Intelligent assembly work station

A workstation and intelligent technology, applied in the field of special-shaped parts production equipment, can solve the problems of inability to ensure assembly quality, inability to locate multiple products, and unfavorable to enterprise production, and achieve the effect of wide application range, shortened processing time, and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

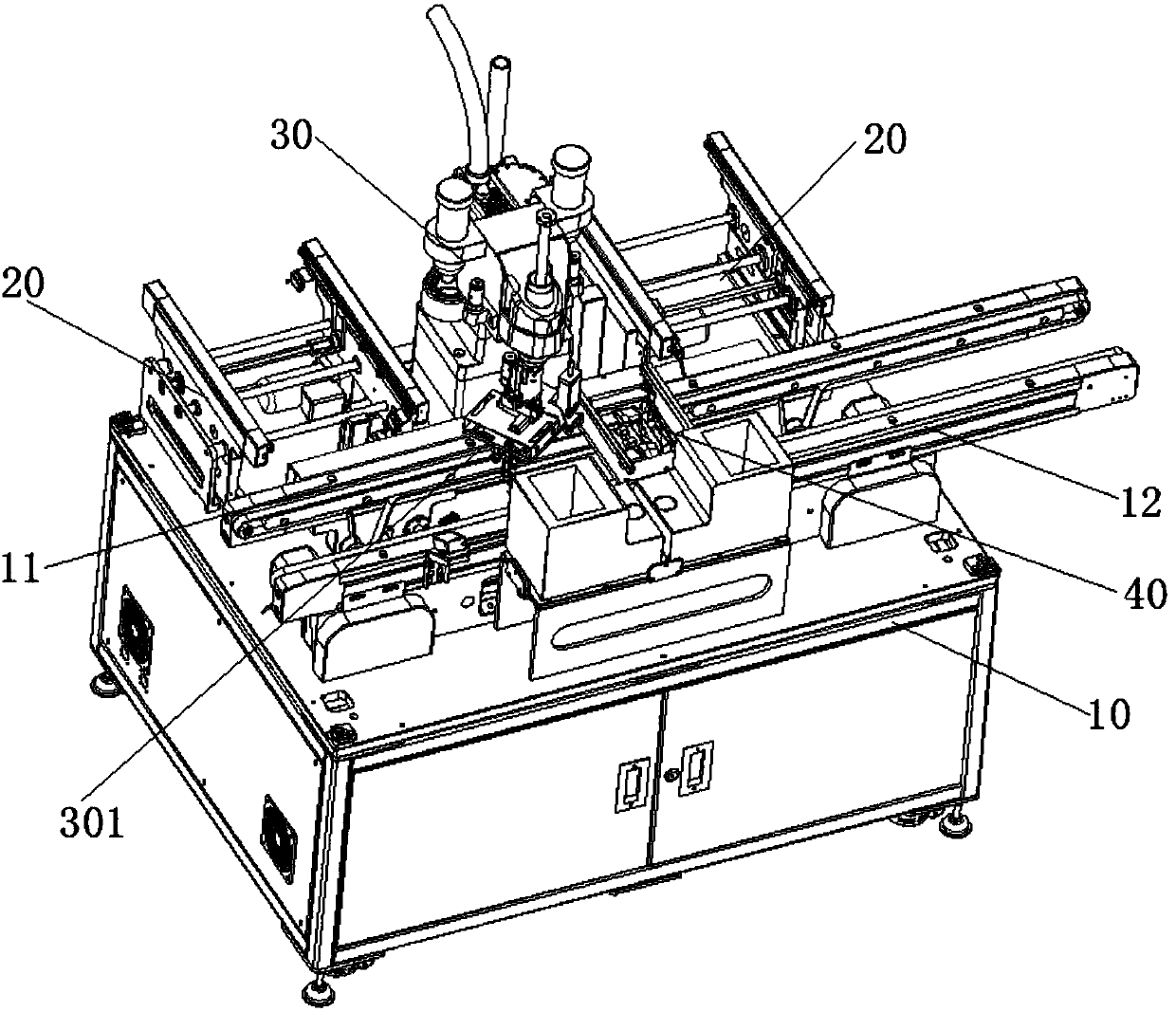

