Precise conveying locating system for product parts

A positioning system and component technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor positioning accuracy, inability to guarantee the stability and accuracy of the product transfer process, product drop, etc., to improve accuracy and Safety, meet the needs of automatic transfer, easy installation and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

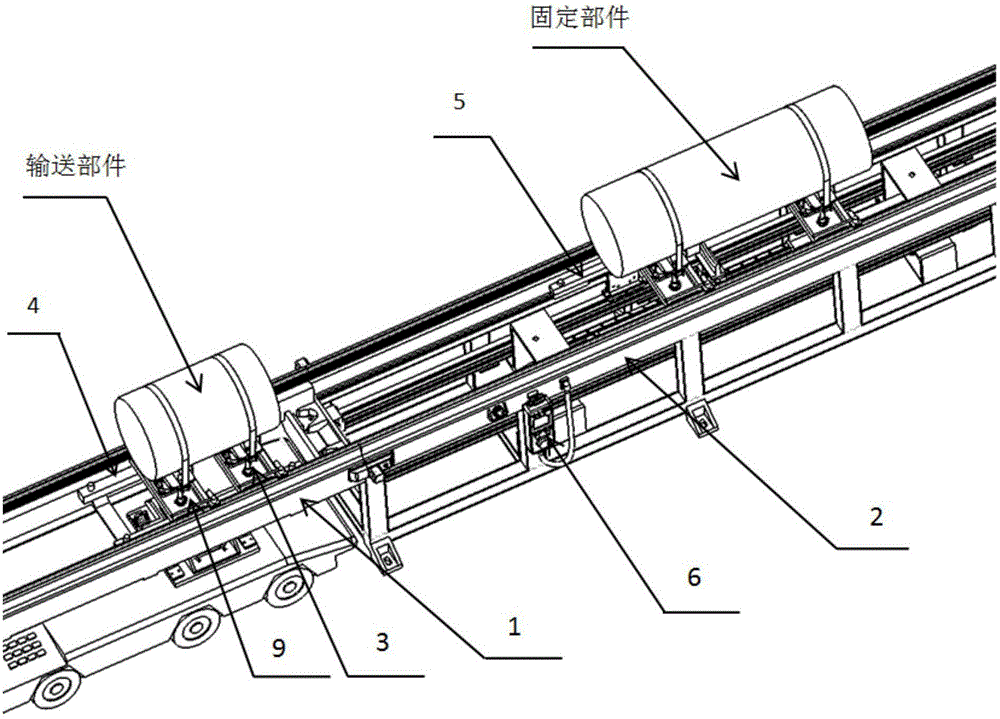

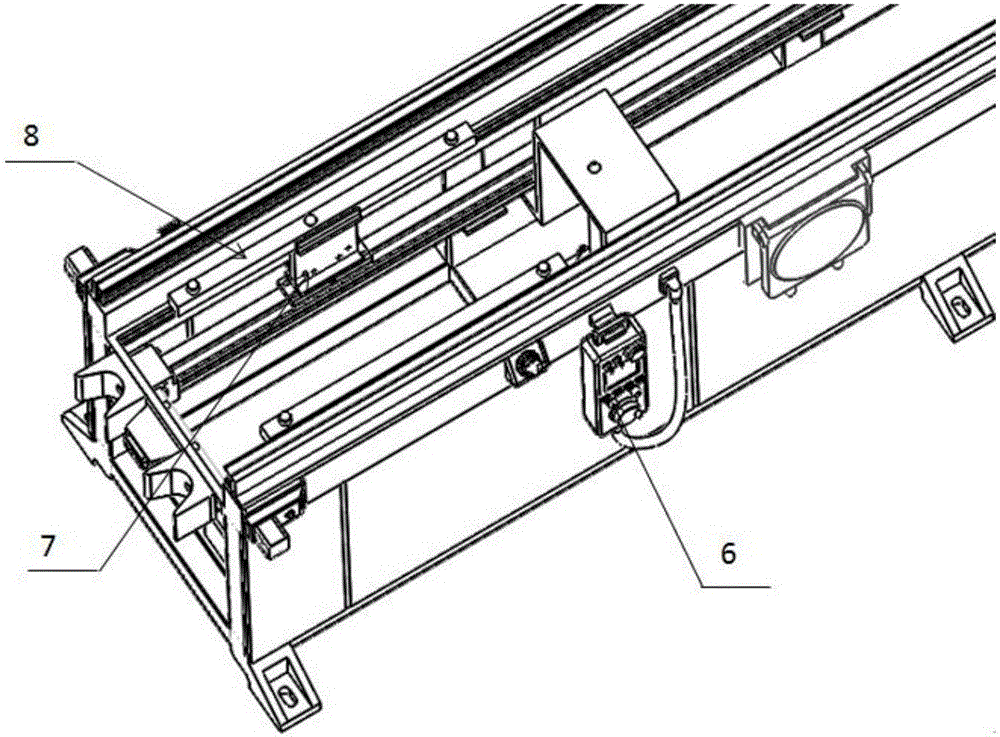

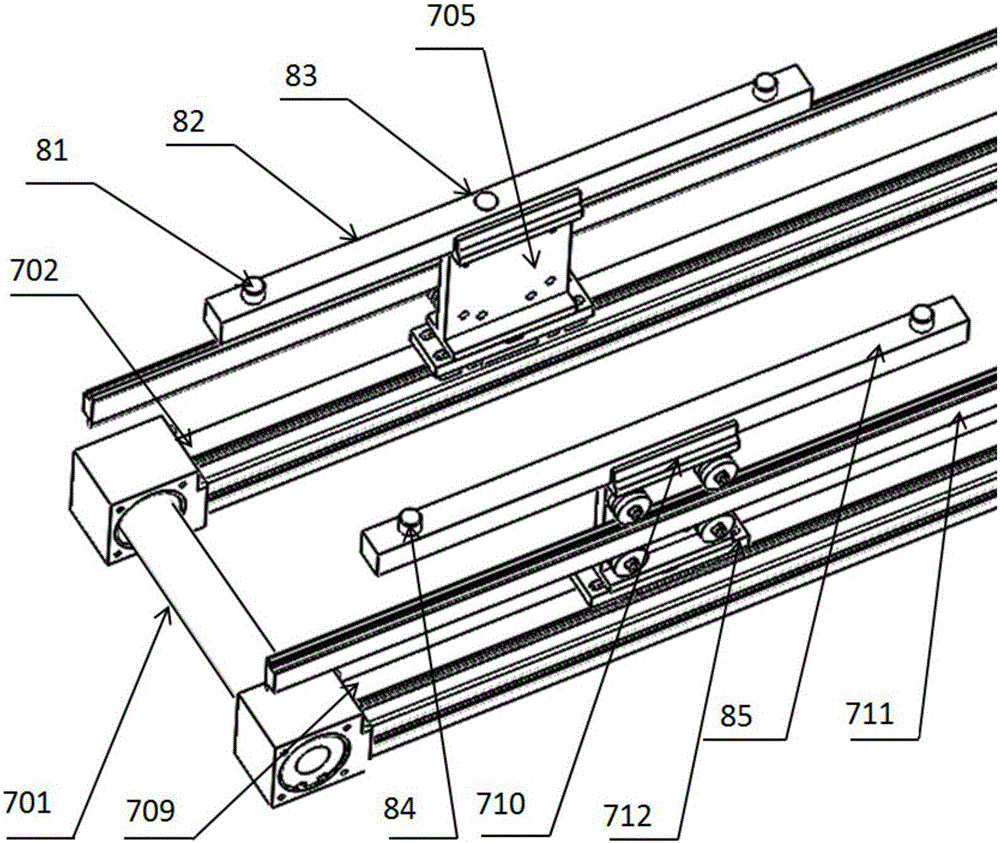

[0029] see figure 1 , the precise conveying and positioning system for product parts of the present invention includes a moving base 1, a static base 2, a first bracket 3, a second bracket 9, a first transfer positioning device 4 and a second transfer positioning device 5 . The moving base 1 is used to transfer product parts, the static base 2 is used to receive product parts, the first bracket 3 and the second bracket 9 are used to support product parts; the moving base 1 and the static base 2, the two The guide rails are used to dock the first bracket 3 and the second bracket 9 from the position of the driven base 1 to the position of the static base 2; the first transfer positioning device 4 is installed on the moving base 1, and is It is used to push the first bracket 3 and the second bracket 9 to move on the movable base 1, and the first transfer and positioning device 4 adjusts the distance between the first bracket 3 and the second bracket 9 for supporting different T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com