Flexible combined belt conveyor

A belt conveyor and combined technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problem that the angle of mutual misalignment should not be too large, it is difficult to adapt to turning transportation, and affect the flexibility of belt conveyors, etc. problem, to achieve the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

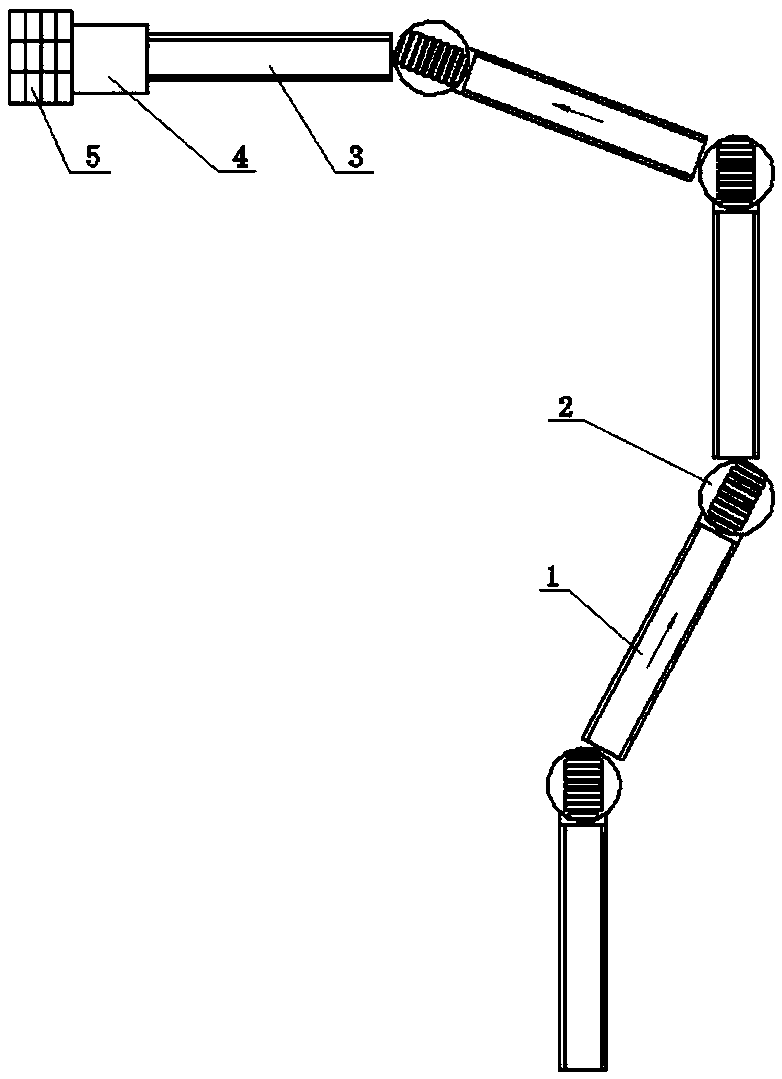

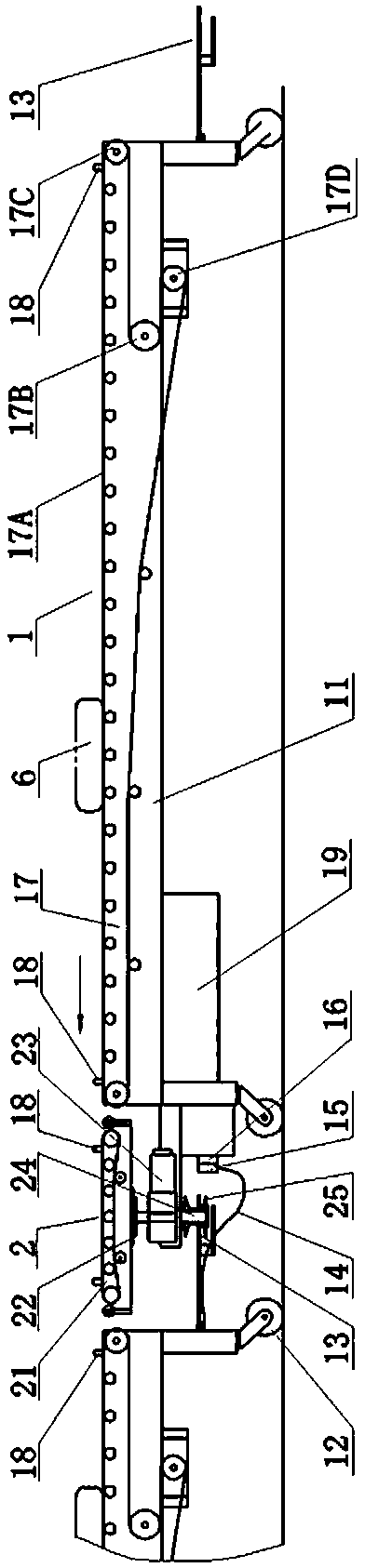

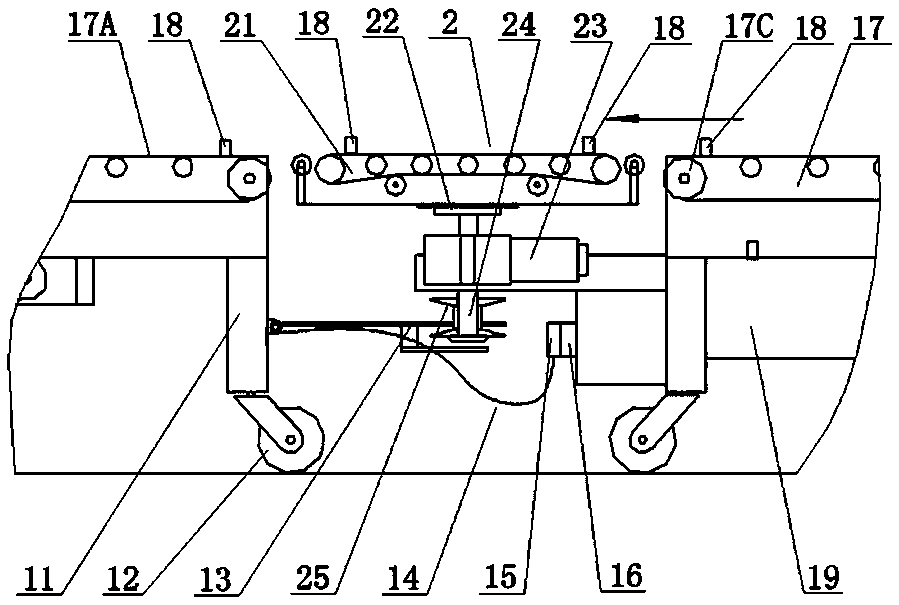

[0019] like figure 1 and 2 As shown, the present invention includes at least two groups of mobile conveying units composed of a mobile belt conveyor 1 and a transfer platform 2 fixedly arranged at one end of the mobile belt conveyor 1, which are connected head to tail in series. The belt conveyor 1 includes a body 11, a universal wheel 12 arranged at the bottom of the body 11, a quick connection device 13 fixed at the end of the body 11 away from the transfer platform 2, and an electrical connection socket 15 fixed at one end of the body 11 And the electrical connection plug 16 that the other end is connected by flexible cable 14, the belt conveyor 17 that is fixedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com