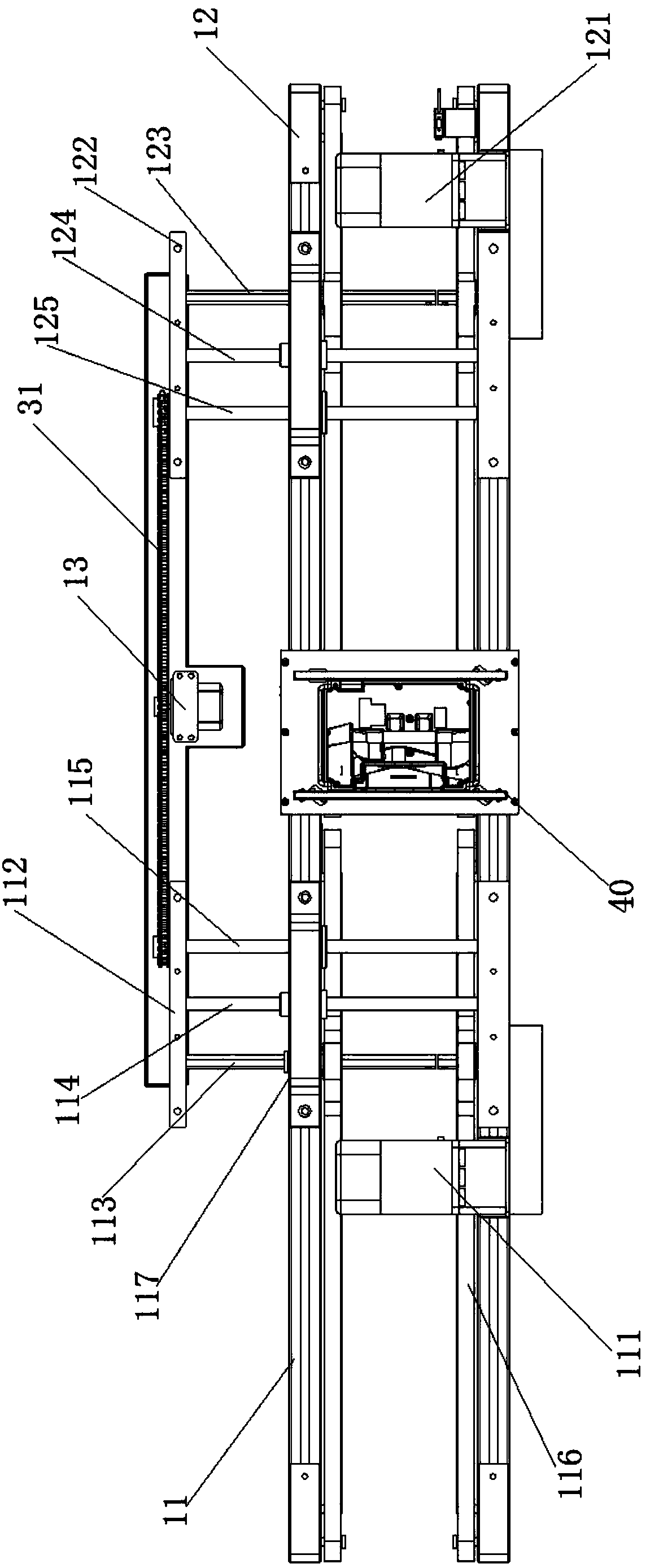

[0030] refer to figure 1 , an intelligent assembly workstation, including a frame 10, the frame 10 is provided with an adjustable track mechanism 20, two adjustable connecting mechanisms and a dispensing suction cup manipulator, and the adjustable track mechanism 20 is provided with special-shaped parts Fixture 40, two adjustable connecting mechanisms are arranged on both sides of the glue dispensing suction cup manipulator;

