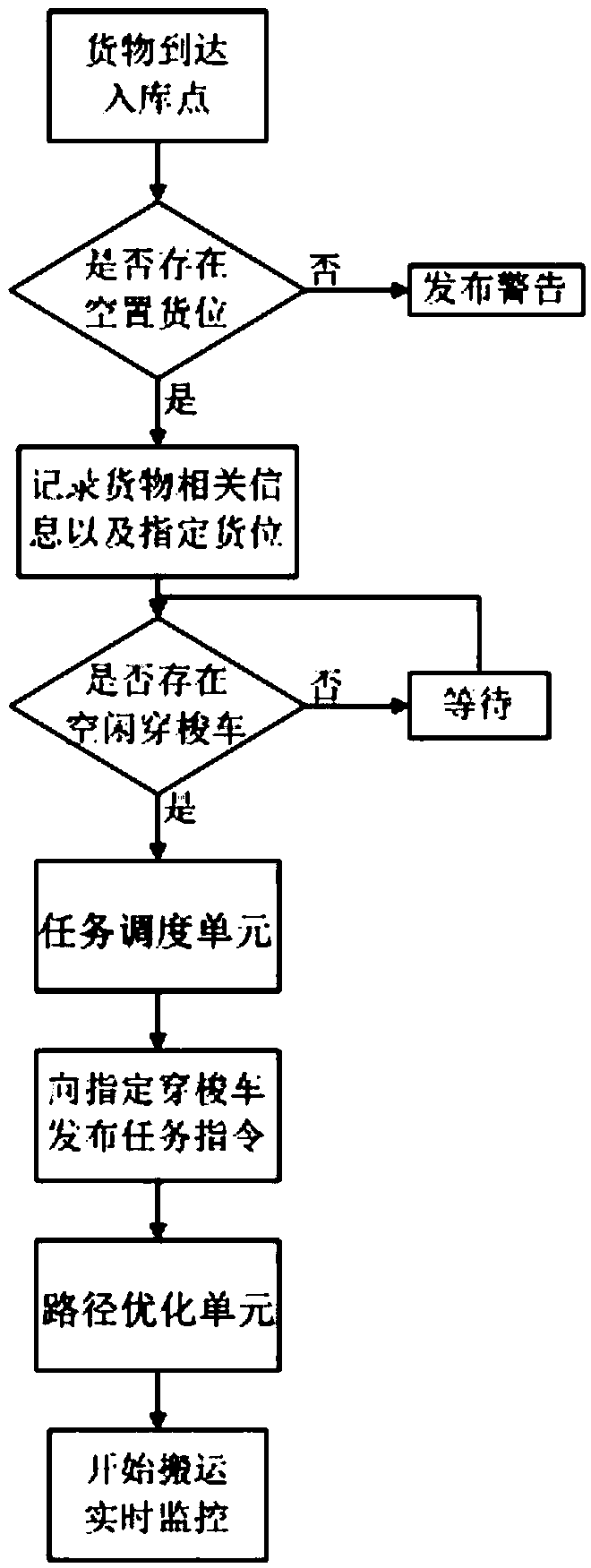

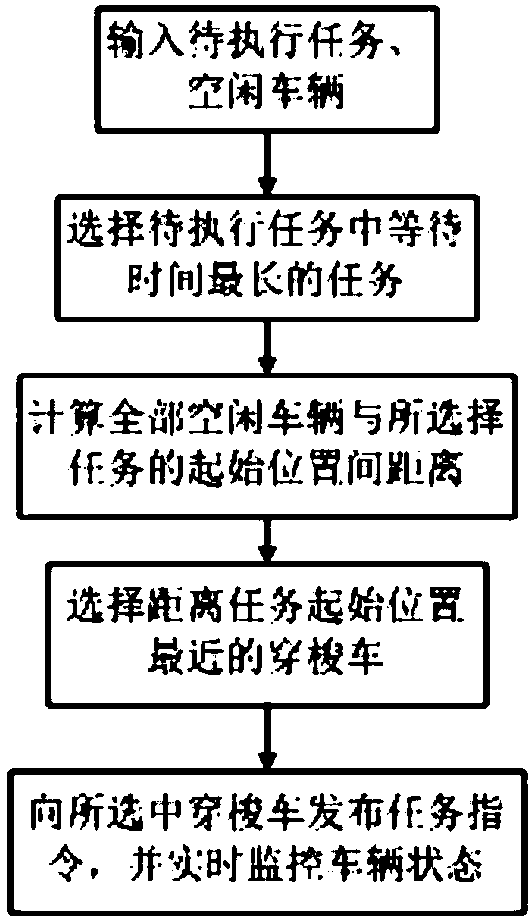

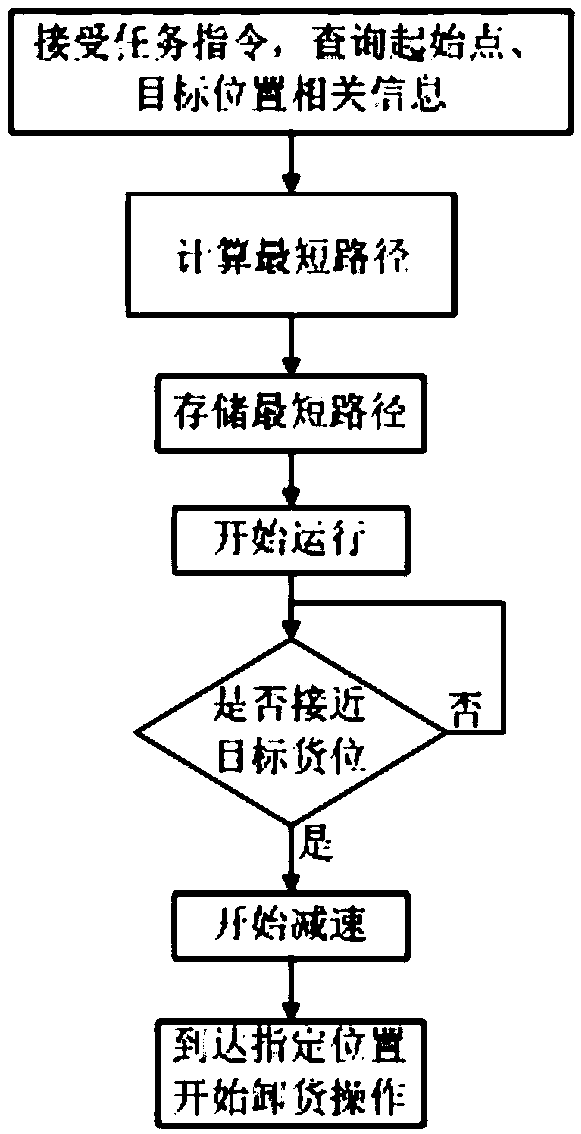

The invention discloses a shuttle vehicle dispatching management system and dispatching method for a cold storage, belonging to the field of shuttle vehicle storage system. The system includes a shuttle vehicle management system, and a vehicle-mounted terminal arranged on the shuttle vehicle, wherein the vehicle-mounted terminal is in communication with the shuttle vehicle management system, the vehicle-mounted terminal is used for recording the working state of the shuttle vehicle itself and uploading the working state to the shuttle vehicle management system, and the working state includes the vehicle number, the remaining power, the position, the state and the task of the vehicle; the shuttle vehicle management system comprises a dispatching module which monitors and dispatches the shuttle vehicle managed in the shuttle management system and optimizes the route according to the transportation task, and sends a dispatching instruction to the corresponding shuttle vehicle through thevehicle-mounted terminal. By adopting the dispatching management system and the dispatching method of the invention, the intelligent dispatching and the path optimization of a plurality of shuttle vehicles can be realized, and the logistics efficiency can be improved.

Owner:CHINA INFORMATION & ELECTRONICSE DEV HEFEI

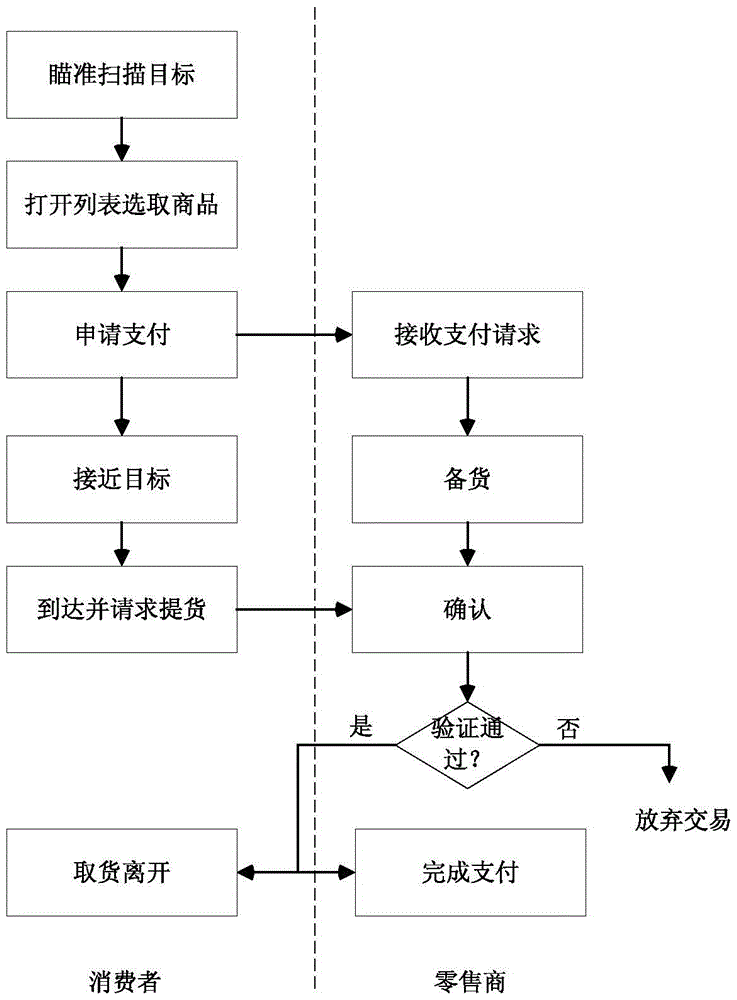

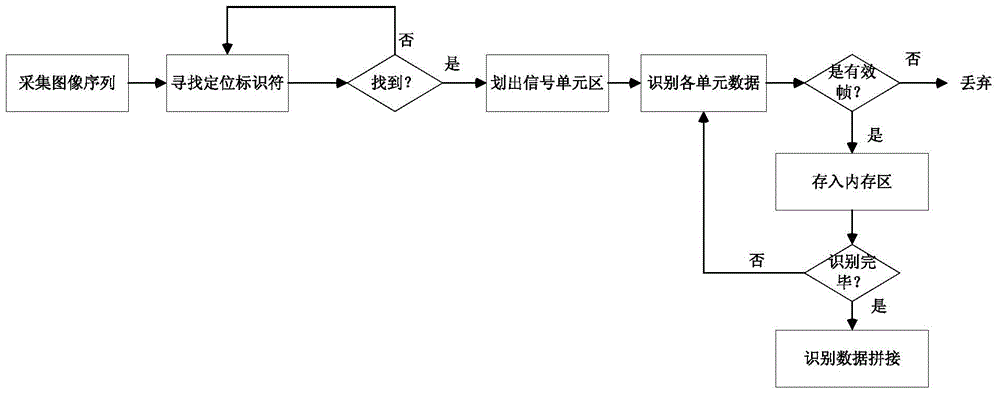

Optical label based information interaction system and method

ActiveCN105718840AImprove recognition distanceIncrease encoding capacityCo-operative working arrangementsClose-range type systemsLibrary scienceImaging processing

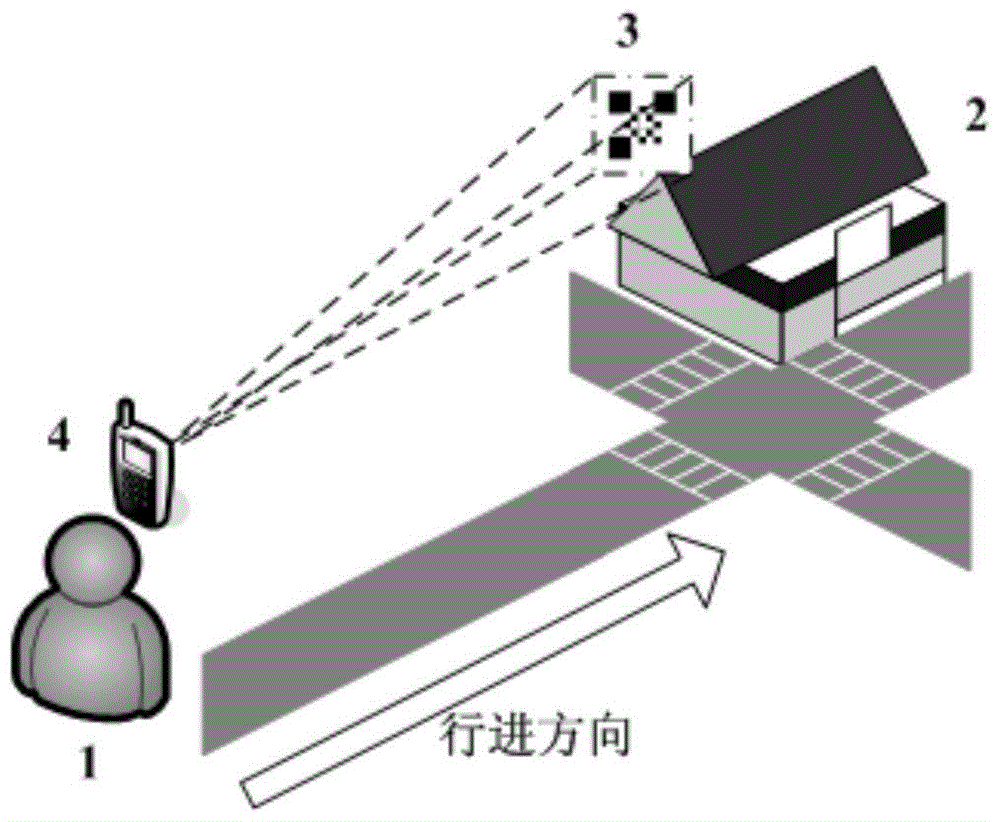

The invention provides an optical label based information interaction system and method, and the system and method are high in directionality, long in identification distance and large in information capacity. The information comprises the information coding optical label, a data server, a mobile terminal and a wireless communication network, wherein the data server provides information, the mobile terminal decodes the information and is connected with the data server, and the wireless communication network is connected with the mobile terminal and the data server. the optical label comprises a signal unit and a positioning identification; the mobile terminal comprises an image collector and an image processing module, the image collector collects a coded image of the optical label, and the image processing module decodes the coded image; and the mobile terminal is connected with the data server via wireless communication network according to decoding information and makes information interaction. The method comprises the following steps that 1) supply information is coded; 2) the mobile terminal is used to decode the image to obtain demand information transmitted by the optical label; and 3) after decoding, interaction between demand information and supply information is realized.

Owner:BEIJING WHYHOW INFORMATION TECH CO LTD

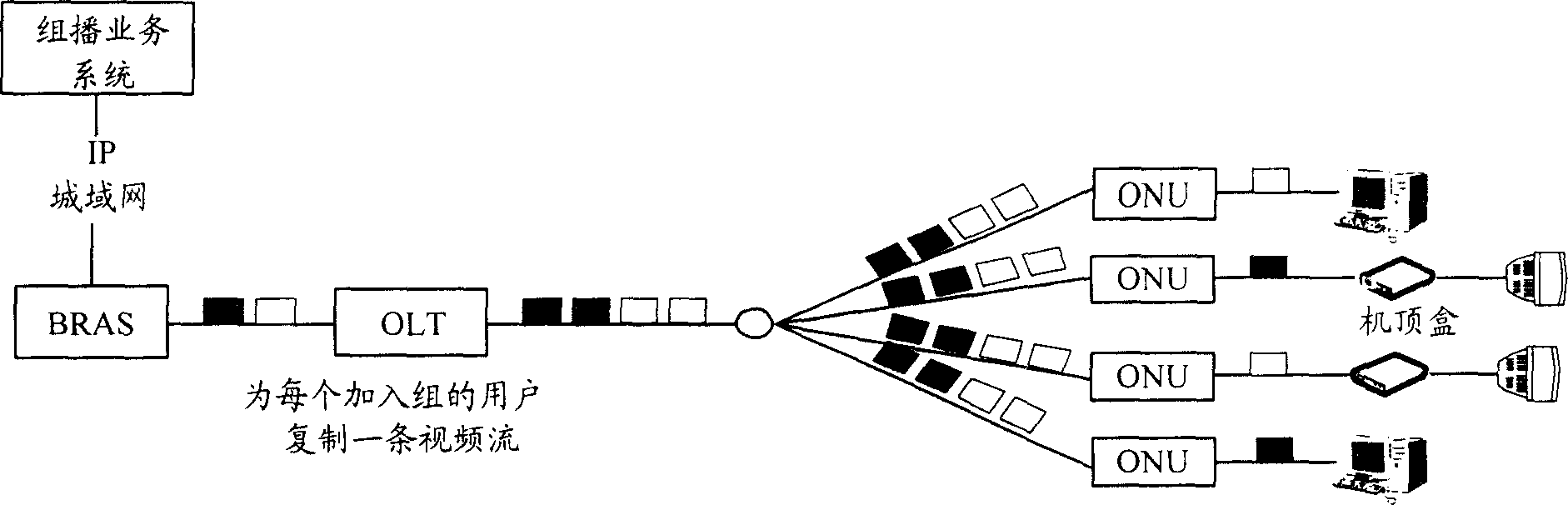

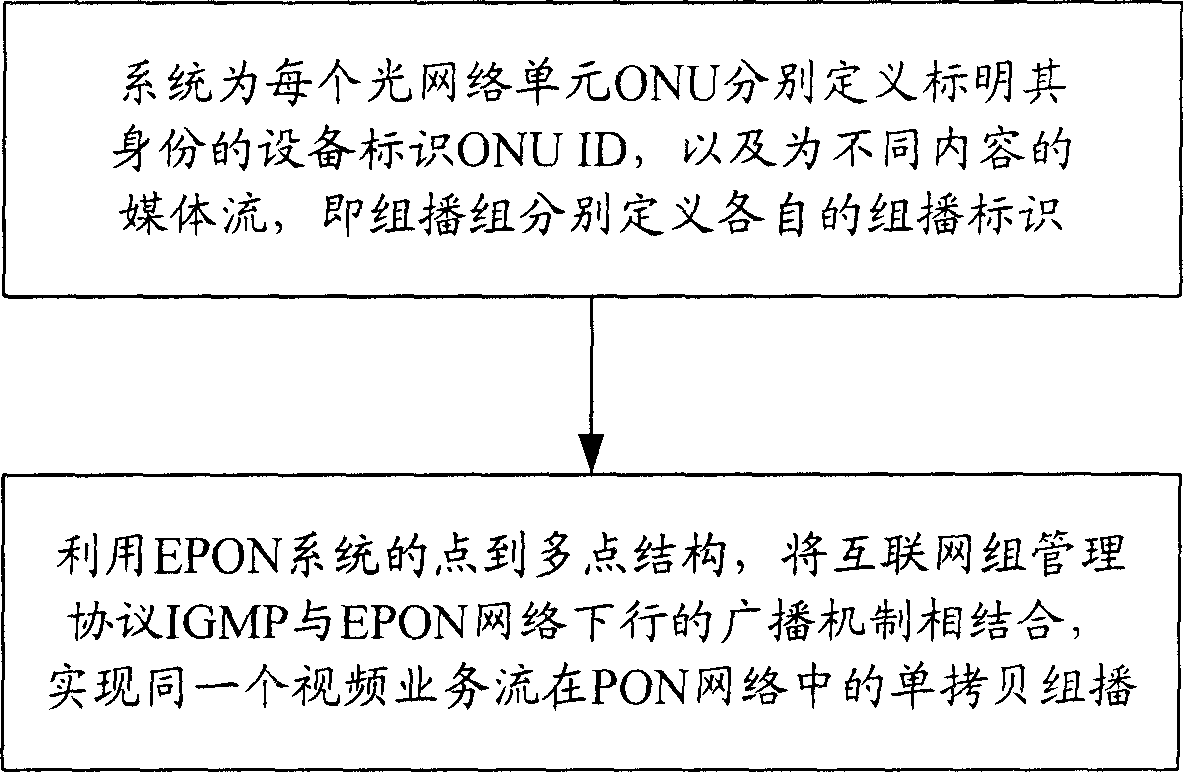

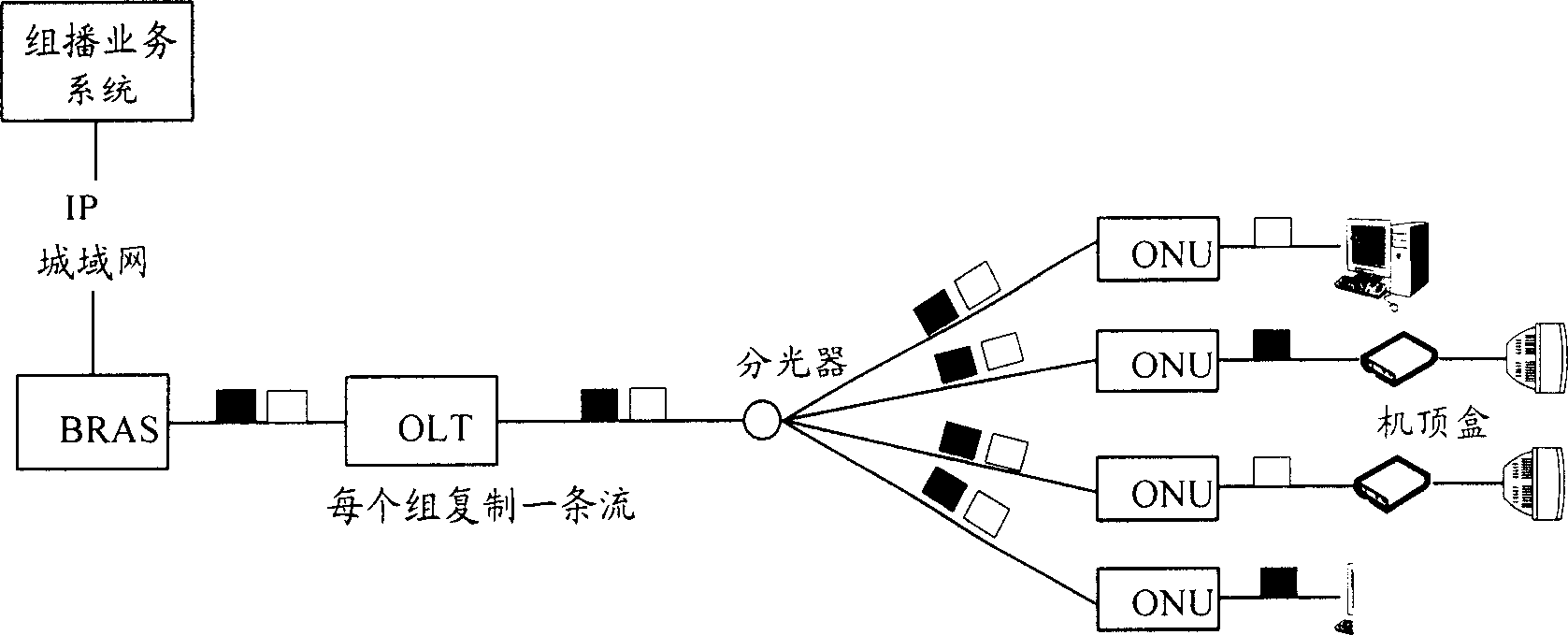

Method for realizing efficient video multicasting in ethernet passive optical entwork system

ActiveCN1744570AIncrease profitEfficient multicastTwo-way working systemsData switching networksNetworked systemThe Internet

The disclosed method is realized based on video multicast by using Internet group management protocol (IGMP) Proxy / Snooping. The method includes following operations: (1) for each optical network unit (ONU), the system defines their ID i.e. ONU ID, and defines each multicast ID for multicast group of video service stream in different content; (2) using structure from point to multipoint of Ethernet passive optical network (EPON), the method combines IGMP with down going broadcast mechanism of EPON network to realize single copy multicast of same video service stream in EPON network. Overcoming disadvantages of low use ratio of multicast bandwidth, the method reproduces only one piece of video service stream for each group on OLT for users in same group share. The invention saves network bandwidth, lowers network load. Features are: easy of implementation, forward compactable and easy to realize intercommunication with multicast protocol of data network IGMP.

