Cylinder hole honing clamping device

A clamping device and cylinder hole technology, used in grinding/polishing safety devices, honing machine tools, grinding/polishing equipment, etc., can solve problems such as cylinder hole diameter and roundness, achieve compact layout, avoid jamming, Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

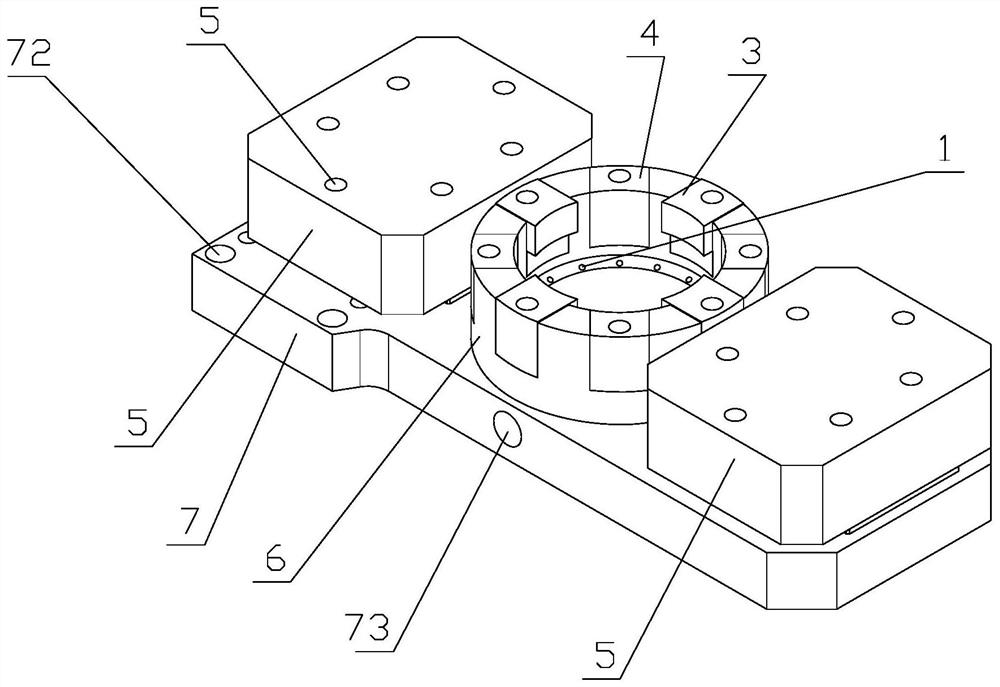

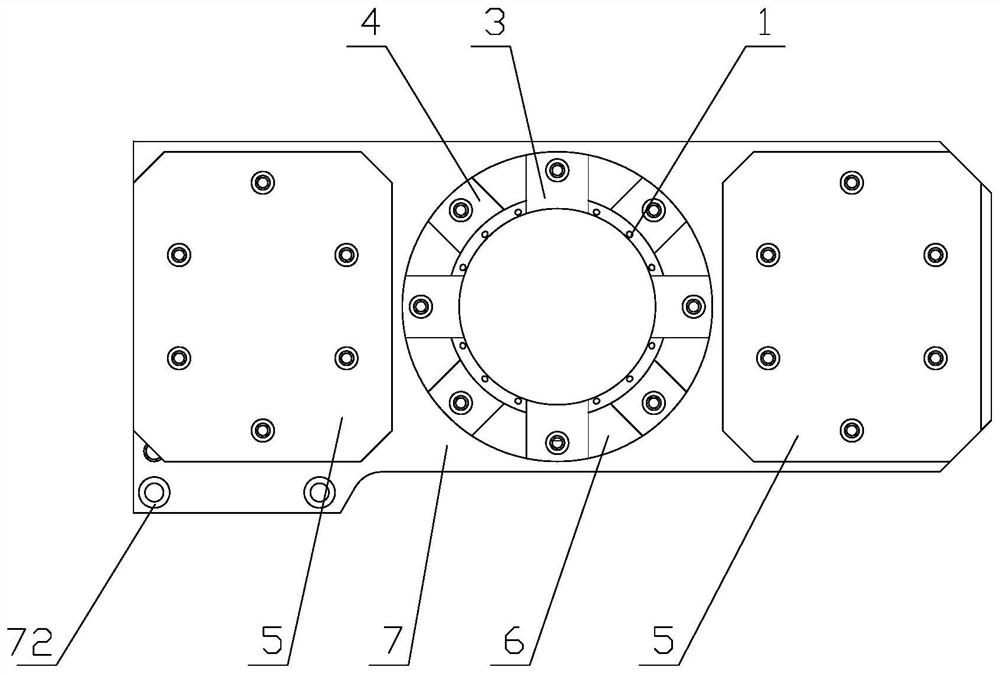

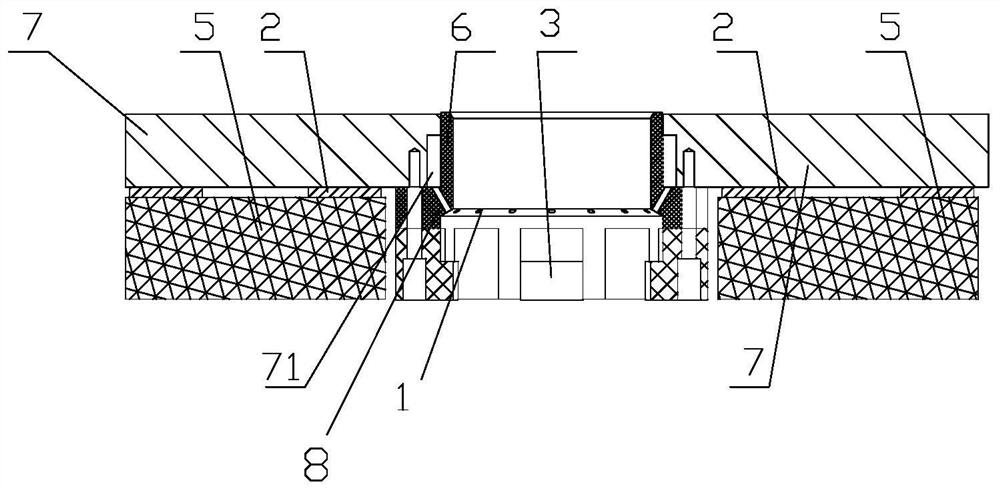

[0026] The present invention will be further described below in conjunction with specific drawings.

[0027] Such as figure 1 and figure 2 As shown, a clamping device for cylinder bore honing includes a support base 7, a support limit block 5 and a clamping ring body 6. The clamping ring body 6 is arranged in the middle of the support base 7, and the two sides of the support base 7 are Support the limit block 5; the outer end array of the clamping ring body 6 is provided with several installation positions 61 (the number of installation positions can be designed and set according to needs, preferably 8), and the installation positions 61 are used for Freely install the cylinder hole limit block 4 or the cylinder hole clamp block 3, the cylinder hole clamp block 3 is higher than the cylinder hole limit block 4, when the clamping point clamps the workpiece, the cylinder hole limit block 4 plays a role in the workpiece The limit and auxiliary support function can avoid the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com