Mechanical part machining guiding device

A technology of guiding devices and mechanical parts, which is applied in the field of mechanical parts processing, can solve the problems of low efficiency of mechanical parts, and achieve the effects of cost saving, strong practicability, and accelerated processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

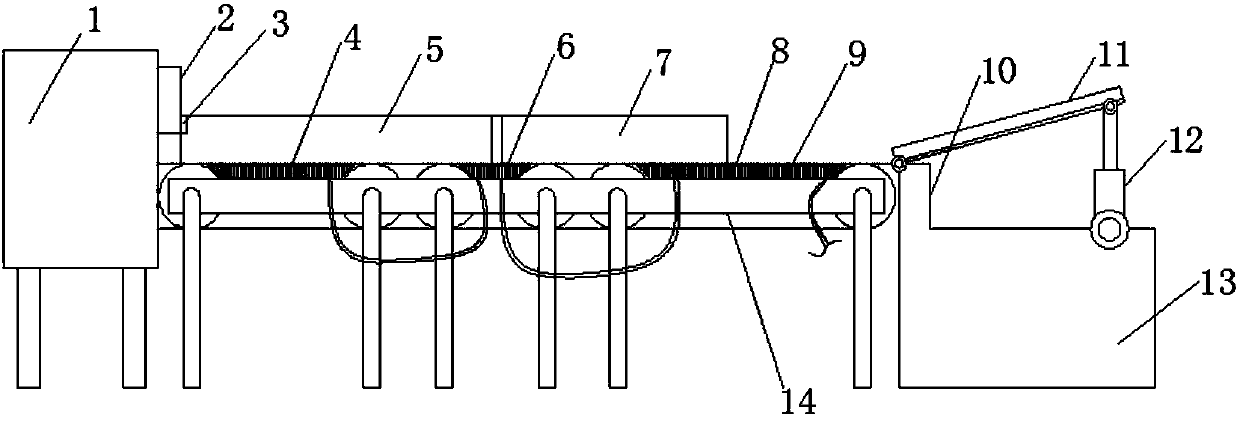

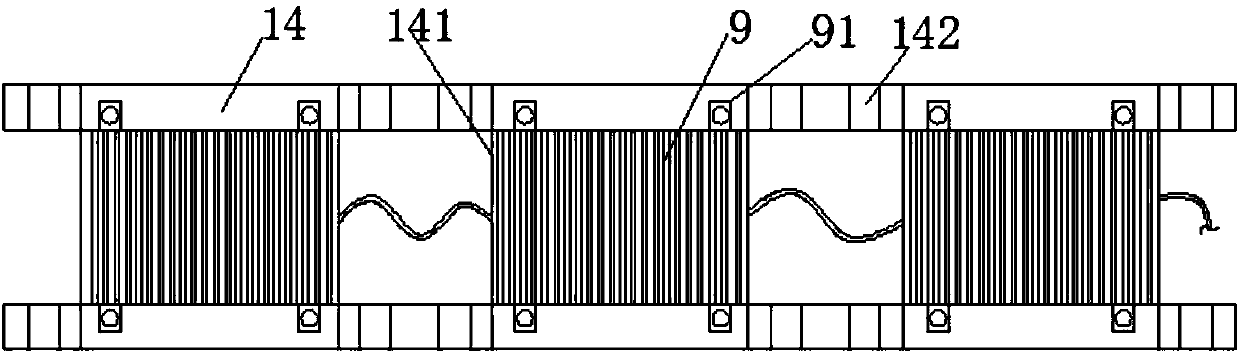

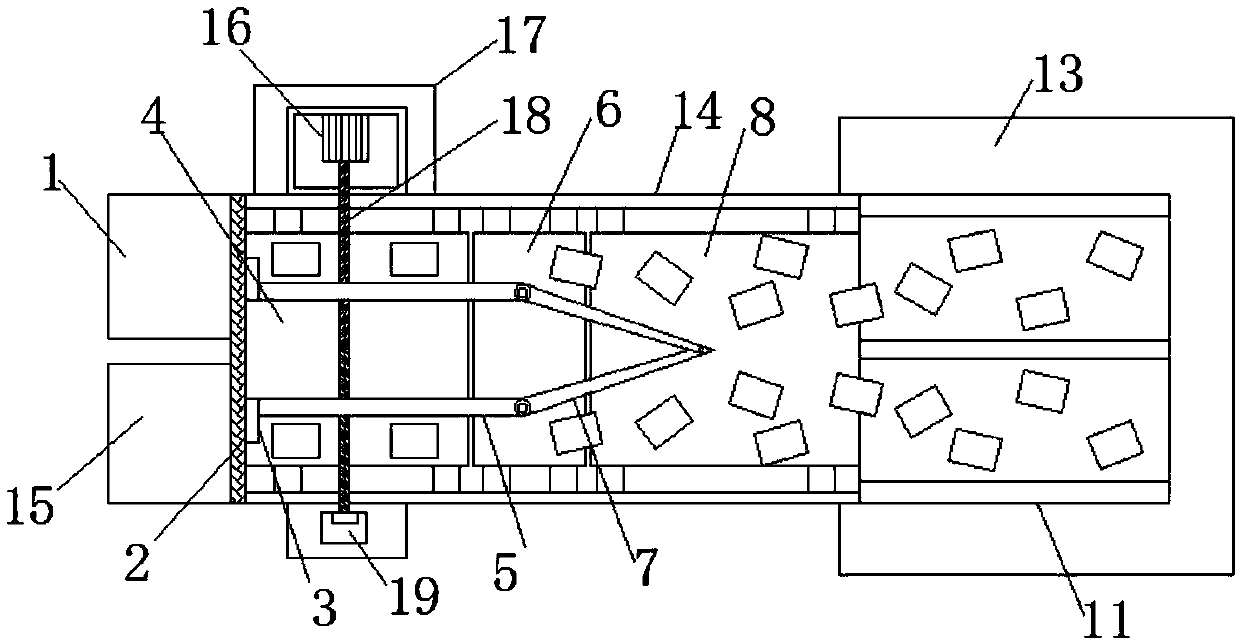

[0029] Embodiment: When the present invention is in use, the mechanical parts are placed randomly on the two feeding plates in the feeding slide 11 manually, and the cylinder 12 can adjust the angle of the feeding slide 11, thereby adjusting the feeding speed, and then The mechanical parts slide down from the feeding plate 11 to the first guide conveyor belt 8, and the two second guide plates 7 divide the conveying path into two. When the mechanical parts pass through the second material guide plate 7, the mechanical parts follow two symmetrical paths Conveying, when the mechanical parts are being conveyed, since the winding 9 is energized, the winding 9 and the metal mounting plate 141 form a magnetic field, so that the metal mechanical parts on the surface of the conveyor belt are adsorbed downward, so that the friction between the mechanical parts and the surface of the conveyor belt Greatly increased, even smoother mechanical parts or smaller parts can be transported using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com