Owner:CHINA TELECOM CORP LTD

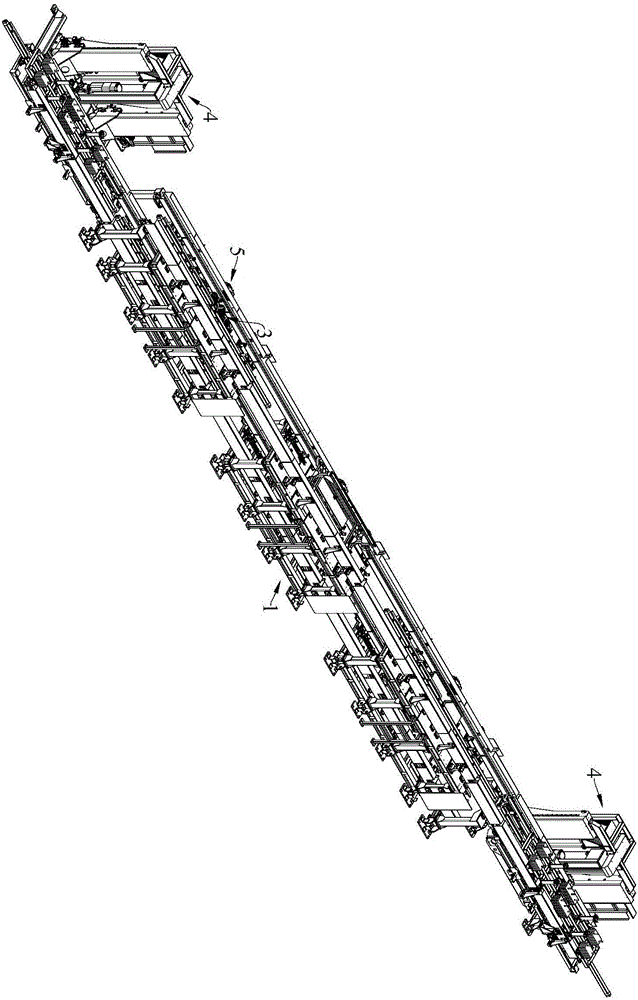

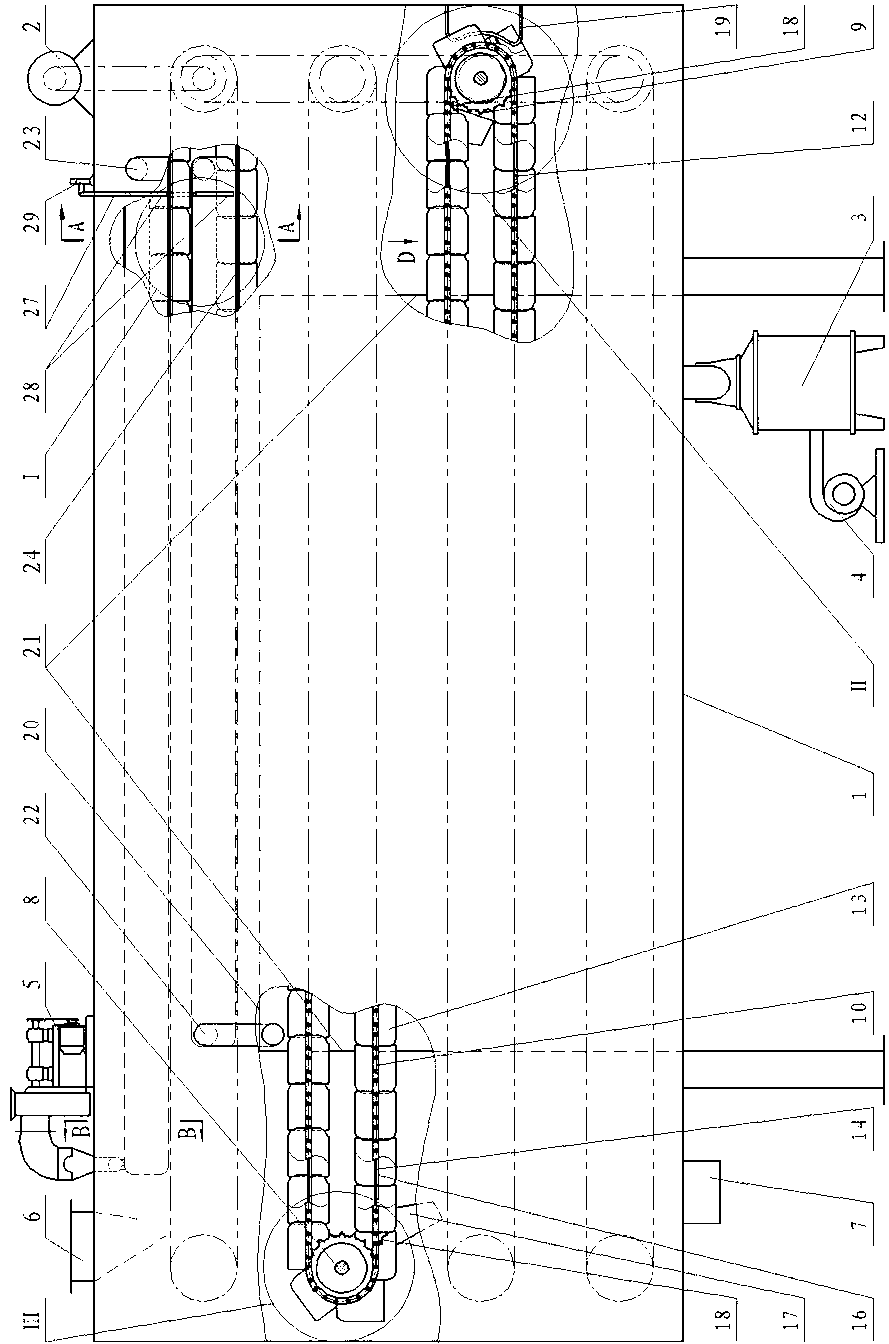

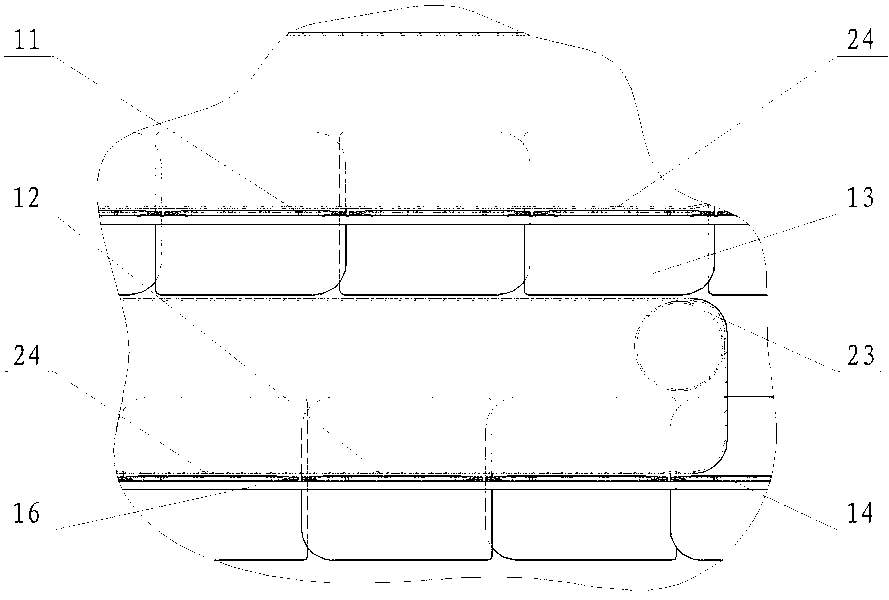

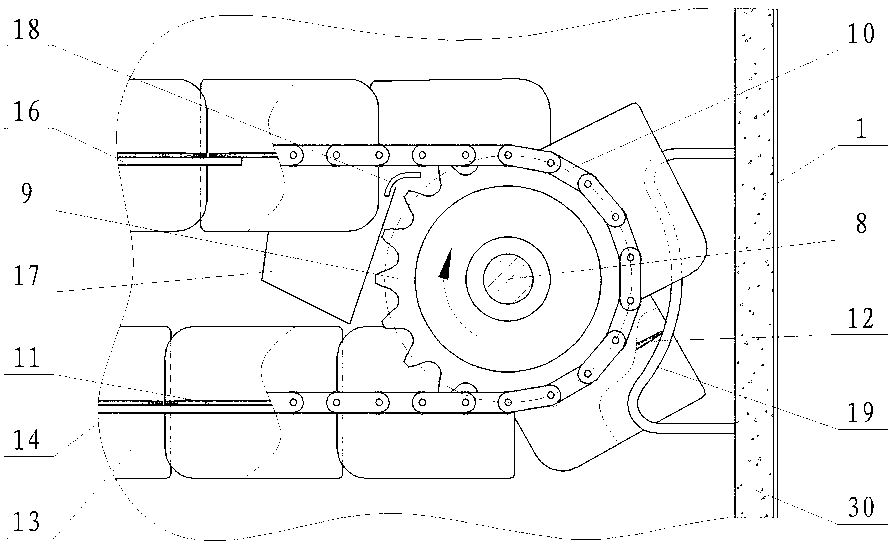

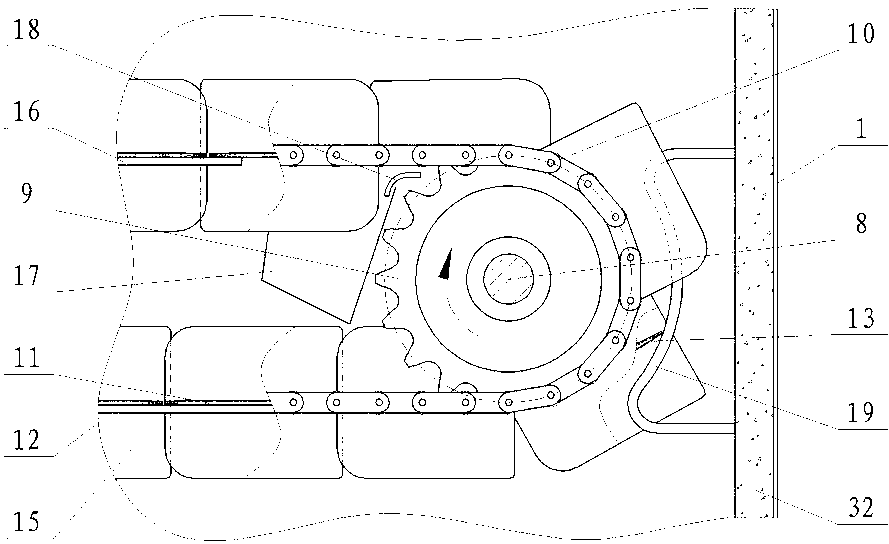

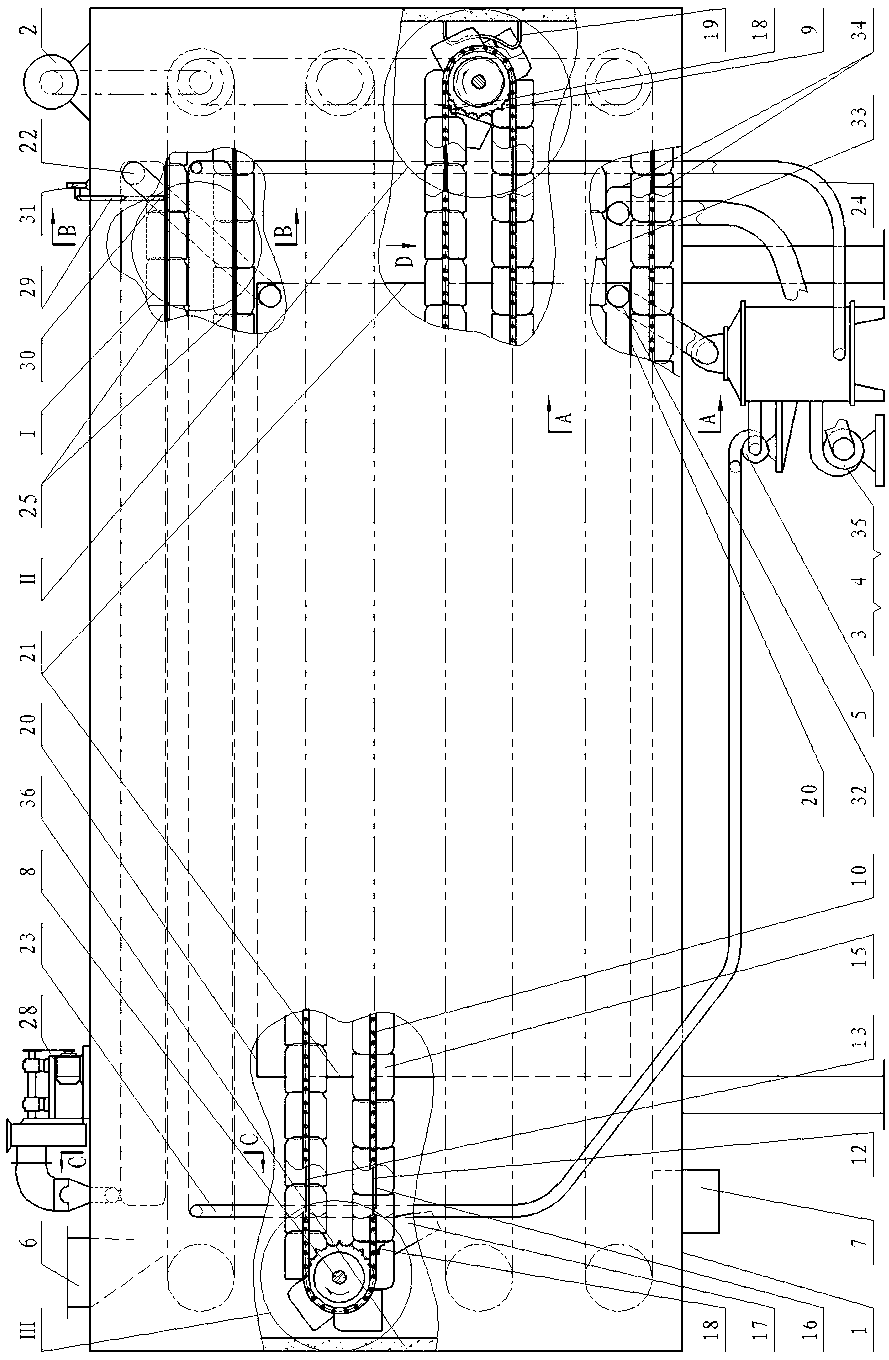

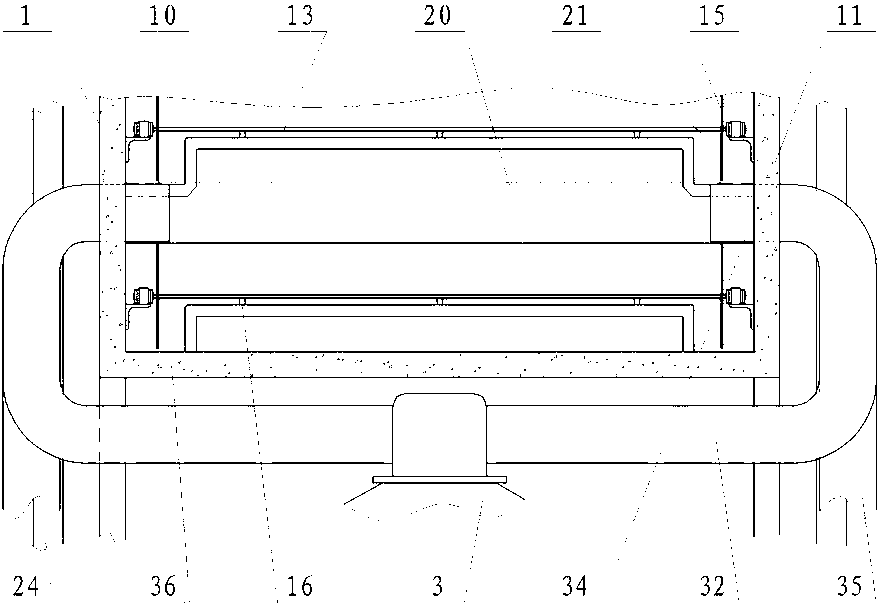

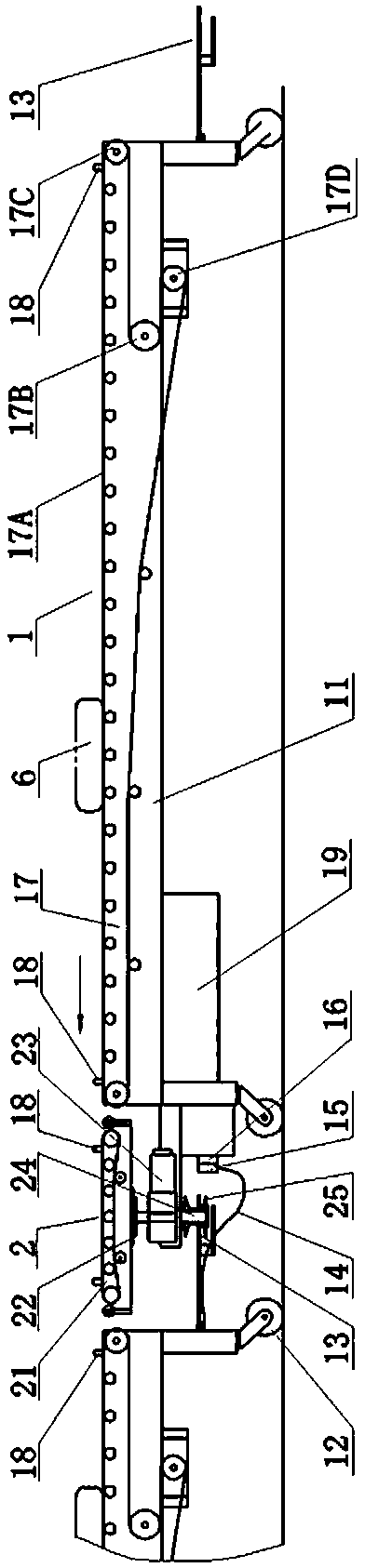

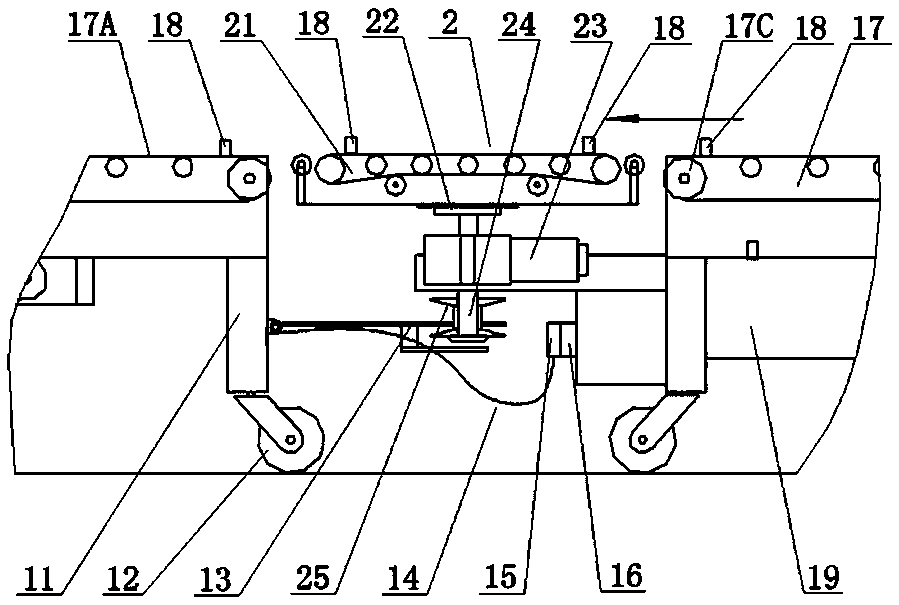

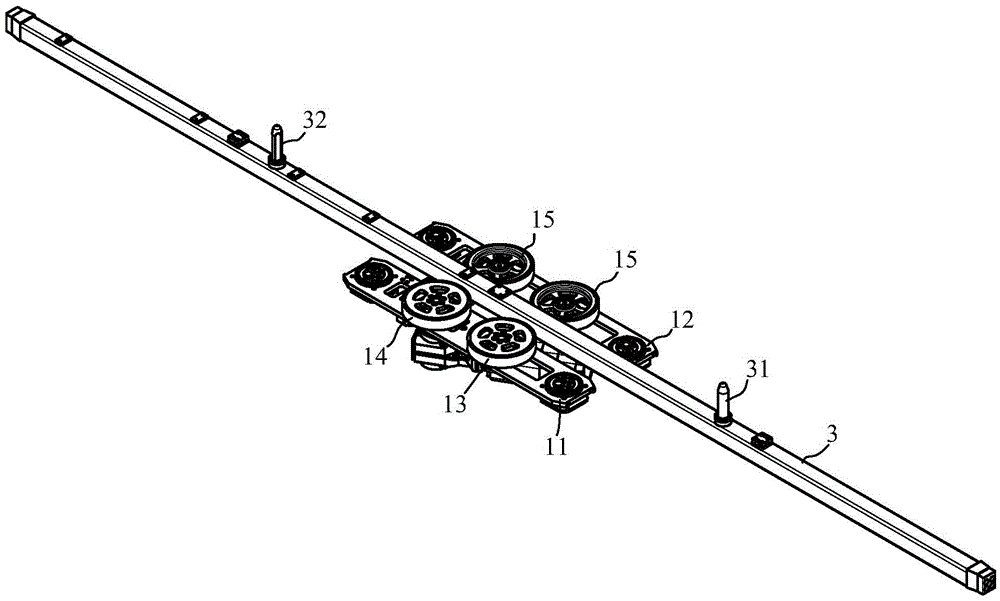

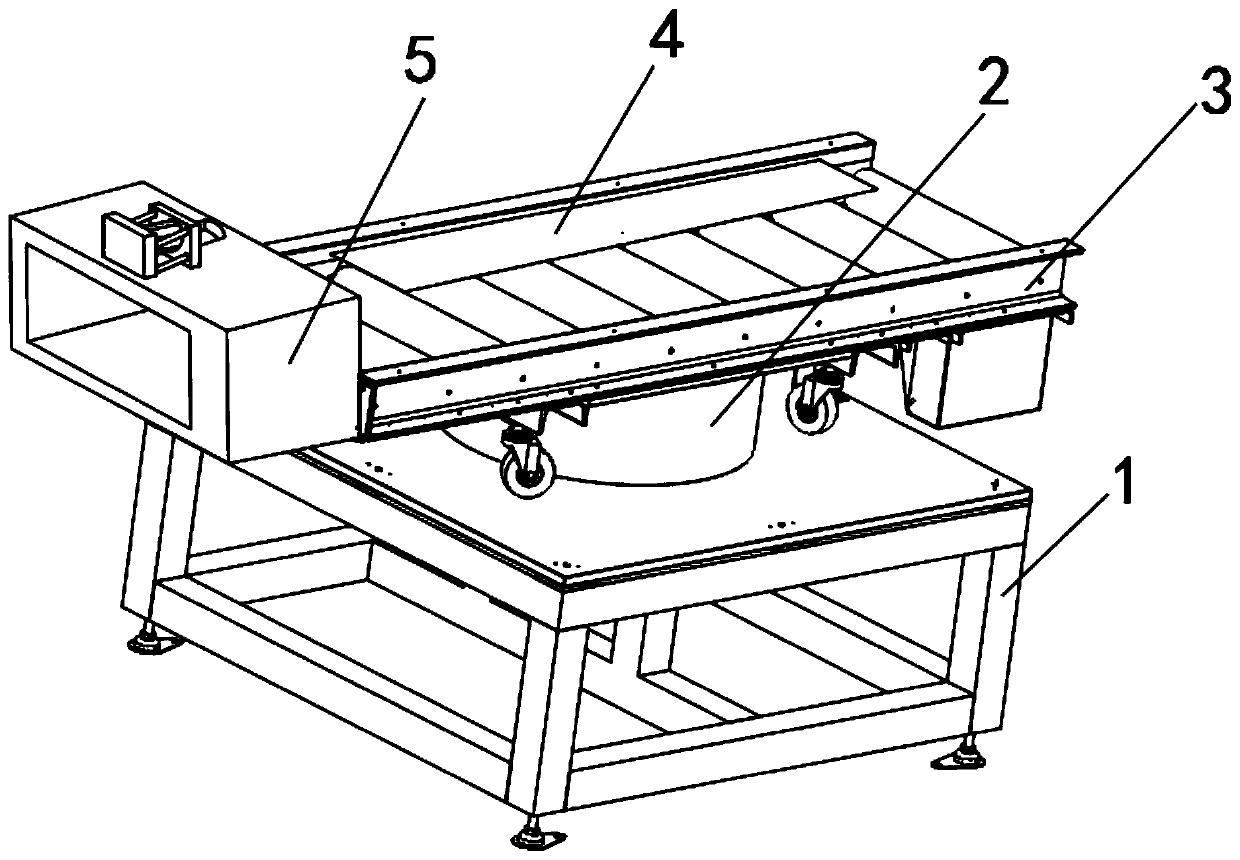

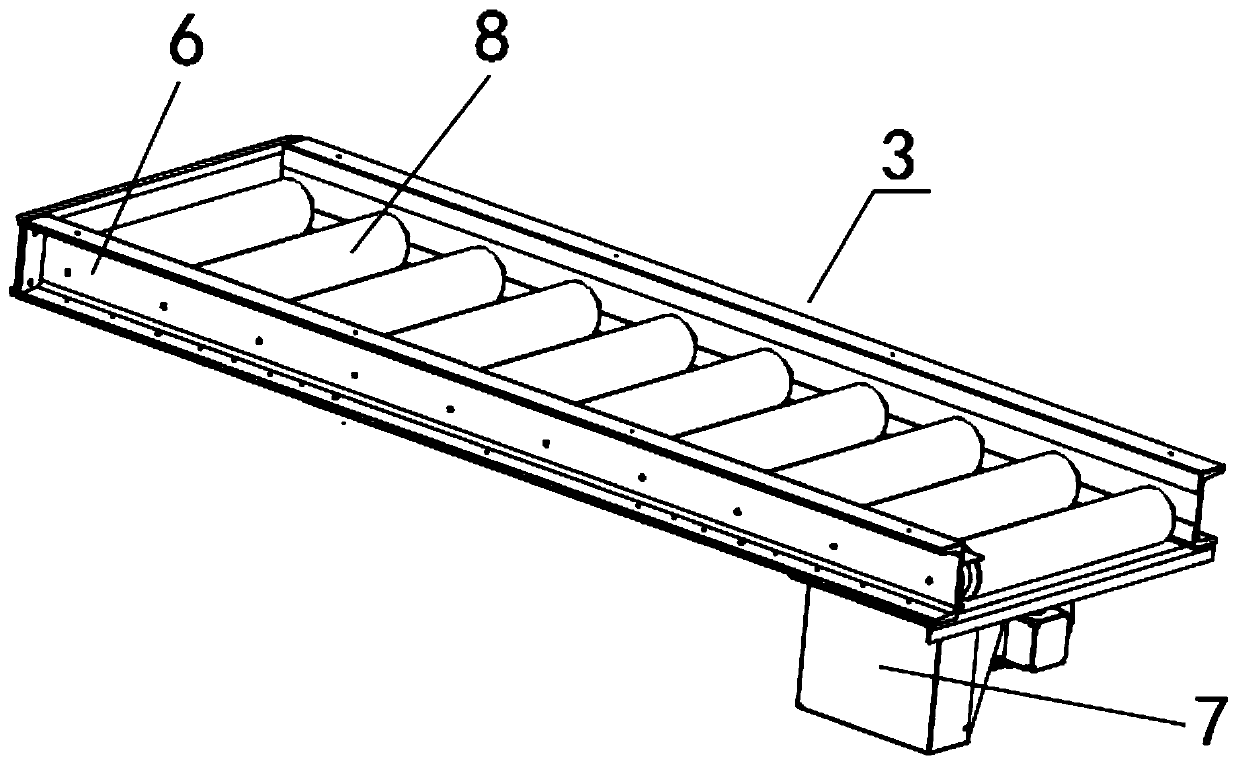

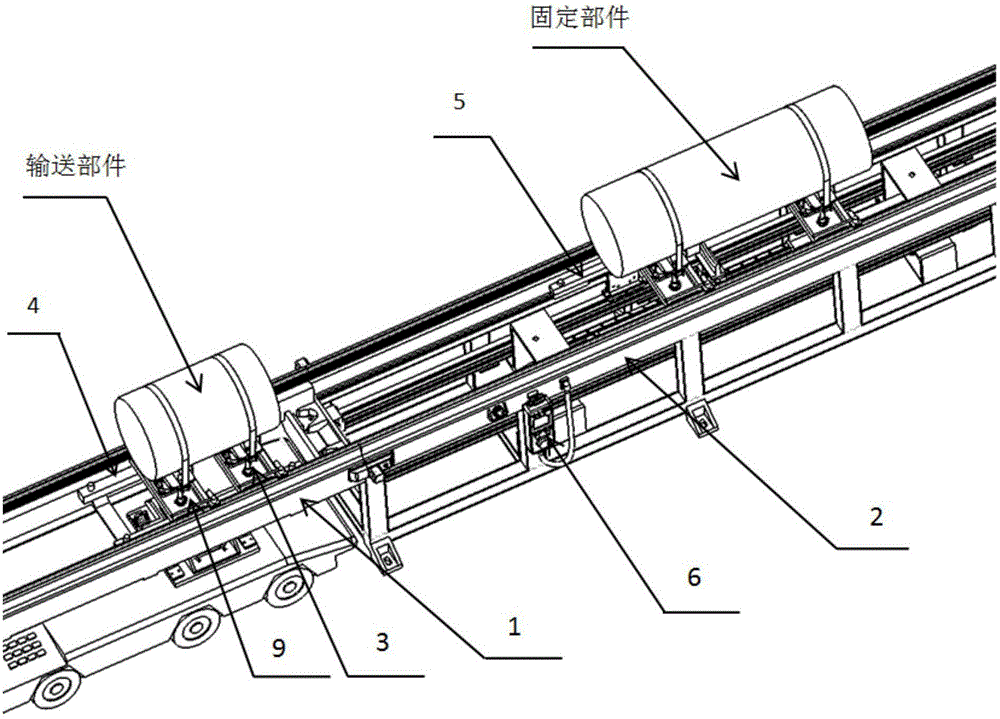

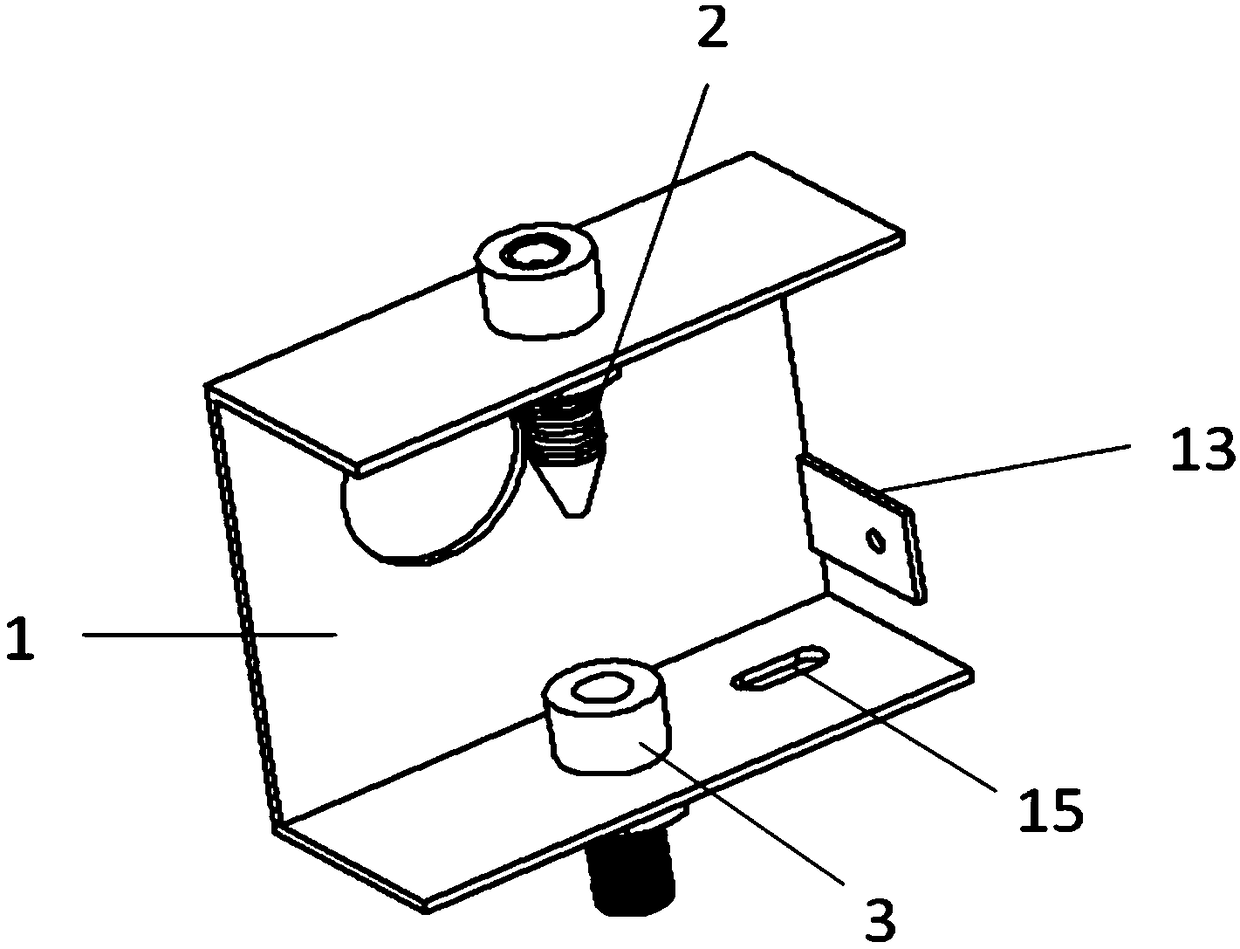

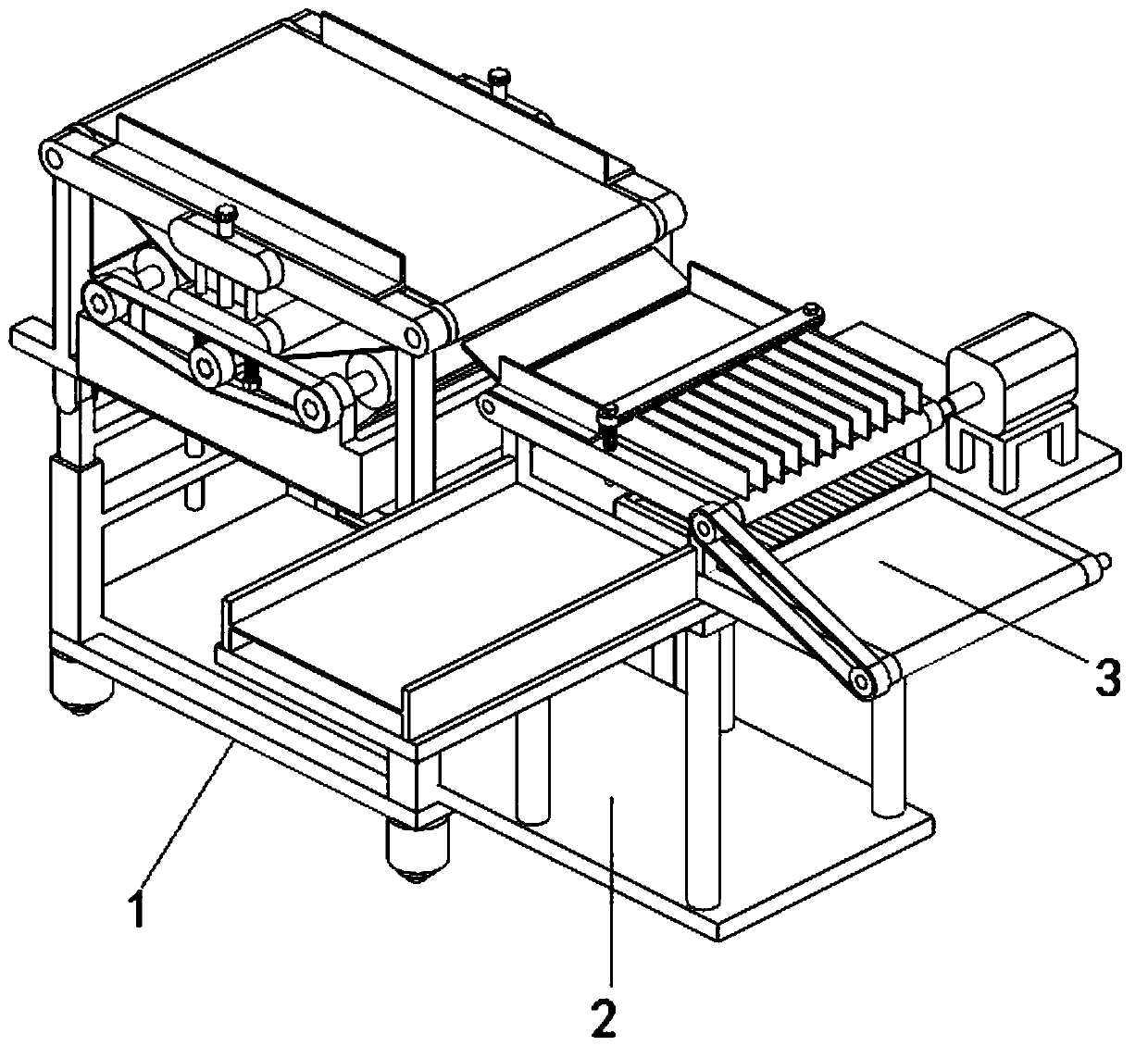

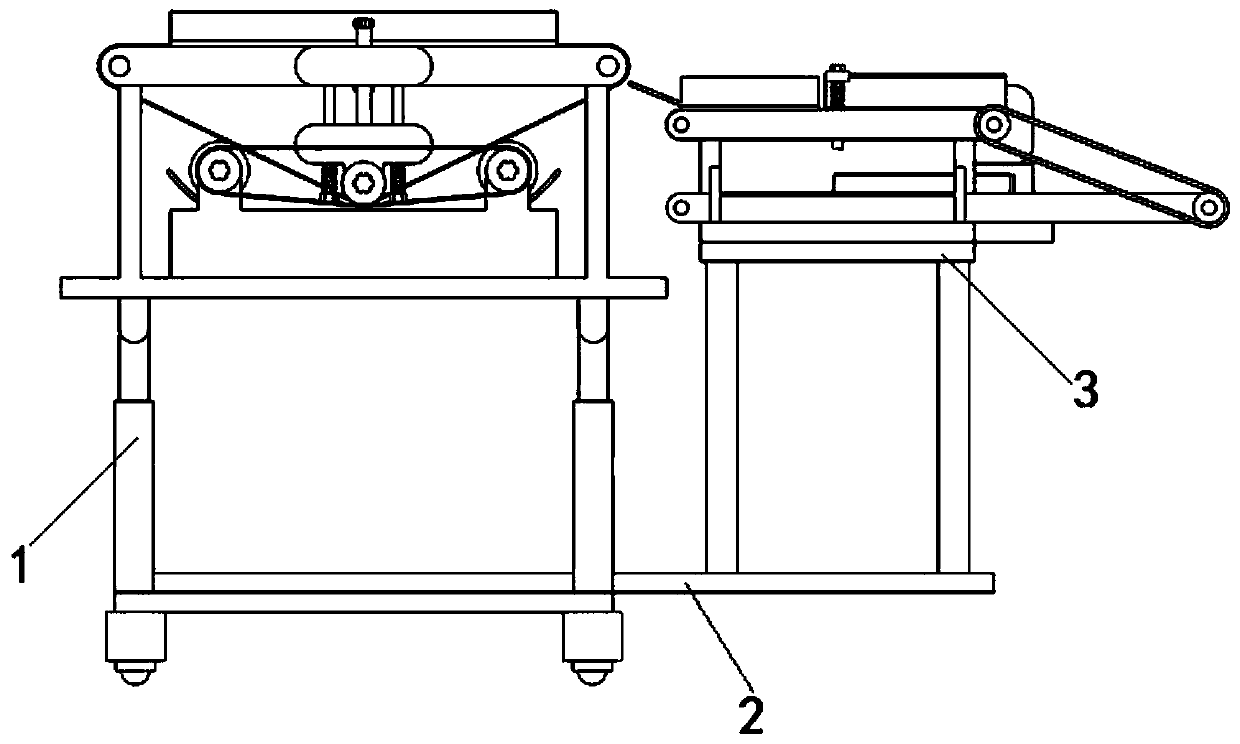

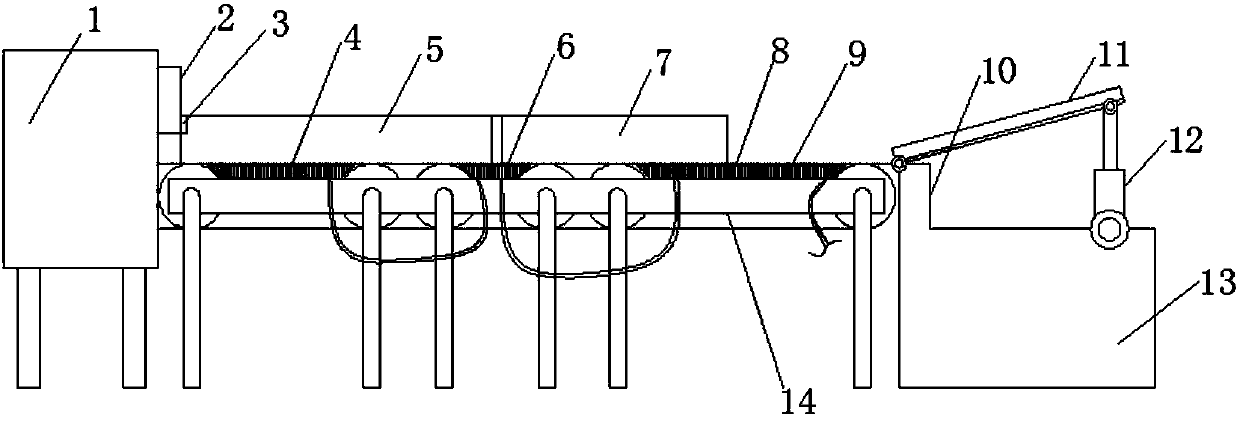

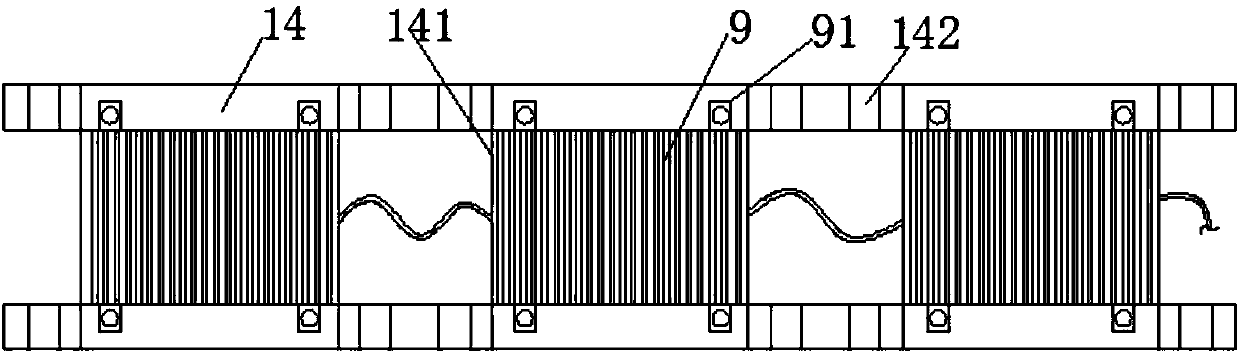

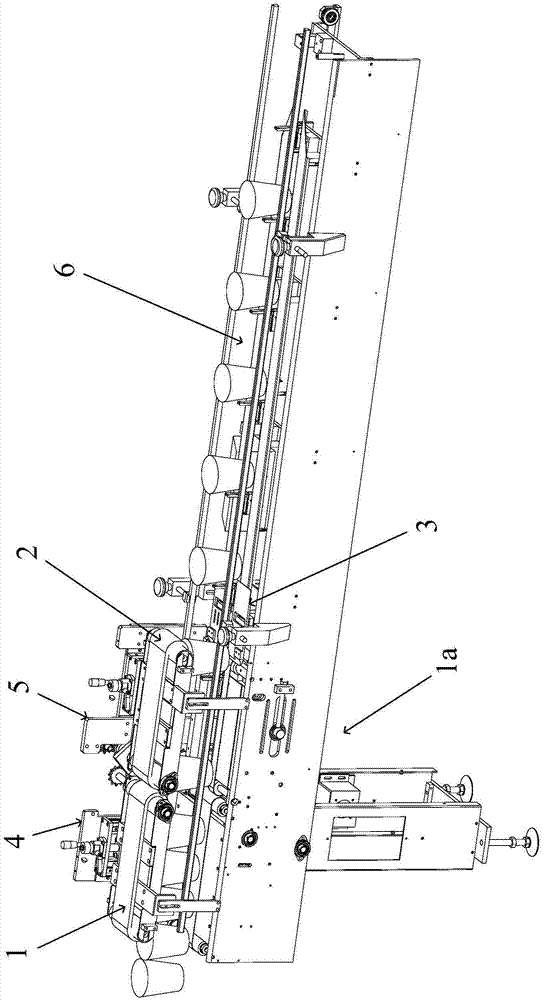

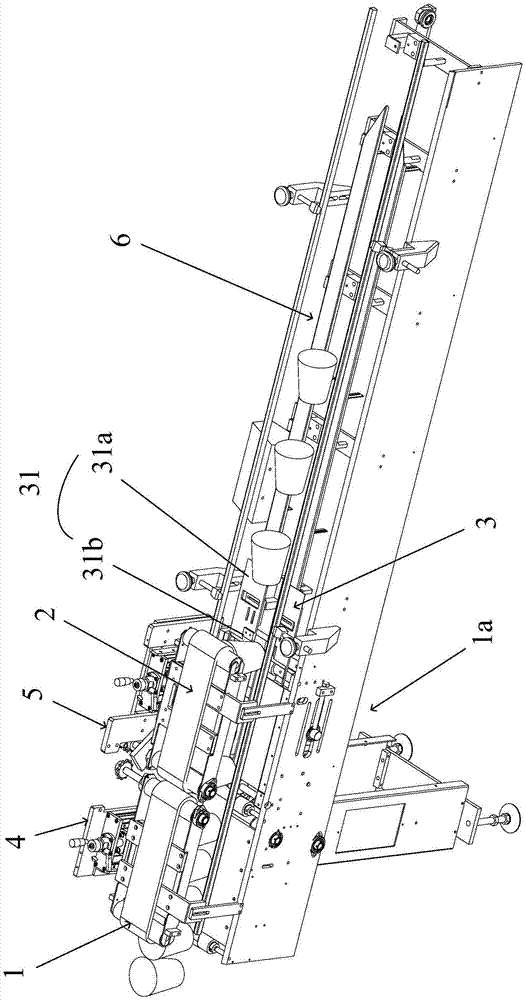

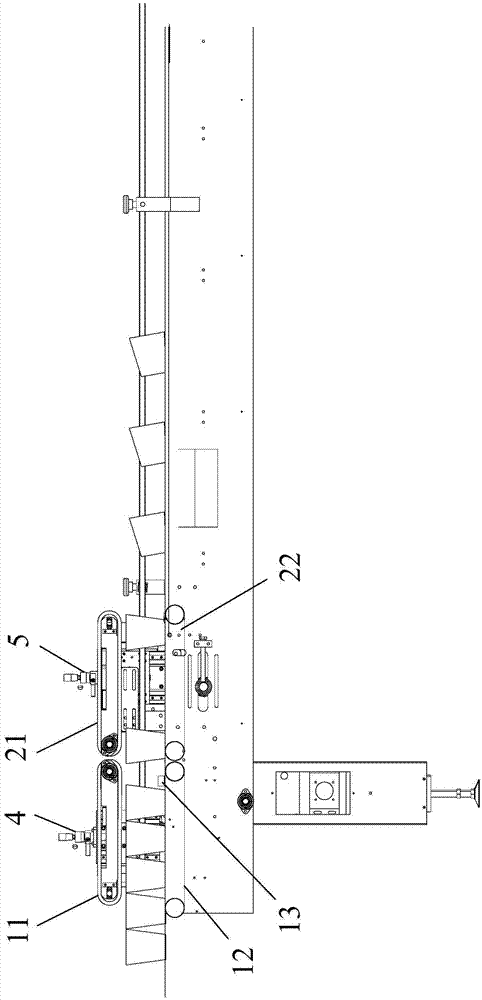

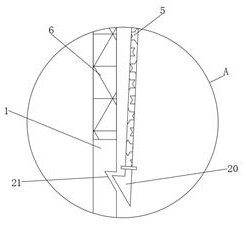

Double-layer conveying system

ActiveCN105692104AMeet delivery needsLow costConveyor partsMechanical conveyorsProduction lineUpper floor

The invention discloses a double-layer conveying system. The double-layer conveying system comprises a supporting part and a conveying trolley, and further comprises an elevator part, wherein the supporting part is provided with an upper layer of guide rails and a lower layer of guide rails; a drive part capable of driving the conveying trolley to move along the upper layer of guide rails or the lower layer of guide rails is arranged on the supporting part; a positioning unit capable of positioning the conveying trolley which moves along the upper layer of guide rails on each station is arranged on the supporting part; and the elevator part can be used for switching the conveying trolley between the upper layer of guide rails and the lower layer of guide rails. During working, a workpiece which is needed to be conveyed on a production line is placed onto the conveying trolley, and the drive part drives the conveying trolley to move along the upper layer of guide rails; when the workpiece reaches the corresponding station, the positioning unit is used for positioning and locking the conveying trolley, and the positioning unit is combined with the elevator