Air inlet system of aero-engine and aero-engine

A technology of aero-engine and air intake system, applied in the direction of engine components, machines/engines, fuel air intake, etc., can solve the problem of carbon deposition at the input port and fuel injection port of the mixed gas, affecting the efficiency of the combustion chamber, entering the combustion chamber, etc. problem, to achieve the effect of improving combustion efficiency, improving vibration phenomenon, and facilitating uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

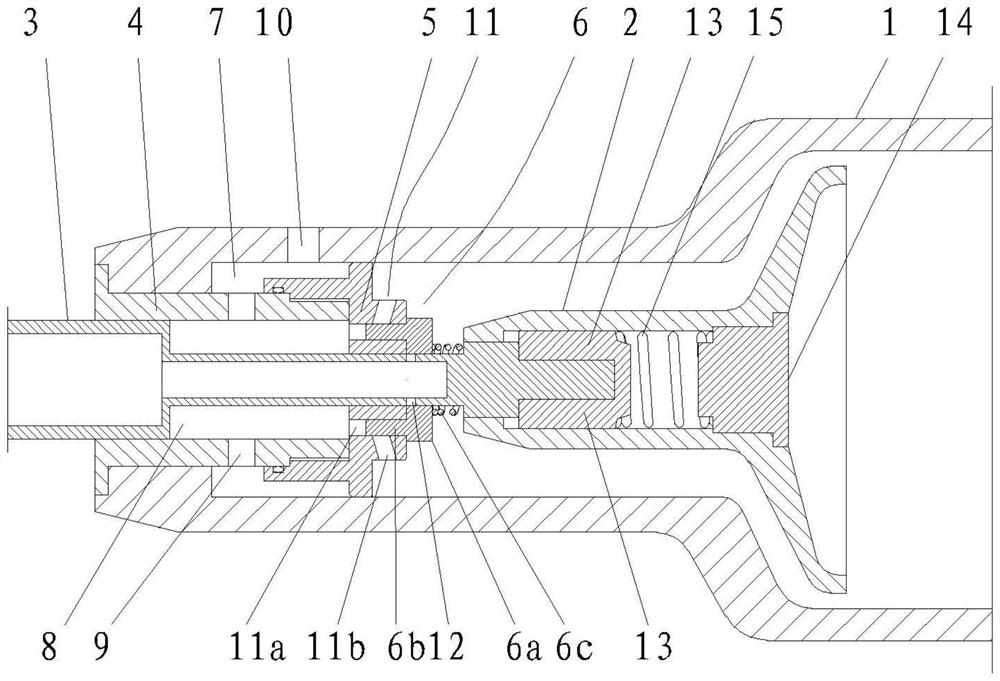

[0020] As shown in the figure, this embodiment provides a linear control device for the accelerator pedal, including an air intake seat 1 and a valve 2, and the valve 2 is installed on the right side of the air intake channel in the air intake seat 1 in an elastic sliding manner , also includes fuel injection pipe 3, mixture gas pipe sleeve 4, mixture gas nozzle 5 and opening and closing door 6;

[0021] The mixed gas pipe cover 4 is set inside the air intake seat 1, the mixed gas nozzle 5 is closed on the right end of the mixed gas pipe sleeve 4, and the outer circle of the mixed gas nozzle 5 is sealed with the inner circle of the air intake seat 1, so that the mixed gas nozzle 5 A closed annular outer air storage chamber 7 is formed between the trachea sleeve 4 and the air intake seat 1;

[0022] The fuel injection pipe 3 is set inside the mixed gas pipe sleeve 4, and a closed annular inner gas storage chamber 8 is formed between the fuel injection pipe 3 and the mixed gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com