Ceramic glazing system and control method

A control method and ceramic technology, applied in the direction of ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of high cost, achieve low cost, reduce production cost, and good effect of spraying glaze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

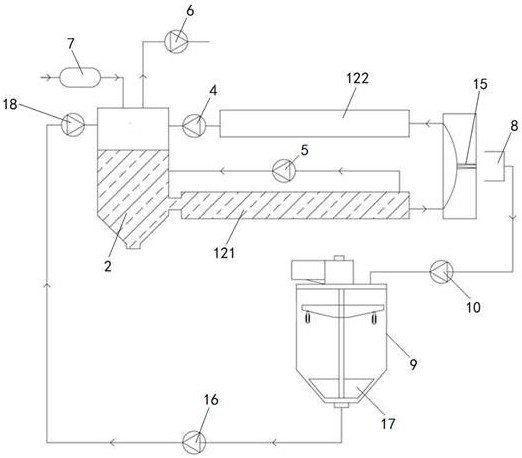

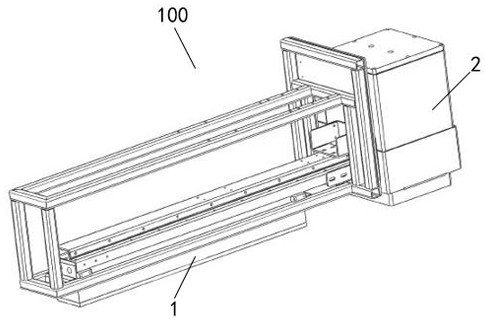

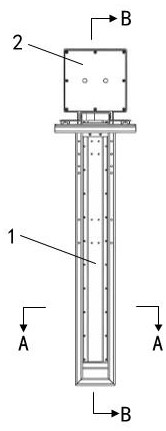

Method used

Image

Examples

no. 3 example

[0141] Therefore, see Figure 11 , the present invention also discloses a third embodiment of the control method based on the above-mentioned ceramic glazing system, which includes:

[0142] S301 , the stirring mechanism in the second glaze storage container is driven to perform stirring processing on the glaze in the second glaze storage container.

[0143] During work, the glaze can be manually input into the second glaze storage container by the worker, or can be automatically flowed into the second glaze storage container through the glaze supply pipeline. At the same time, a stirring mechanism is provided in the second glaze storage container, through which the glaze in the second glaze storage container can be effectively stirred to avoid glaze precipitation.

[0144] S302, obtain the glaze quantity information of the first glaze storage container in real time, and drive the fourth conveying mechanism to extract the glaze in the second glaze storage container to the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com