part for switching the conveying trolley between the upper layer of guide rails and the lower layer of guide rails, so that long-distance, high-speed and high-precision conveying of the industrial manufacturing automatic production line is completed; and with the design, the cost can be reduced, the performances are reliable, the mounting is convenient, and the conveying needs of the industrial automatic production line are met.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

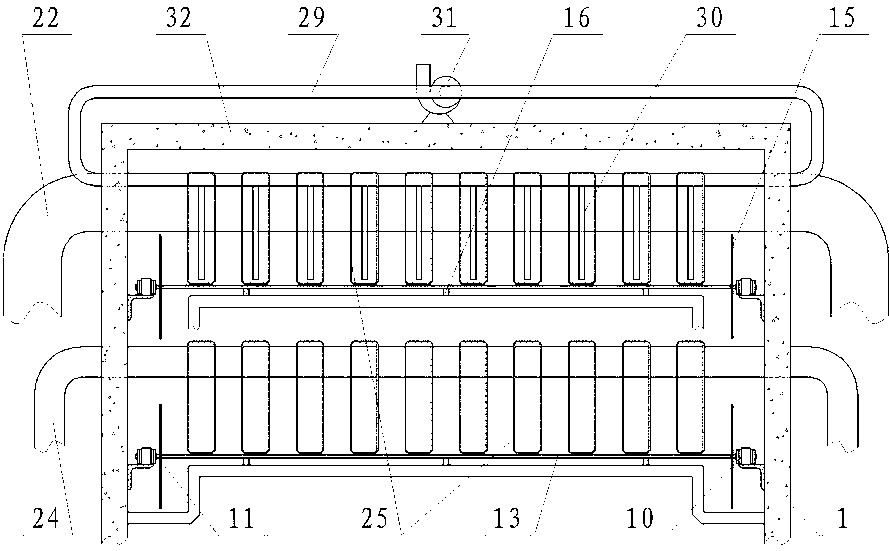

Waste heat recovering ear-corn drying machine

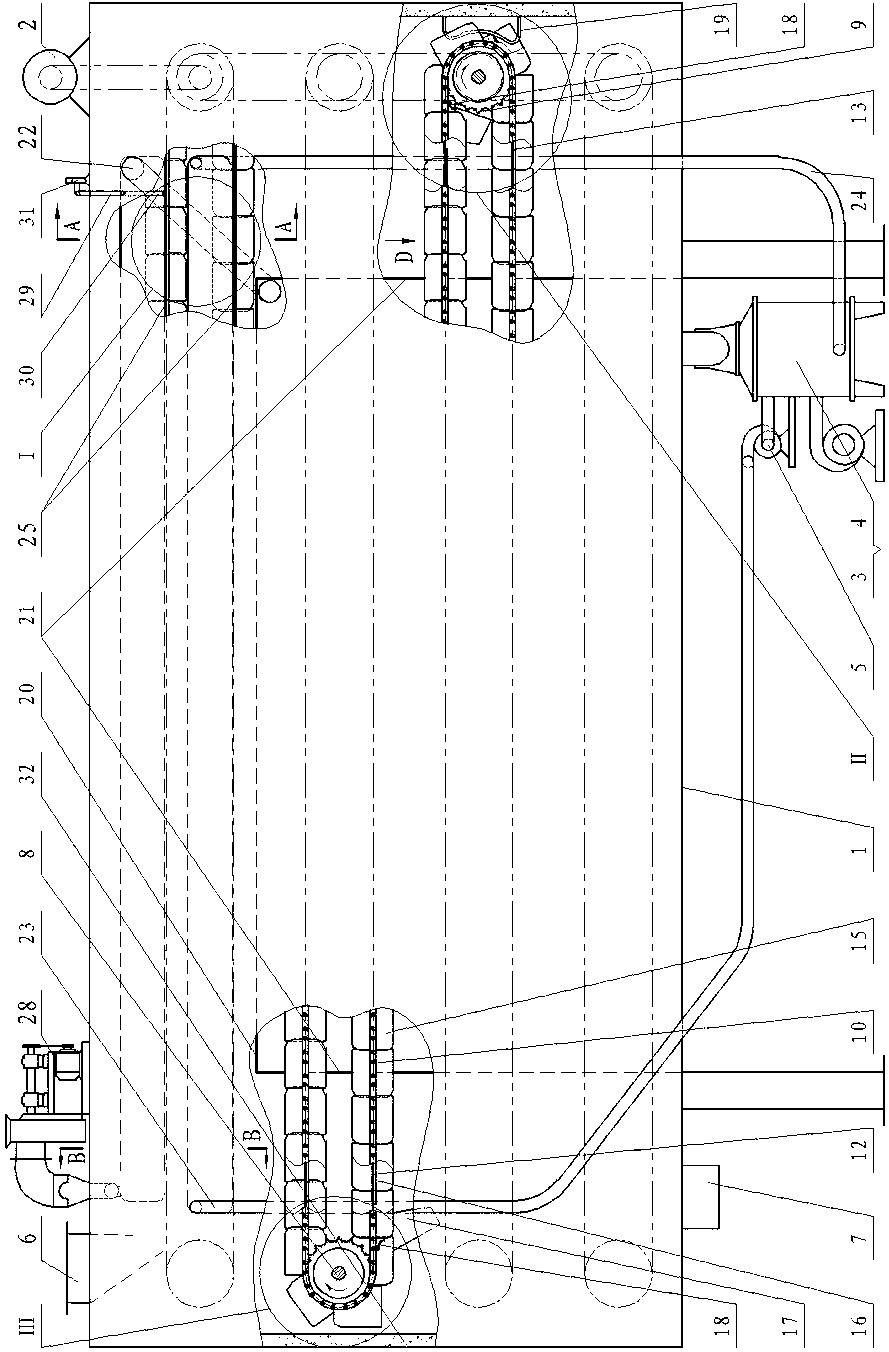

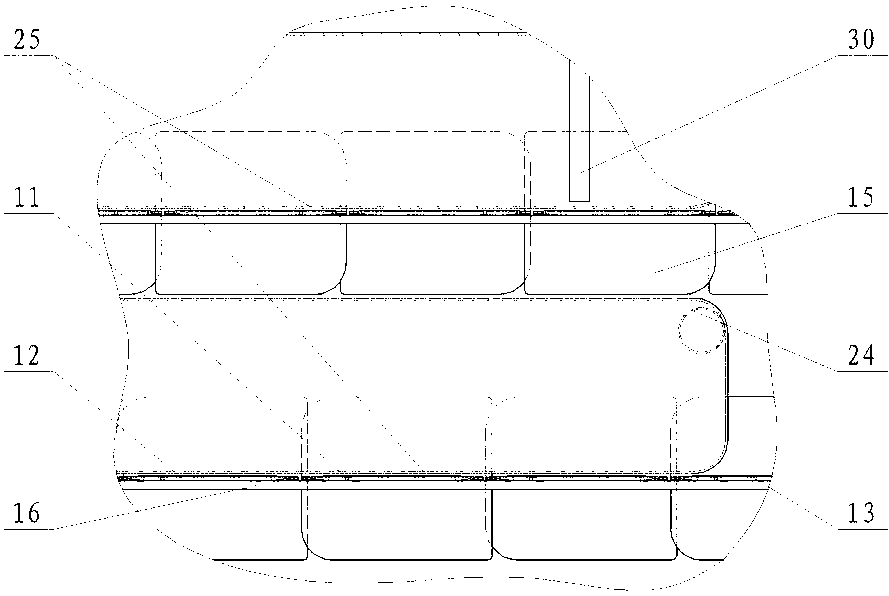

InactiveCN103070234AOptimized drying programKeep dryFood processingClimate change adaptationChinese charactersEngineering

The invention provides a waste heat recovering ear-corn drying machine, which is characterized in that the chamber of the drying machine is divided into an upper area and a lower area by a partition I; the lower area is divided into three parts by partitions II; the bottom of the middle chamber is provided with an air heater with a blower; a plurality of heat exchange boxes are arranged in the upper area and are communicated with one another by annular air pipes; the heat exchange boxes on the lower part are communicated with the middle of the lower area of the chamber; the heat exchange boxes on the upper part are connected with an induced draft fan mounted at the top of the chamber; a water pump at the top of the chamber is connected with a straight pipe inserted in each heat exchange box by a water pipe which is shaped like a Chinese character 'YUE'; a plurality of conveying devices running under the driving of a driving device are arranged in the chamber; molding link plates of I and II types are hung on a pin shaft extending out of the inner side of a conveying chain at intervals and are arrayed and supported on a guide rail to form a trough material channel; a guide chute is arranged below the tail end of the channel; and a feed inlet and a discharge port are formed at the top and the bottom of the chamber respectively. The waste heat recovering ear-corn drying machine is large in moisture reducing range, good in preheating effect and reliable in working.