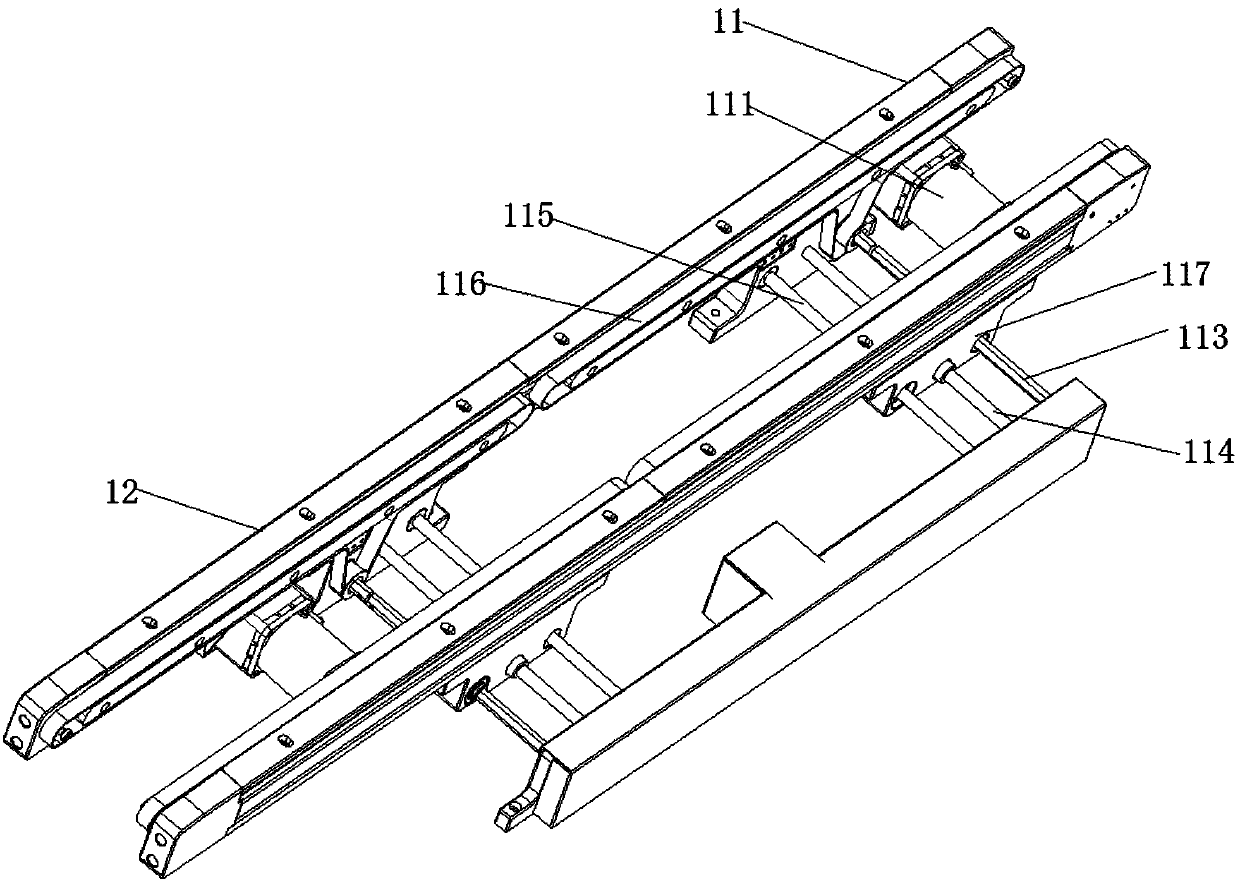

[0031] The adjustable track mechanism 20 includes an adjustment assembly, a first track 11 and a second track 12, the adjustment assembly is arranged between the first track 11 and the second track 12, and the first track 11 and the second track 12 same str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com