Cooling discharge type corncob drying machine

A corn cob and drying machine technology, applied in the direction of drying and preserving seeds, etc., can solve the problems of inconvenient packaging, waste of energy, high temperature of corn cobs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

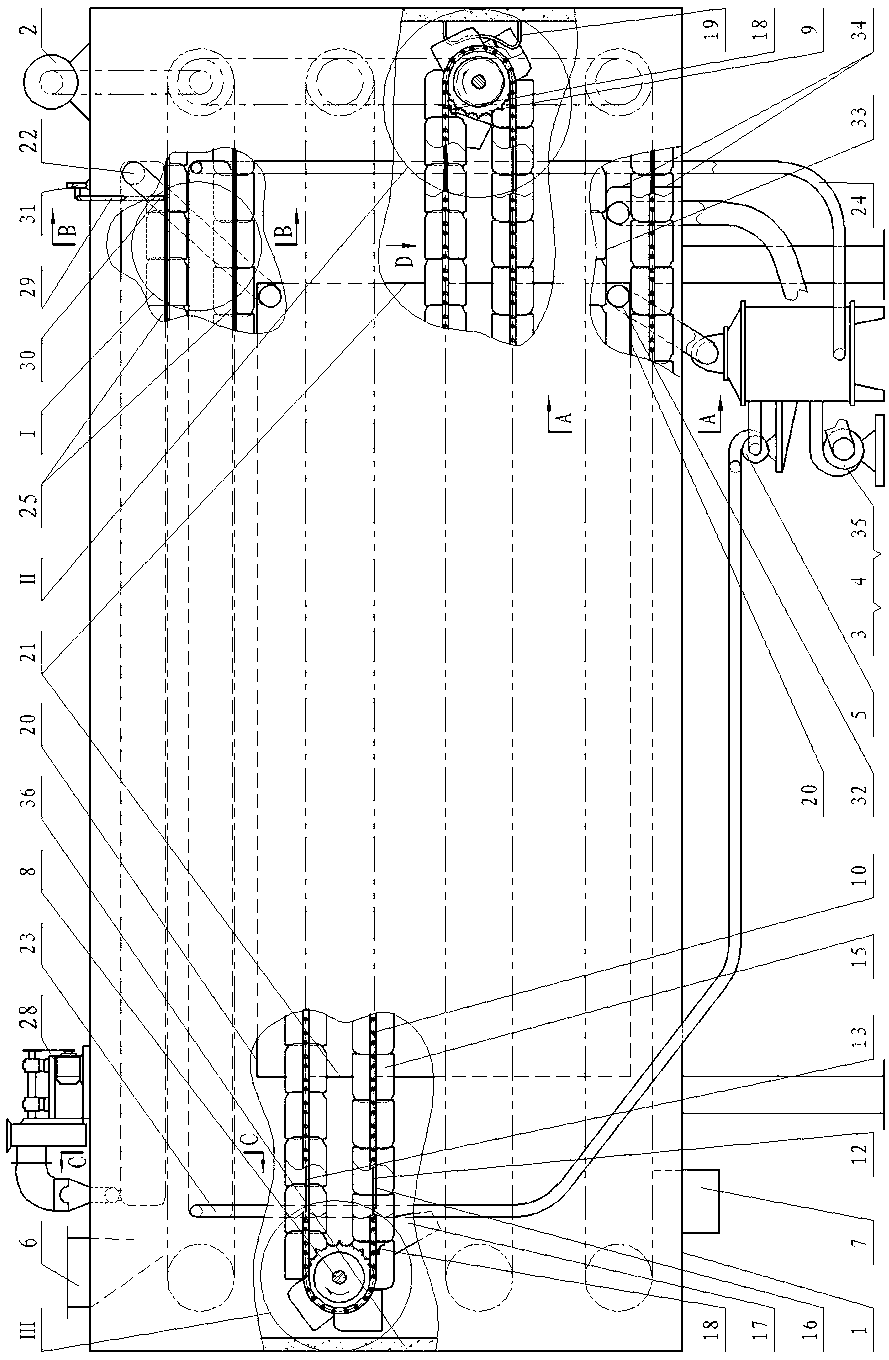

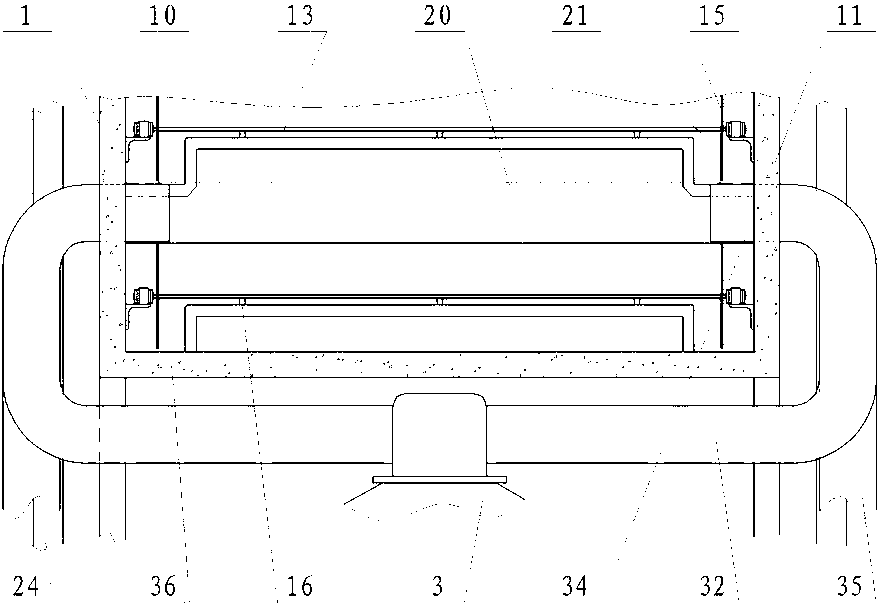

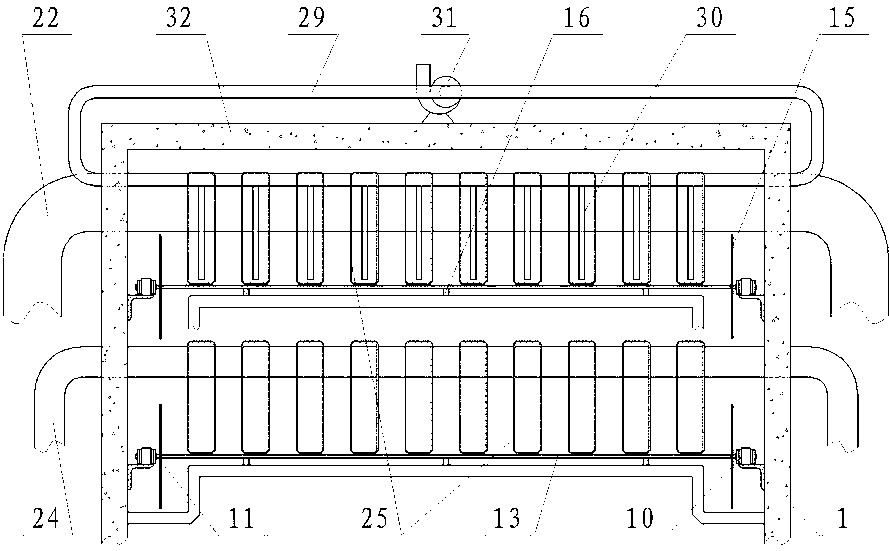

[0031] 1. Box body 2, transmission device 3, water and air heater 4, blower 5, circulating water pump 6, material inlet 7, material outlet 8, shaft 9, sprocket 10, chain 11, pin shaft 12, ventilation hole 13 , forming panel 14, hanging hole 15, baffle plate 16, guide rail 17, material guide groove 18, guide rod 19, limit rod 20, partition I 21, partition II 22, "C" shaped air duct 23, Water supply pipe 24, return water pipe 25, heat exchange box 26, "T" shaped air duct 27, straight air duct 28, induced draft fan 29, annular water pipe 30, straight water pipe 31, condensate pump 32, "L" shaped air duct 33, Partition III 34. Partition IV 35. "J" shaped air duct 36. Insulation layer.

[0032] exist Figure 1~13 In the shown embodiment: the top left end of the rectangular box body 1 is provided with a feed inlet 6, and the same end is provided with a discharge port 7 at the bottom of the box body 1, and the box body 1 is provided with 4 conveying devices along the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com