Owner:SHANDONG UNIV OF TECH

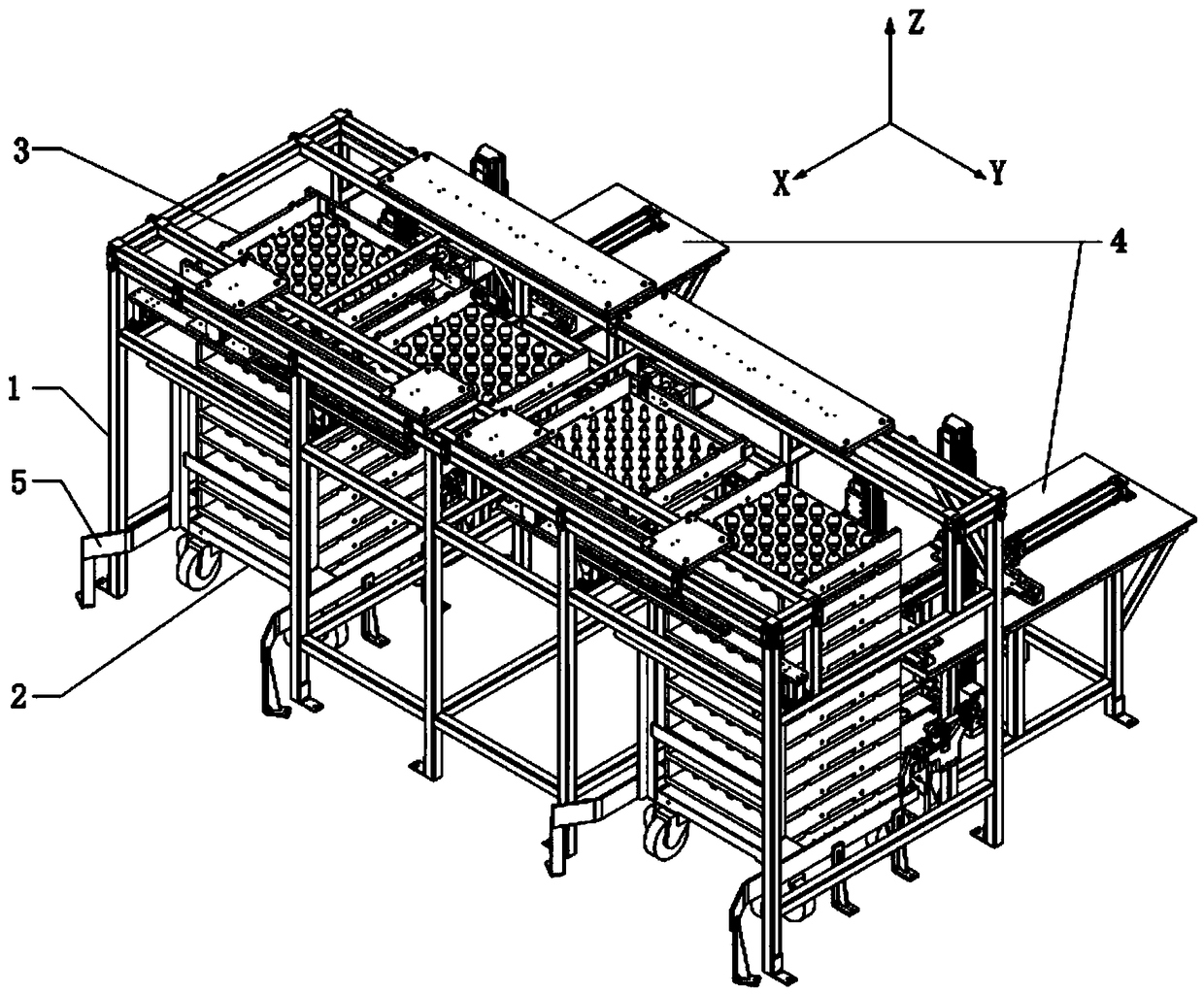

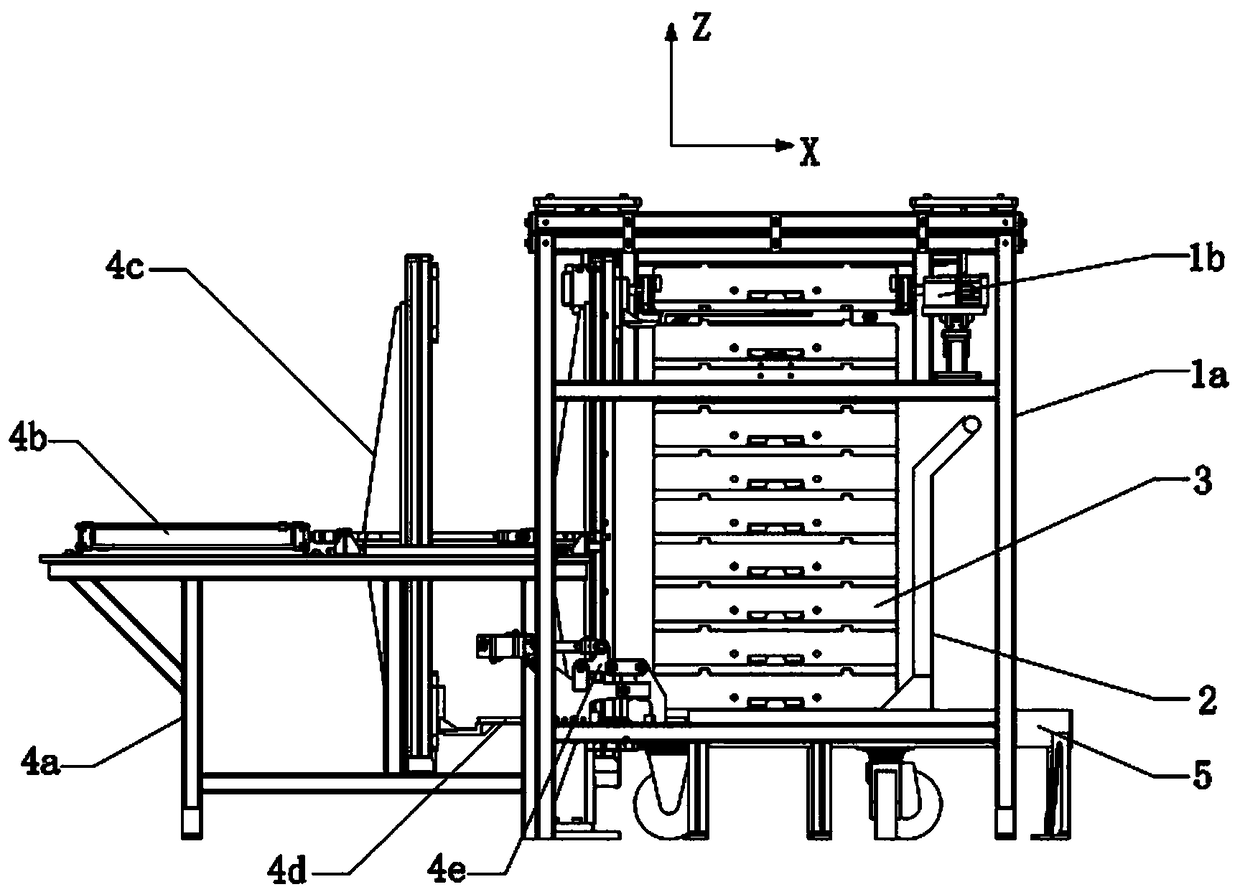

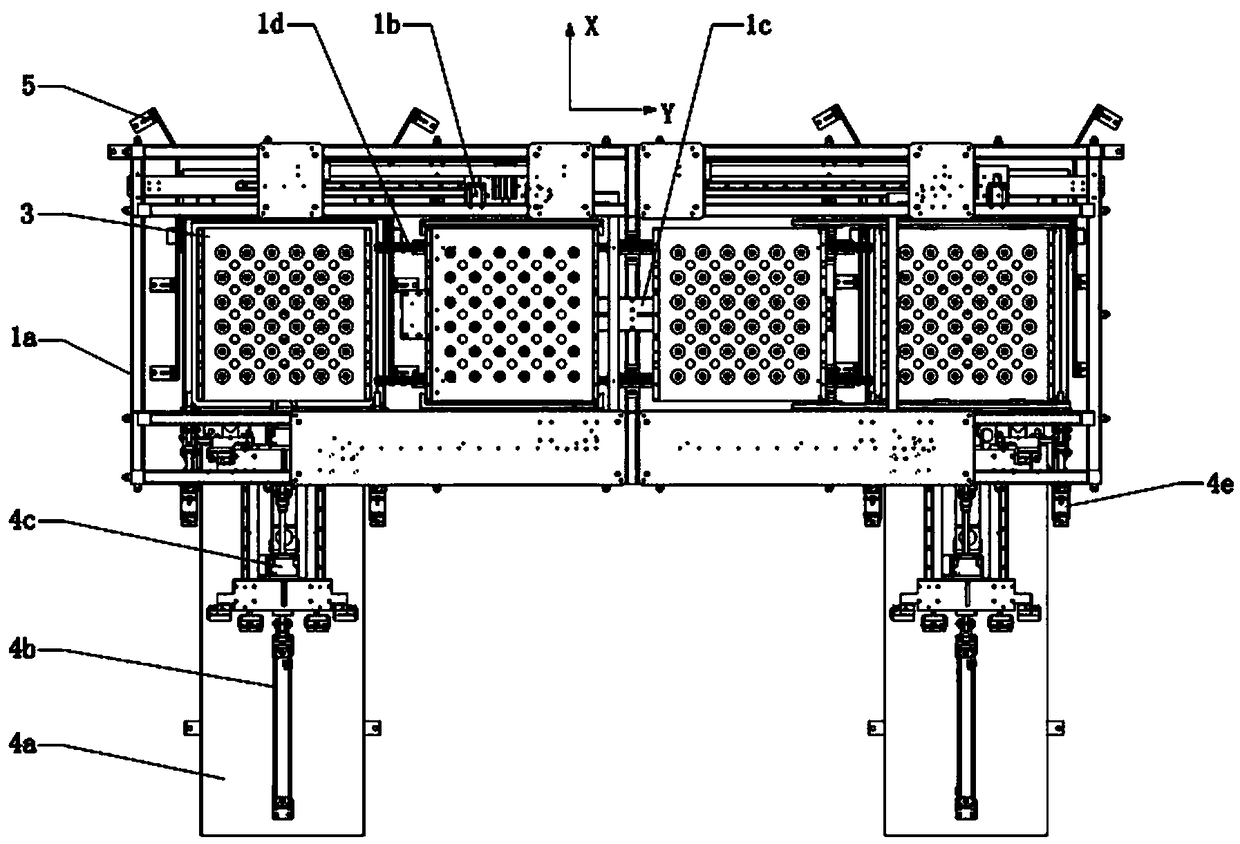

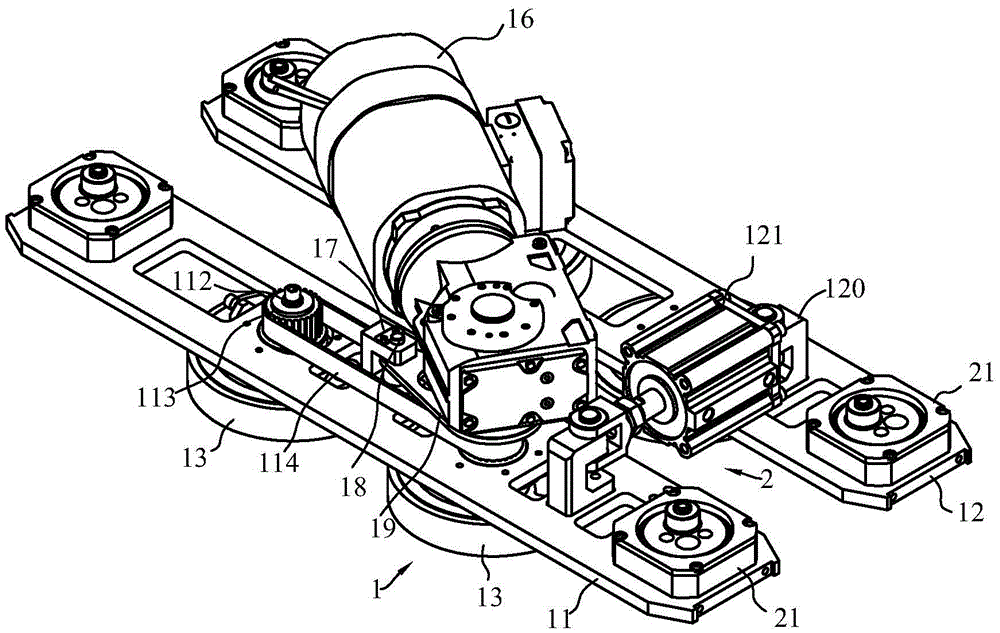

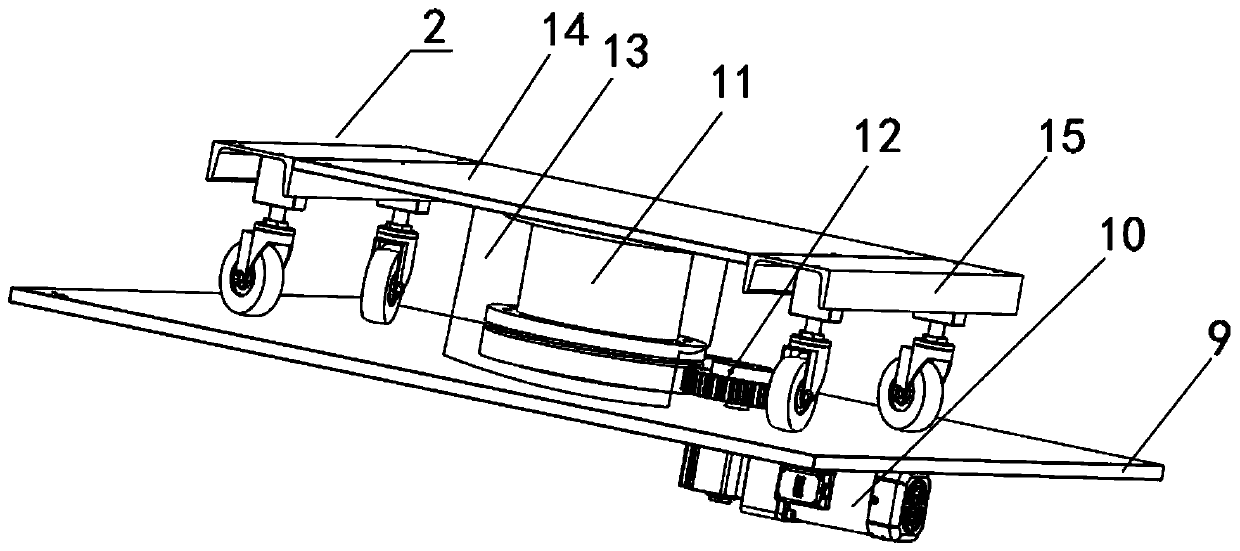

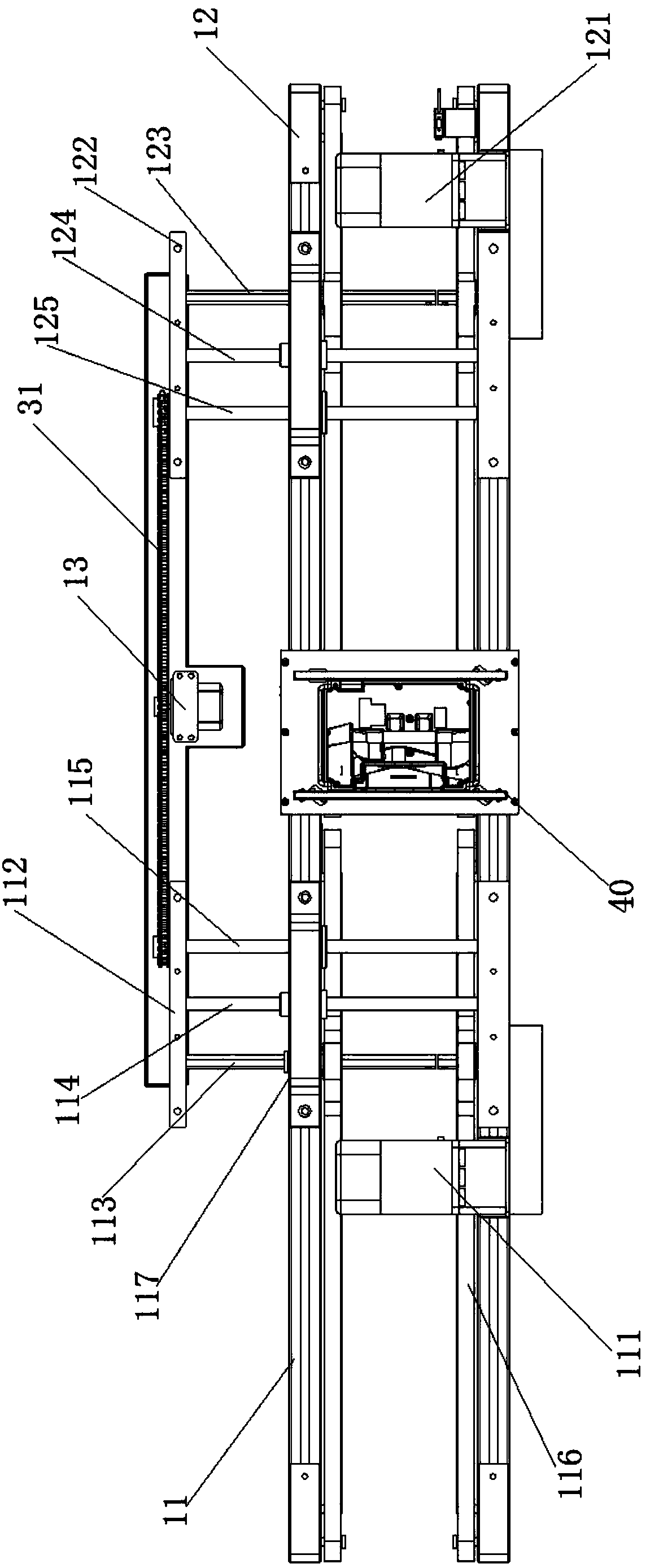

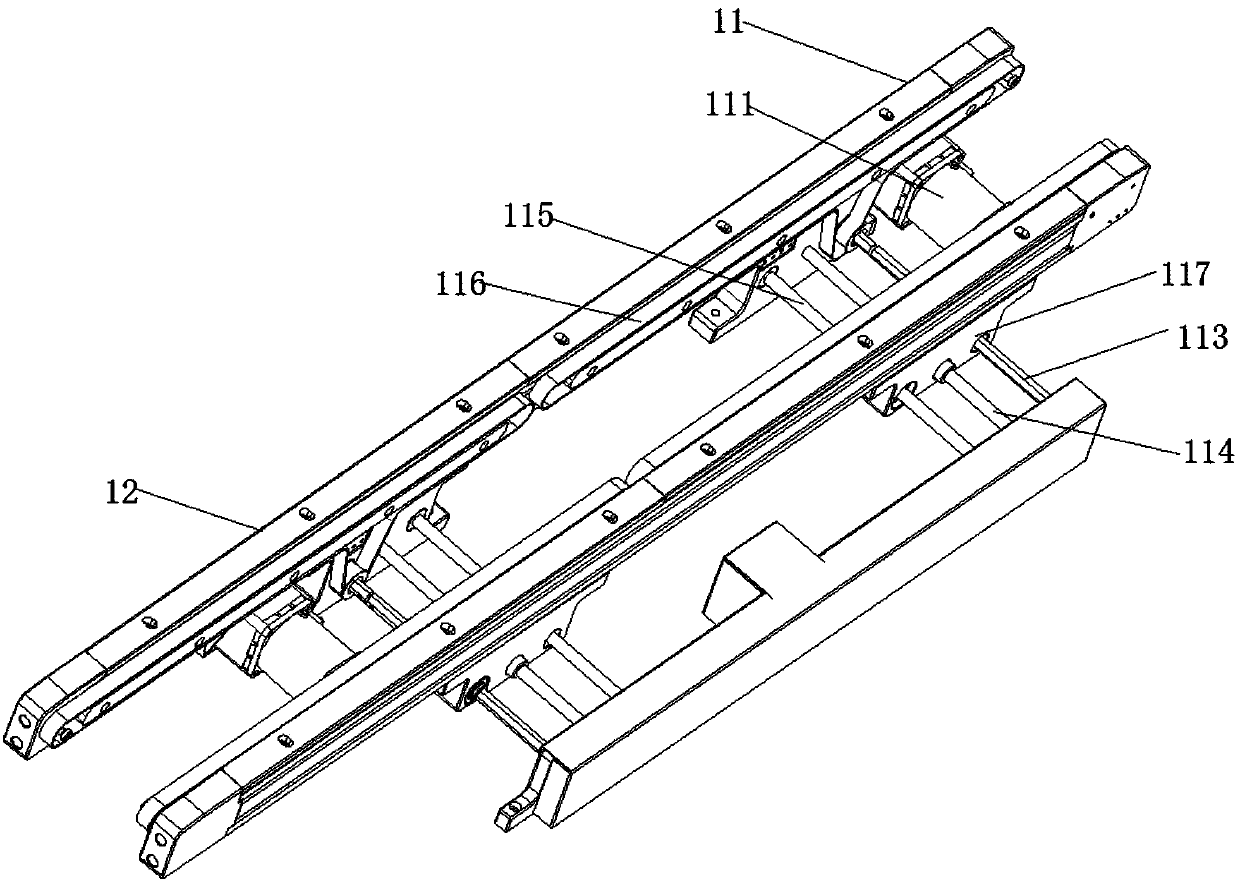

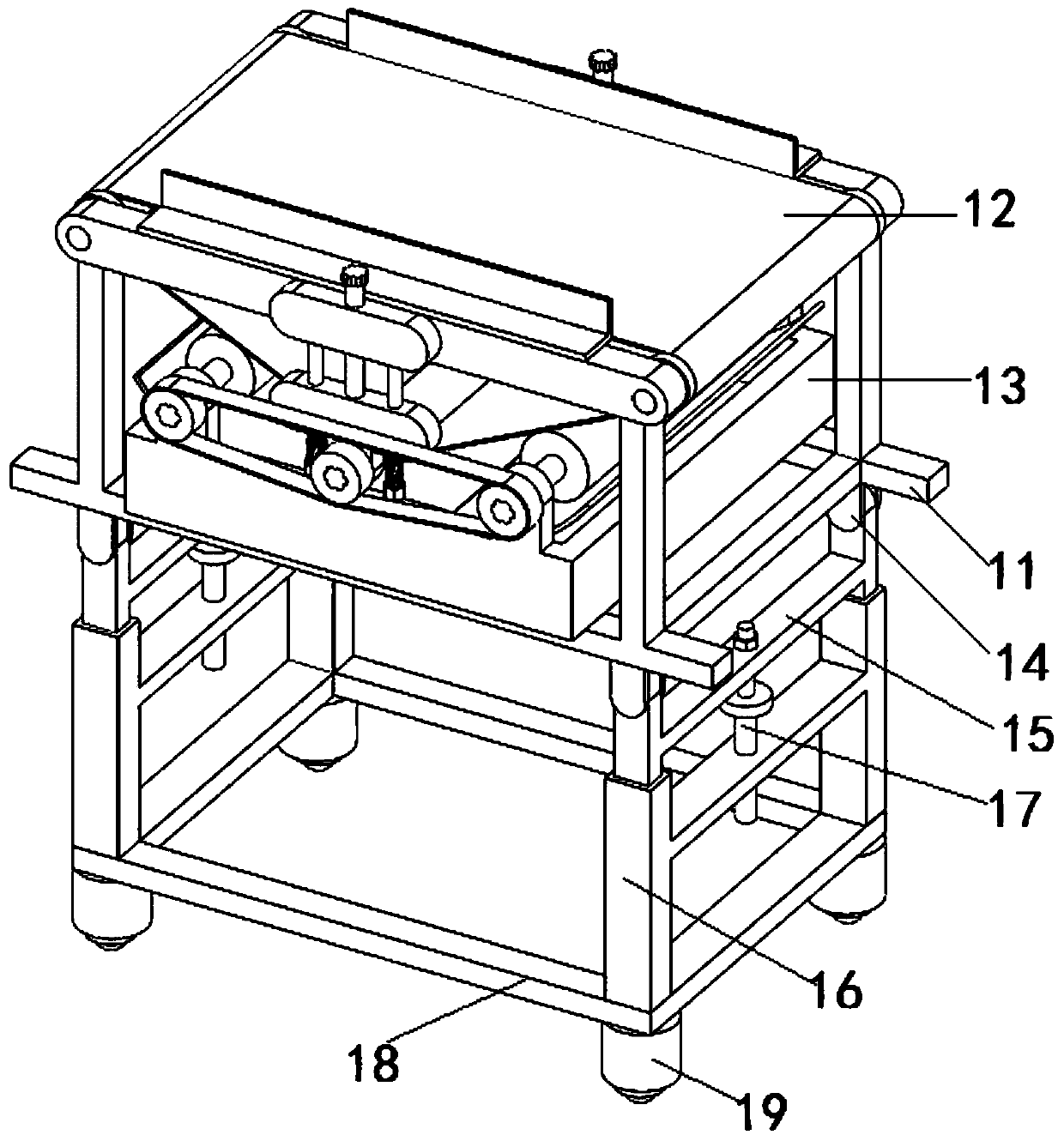

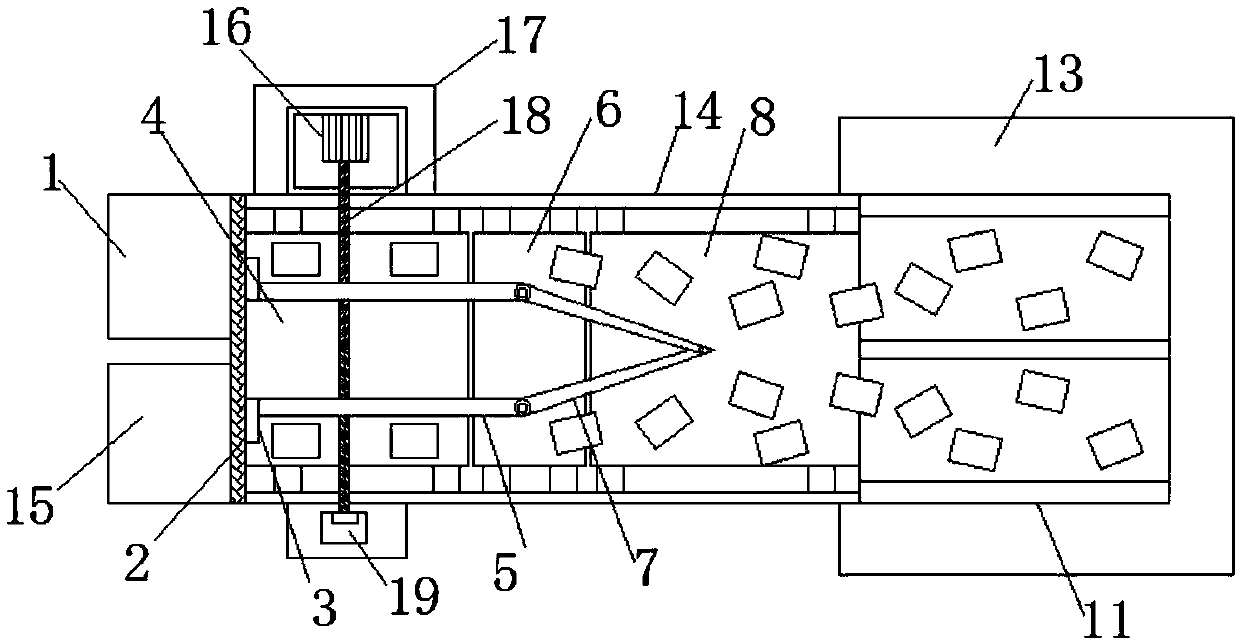

Tray conveying and switching system on automatic production line

ActiveCN109018951AMeet delivery needsSmall footprintTotal factory controlConveyor partsProduction lineManufacturing cost reduction

The invention relates to a tray conveying and switching system on an automatic production line. The tray conveying and switching system comprises a supporting unit, trolleys, trays and tray lifting units. The supporting unit comprises a supporting frame, a tray Y-direction translation clamping mechanism and a tray locating mechanism. The supporting frame comprises a feeding station, a grabbing station, a reassembly station and a discharging station. The two tray lifting units are mounted on the back face of the supporting frame, one tray lifting unit is aligned to the back face of the feedingstation, and the other tray lifting unit is aligned to the discharging station. The number of the trolleys is two, one trolley is pushed in from the front face of the supporting frame and is fixed below the feeding station, and the other trolley is pushed in from the front face of the supporting frame and fixed below the discharging station. The multiple layers of trays are stacked on the trolleylocated below the feeding station, and the tray lifting units can move the trays in the direction Z. The tray conveying and switching system has the advantages of being simple in structure, convenientto mount and small in occupied area, reducing the manufacturing cost and achieving automatic line production.

Owner:GUANGZHOU ZSROBOT INTELLIGENT EQUIP CO LTD

Water circulation pre-heating type corncob drier

InactiveCN103070235AKeep dryImprove uniformitySeed preservation by dryingWater circulationEngineering

The invention provides a water circulation pre-heating type corncob drier. The water circulation pre-heating type corncob drier is characterized in that a box is partitioned into an upper region and a lower region by a partition plate I; the lower region is partitioned into three parts by partition plates II; a water gas heater is arranged at the bottom of the middle of the box; one end of a heat exchange box above a first conveying device is communicated with the middle of the box, and the other end of the heat exchange box is connected with an induced draft fan which is arranged on the top of the box; two ends of each heat exchange box between upper and lower groove-shaped material channels of the first conveying device are connected with the water gas heater through a circulating water pump; a condensing water pump which is arranged on the top of the box is connected with a straight water pipe which is inserted into each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device to rotate are arranged in the box; a first moulding chain plate and a second moulding chain plate are suspended on a pin shaft of a chain extending inwards at intervals and supported on a guide rail to form a groove-shaped material channel; a material guide groove is formed below the tail end of the channel; a charging hole is formed on the top of the box; and a discharging hole is formed at the bottom of the box. The water circulation pre-heating type corncob drier is good in preheating and drying effect, and reliable in operation.

Owner:SHANDONG UNIV OF TECH

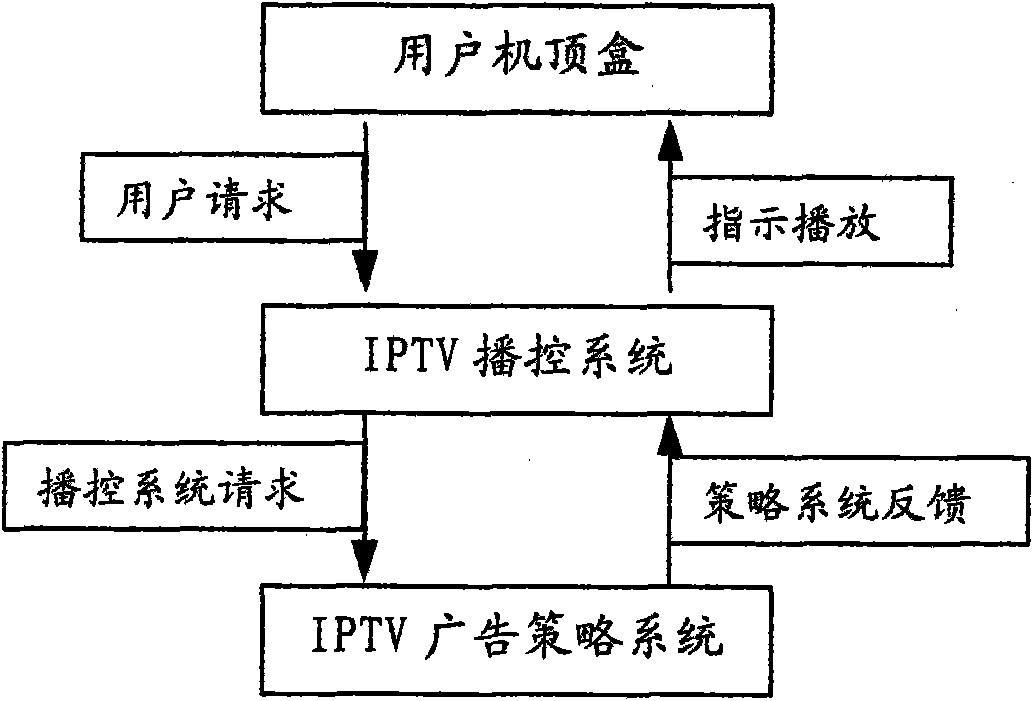

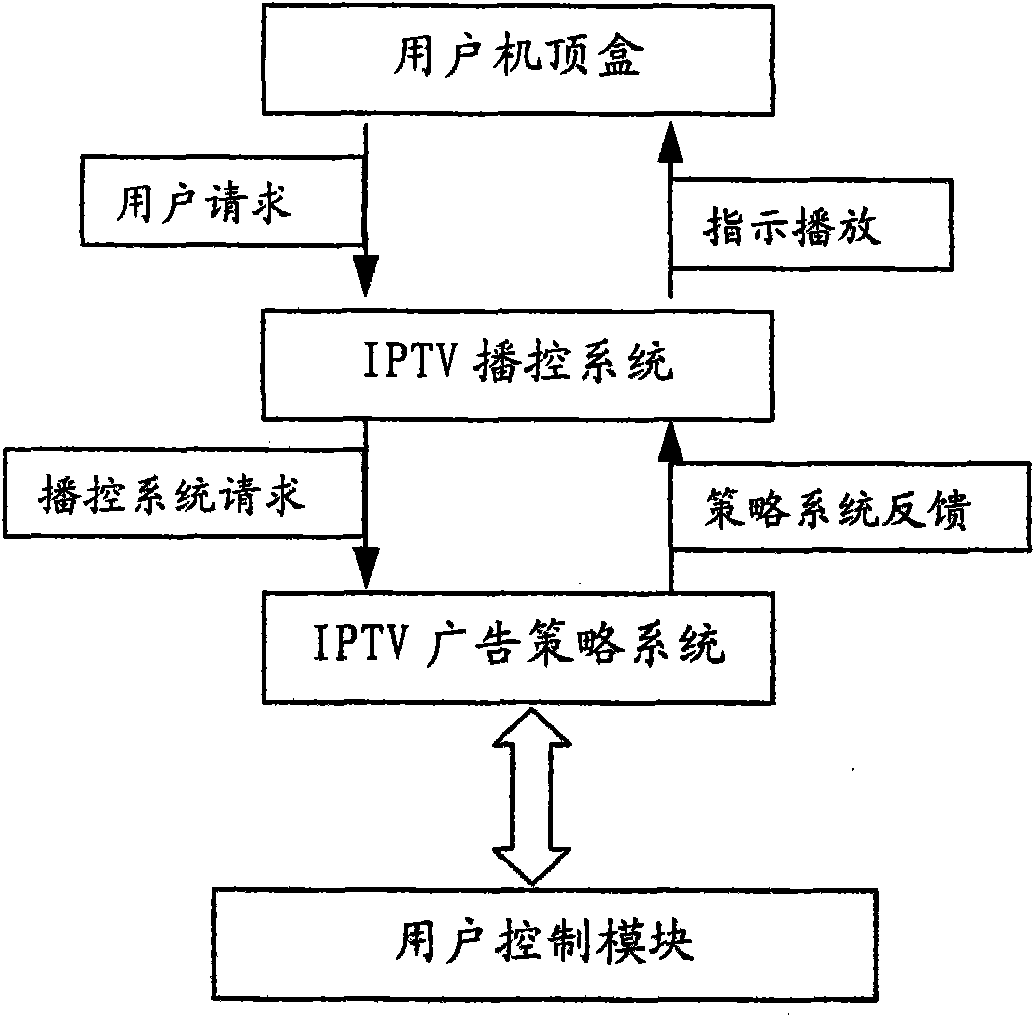

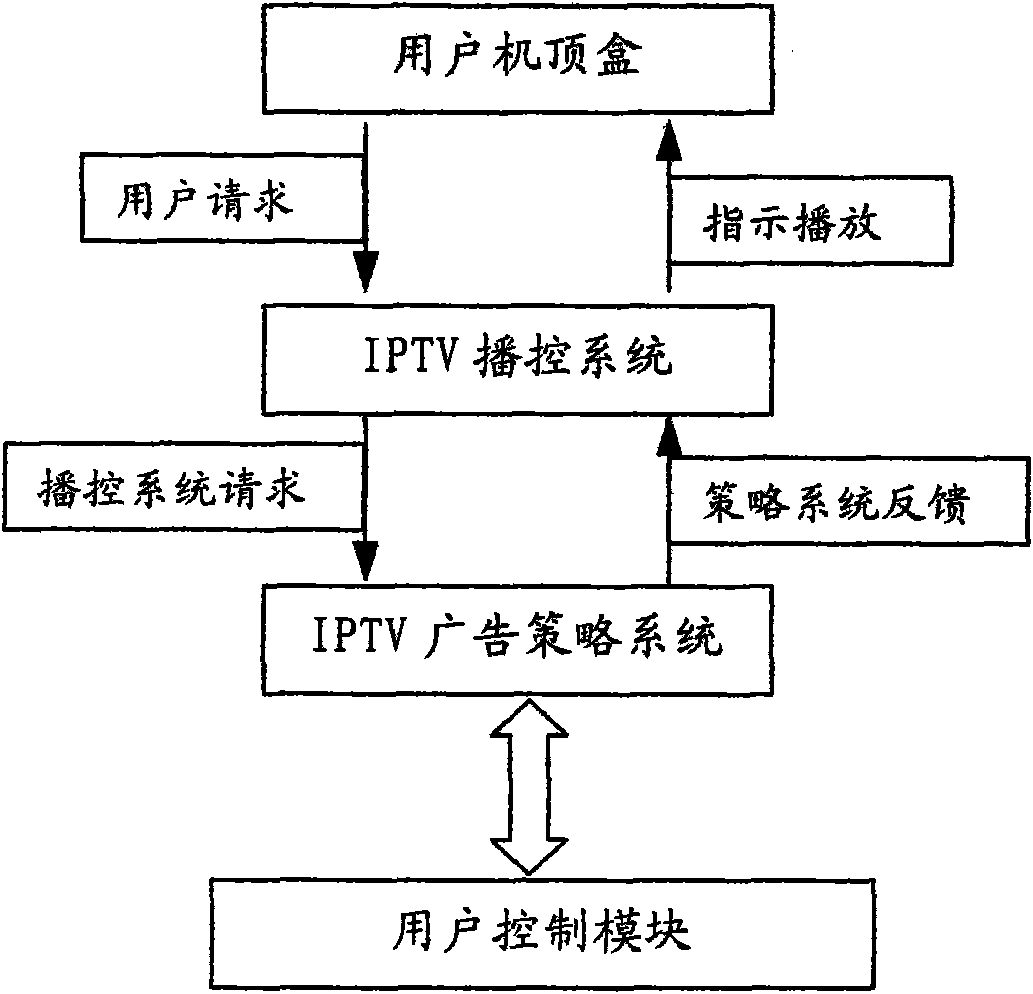

Advertisement playing control system and method thereof

InactiveCN101882289AImprove experienceMeet delivery needsTwo-way working systemsCommerceControl systemWorld Wide Web

The invention relates to a system and a method thereof for controlling advertisement playing in an IPTV system. On one hand, the invention provides an advertisement playing control system, which comprises an advertisement policy system, the advertisement policy system comprises a user control module, which is used for recording the advertisement playing records of the advertisement policy system and processing the advertisement playing records according to an advertisement playing rule, and the advertisement policy system is used for playing advertisements according to processing results. On the other hand, the invention also provides an advertisement playing control method, the user control module records the advertisement playing records of the advertisement policy system and processes the advertisement playing records according to the advertisement playing rule, and the advertisement policy system plays advertisements according to processing results. The system and the method can effectively enhance the experience of users.

