Automatic cut-off machine used for band saw blade grinding production and machining

An automatic cut-off and band saw blade technology, which is applied in metal processing equipment, manufacturing tools, metal sawing equipment, etc., can solve laborious and labor-intensive problems, and achieve the effect of simple and convenient cutting and blanking, and simple and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

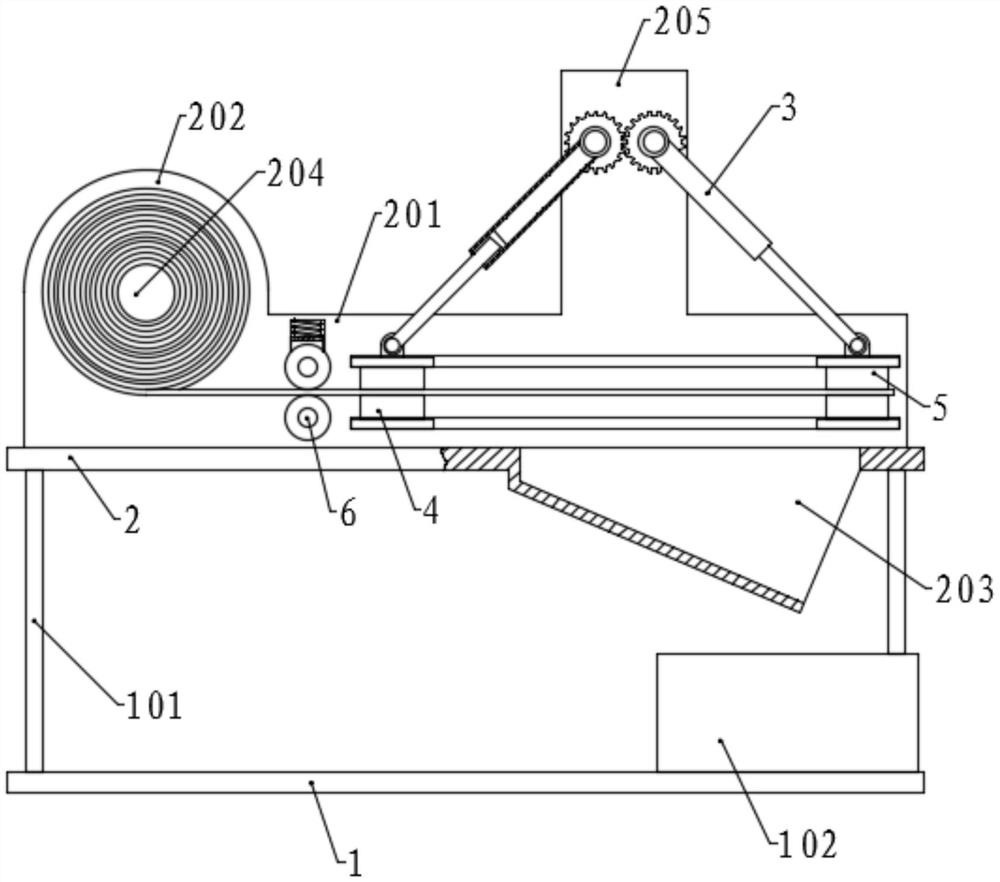

[0057] Please refer to the accompanying drawings, the present invention provides a technical solution: an automatic cutting machine for band saw blade grinding, production and processing, including a base 1, vertical support rods 101 are fixed at the four corners of the top surface of the base 1, and the support rods 101 The top of the workbench 2 is fixed together, the right section of the workbench 2 is provided with a hopper 203, the bottom surface of the chute 203 is inclined, and the base 1 is provided with a collection box 102 at the position corresponding to the chute 203, Both sides of the workbench 2 are symmetrically fixed with a vertical first side plate 201, a vertical extension plate 205 is fixed in the middle of the top of the first side plate 201, a second side plate 202 is fixed at the left end, and the second side plate 202 The top of is set as a semicircle;

