Material neatening and conveying device

A conveying device and material transfer technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as side wall scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

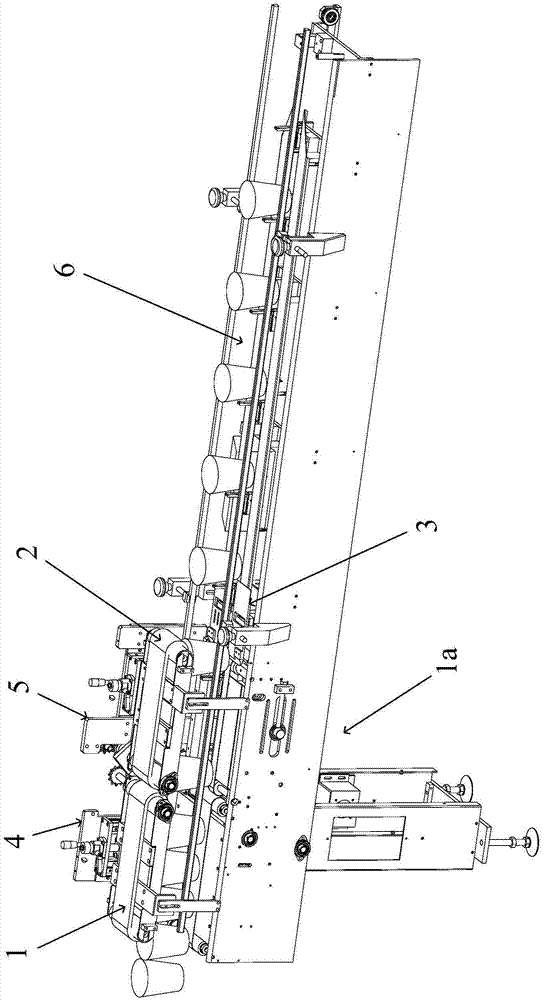

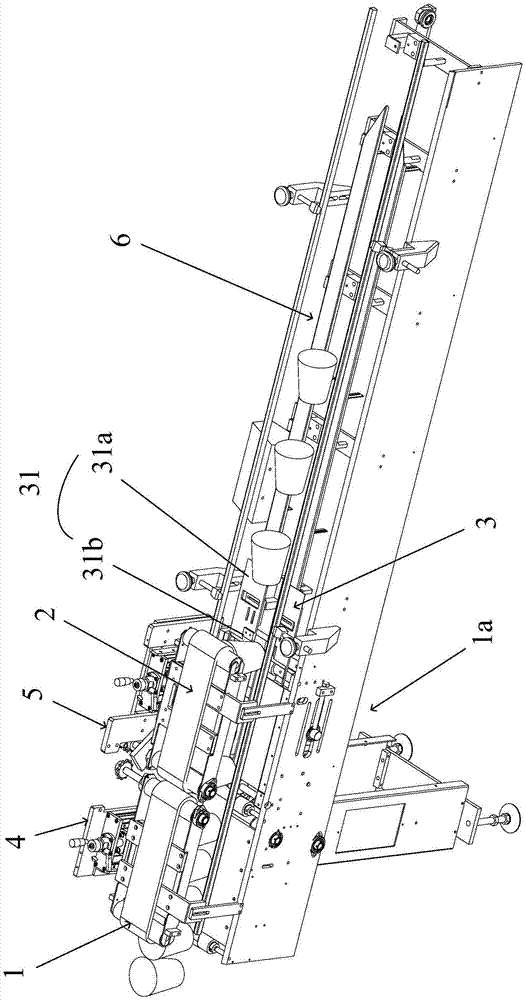

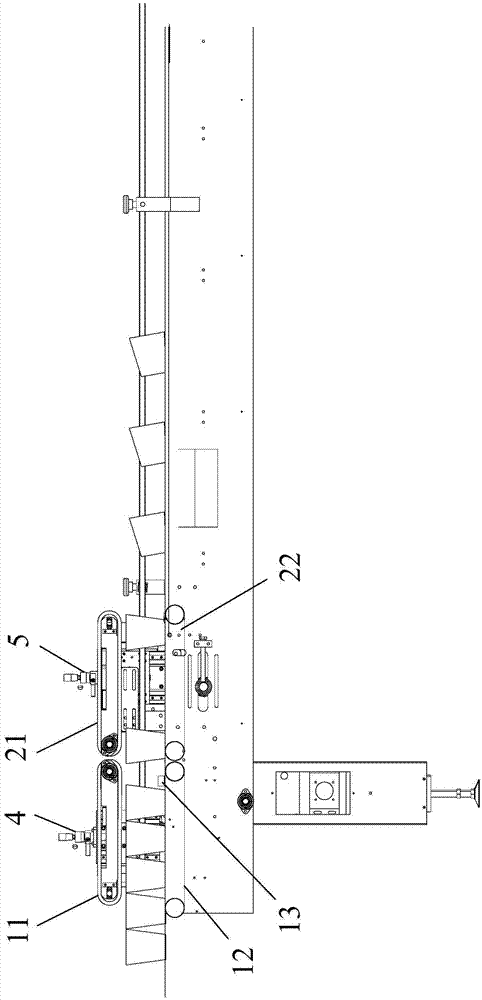

[0025] Take the cup-shaped material as an example for reference Figure 1~4 The specific implementation of the material conveying device of the present invention will be described in detail. In the following description, the front end corresponds to Figure 1~4 The left end in , the back end corresponds to Figure 1~4 In the right end, the transmission direction is from left to right.

[0026] Such as Figure 1~4 As shown, the material conveying device of the present invention usually has a main body bracket that supports and installs together and extends along the material conveying direction. The material handling part 1, the auxiliary material handling part 2 and the transition mechanism part 3 are also provided with a packaging conveyor belt 6 connected with the rear end of the aforementioned transition mechanism part 3 on the main support 1a, and the materials are transported to the On the packaging conveyor belt 6. Wherein, a first lifting mechanism 4 is provided co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com