Owner:百视通网络电视技术发展有限责任公司

Cooling discharge type corncob drying machine

InactiveCN103070236AReduce the temperatureGuaranteed temperatureSeed preservation by dryingWater pipeCondensate pump

The invention provides a cooling discharge type corncob drying machine. The cooling discharge type corncob drying machine is characterized in that the inner part of a box is divided into an upper region and a lower region by a separator plate I; the lower region is divided into three parts by a separator plate II; the separator plate I and separator plates III and IV located at the lower part of the box form a cooling region; a water heater is arranged at the bottom of the middle box; the cooling region is connected with the air inlet of the water heater by a blower; the air outlet of the water heater is connected with the middle part of the box; one end of each heat exchange box at the uppermost part in the box is communicated with the middle part of the box, and the other end of the heat exchange box is connected with an induced draft fan; two ends of each heat exchange box in the lower place are connected with the water heater by a circulating water pump; a condensate water pump is connected with straight water pipes in each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device are arranged in the box; each forming chain plate is supported on a guide rail to form a groove-shaped material channel; a guide chute is arranged under the tail end of the channel; a feed port is formed in the top part of the box; and a discharge port is formed in the bottom of the box. The cooling discharge type corncob drying machine is good in drying effect and low in energy consumption, and corncobs can be packaged directly after being dried by the drying machine.

Owner:SHANDONG UNIV OF TECH

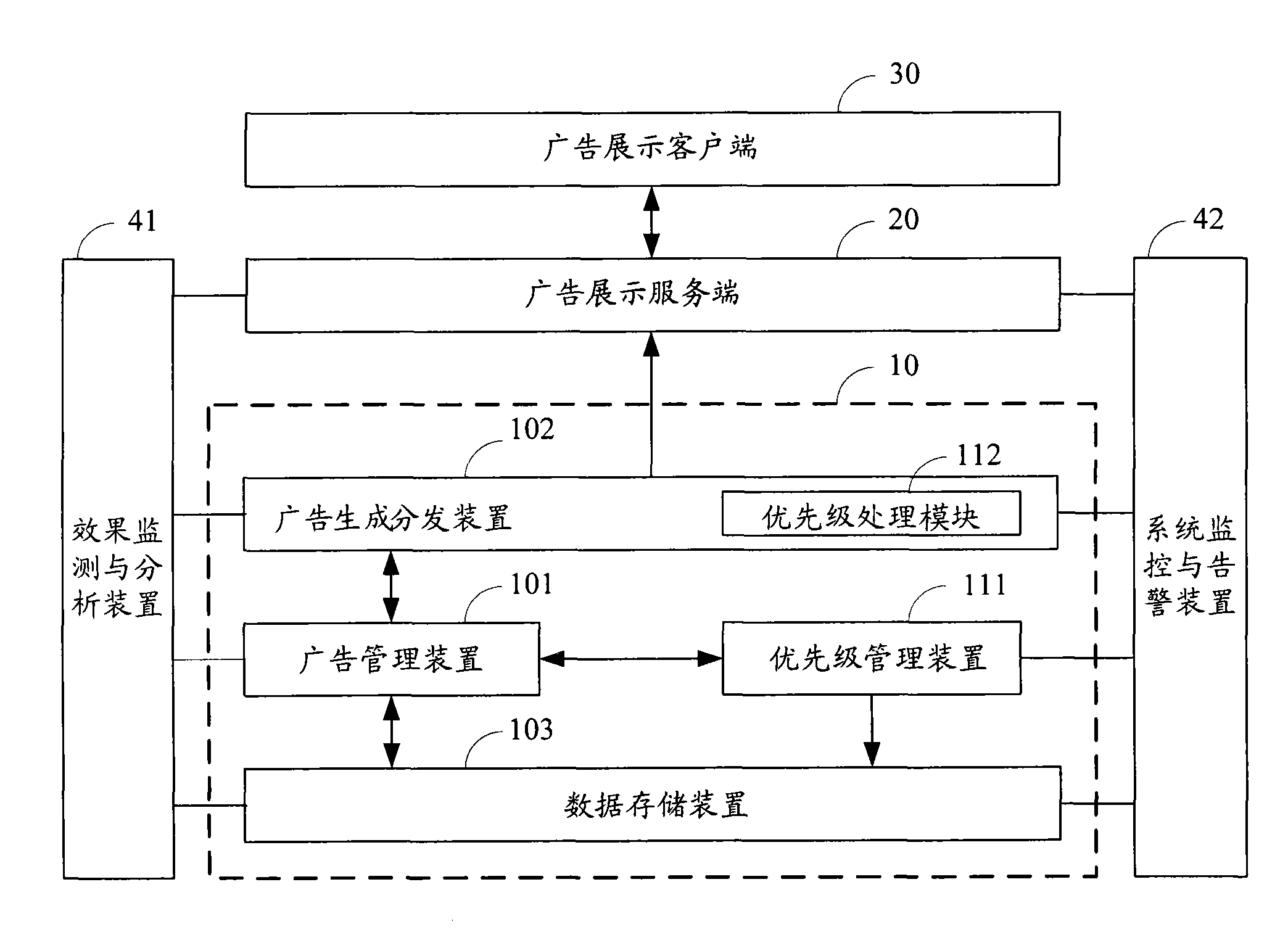

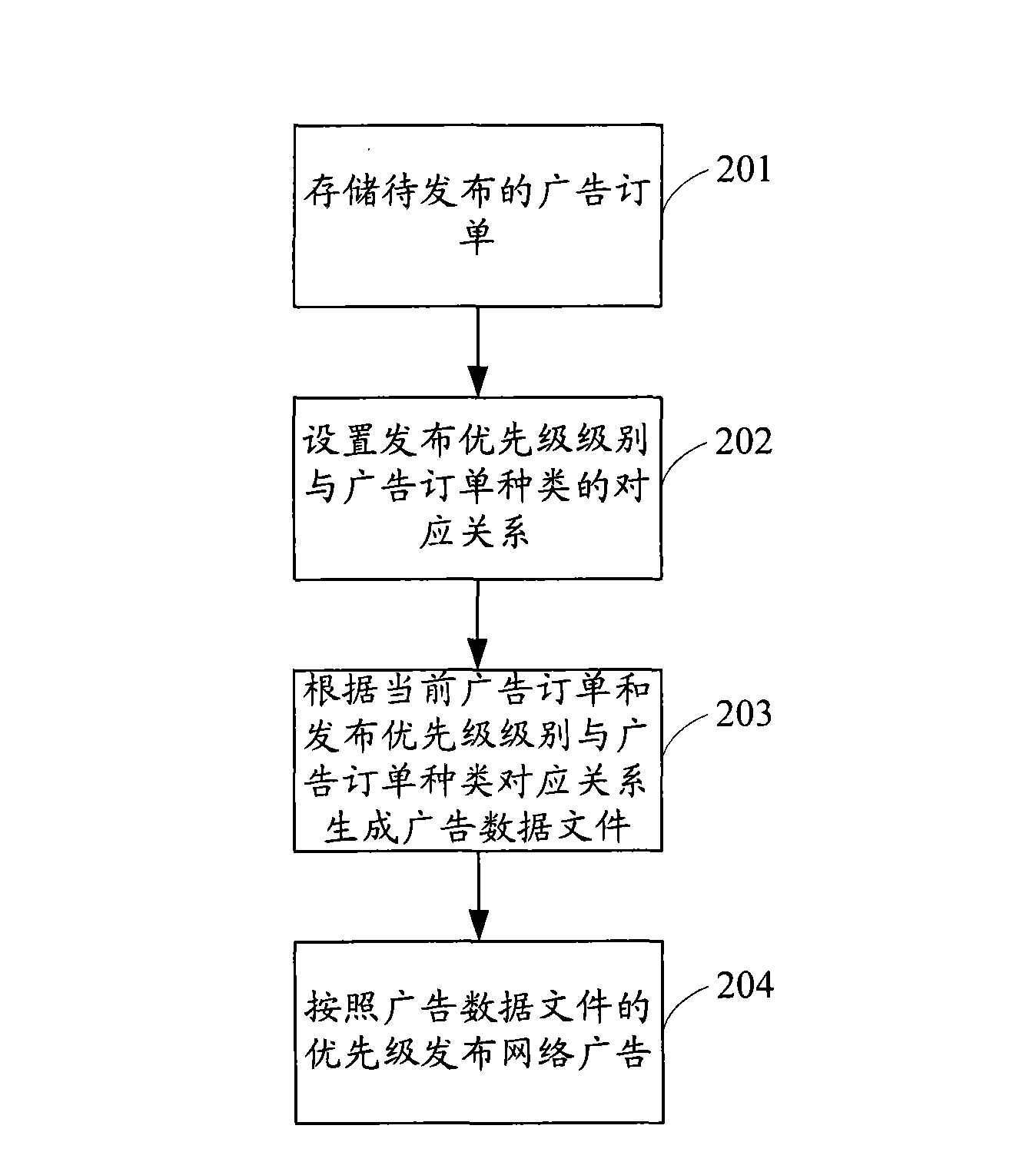

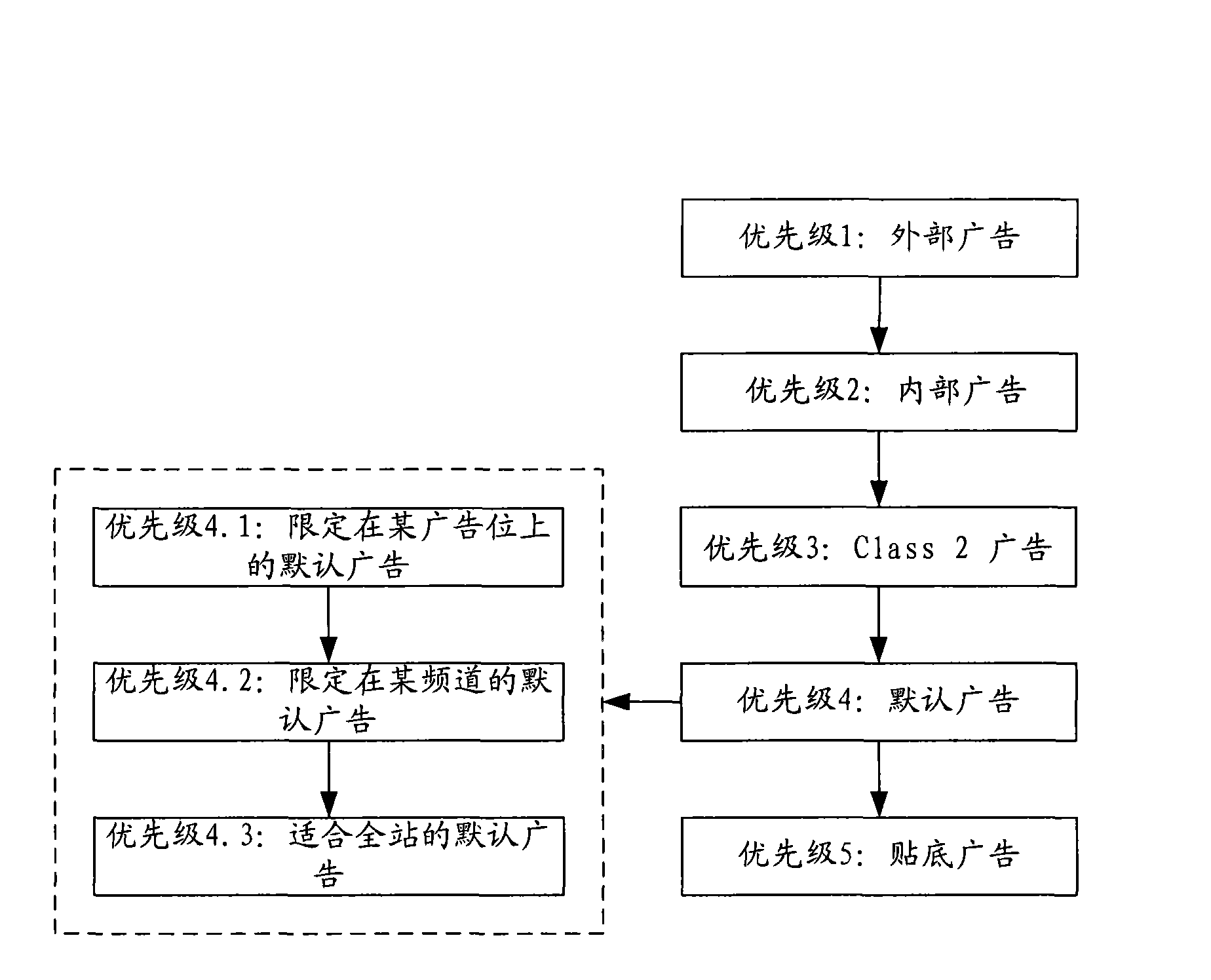

Online advertising release method, system and online advertising generation device

InactiveCN101582149AMeet delivery needsEnhanced Response FlexibilityCommerceOnline advertisingData file

The invention discloses an online advertising release method, a system and an online advertising generation device, and the advertising release method comprises the following steps: setting a corresponding relation between the priority level and the advertising order level in advance by a priority management device; determining the online advertising release priority level by a advertising generation distribution device according to the present type of the advertising order, when an online advertisement is released; generating an online advertising data document according to the present advertising order, wherein adding the release priority level of the present advertising order into the online advertising data document; releasing the online advertising data document according to the release priority level of the online advertising data document. By adopting the online advertising release method, system and online advertising generation device of the invention, an online advertising data document with the priority level can be generated and released according to the priority level, thereby meeting the requirements of class 2 advertising putting, improving the utilization ratio, and strengthening response flexibility, expandability and friendliness of user experience.

Owner:TENCENT TECH (BEIJING) CO LTD

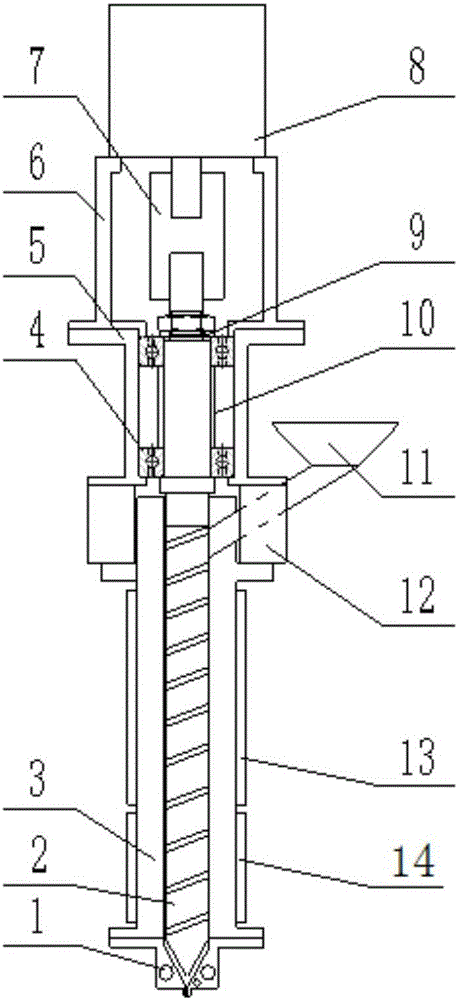

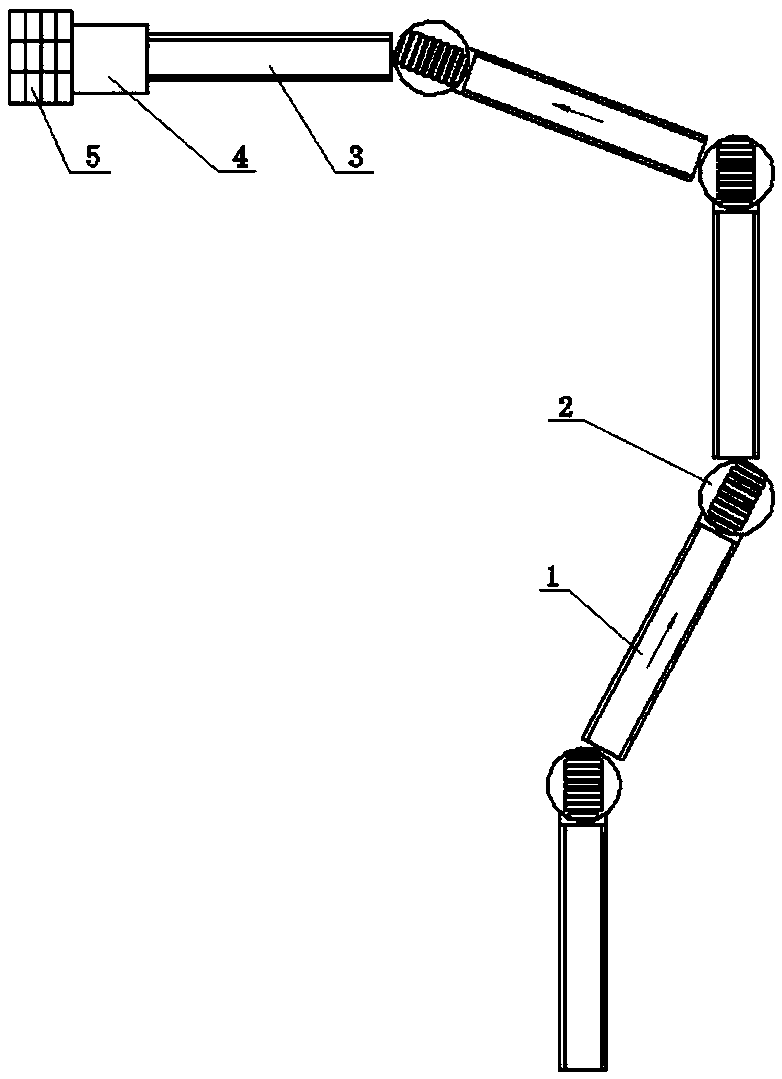

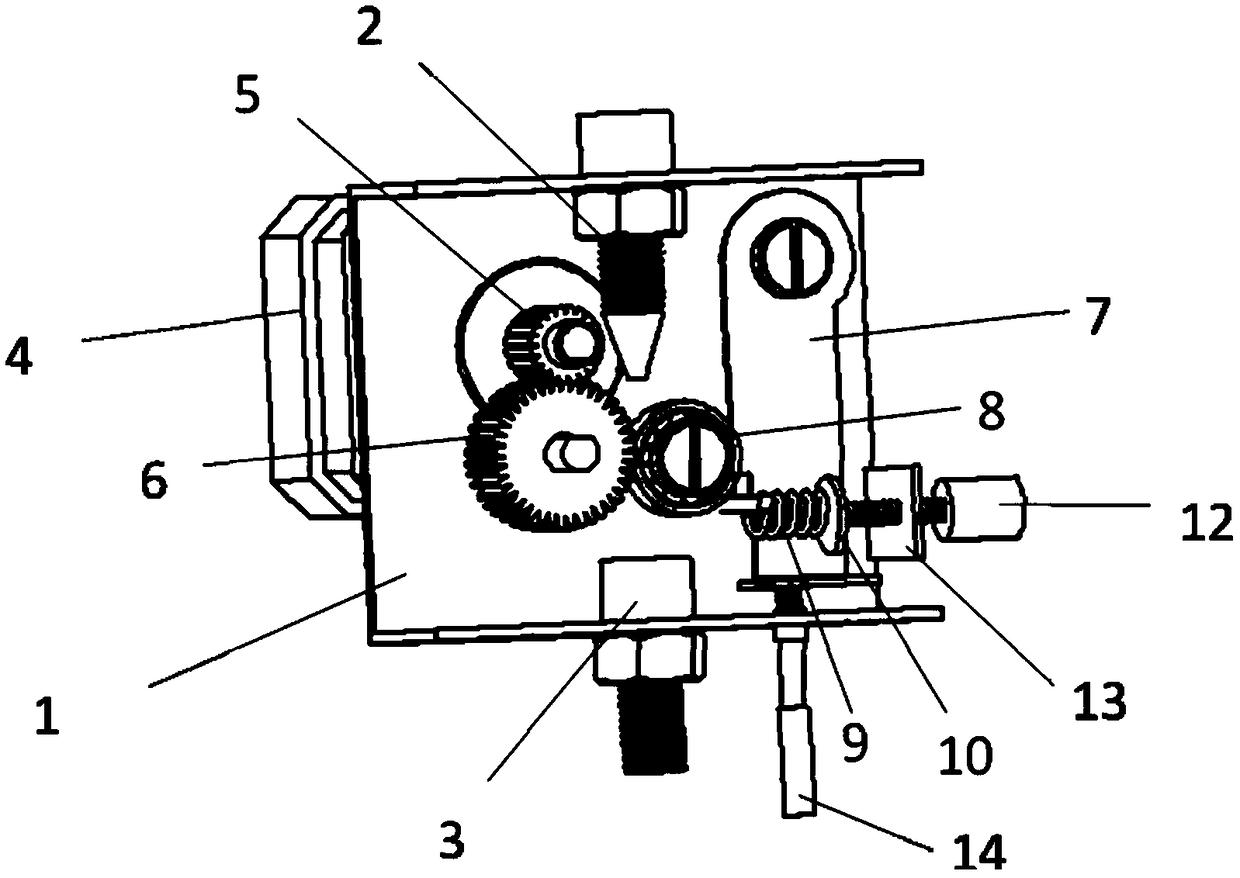

Screw type additive manufacturing spray head

InactiveCN106217867AEasy to useLow costAdditive manufacturing apparatusHeater RodPulp and paper industry

The invention discloses a screw type additive manufacturing spray head. Particles of the conventional size can be used as a raw material, the material extrusion process is stable, the extrusion force is large, and the forming efficiency is high. The screw type additive manufacturing spray head comprises a machine barrel, a nozzle fixed to the front end of the machine barrel, a screw arranged in the machine barrel and a drive motor fixed to the rear end of the machine barrel. The tail end of the screw is arranged in a cone shape. The front end of the screw is connected with the output end of the drive motor. The part, provided with a thread, of the screw is sequentially provided with a feeding segment, a compression segment and a metering segment from the front end to the tail end according to threaded groove depths. The groove depth of the feeding segment is the maximum, and the feeding segment is arranged in an equal groove depth manner. The groove depth of the metering segment is the minimum, and the metering segment is arranged in an equal groove depth manner. The groove depth of the compression segment is gradually changed into the minimum groove depth from the maximum groove depth. A feeding opening is formed in the position, corresponding to the feeding segment of the screw, of the machine barrel. A first heating ring is arranged at the position, corresponding to the compression segment, of the machine barrel, and a second heating ring is arranged at the position, corresponding to the metering segment, of the machine barrel. The interior of the nozzle is arranged in the manner of a conical face matched with the tail end of the screw. A set of heating bars is arranged on the nozzle in an inserted manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Flexible combined belt conveyor

PendingCN108394675ARealize free angle changeIncrease or decrease quantityConveyorsControl devices for conveyorsEngineeringFuselage

The invention discloses a flexible combined belt conveyor. The flexible combined belt conveyor is formed by at least two movable conveying units which are each composed of a movable belt conveyor anda transferring platform and are connected end to end. Each movable belt conveyor comprises a conveyor body, universal wheels arranged at the bottom of the conveyor body, a belt conveying device on theupper portion, an electrical connecting socket fixedly arranged at one end of the conveyor body, and an electrical connecting plug connected to the other end of the conveyor body through a soft cable. Each transferring platform comprises a transferring conveying device, a rack, a rotation driving device arranged at one end of the corresponding conveyor body, and a connecting shaft, wherein the transferring conveying device is arranged on the upper portion of the rack, and the rack is arranged on an output shaft of the rotation driving device. A rapid connecting device between every two adjacent movable conveying units is hinged to the corresponding connecting shaft. The electrical connecting sockets are connected with the electrical connecting plugs. The electrical connecting sockets or plugs are electrically connected with the belt conveying devices and the rotation driving devices. The transferring conveying devices are as high as the top surfaces of conveying belts of the belt conveying devices. The flexible combined belt conveyor has the characteristics of being simple in structure, capable of being freely moved and deformation, and variable in length.

Owner:周兆平

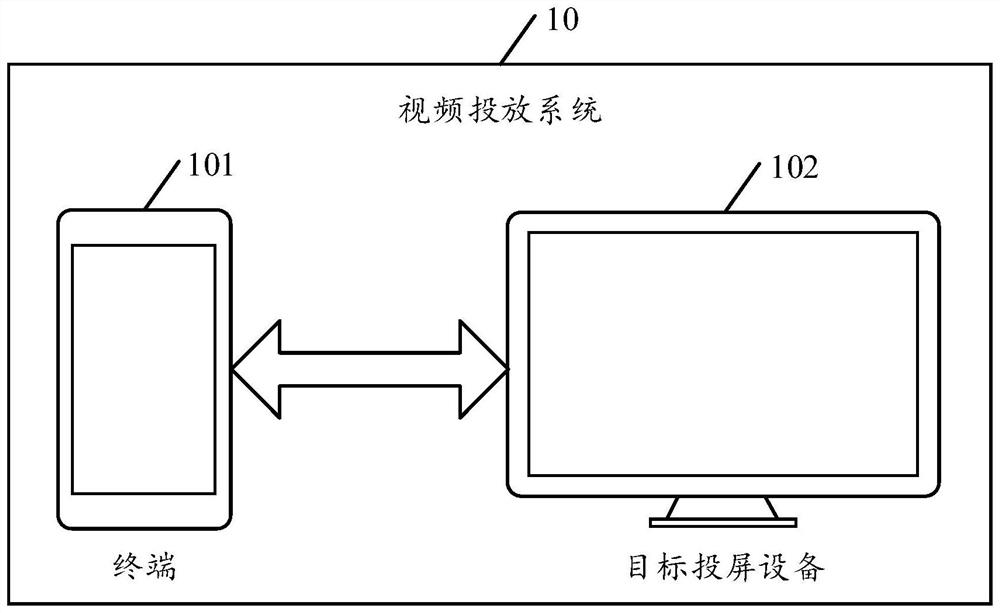

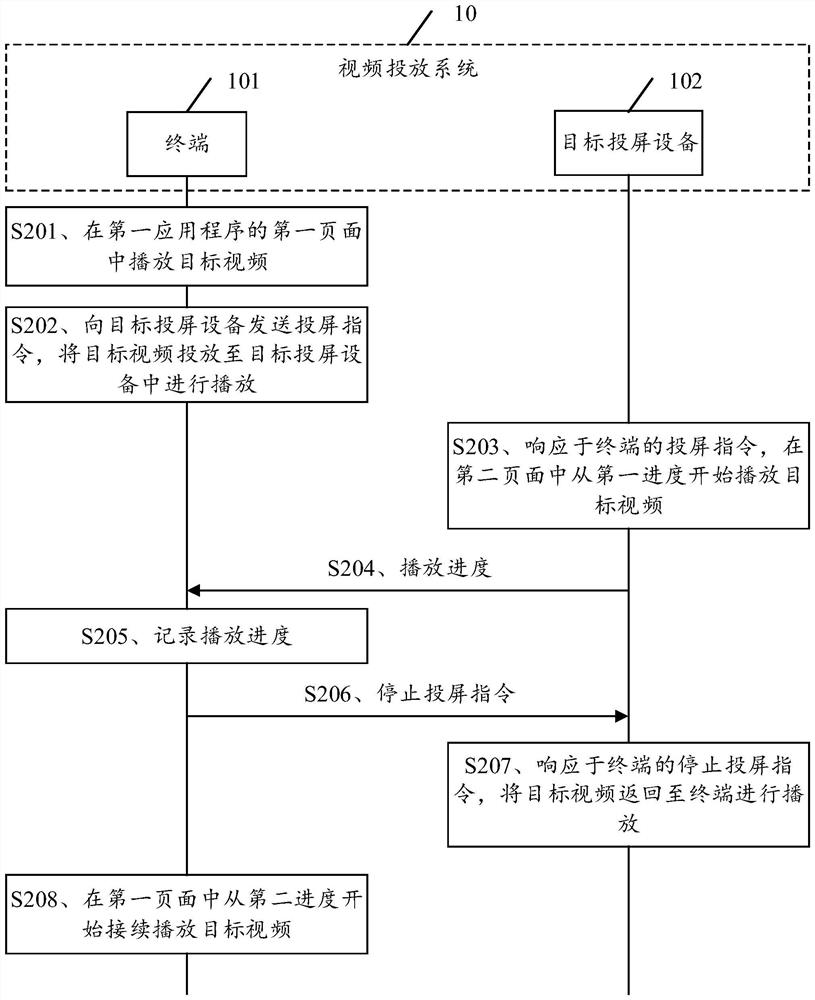

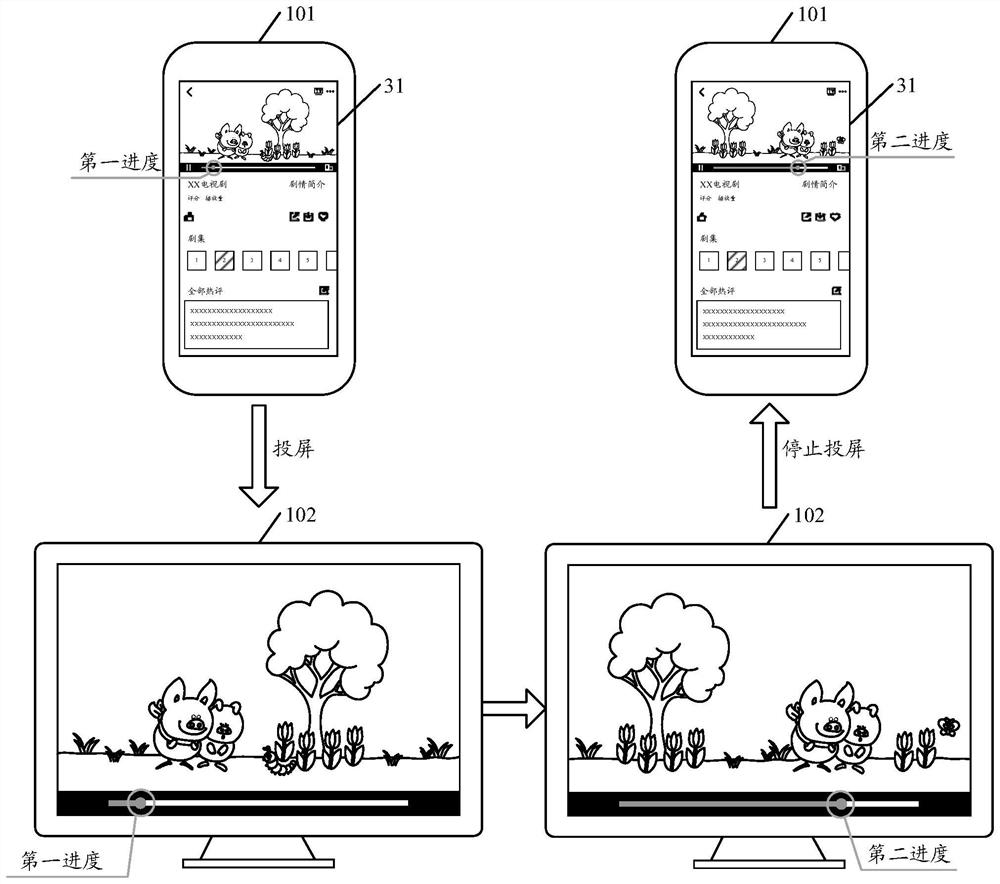

Video delivery method, device and equipment

ActiveCN111770379AFlexible switch playbackMeet delivery needsSelective content distributionMedicineComputer graphics (images)

The embodiment of the invention discloses a video delivery method, device and equipment. The video delivery method comprises the following steps: playing a target video in a first page of a first application program of a terminal; when the playing progress of the target video in the first page reaches the first progress, if a screen projection triggering event exists, projecting the target video is projected into target screen projection equipment to be played; when the playing progress of the target video in the target screen projection equipment reaches a second progress, if a screen projection stopping triggering event exists, continuously playing the target video from the second progress in the first page,; wherein the screen projection triggering event comprises an event enabling thefirst application program to be in an inactive state, and the screen projection stopping triggering event comprises an event enabling the first application program to be in a survival state.; Bby adopting the embodiment of the invention, the target video can be continuously played between the terminal and the target screen projection equipment in the screen projection process, and the real-time synchronization of the playing progress of the target video between the terminal and the target screen projection equipment can be better realized.