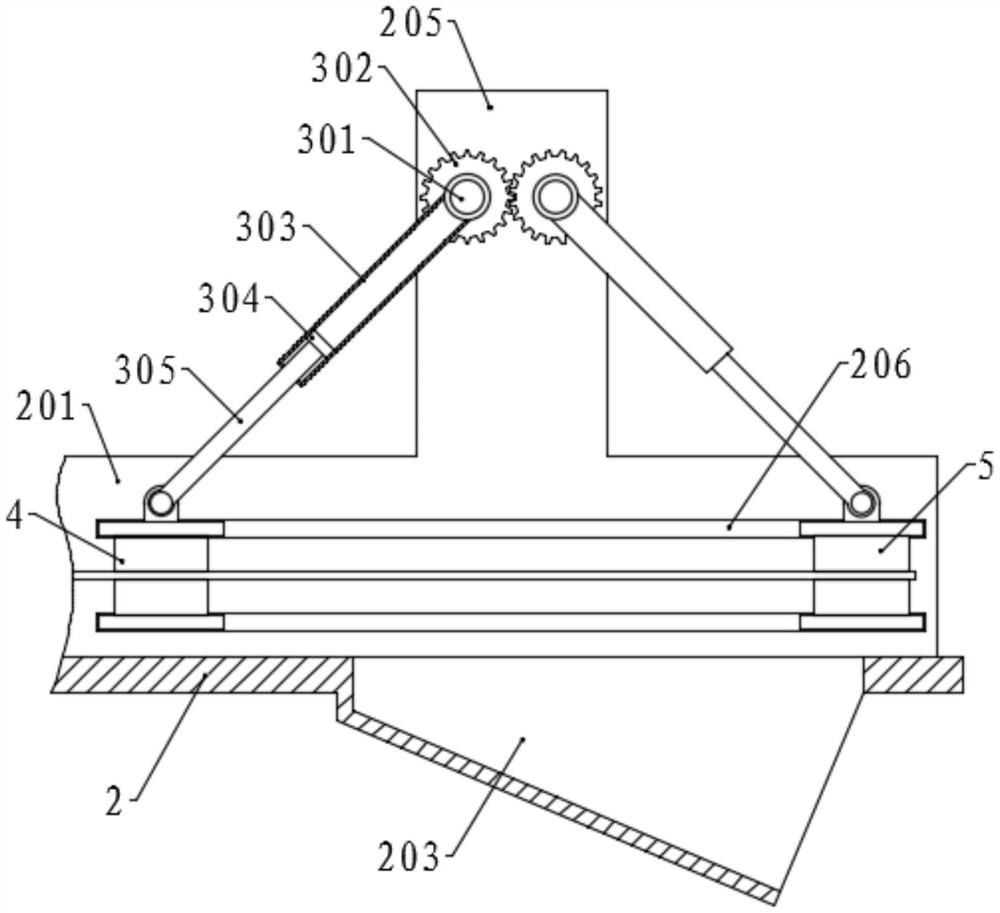

[0058] The first side plate 201 is provided with two horizontal slide grooves 206, and the first posi...

Embodiment 2

[0072]The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that a plurality of clamping blocks 707 are uniformly fixed on the right side ends of the upper pressing plate 705 and the lower pressing plate 701 on the first positioning assembly 4, and the width of the clamping blocks 707 is smaller than steel. The length of the clamp block 707 on the lower platen 701 is greater than that of the clamp block 707 on the upper platen 705, and the top surface of the clamp block 707 on the lower platen 701 is provided with a cutting groove 708 corresponding to the position of the cutting knife 8, and the second positioning The upper pressing plate 705 on the assembly 5 and the left end of the lower pressing plate 701 are provided with a block groove 709 at the position corresponding to the clamping block 707 , and the length of the block groove 709 on the lower pressing plate 701 is longer than that of the upper pressing plate 705 .

[0073] W...

