Double-layer conveying system

A technology of double-layer conveying and conveying trolleys, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of insufficient precision, insufficient transmission precision, fixed lifting stroke of the swing arm, etc., and achieve reliable performance and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

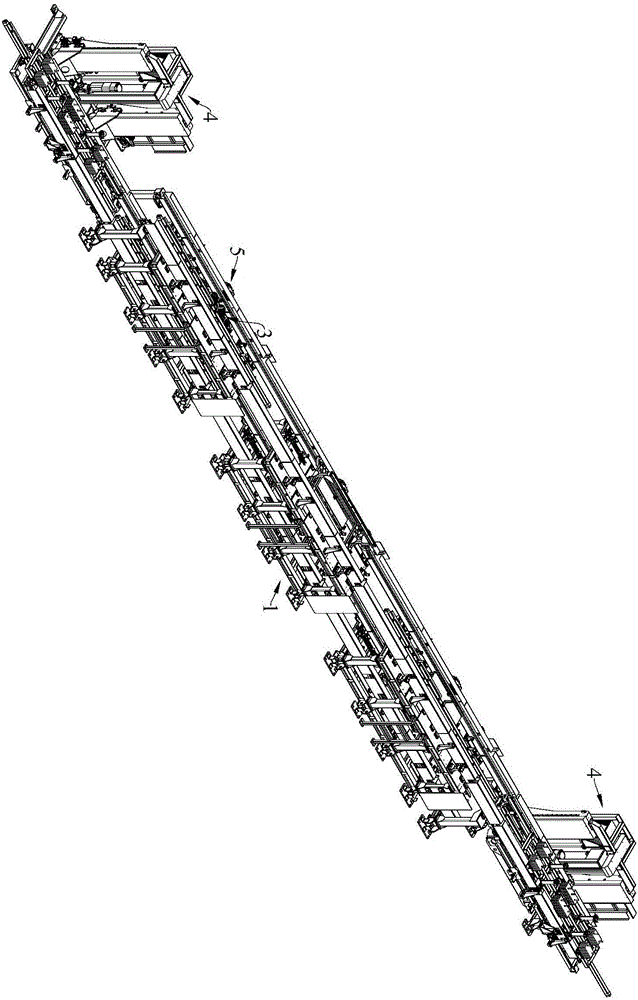

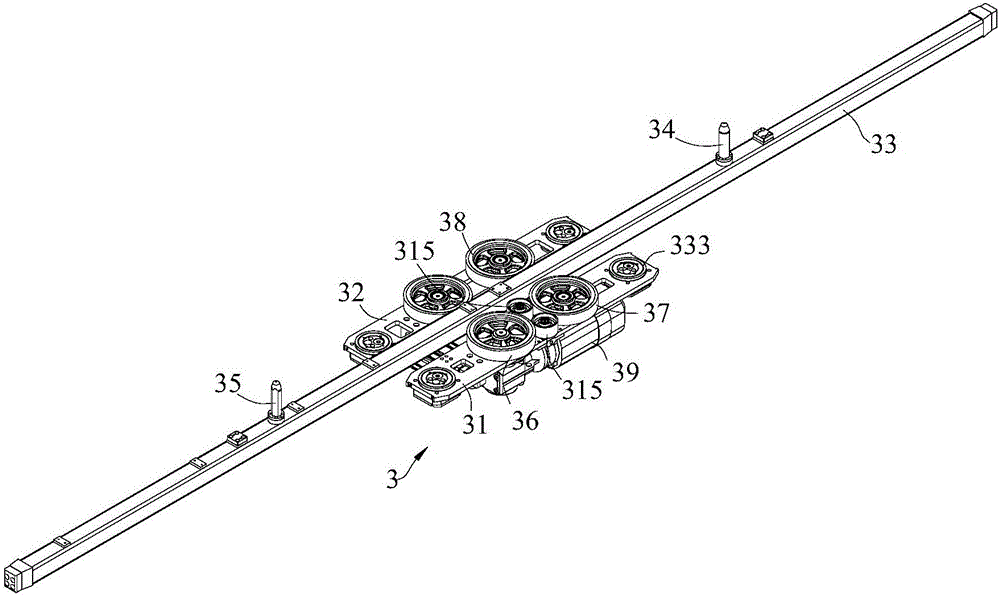

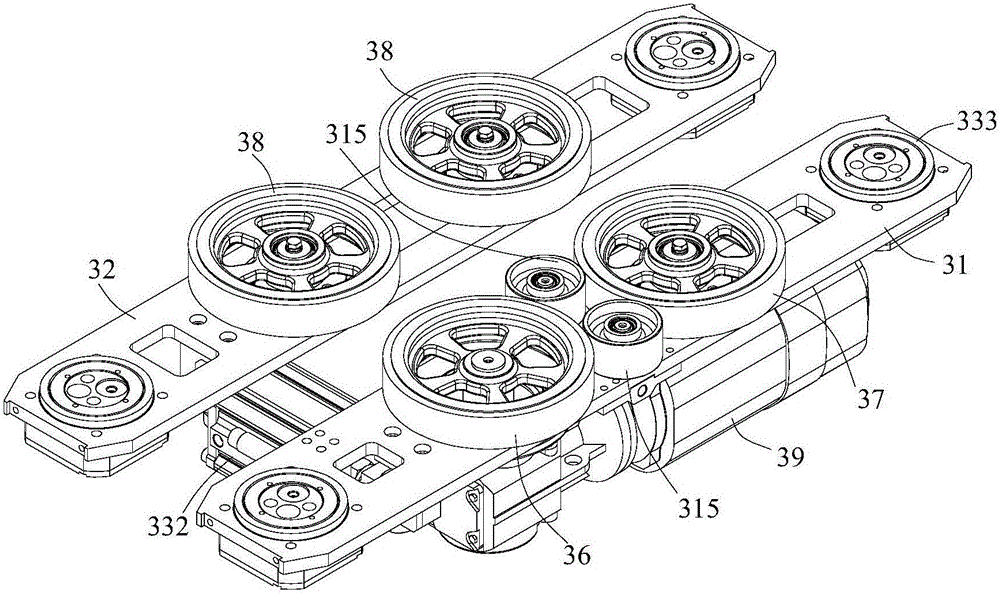

[0042] refer to Figure 1 to Figure 14 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, but the actual application direction of the present invention is not limited thereto.

[0043] see figure 1 , the present invention provides a double-layer conveying system, comprising a supporting part 1 and a conveying trolley 2, the supporting part 1 has an upper guide rail and a lower guide rail, and the supporting part 1 is provided with a drive conveying trolley 2 along the upper guide rail or the lower guide rail. The driving part 3 of the movement, the supporting part 1 is equipped with a positioning unit 5 that can position the conveying trolley 2 moving along the upper guide rail at each station, and also includes an elevator part that can switch the conveying trolley 2 between the upper guide rail and the lower guide rail 4. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com