Owner:TENCENT TECH (SHENZHEN) CO LTD

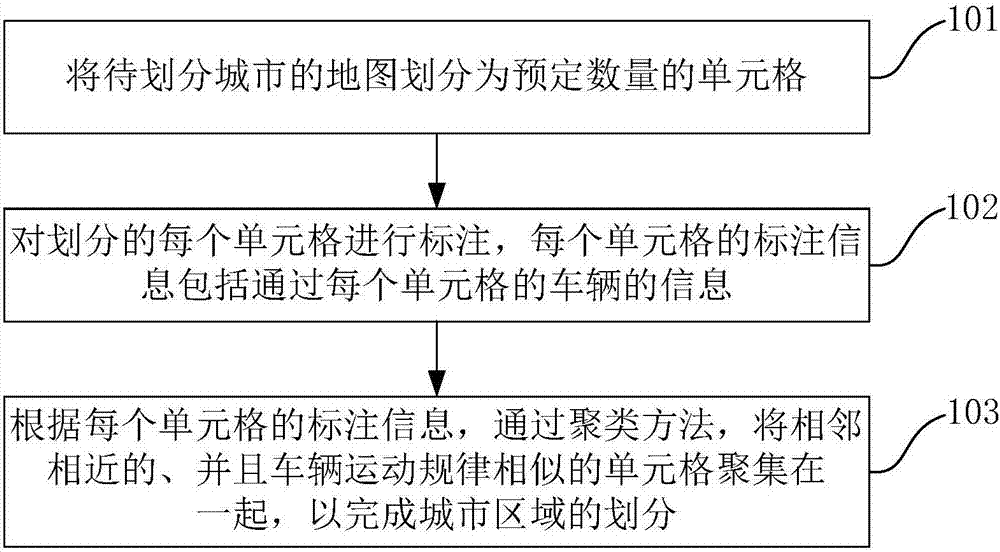

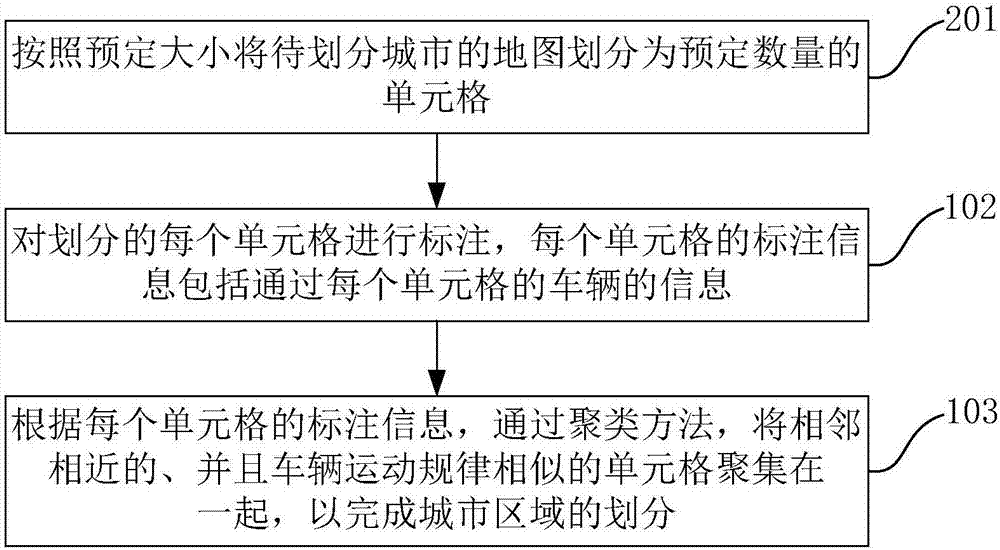

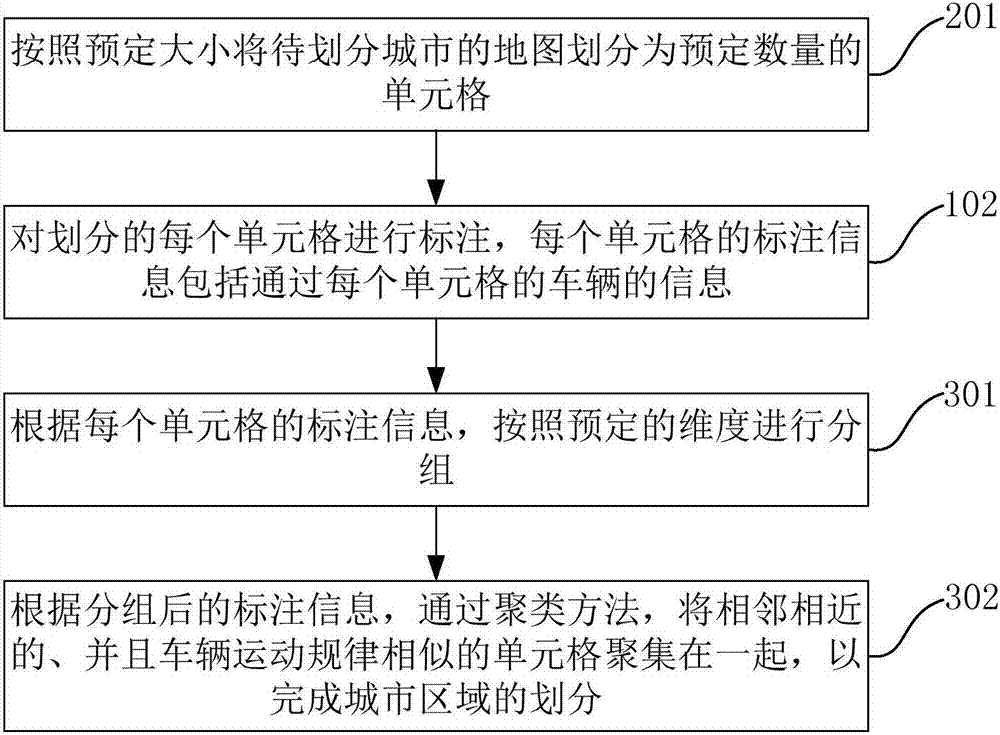

City region division method, device and terminal equipment

InactiveCN106886607AMeet delivery needsImprove the efficiency of information transmissionSpecial data processing applicationsInformation transmissionTerminal equipment

The application discloses a city region division method, a device and terminal equipment, relates to the technical field of computer applications, and solves the problems that the existing urban division method cannot meet the regional information transfer needs using district as the target in the city, the information transmission efficiency is low, and user experiences are poor. The scheme specifically comprises the steps that the city map to-be-divided is divided into a preset number of unit grids; each divided unit grid is marked, the mark information of each unit grid includes the information of vehicles passing through each unit grid; according to the mark information of each unit grid, through the clustering method, unit grids of the adjacent and the close and with similar vehicle movement law are gathered, to complete the division of city regions. The scheme achieves the division of the city area based on the vehicle trajectory information, meets the information transfer needs in the city using region as the target, and improves the efficiency of information transfer between city areas, so as to improve the technical effects of user experience.

Owner:HONG KONG LIVEME CORP LTD

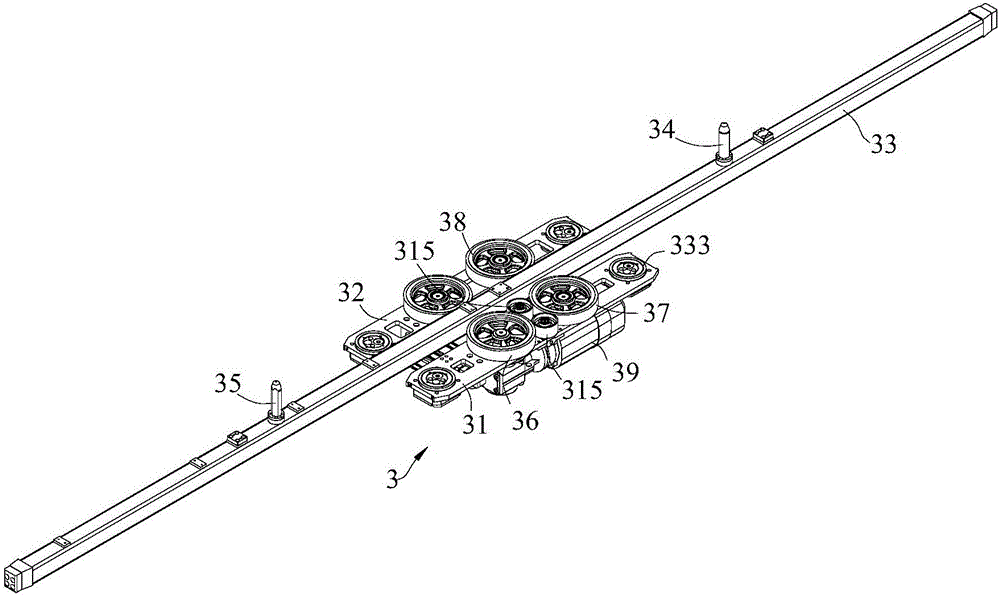

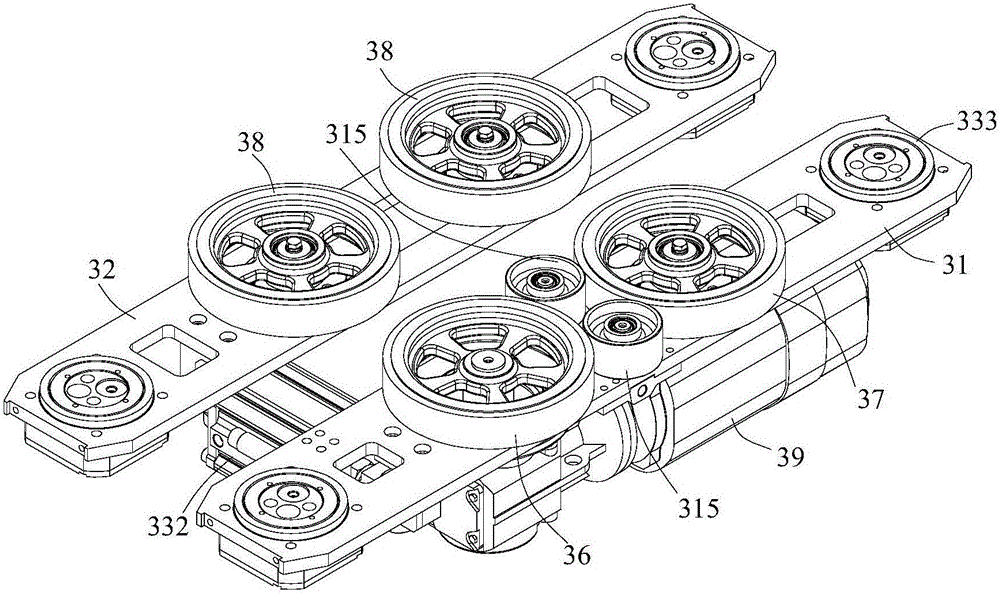

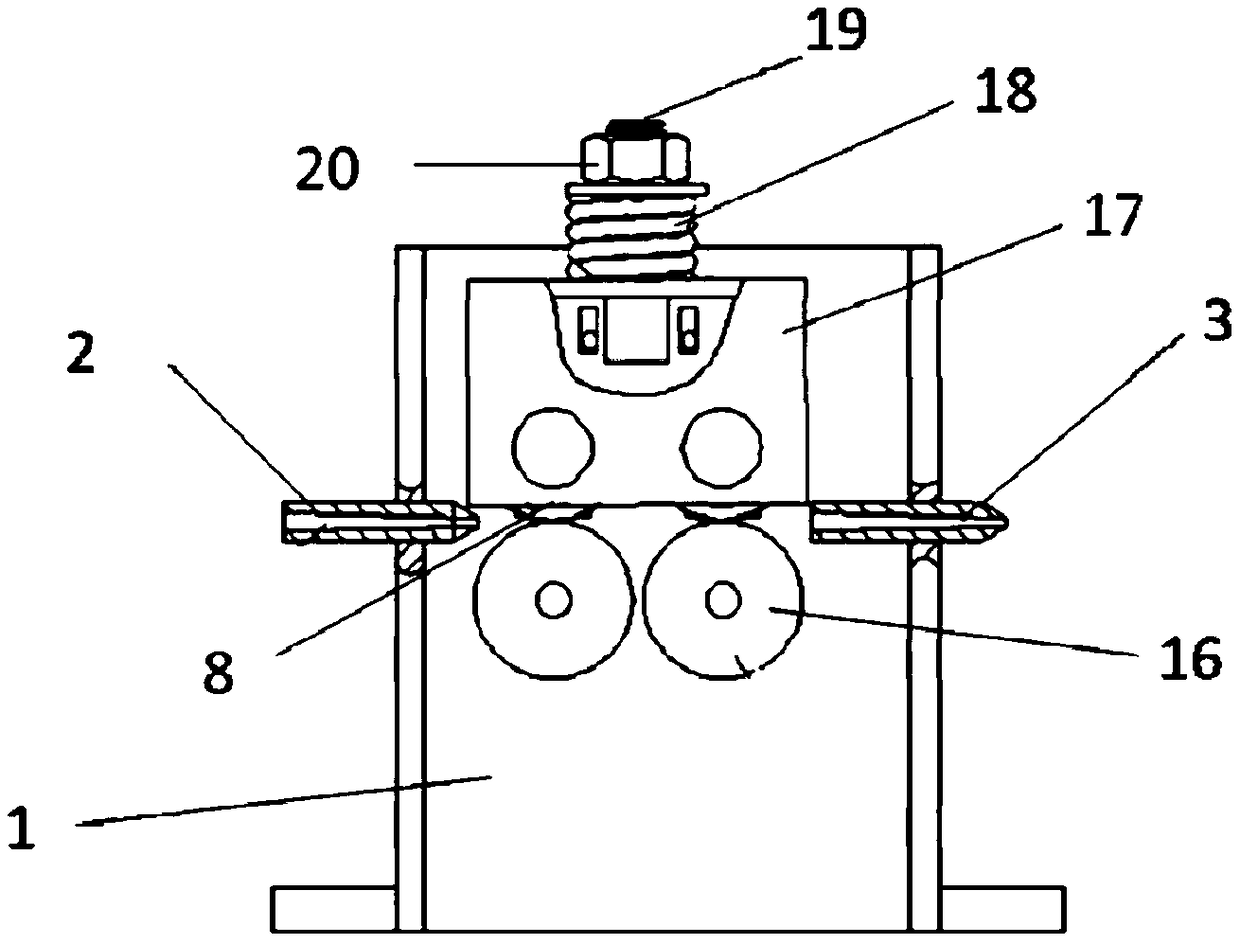

Friction conveying system

ActiveCN105645059AMeet delivery needsIncrease production costMechanical conveyorsRoller-waysEngineeringFriction force

The invention discloses a friction conveying system. The friction conveying system comprises a friction drive unit, a clamping unit and a friction drive part. The friction drive unit comprises a rotation drive part, a first connecting rod, a second connecting rod, a first wheel arranged on the first connecting rod and a second wheel arranged on the second connecting rod. The clamping unit comprises a clamping drive part capable of driving the first connecting rod and the second connecting rod to get close to each other so as to enable the outer circle face of the first wheel and the outer circle face of the second wheel to clamp the friction drive part. The rotation drive part can drive the first wheel and / or the second wheel to rotate and enables the friction drive part clamped between the first wheel and the second wheel to move through friction force. By means of the wheels, the friction drive part is driven at a high speed through friction, so that the low-cost and high-speed transportation is achieved, the cost is reduced, performance is reliable, installing is convenient, and the conveying requirement of an industrial automatic production line is met.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

Automatic rotating upper plate conveying device for circuit board machining and working method of the upper plate conveying device

ActiveCN110239876AChange delivery angleMeet delivery needsCharge manipulationPrinted circuit manufactureFixed frameEngineering

The invention discloses an automatic rotating upper plate conveying device for circuit board machining. The automatic rotating upper plate conveying device comprises a main support, a rotating mechanism is arranged at the top end of the main support, a conveying frame is arranged at the top end of the rotating mechanism, one end of the conveying frame is connected with an upper plate assembly, a limiting assembly is arranged at the top end of the conveying frame, the conveying frame comprises a fixing frame, and a plurality of groups of guide rollers are arranged on the inner side of the fixing frame. According to the upper plate conveying device and a working method, the rotating mechanism is arranged, so that the conveying frame can be driven to carry out omni-directional rotary adjustment, the angle of the conveying frame can be flexibly adjusted, so that the conveying of different directions can be met; by arranging the upper plate assembly, a circuit board can be conveniently and rapidly conveyed to the conveying frame, and the situation that a placement position is not accurate during manual plate feeding is avoided; and the limiting assembly is arranged, the conveying space of the conveying frame can be limited according to the width of the circuit board, so that the circuit board can be kept stable during conveying on the conveying frame, and deviation is avoided.

Owner:安徽天通精电新科技有限公司

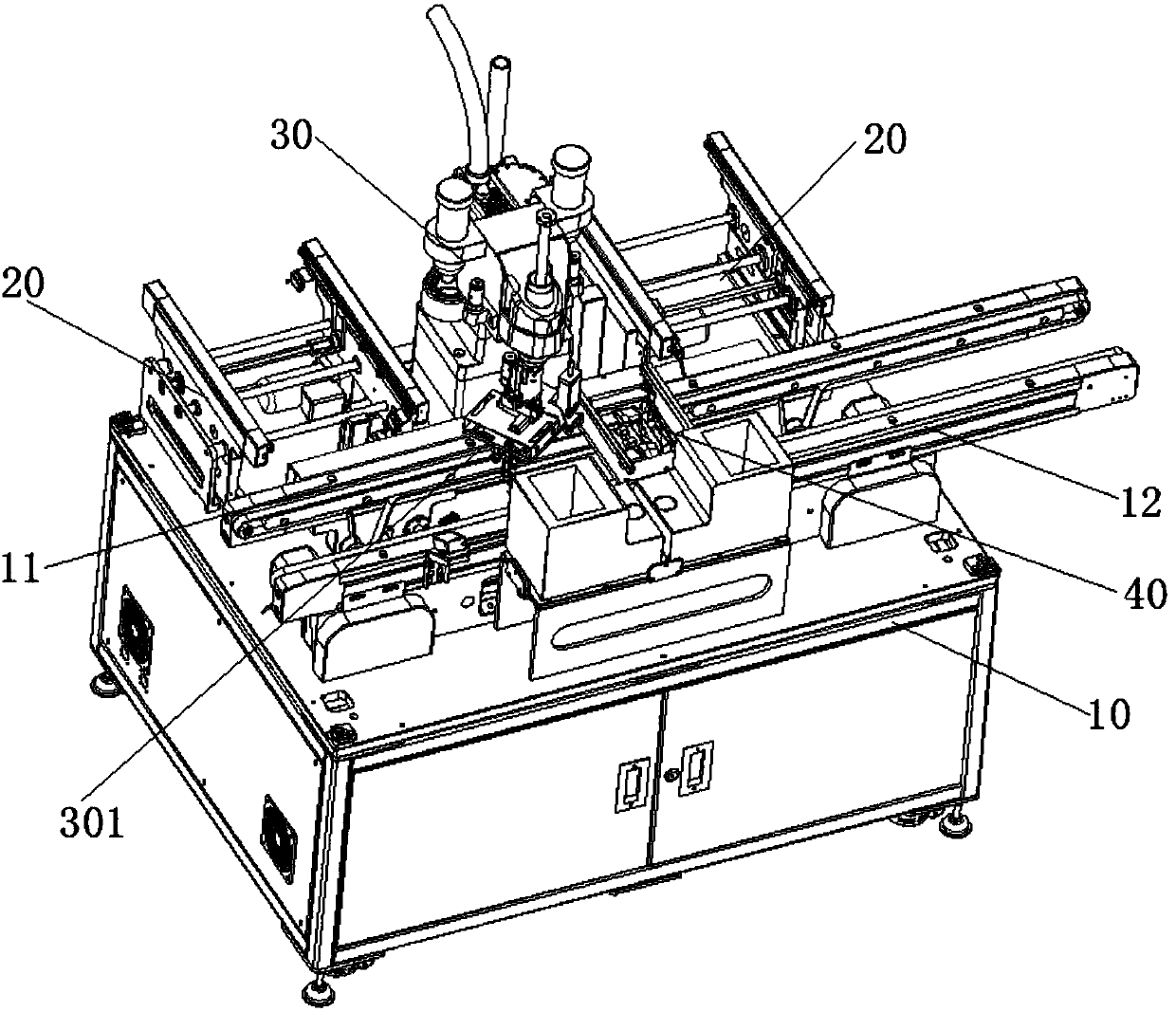

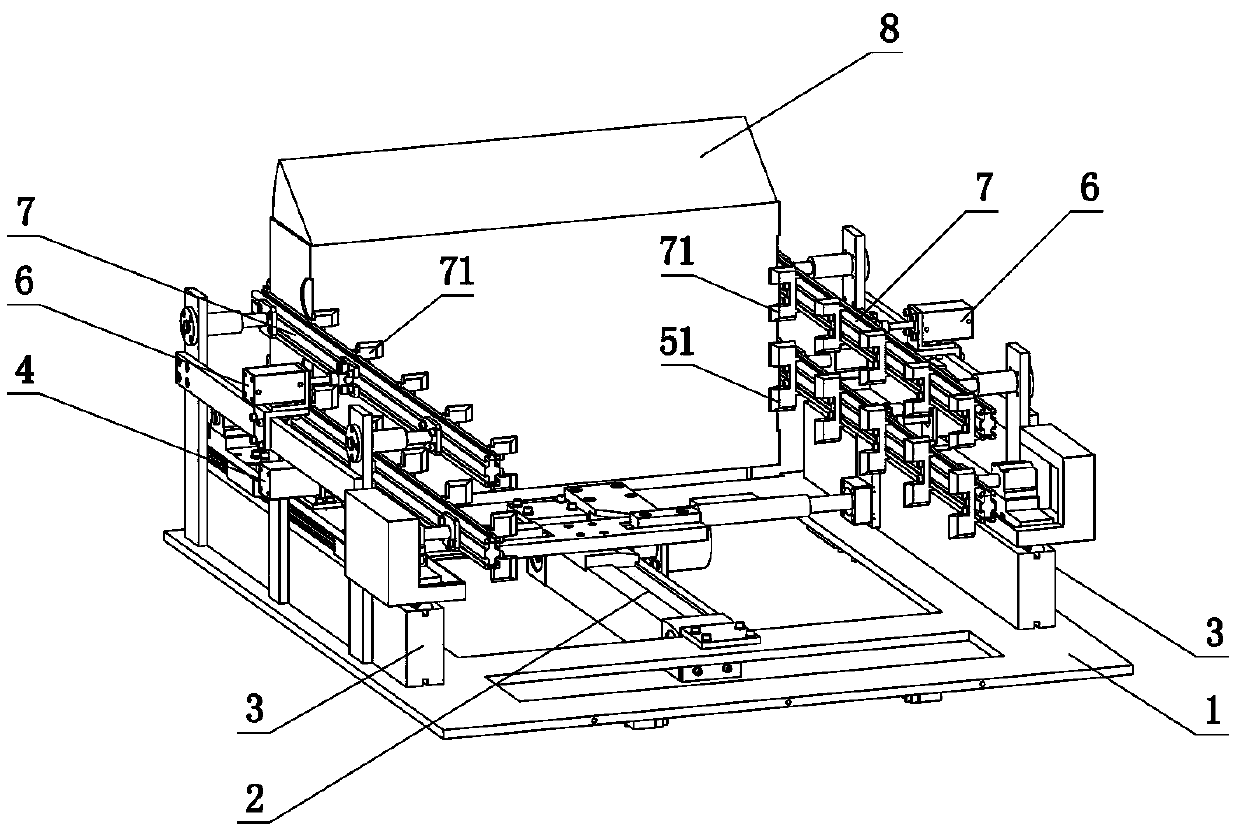

Intelligent assembly work station

PendingCN107775337AEasy to useGood practicalityGripping headsAssembly machinesManufacturing engineeringMachining time

The invention relates to the technical field of special-shaped part production equipment, in particular to an intelligent assembly work station. By means of an adjustable connection mechanism and an adjustable track mechanism, feeding and assembling section width can be changed to adapt to width requirements of various workpieces, and conveying requirements of workpieces with different widths canbe met, flexible assembly of materials is realized, use is convenient, and practicability is better; with adoption of a mechanical structure, mechanism balance performance can be effectively improved,so that conveying stability is guaranteed, and safety and reliability are high; feeding operation can be performed on various models of special-shaped parts by a sucker gripper, and the use range iswide; goods cannot be damaged when suckers are adopted for sucking the goods, meanwhile, the suckers are safe and reliable during working, the special-shaped parts are conveyed to a special-shaped part jig through the adjustable track mechanism for assembly, repeated carrying is not needed, and accordingly, machining time is greatly shortened.

Owner:嘉孚朗机器人设备(苏州)有限公司

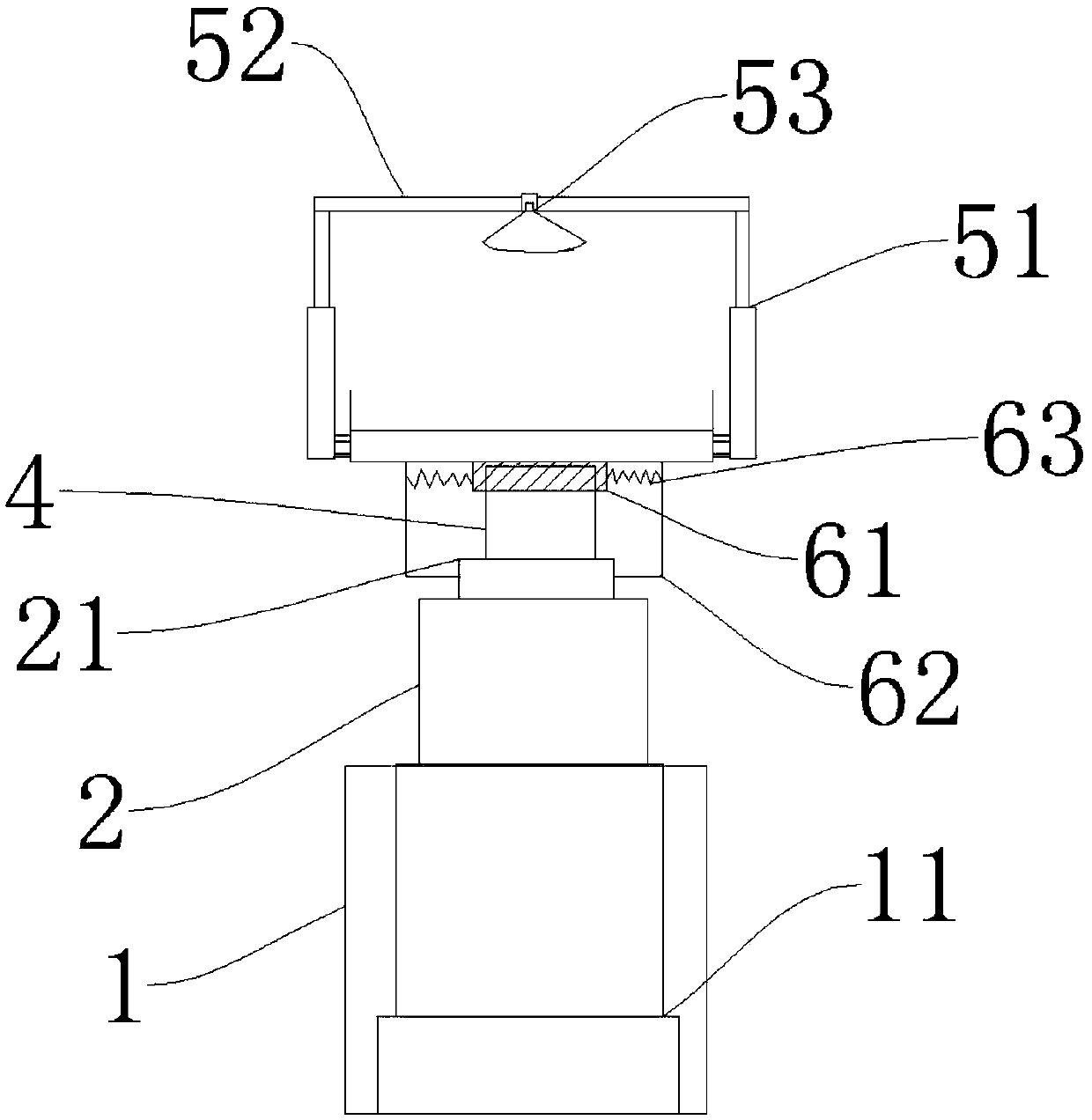

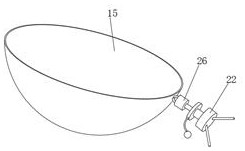

Floor projector stand

The invention discloses a floor projector stand which comprises a shell, a supporting column, an accommodating tank, a rotating shaft, a lifting locking assembly and a rotating locking assembly, wherein an electric jack is arranged inside the shell; the bottom of the supporting column is fixedly connected with a piston rod of the electric jack; a bearing sleeve is arranged at the top of the supporting column; a projector is placed inside the accommodating tank; the top of the rotating shaft is fixedly connected with the lower surface of the accommodating tank; the bottom of the rotating shaftis sleeved by the bearing sleeve; the lifting locking assembly comprises a pair of pneumatic telescopic rods, a lifting rod and a suction cup assembly; the lifting rod is connected with the movable ends of the pneumatic telescopic rods; the suction cup assembly is arranged on the lifting rod; the rotating locking assembly comprises a fixing sleeve, three L-shaped supporting rods and three springs;and when the end parts of the horizontal parts of the L-shaped supporting rods are all connected with the bearing sleeve, the springs are all in the natural state. By adoption of the floor projectorstand disclosed by the invention, the up-down adjustment and the 360-degree rotating adjustment of the projector can be achieved, thereby meeting the projection demand of the projector; and the floorprojector stand has no exacting demand for a floor placement point and can be properly placed according to the floor space, thereby improving the utilization ratio of the floor space.

