Empty carton delivery device of rod-like material boxing machine and delivery method thereof

A technology of conveying device and cartoning machine, which is applied in the direction of packaging and packaging cigarettes, and can solve the problems of low production efficiency, a large amount of manpower and material resources, cumbersome loading and unloading operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

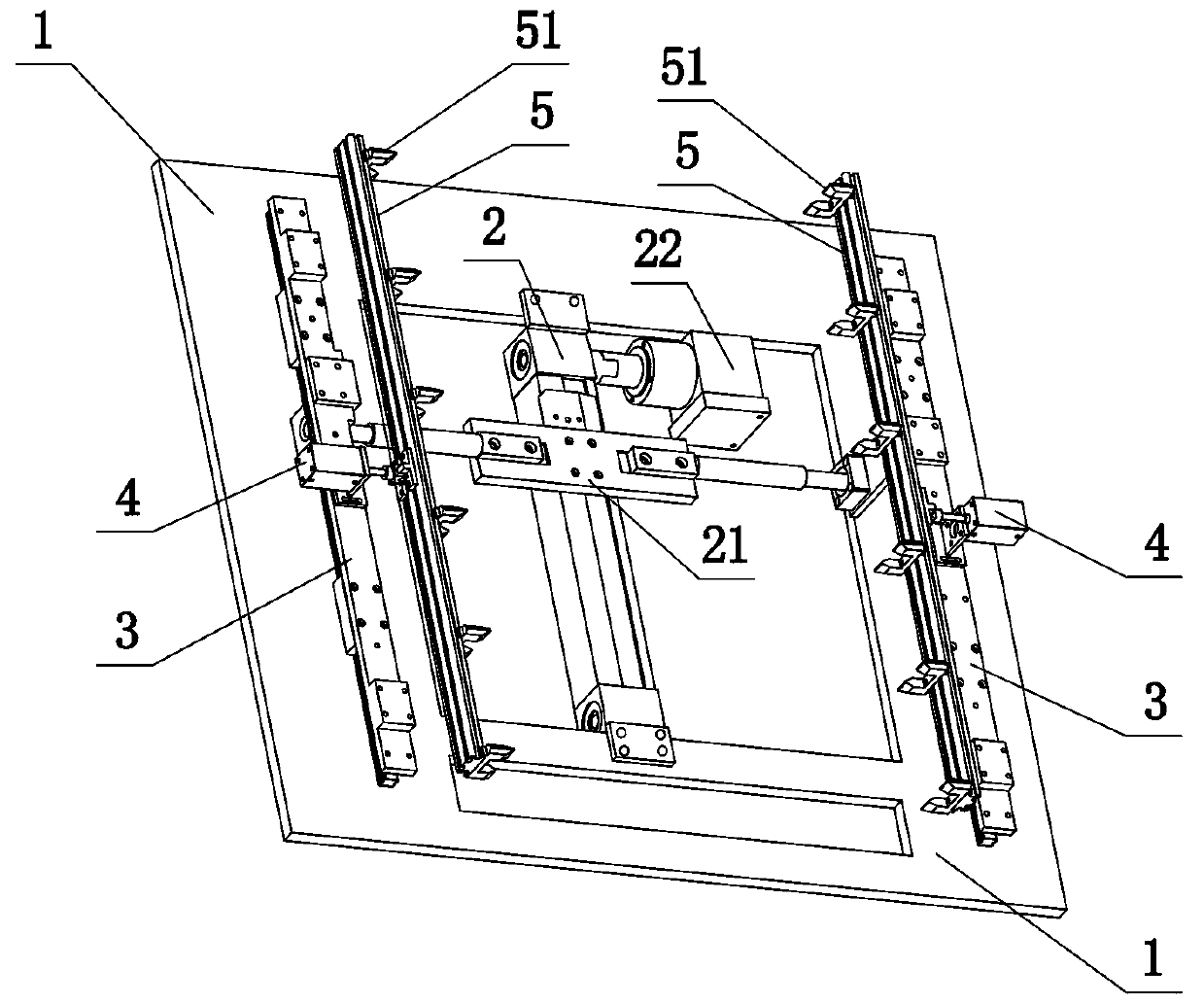

[0025] Such as figure 1 As shown, an empty carton conveying device for a rod-shaped material cartoning machine includes a bottom frame 1 , an electric cylinder 2 vertically arranged on the bottom frame 1 , and a servo motor 22 for driving the electric cylinder 2 .

