Feed conveying device with side leakage prevention function

A conveying device and anti-side leakage technology, applied in the field of feed conveying devices with anti-side leakage function, can solve problems such as blockage, side leakage of feed, accumulation of feed conveying, etc., improve conveying speed and smoothness, and prevent feed leakage detection , The effect of preventing side leakage of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

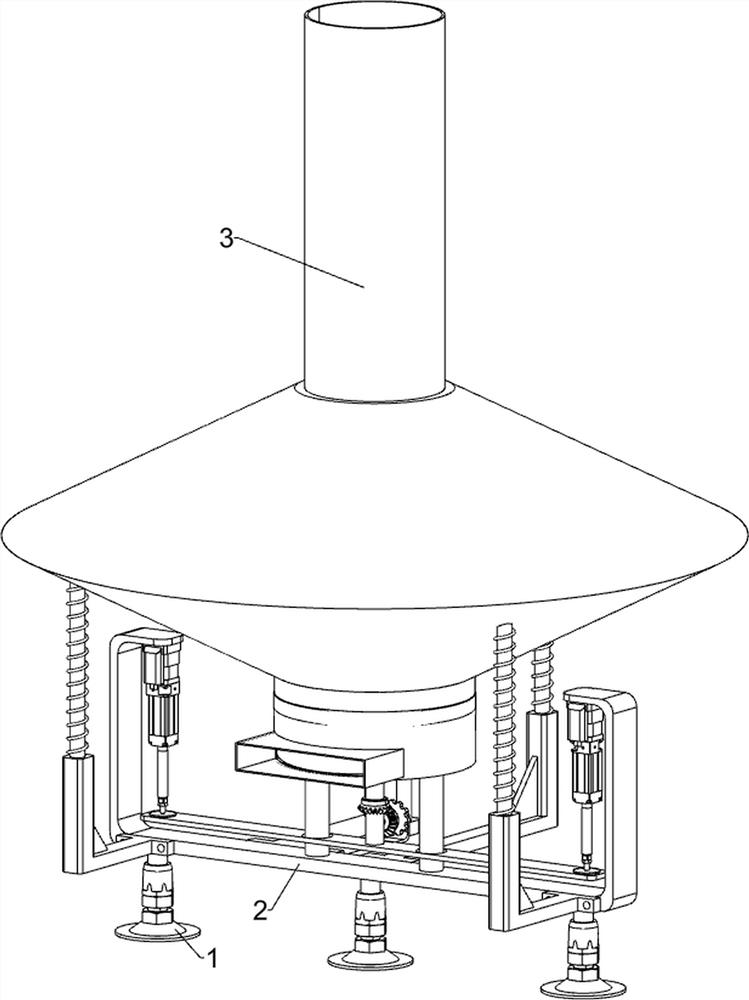

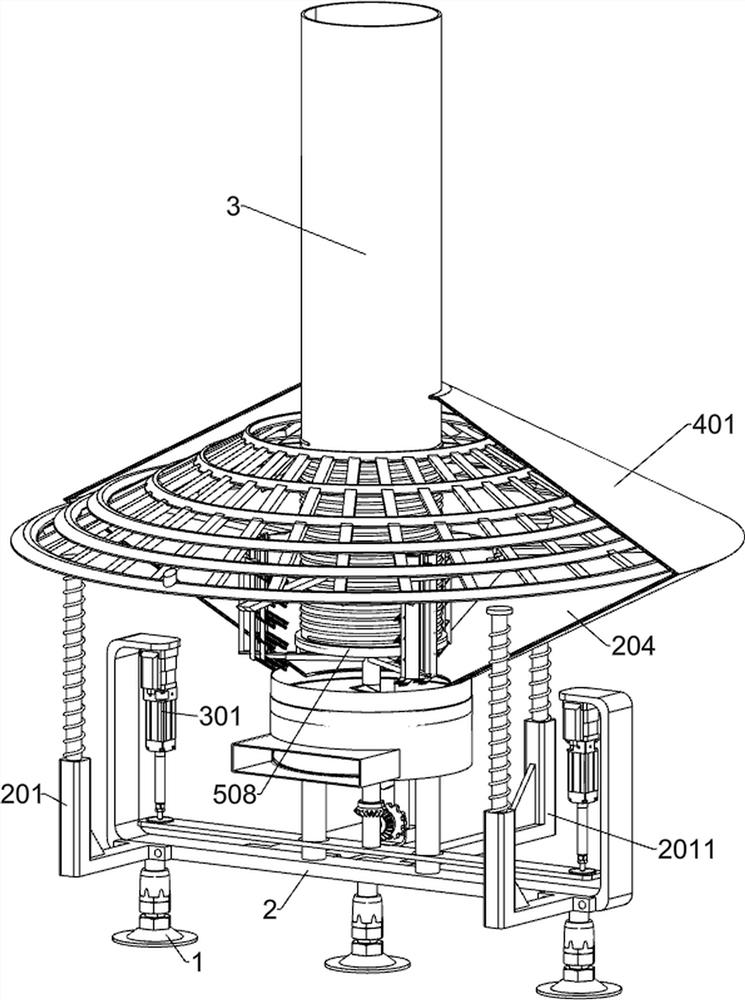

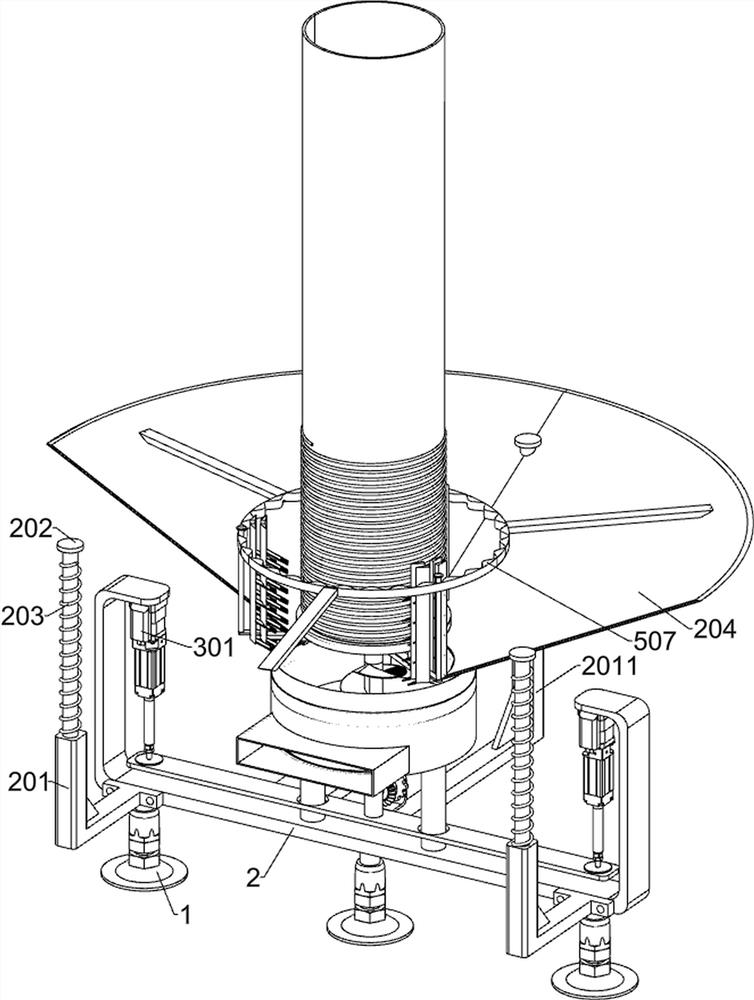

[0032] A feed conveying device with anti-side leakage function, such as Figure 1-Figure 9 As shown, it includes a fixed foot 1, a U-shaped fixed frame 2, a feeding pipe 3, a gravity switch system, an anti-blocking system and a return system; there are three fixed feet 1; the upper surface of the three fixed feet 1 is fixed. U-shaped fixed frame 2 is connected; gravity switch system is installed on U-shaped fixed frame 2; anti-blocking system is installed on the lower side of gravity switch system; anti-blocking system is connected with U-shaped fixed frame 2; return system is installed on the upper side of gravity switch system ; The return system is connected with a feeding pipe 3, and the lower part of the feeding pipe 3 is set as a telescopic structure.

[0033]The gravity switch system includes a first L-shaped plate 201, a round rod 202, a first elastic member 203, a funnel 204, a first connecting rod 205, a hollow limit rod 206, a first shifting block 207, a second shif...

Embodiment 2

[0044] On the basis of Example 1, such as figure 1 and Figure 10-Figure 12 As shown, an auxiliary dredging system is also included. An auxiliary dredging system is installed on the upper side of the dredger 306. The auxiliary dredging system includes a second elastic member 501, a connecting column 502, a first separating plate 503, a second separating plate 504, and a pushing plate. 505, the third connecting plate 506, the shaking ring 507, the connecting ring 508 and the sliding rod 509; the upper side of the dredge 306 is fixedly connected with three second elastic members 501 arranged in an annular array; the telescopic ends of the three second elastic members 501 are connected by Each block is fixed with a connecting column 502; the telescopic ends of the three second elastic members 501 are respectively fixed with two first separation plates 503 and two second separation plates 504; the six first separation plates 503 are located in the six The outer sides of the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com