Owner:黄世仁

Intelligent regulation and control type garbage collection method and system, storage medium, device and application

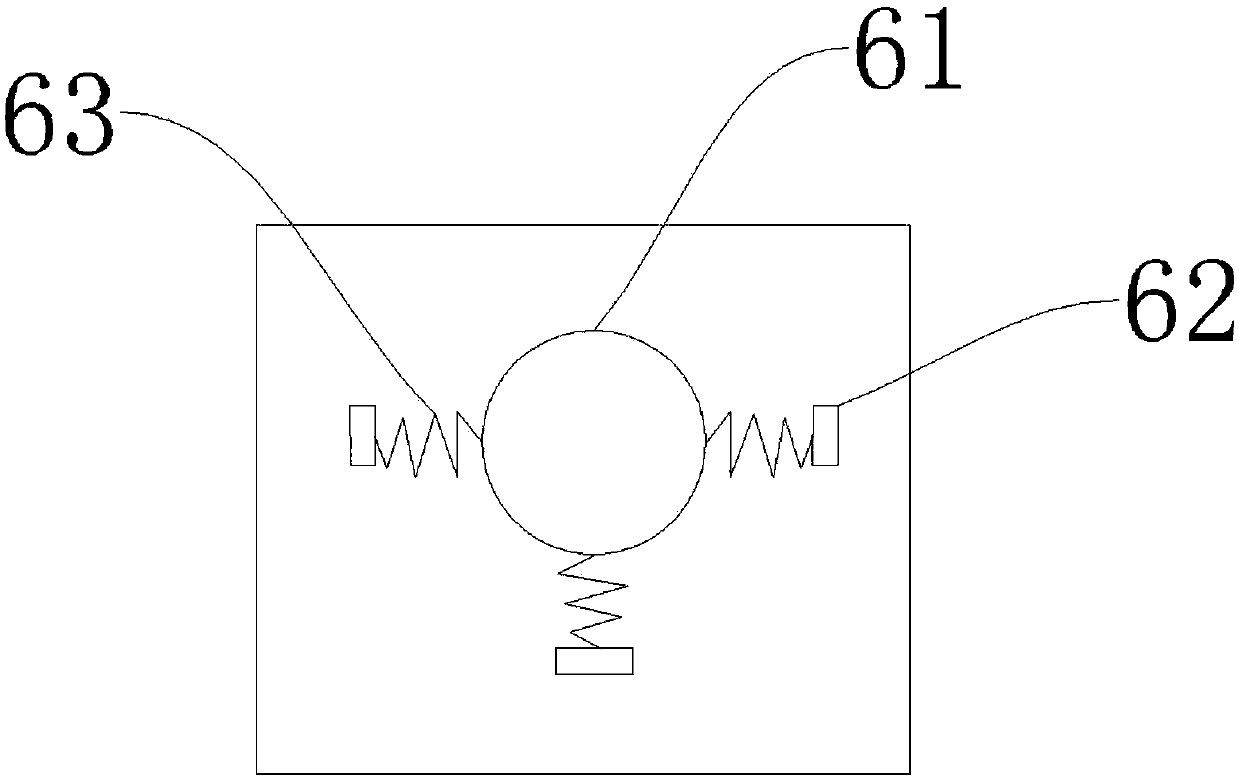

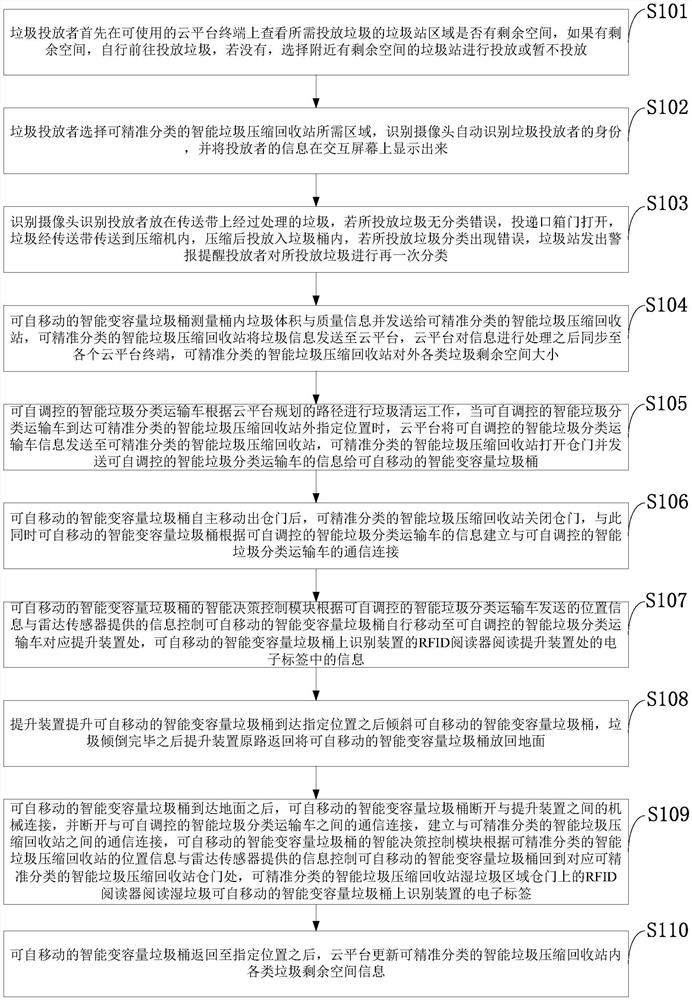

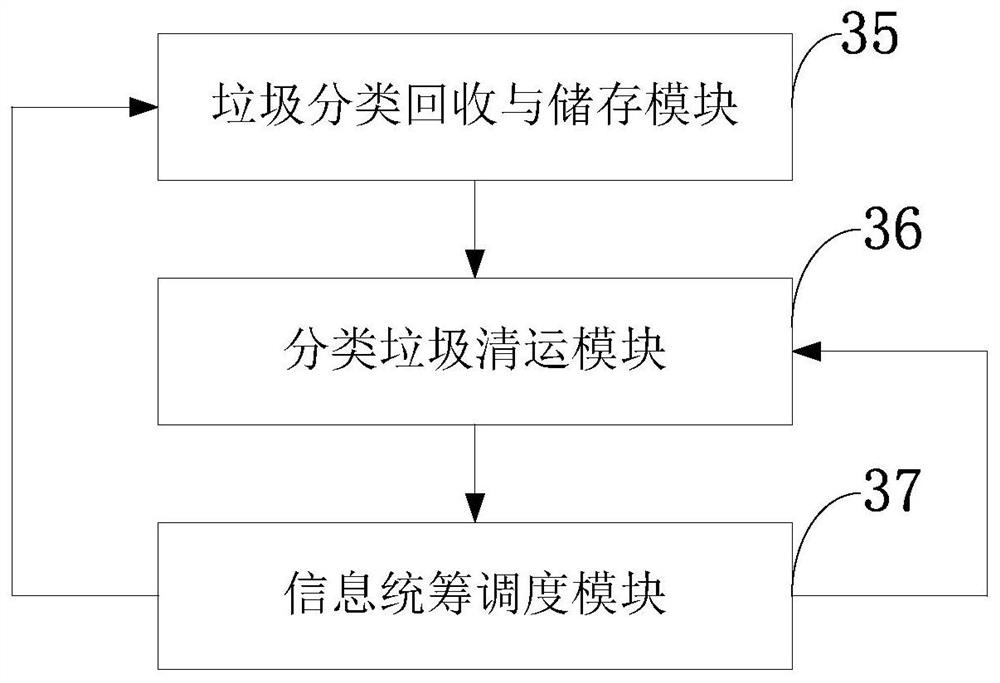

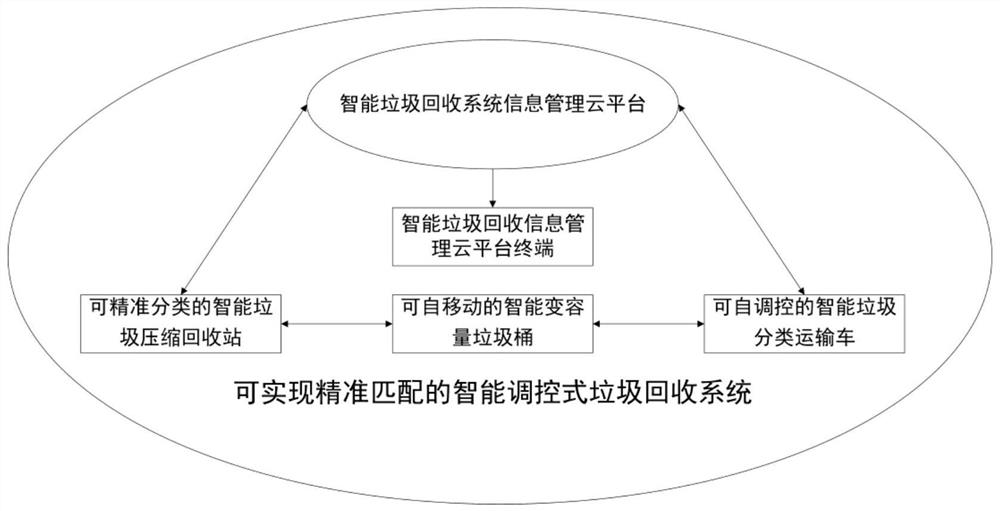

PendingCN112046978ASimple processWaste less timeRefuse transferringLoading/unloadingGarbage collectionOperating system

The invention belongs to the technical field of garbage collection, and discloses an intelligent regulation and control type garbage collection method and system, a storage medium, a device and an application. The system involves an information management cloud platform, an intelligent garbage compression recycle bin, an intelligent variable-capacity garbage can, an intelligent garbage classification carrier vehicle and an intelligent garbage recycling system information management cloud platform terminal. Information data transmission and exchange are carried out between the information management cloud platform and the intelligent garbage compression recycle bin, between the information management cloud platform and the intelligent variable-capacity garbage can and between the information management cloud platform and the intelligent garbage classification carrier vehicle, the intelligent garbage compression recycle bin identifies whether garbage classification is wrong or not and compresses garbage, the size of the space in the can can be changed through the intelligent variable-capacity garbage can capable of moving automatically, the intelligent variable-capacity garbage can can move automatically to assist in completing garbage collection and transport work, and the intelligent garbage classification carrier vehicle can achieve reasonable distribution of the internal space of a carriage, so that garbage recycling work is more reasonable, waste generated in the garbage recycling work is reduced, the labor intensity of workers is relieved, and the efficiency of the garbage collection and transport work is improved.

Owner:SHANDONG UNIV OF SCI & TECH

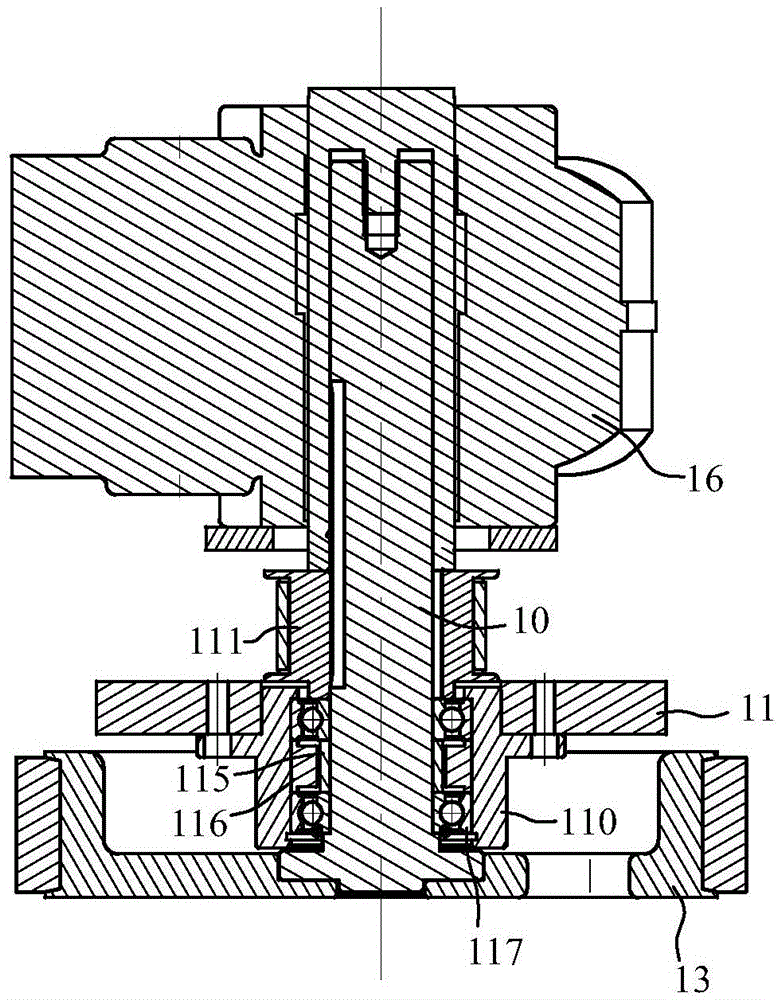

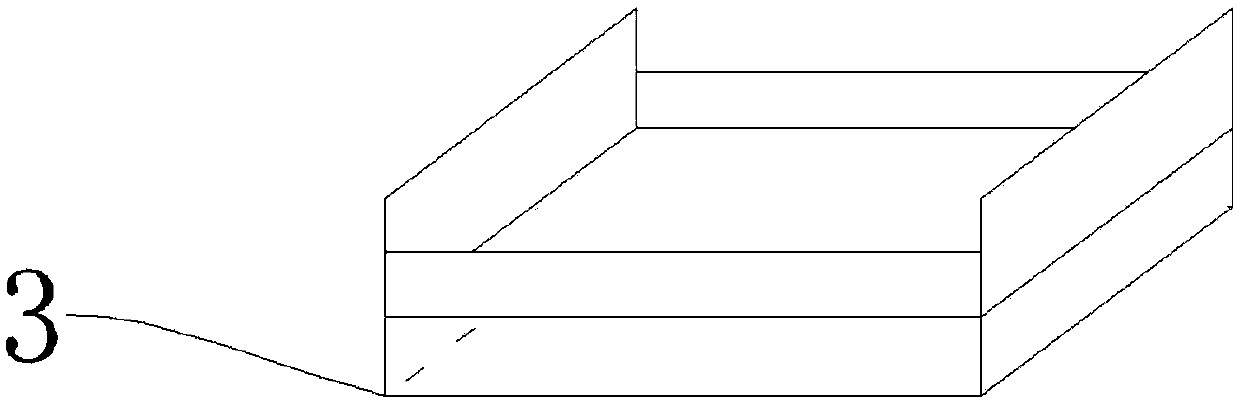

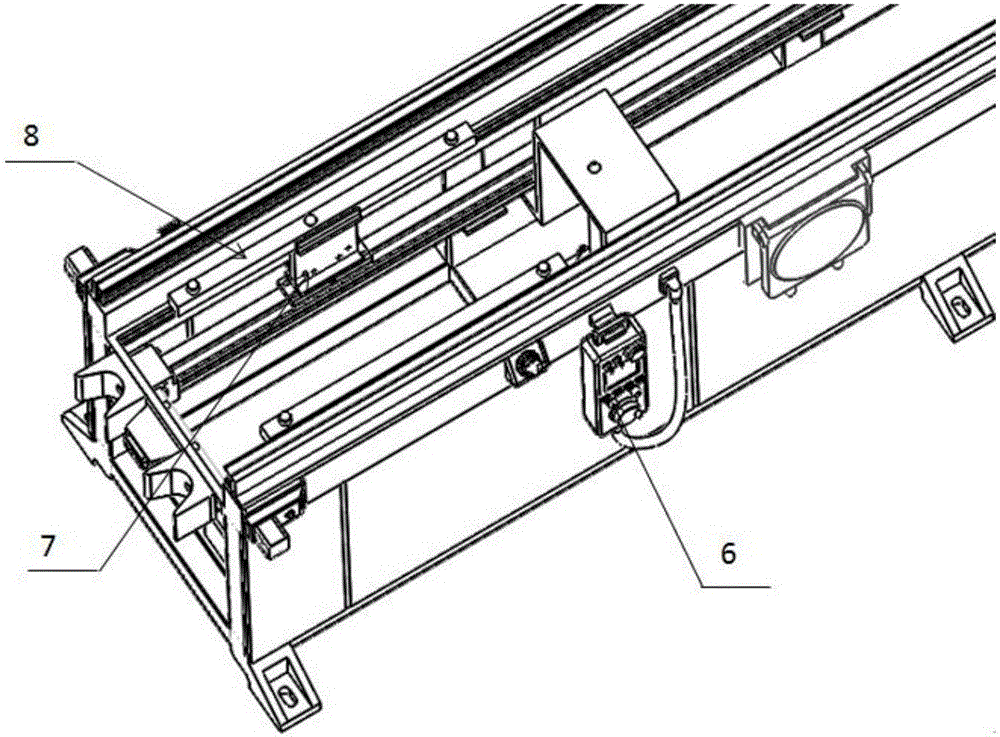

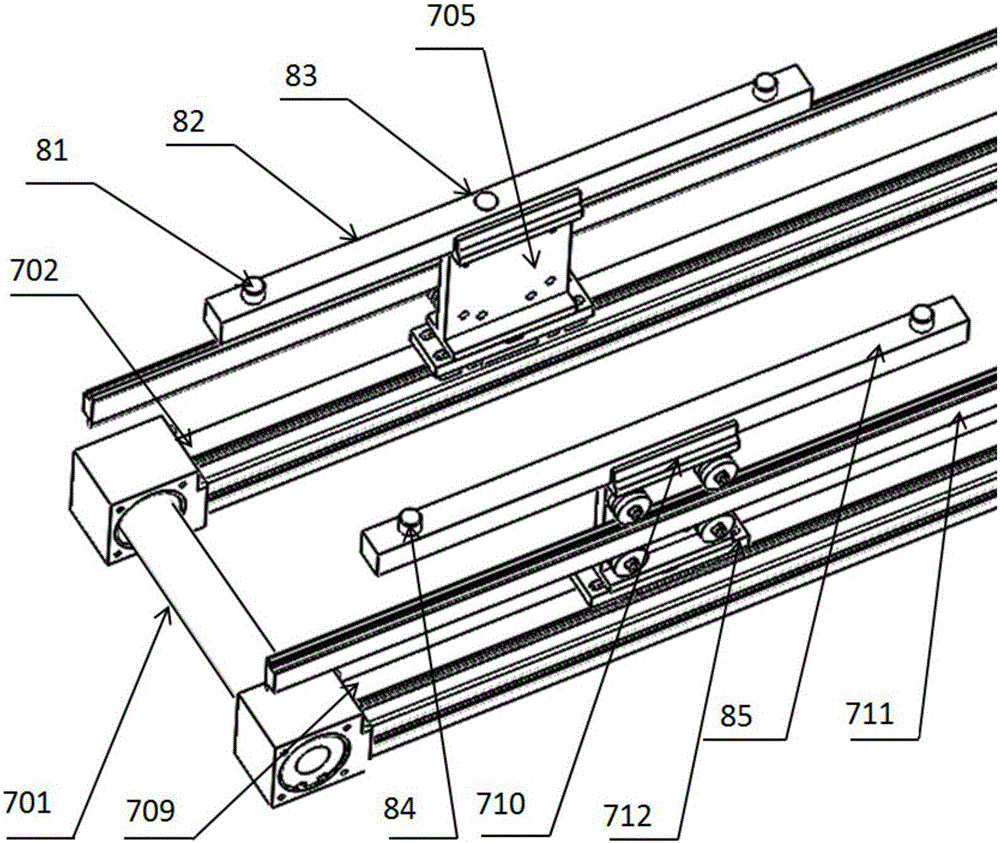

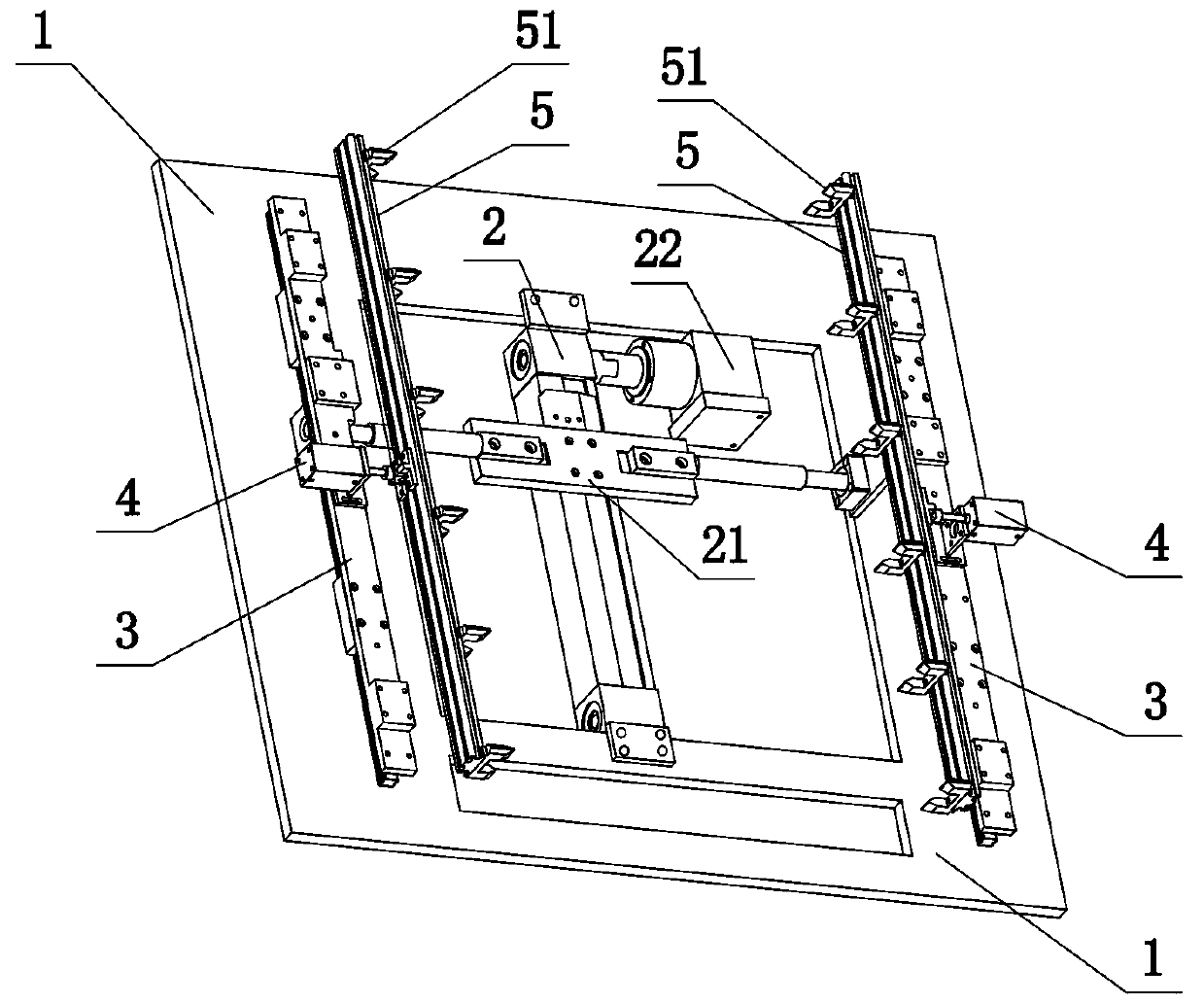

Precise conveying locating system for product parts

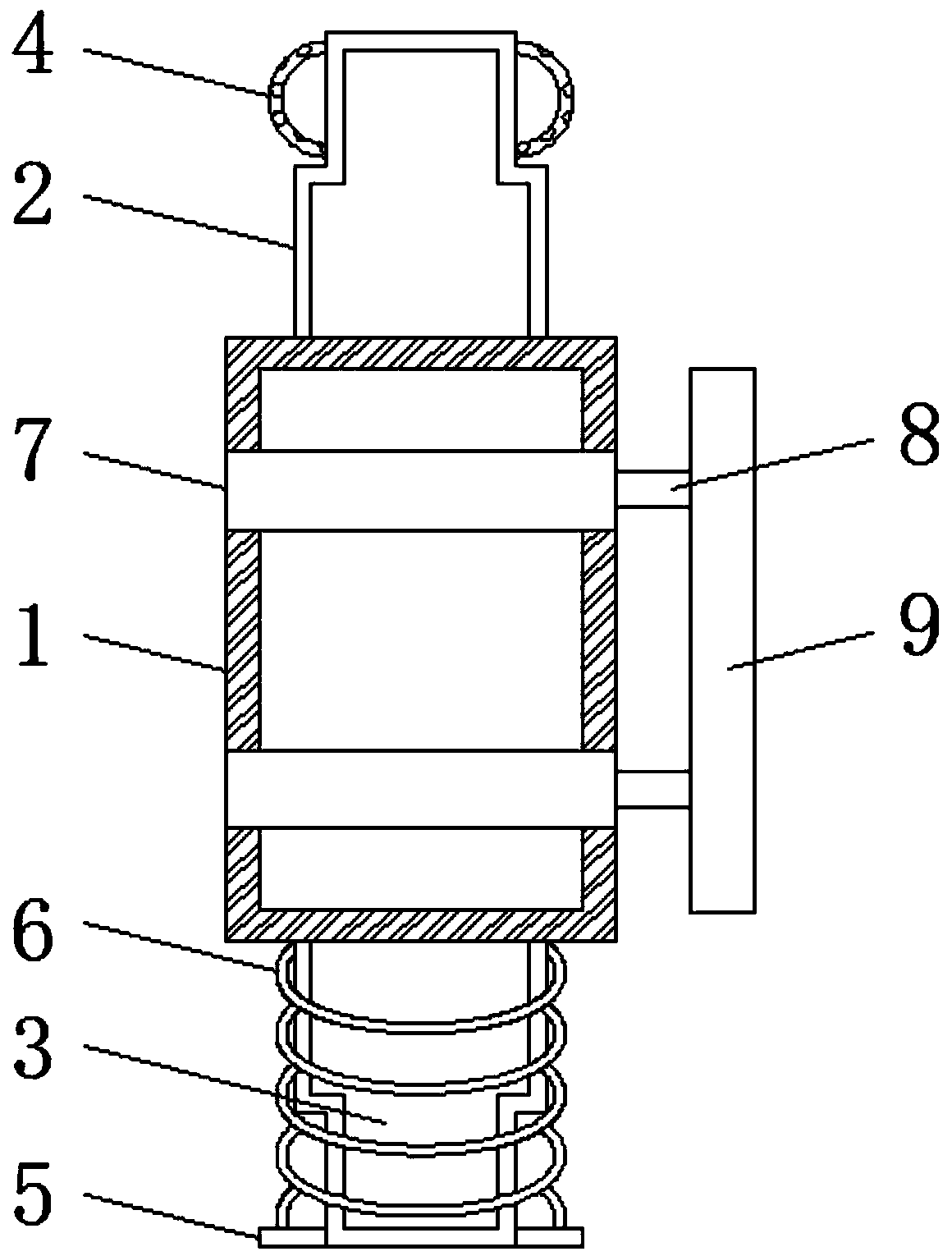

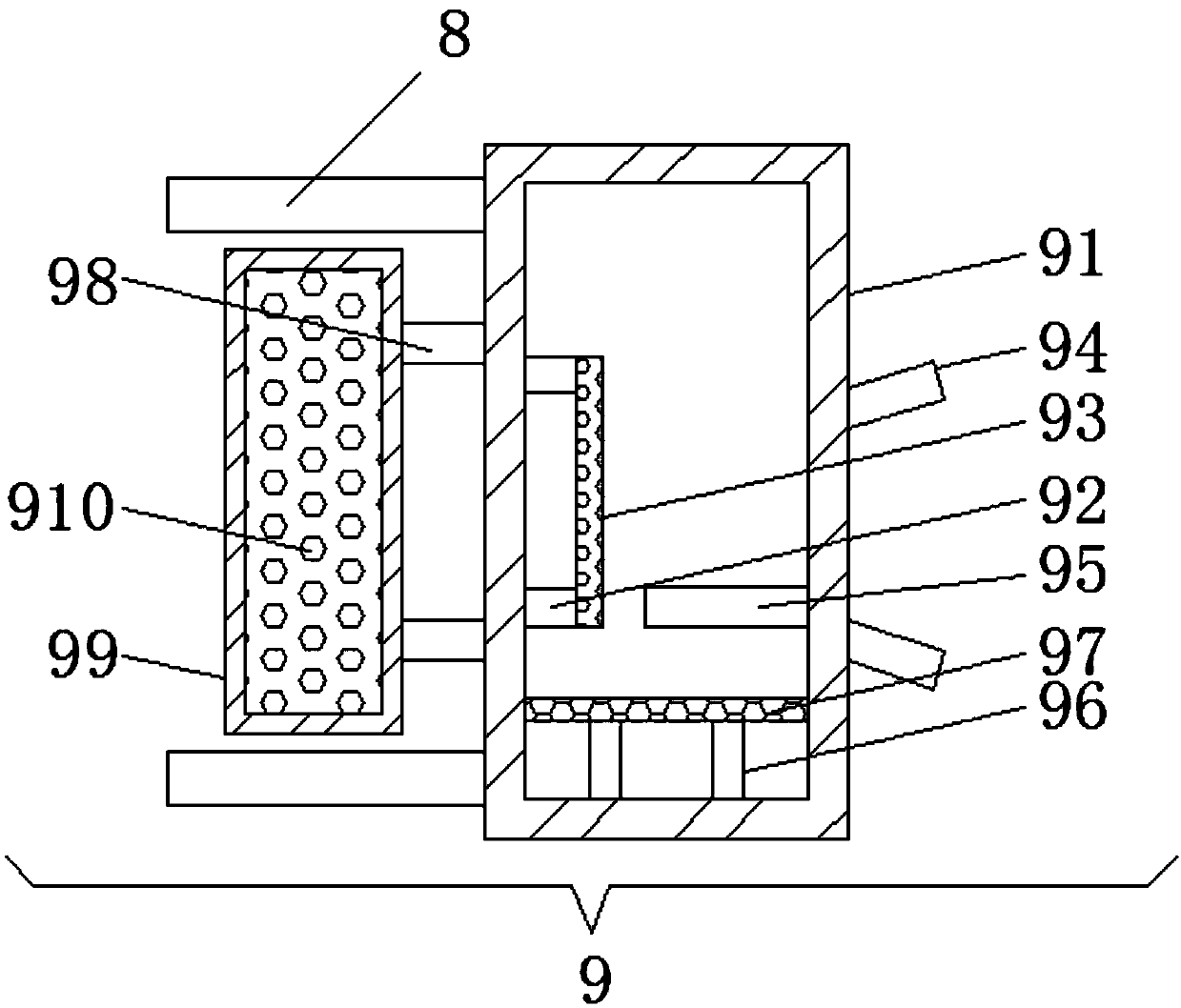

The invention discloses a precise conveying locating system for product parts. The precise conveying locating system comprises a movable base (1), a fixed base (2), two carriers (3 and 9) and two transferring locating devices (4 and 5), wherein the movable base is butt joint with the fixed base through a guide rail; the carriers support the product parts, and the transferring locating devices push the carriers to move on the movable base and the fixed base; each transferring locating device comprises a horizontal movement mechanism (7), a lifting mechanism (8) and a handle (6); the lifting mechanisms are fixed to the upper ends of the horizontal movement mechanisms; the handles are fixed to the fixed base and are separately connected with the horizontal movement mechanisms and the lifting mechanisms; the horizontal movement mechanisms are separately fixed to the inner sides of the movable base and the fixed base and horizontally move in the length directions of the bases to which the horizontal movement mechanisms are fixed; and the transferring locating devices are sequentially separately in rigid connection with the two carriers, and the carriers are moved to the fixed base from the movable base. Lifting action is avoided in a product transferring process, and precision and safety are improved in the product transferring process.

