Semi-automatic derusting and paint spraying device for surface of metal tube and derusting and paint spraying method thereof

A metal tube, semi-automatic technology, applied to the surface coating liquid device, special surface, metal processing equipment, etc., can solve the problems of uniform thickness, low work efficiency, dripping to the ground, etc., to ensure the quality of spray paint, Improve work efficiency and facilitate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

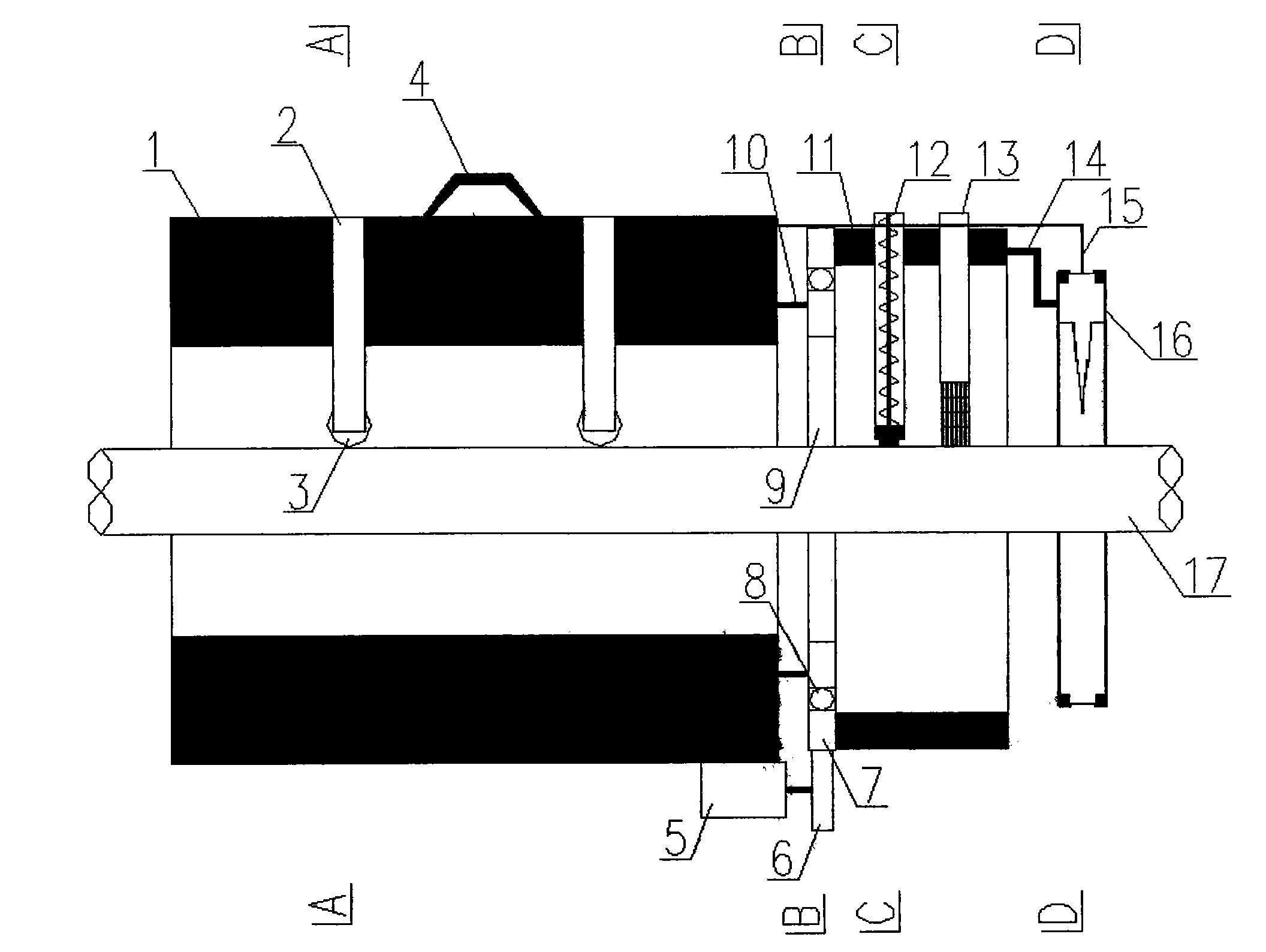

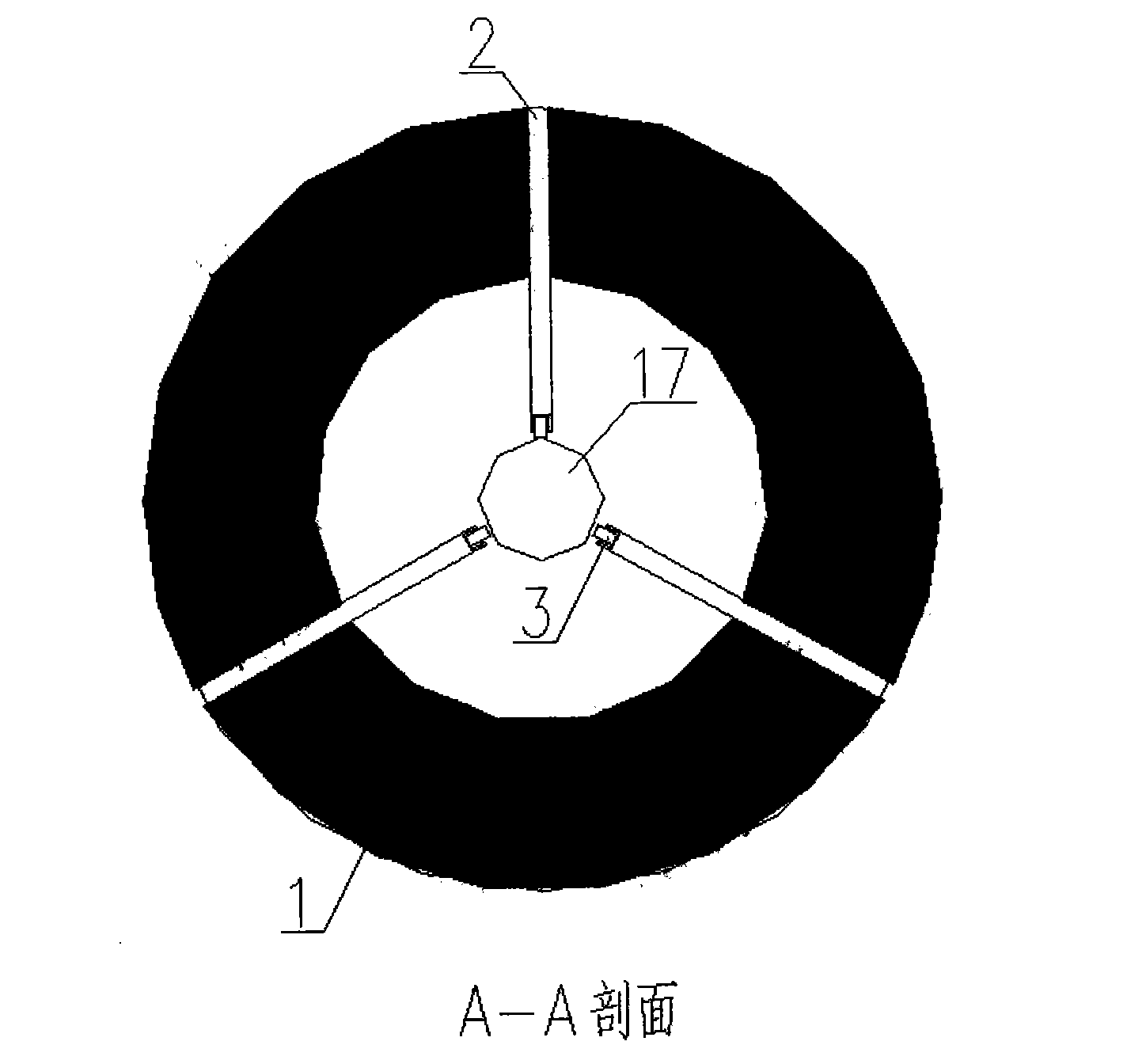

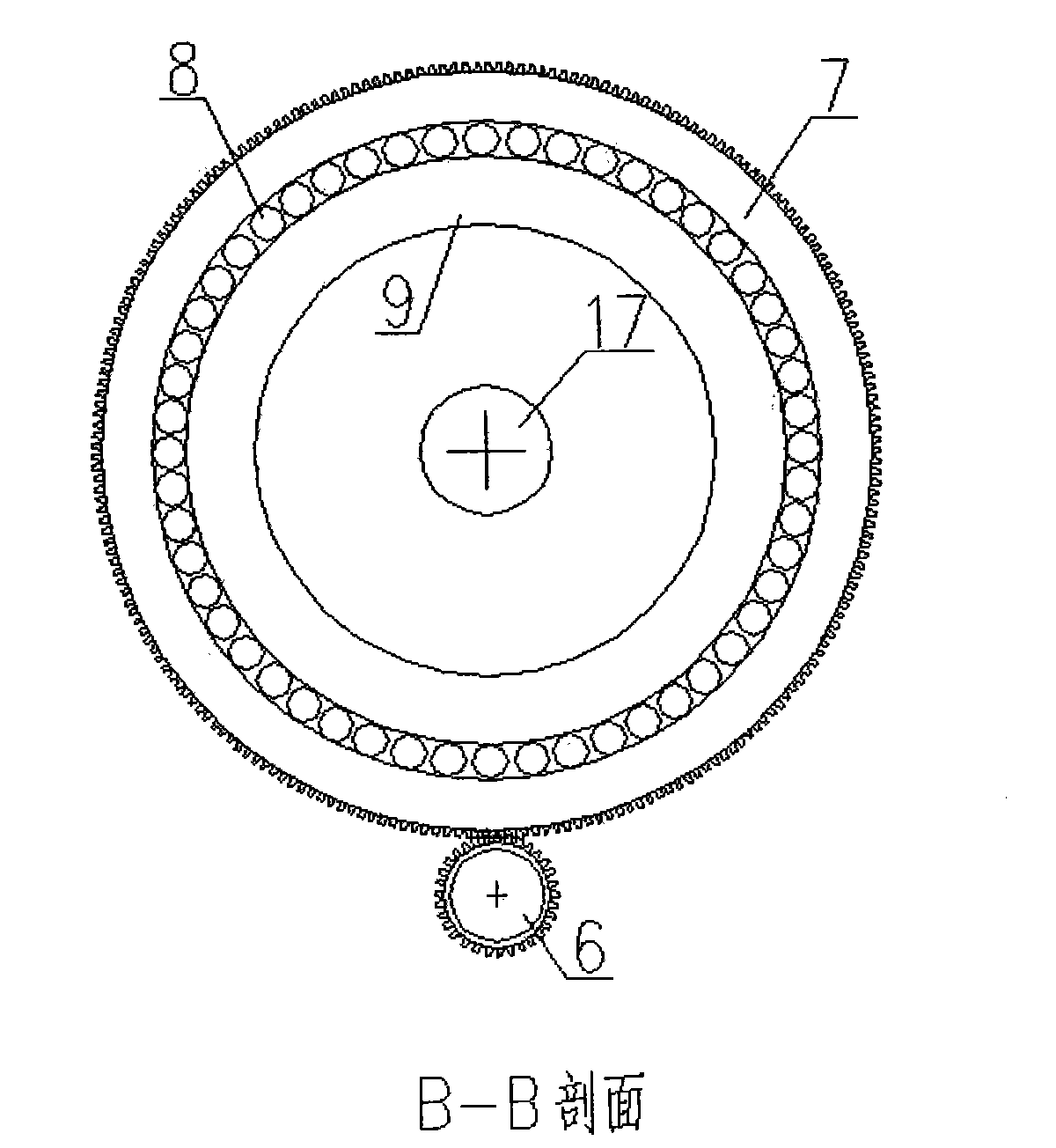

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are cited hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to Figure 1-Figure 7 .

[0023] Such as Figure 1-Figure 7 As shown: the present invention includes five parts: a movable hollow shaft system, a low-speed transmission system, a rust removal system, a cleaning system and a painting system, and is characterized in that: the present invention includes a hollow shaft (1), a telescopic support (2), a Wheel(3), Handle(4), Motor(5), Gear 1(6), Gear 2(7), Bearing(8), Bearing Inner Connecting Part(9), Connecting Part 1(10), Connecting Part 2 (11), rust removal device (12), cleaning device (13), connector 3 (14), paint delivery pipe (15), paint spraying device (16), metal pipe (17), square rust removal bracket (18) , spring (19), grinding part (20), grinding part rail rod (21),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com