Sealing material for impermeability tests

A technology for sealing materials and impermeability testing, which is applied in suspension and porous material analysis, permeability/surface area analysis, and measuring devices, etc. It can solve the problem that the impermeability pressure cannot meet the requirements, the height of the mortar specimen is small, and the specimen is uneven and other problems to achieve the effect of eliminating side leakage, remarkable sealing effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

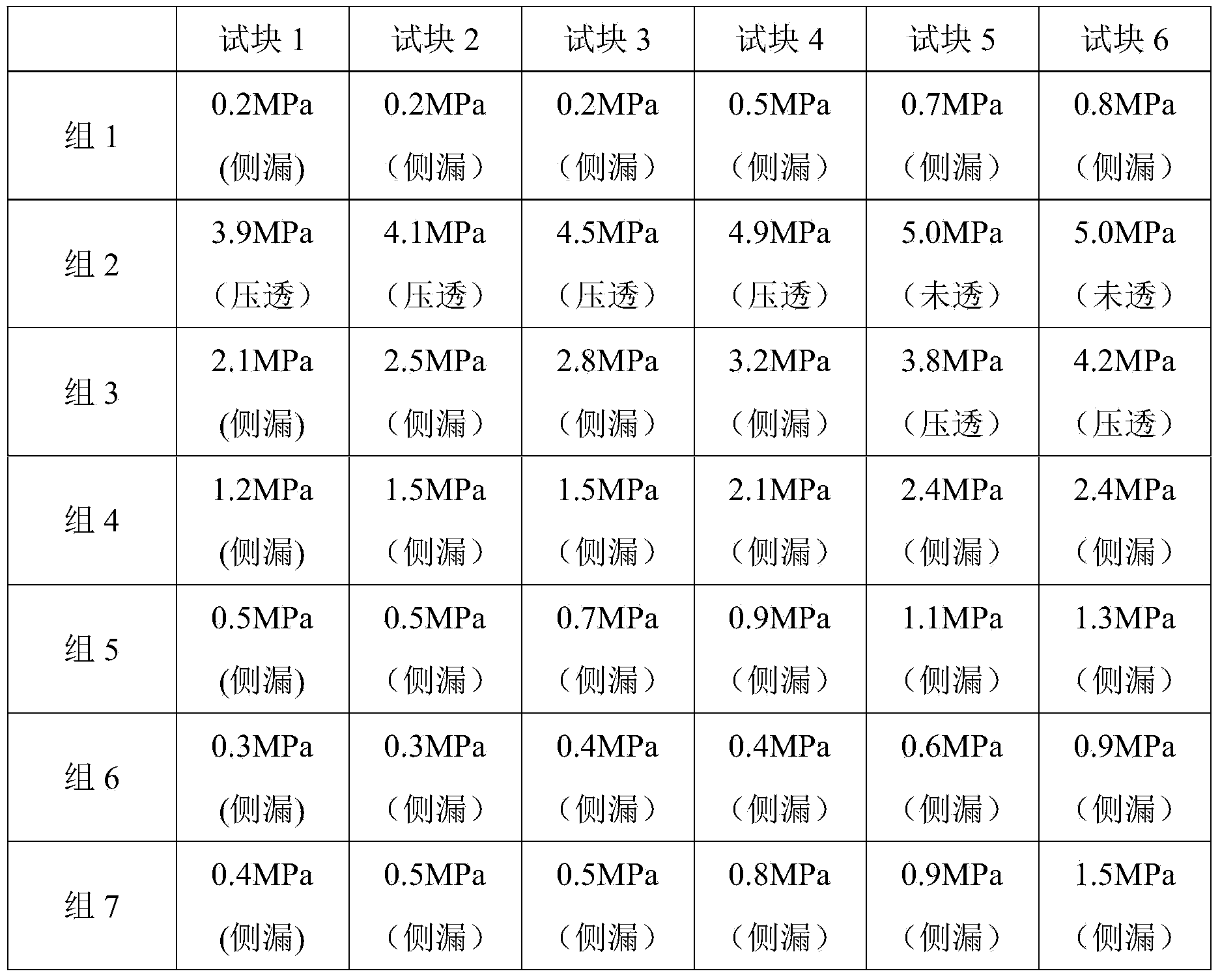

Examples

Embodiment 1

[0026] The cement and butter with a mass ratio of 2:1 are mixed uniformly to obtain a mixture A, and then the powder of sodium polyacrylate water-absorbing resin with a volume ratio of 1:1 is added to the mixture A and mixed uniformly to obtain the final sealing material. When in use, use a triangular knife to evenly scrape the sealing material on the side of the test piece, the thickness should be (1~2) mm, then put on the test mold and press the test piece in, so that the test piece is flush with the bottom of the test mold level. It can be immediately loaded into the impermeability instrument for pressurization.

Embodiment 2

[0028] First mix cement and butter evenly (mixture A), the mass ratio of cement and butter is 3:1, then add the powder of sodium polyacrylate water-absorbing resin to mixture A and mix it evenly, the volume ratio of mixture A and water-absorbing resin is 3 :1, get the final sealing material. When in use, use a triangular knife to evenly scrape the sealing material on the side of the test piece, the thickness should be (1~2) mm, then put on the test mold and press the test piece in, so that the test piece is flush with the bottom of the test mold level. It can be immediately loaded into the impermeability instrument for pressurization.

Embodiment 3

[0030] First mix cement and butter evenly (mixture A), the mass ratio of cement and butter is 4:1, then add sodium polyacrylate water-absorbing resin powder to mixture A and mix it evenly, the volume ratio of mixture A to water-absorbing resin is 6 :1, get the final sealing material. When in use, use a triangular knife to evenly scrape the sealing material on the side of the test piece, the thickness should be (1~2) mm, then put on the test mold and press the test piece in, so that the test piece is flush with the bottom of the test mold level. It can be immediately loaded into the impermeability instrument for pressurization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com