Owner:XIDIAN UNIV

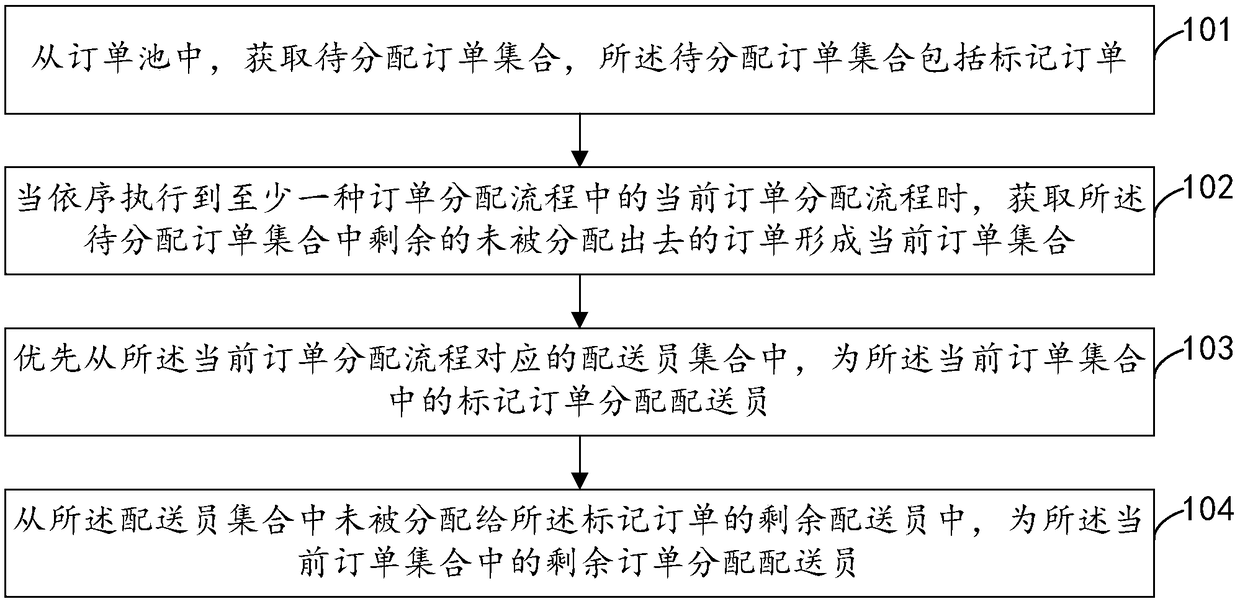

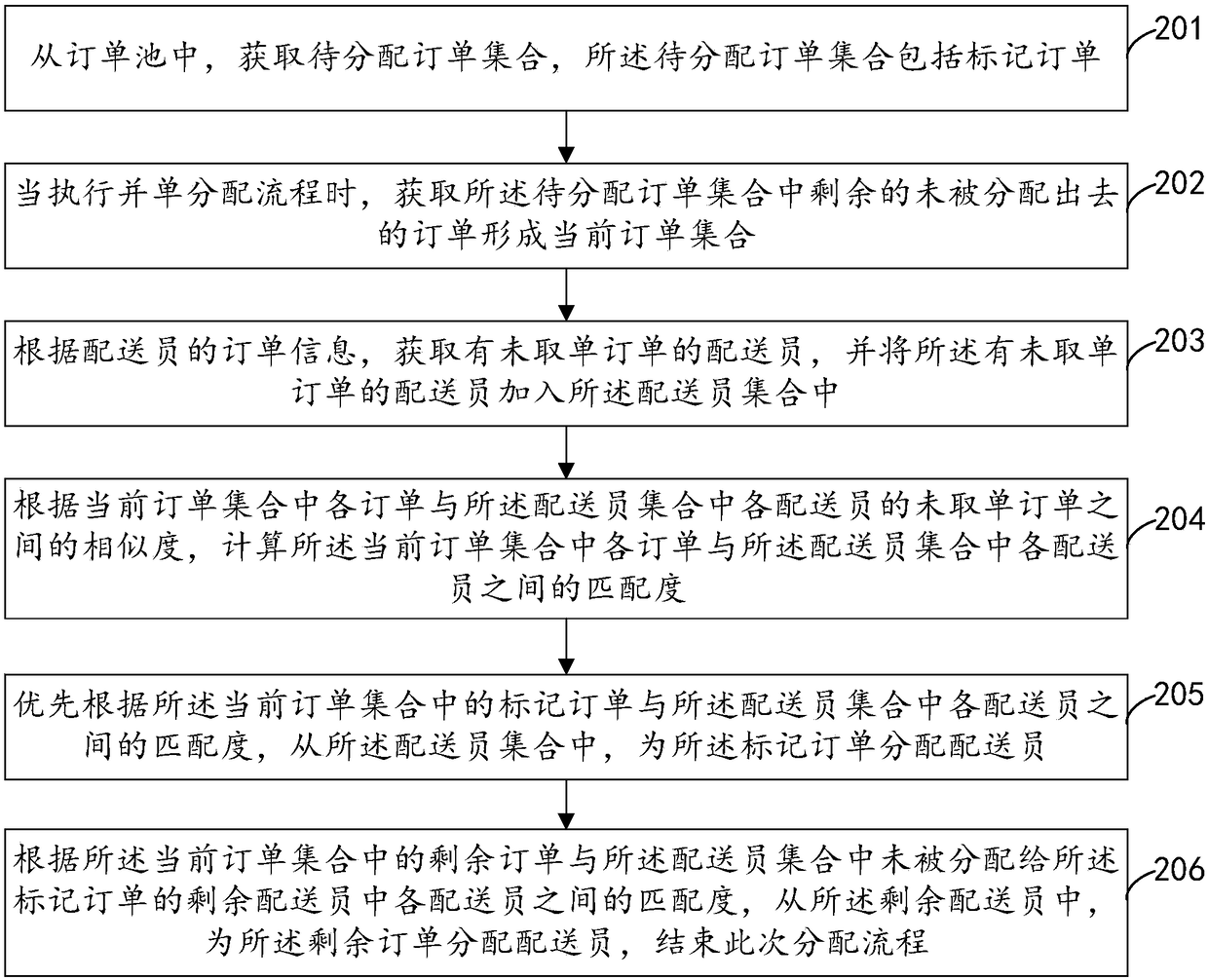

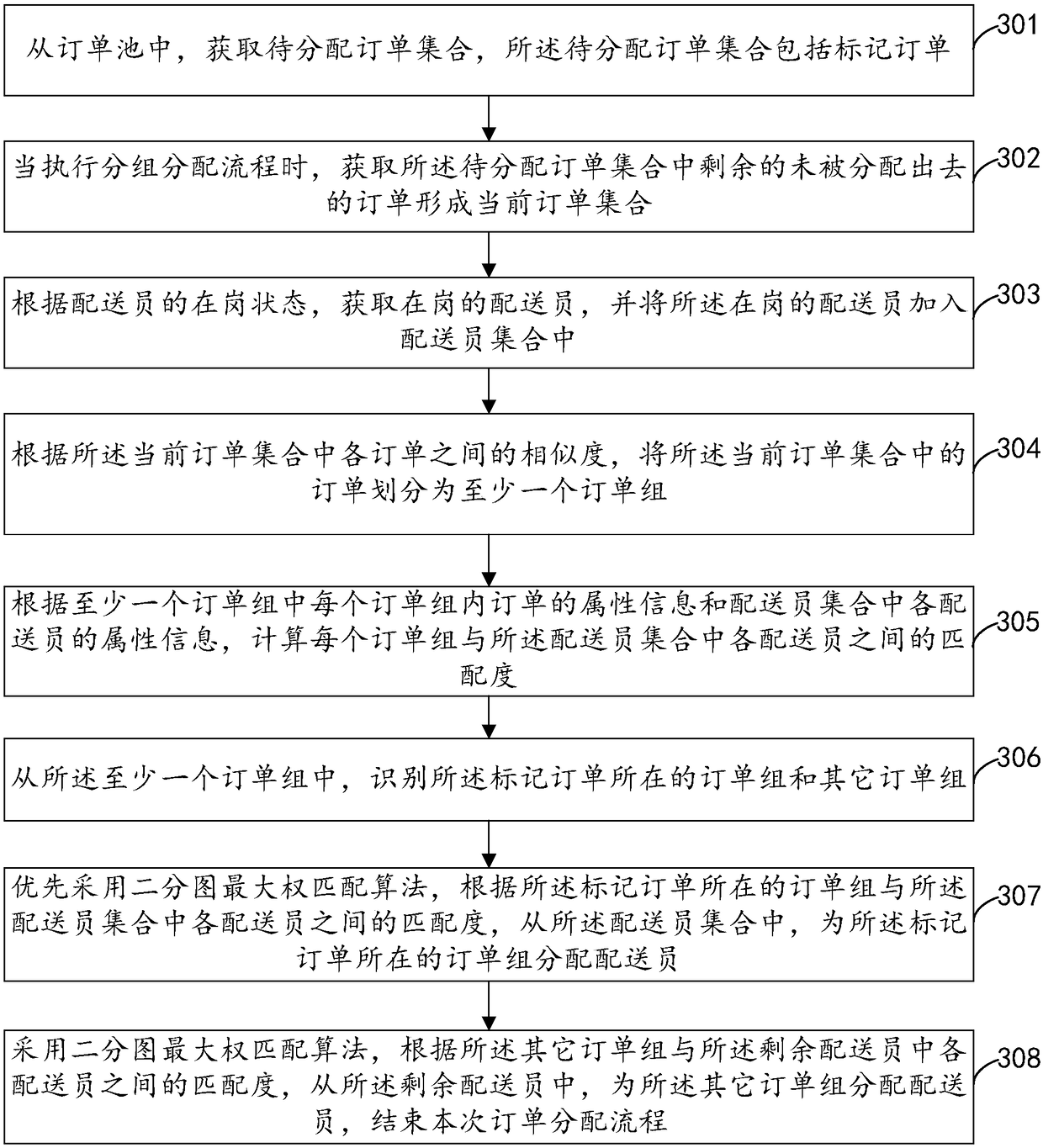

Order allocation method and device

Embodiments of the present application provide an order allocation method and apparatus. The order allocation method comprises the following steps: obtaining an order set to be allocated from an orderpool, wherein the order set to be allocated comprises a marked order; when the current order allocation process in at least one order allocation process is sequentially executed, obtaining the remaining orders in the order set to be allocated that are not allocated to form the current order set; Priority from the current order allocation process corresponding to the set of distributors, for the current order set of marked orders to assign distributors; and assigning a dispatcher to the remaining orders in the current order set from among the remaining dispatchers not assigned to the marked orders in the dispatcher set. Embodiments of the present application can give full play to the advantages of existing order allocation, take into account the situation with special distribution needs, assign priority to the special order dispatcher, ensure the distribution efficiency of the special order, and improve the user experience.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

Precise and fine wire feeding machine

PendingCN108772617ARealize precise controlMeet different transmission ratio requirementsArc welding apparatusDrive wheelTooth number

The invention provides a precise and fine wire feeding machine which comprises a machine frame groove, a wire feeding guide tube, a wire discharging guide tube and a pressing mechanism. The wire feeding guide tube is arranged on one side wall of the machine frame groove, the wire discharging guide tube is arranged on the other side wall of the machine frame groove, and the wire feeding guide tubeand the wire discharging guide tube are located in the same straight line to form a wire feeding route. The pressing mechanism is mounted in the machine frame groove and located on one side of the wire feeding route. The precise and fine wire feeding machine further comprises a transmission mechanism arranged on the other side of the wire feeding route. The transmission mechanism comprises a motor, a driving wheel and a driven wheel. The motor is fixedly mounted on the machine rack groove, and an output shaft of the motor is provided with the driving wheel. The driven wheel is fixedly mountedin the machine frame groove and is engaged with the driving wheel. The driving wheel and the pressing mechanism are matched to achieve wire feeding. The driving wheel is engaged with the driving wheelwith different tooth number, the different transmission ratio requirements can be met, and different wire feeding speed is obtained.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

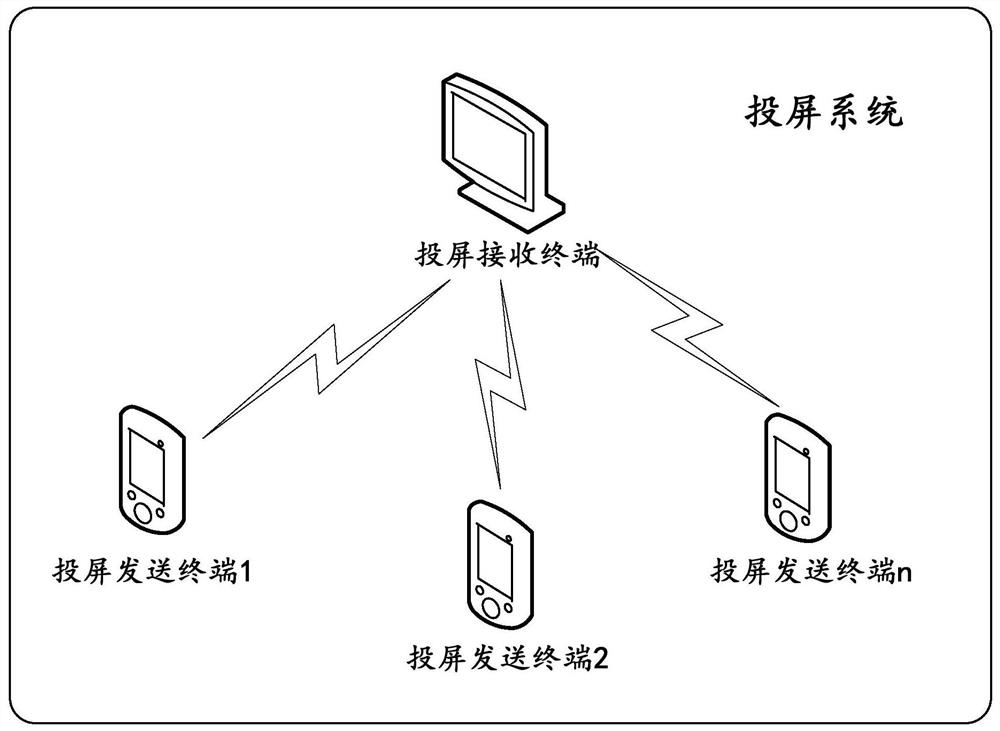

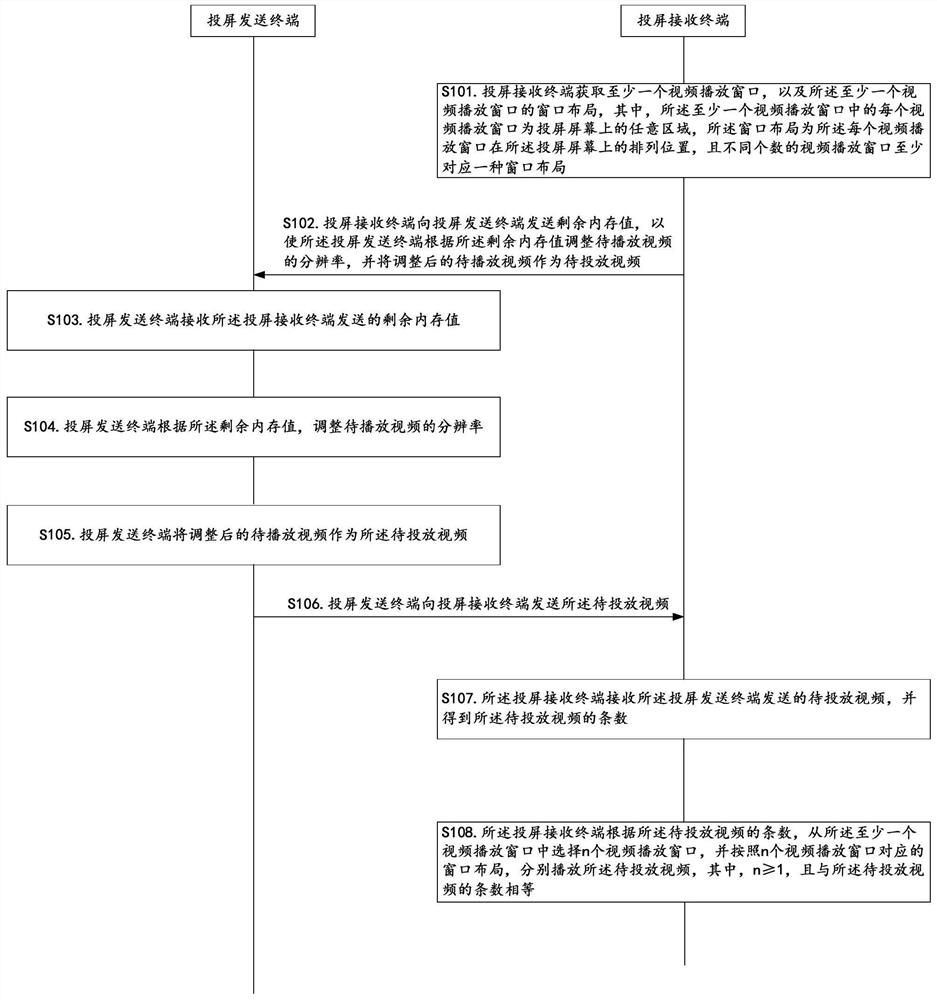

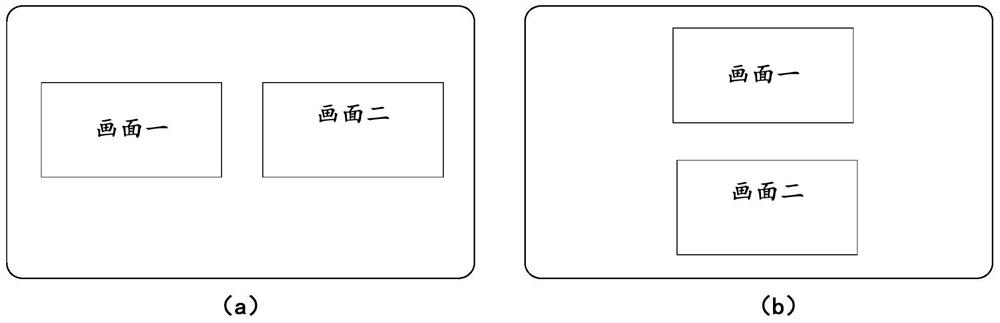

Screen projection method, screen projection receiving terminal and screen projection sending terminal

PendingCN112637672ARealization of screen projectionRealize multi-channel projectionSubstation equipmentSelective content distributionComputer graphics (images)Algorithm

The invention discloses a screen projection method, a screen projection receiving terminal and a screen projection sending terminal. The method comprises the steps of obtaining at least one video playing window and a window layout of at least one video playing window; sending the residual memory value to a screen projection sending terminal, so that the screen projection sending terminal adjusts the resolution of the to-be-played video according to the residual memory value, and takes the adjusted to-be-played video as the to-be-played video; receiving to-be-released videos sent by the screen projection sending terminal, and obtaining the number of the to-be-released videos; selecting n video playing windows from the at least one video playing window according to the number of the to-be-played videos, and playing the to-be-played videos according to the window layouts corresponding to the n video playing windows, wherein n is greater than or equal to 1 and is equal to the number of the to-be-played videos. According to the invention, a plurality of videos to be projected can be played at the same time, the function of multi-channel screen projection is achieved, the application scene of multi-person screen projection is satisfied, and the application range of screen projection is greatly increased.

Owner:深圳乐播科技有限公司

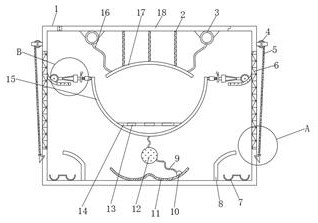

Auxiliary equipment for speaker assembly processing

The invention discloses auxiliary equipment for speaker assembly processing, and the auxiliary equipment comprises a finished product conveying and moving mechanism and a supporting installation bottom plate horizontally fixed at the bottom of the finished product conveying and moving mechanism; a finished product assembling mechanism is installed at the right side of the supporting installation bottom plate; the finished product conveying and moving mechanism comprises an installation bracket and a conveying and adjusting mechanism distributed at the top of the installation bracket; the center of the bottom of the conveying and adjusting mechanism is provided with a self-cleaning mechanism; the left and right ends of the bottom of the installation bracket are connected with lifting brackets through hinging seats, the bottoms of the lifting brackets are connected with support stands by lifting and adjusting mechanisms; the bottoms of the support stands are horizontally provided with support bases; and four internal thread adjusting and supporting cylinders in rectangular distribution are installed around the bottoms of the support bases. Through scientific and reasonable structuraldesign, the auxiliary equipment for the speaker assembly processing provided by the invention can quickly assemble the speaker finished product into a box, reduce the labor cost input, improve the assembly efficiency, ensure the stability during the assembly process, and have wide application range and good practical and popularization value.

Owner:HEFEI VANSON ELECTRONICS

Empty carton delivery device of rod-like material boxing machine and delivery method thereof

ActiveCN104176322APrevent lodgingReduce production processPackaging cigaretteCartoning machineReciprocating motion

The invention provides an empty carton delivery device of a rod-like material boxing machine. The device comprises an underbed, an electric cylinder arranged on the underbed and a servo motor which drives the electric cylinder to work, wherein slide supporting rods parallel to the electric cylinder are respectively arranged on the two sides of the electric cylinder; an empty carton delivery plate parallel to the underbed is mounted on the underbed; an empty carton pushing device is mounted on each slide supporting rod. The invention also provides an empty carton delivery method which comprises steps of carton packaging, carton delivery, backwards movement of the slide supporting rods, and the like; the slide supporting rods can perform reciprocating movement forwards and backwards by operating the steps repeatedly, so that each empty carton delivered to the empty carton delivery plate can move forwards by the distance between two fixing pushing blocks and the empty carton on the rear side of the empty carton delivery plate can be conveyed to downstream equipment, as a result, automatic delivery of empty cartons is realized.

Owner:XUCHANG TOBACCO MACHINERY

Mechanical part machining guiding device

InactiveCN107792627AIncrease delivery rateIncrease frictionConveyorsConveyor partsMachine partsDrive motor

The invention belongs to the field of injection molding machines and particularly relates to a mechanical part machining guiding device. The mechanical part machining guiding device is used for solving the problem that existing mechanical parts which have smooth surfaces and are small in size are difficult to guide and convey. The following scheme is put forwards at present; the mechanical part machining guiding device comprises a conveying rack and a second installation table located on one side of the conveying rack; a first guiding conveying belt, a second guiding conveying belt and a feeding conveying belt are sequentially arranged on the conveying rack; second installation tables which are symmetrically arranged are arranged on the two sides of the conveying rack; and the top end of one of the second installation tables is provided with a driving motor. By means of the mechanical part machining guiding device, mechanical guiding conveying can be achieved in the mechanical part machining process, parts are not likely to slide on the a conveying belt in the conveying process, metal mechanical parts which have different surface smooth degrees or are small in size can be guided and transported, selection space is increased, in addition, the machining efficiency is greatly increased, guiding conveying can be conducted on different specifications of parts, and practicability ishigh.

Owner:HENAN COLLEGE OF IND & INFORMATION TECH +1

Material neatening and conveying device

ActiveCN107117449AAvoid problems such as scratchesAvoid scratchesConveyor partsEngineeringMechanical engineering

The invention provides a material neatening and conveying device. The material neatening and conveying device comprises a servo material neatening part, an auxiliary material neatening part and a transition mechanism part which are sequentially arranged in the material transmission direction; the servo material neatening part comprises a first upper conveying belt mechanism and a first lower conveying belt mechanism which are arranged in parallel in a spaced manner in the up-and-down manner; the auxiliary material neatening part comprises a second upper conveying belt mechanism and a second lower conveying belt mechanism which are arranged in a spaced manner in the up-and-down manner, wherein the second upper conveying belt mechanism can be switched between the manner that the second upper conveying belt mechanism is parallel to the second lower conveying belt mechanism and the manner that the second upper conveying belt mechanism is inclined relative to the second lower conveying belt mechanism; and the transition mechanism part comprises a pair of transition plates arranged in a spaced manner, and each transition plate is provided with a plane part and a protruding part. By means of the material neatening and conveying device, scratches are prevented from being generated on the material side walls during material neatening transportation.

Owner:北京大森包装机械有限公司

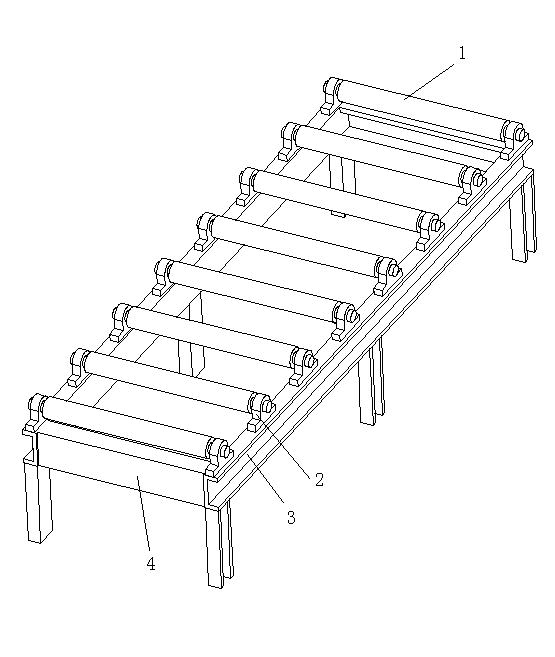

Transmission device

InactiveCN102700893ASimple structural designMeet delivery needsRoller-waysBiochemical engineeringTransmission delay

The invention relates to wall hanging plate processing auxiliary equipment, in particular to a transmission device, which comprises a support frame, wherein support plates are respectively arranged at two sides of the top of the support frame, a plurality of bearing seats are arranged on each support plate, and rolling shafts are arranged among the bearing seats arranged on the two support plates. The transmission device has the advantages that the structural design is simple, the wall hanging plate transportation requirements can be met, meanwhile, the manufacture cost of the equipment is lower, and the production cost of enterprises can be saved.

Owner:WUHU HANGUANG STEREO PARKING EQUIP

Eccentric water distributor dropping-fishing device

The invention discloses an eccentric water distributor dropping-fishing device, and belongs to the technical field of water distributors. The eccentric water distributor dropping-fishing device comprises a sleeve, wherein an upper joint is arranged on the top of the sleeve; a lower joint is arranged on the bottom of the sleeve; arc-shaped grips are separately arranged on the tops of the left sideand the right side of the upper joint; fixing plates are separately arranged on the left side and the right side of the bottom of the lower joint; a damping spring sleeves the outer wall of the lowerjoint; the bottom of the damping spring is fixedly connected with the fixing plates; fixing rings are separately connected to the top and the bottom of the outer wall of the sleeve in a sleeving manner; mounting rods are separately arranged on the top and the bottom of the right side of each fixing ring; the right sides of the two groups of mounting rods are fixedly connected through the dropping-fishing device. The eccentric water distributor dropping-fishing device is simple in structure and convenient to operate, and meets a fishing requirement; the work intensity and labor cost are reducedgreatly; by the damping spring, the circumstance that the dropping-fishing device is damaged due to vibration generated when the dropping-fishing device is placed at a specific position is avoided, the service life is prolonged, and use demands are greatly met.

Owner:FUNING COUNTY PETROL MECHANICAL LIMITED

Take-out box for food delivery service

InactiveCN112173369AEasy to disassemble for cleaning and disinfectionGuaranteed hygieneDomestic cooling apparatusLighting and heating apparatusFood deliveryEngineering

The invention discloses a take-out box for the food delivery service. The take-out box comprises a box body, a rectangular groove is formed in the outer wall of the top of the box body, and a cover plate is connected to the inner wall of one side of the rectangular groove through hinges; through grooves are formed in the inner walls of the two sides of the box body, and glass plates are fixedly connected to the inner walls of the peripheries of the through grooves; and a sliding rail is fixedly connected to the outer wall of one side of each glass plate, and rolling wheels are slidably connected to the inner walls of the bottoms of the sliding rails. According to the take-out box, a take-out deliveryman can place take-out needing to be delivered into a first clamping groove to be fixed, then when the take-out deliveryman passes through a bumpy road to cause inclining and bumping of a vehicle, a containing vessel can rotate in the X-axis direction and the Y-axis direction, because the gravity borne by a counter weight ball arranged at the bottom of the containing vessel is in the vertical downward direction, it can be guaranteed that the containing vessel is kept vertically downwardall the time, the situation that the take-out waggles and scatters is avoided, and meanwhile a rolling ball can slide in a sliding groove at the moment that the counter weight ball is restored to bevertically downward from being inclined.

Owner:李勇超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com