Embodiment 3

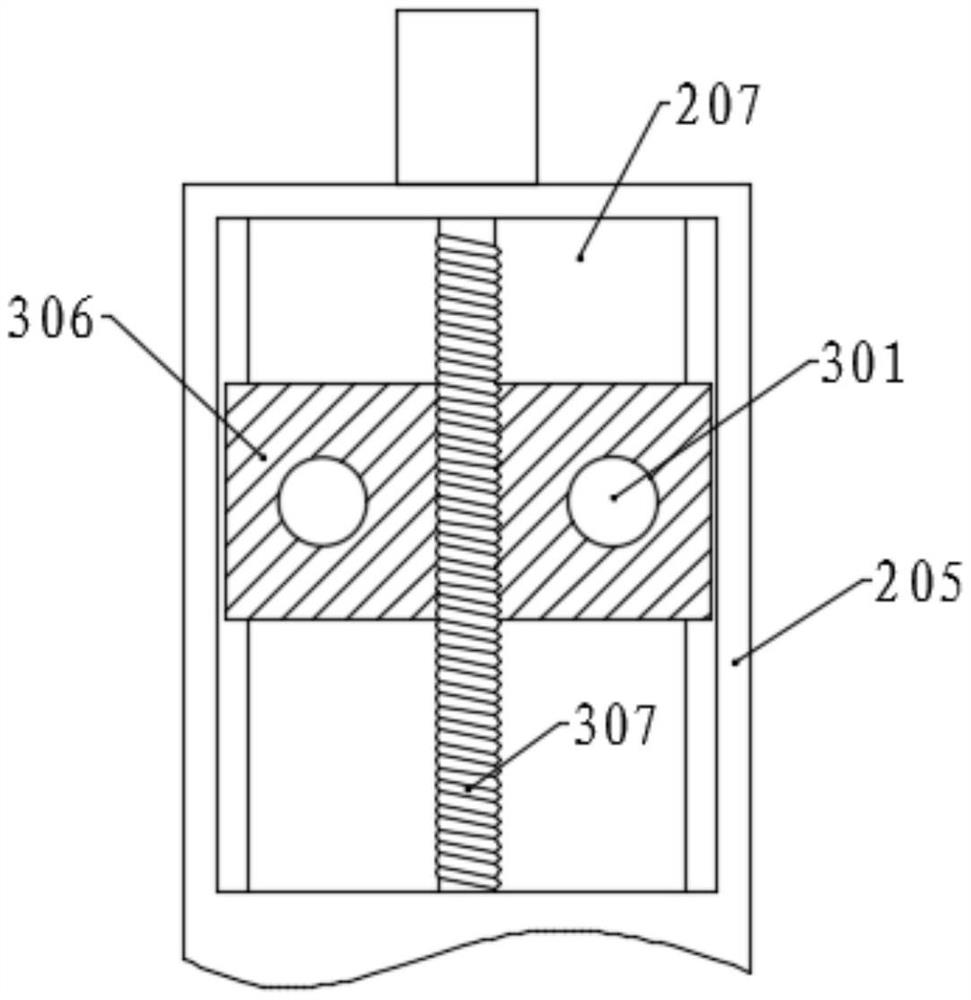

[0075] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that an adjustment slot 207 is provided on the top of the extension plate 205, and an adjustment block 306 is slidably connected to the adjustment slot 207. The ends of the two rotating shafts 301 are connected to the adjustment block. 306 is rotatably connected, and the middle thread of the adjustment block 306 is connected with a vertical threaded shaft 307, and the threaded shaft 307 is rotatably connected with the top surface and the bottom surface of the lift groove, and the top stretches out of the adjustment groove 207, and is connected with a motor.

[0076] When it is necessary to adjust the maximum distance between the ends of the telescopic rods 305 on both sides, that is, the cut-off length of the steel bar, start the motors on the top of the extension plates 205 on both sides to rotate the threaded shaft 307, and the adjustment block 306 will be driven by the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com