[0026] Both sides of the electric cylinder 2 are respectively provided with sliding support rods 3 parallel to the electric cylinder 2, and the two sliding support rods 3 are located above the chassis 1, and the electric cylinder 2 is provided with The sliding table 21 of the chassis 1, the servo motor 22 drives the sliding table 21 of the electric cylinder 2 to reciprocate back and forth; the two sides of the sliding table 21 drive the sliding support rods 3 respectively, so as to realize the The forward and backward reciprocating motion of the sliding support rod 3 is described. In order to allow the sliding support rod 3 to slide smoothly, the bottom frame 1 is provided with a slide groove for sliding the slidi...

Embodiment 2

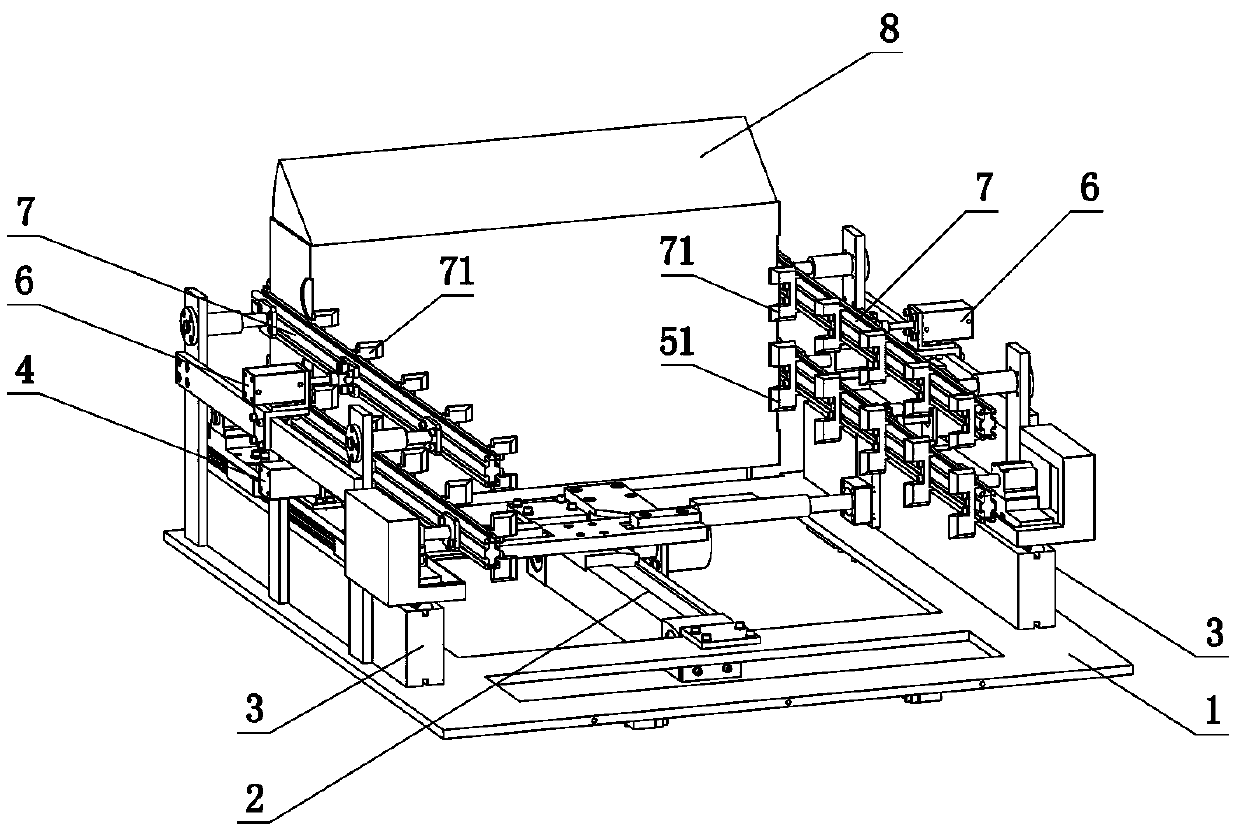

[0041] The main difference between this embodiment and Embodiment 1 is that the empty carton conveying device of the rod-shaped material cartoning machine also includes two sets of empty carton anti-falling devices. Such as figure 2 As shown, the empty carton anti-falling device includes an anti-falling cylinder 6 fixed on the bottom frame 1 and an anti-falling support rod 7 installed on the telescopic rod of the anti-falling cylinder. The anti-falling cylinder 6 is located at Above the cylinder 5 and in a different-plane vertical relationship with the sliding support rod 3, the anti-fall support rod 7 is parallel to the slide support rod 3 and above the push rod 5, and the anti-fall support rod 7. There are six anti-fall supporting blocks 71 equidistantly arranged on the inner side. The anti-fall supporting blocks 71 on the two anti-fall supporting rods 7 are arranged in a one-to-one correspondence. The fixed pushing blocks 51 are arranged in a one-to-one correspondence. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com