Preparation method of nanometer silicon hydroxide-aluminum hydroxide powder

A technology of aluminum hydroxide and silicon hydroxide, which is applied in chemical instruments and methods, catalyst carriers, catalysts for physical/chemical processes, etc., to achieve the effect of facilitating uniform distribution, increasing the amount of B acid, and improving pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Under stirring condition, heating dehydrates in the water glass of 80g, when detaching to the water glass of 55g weight, add in the mixture of 35g polyisobutylene triethanolamine maleate and 148g of 150HVI neutral oil that stir under the condition of 100 ℃, Formation of hypersolubilized micelles. 750g of aluminum nitrate nonahydrate and 130g of urea were mixed and heated to 100°C, then added dropwise to the above-mentioned supersolubilized colloid, mixed uniformly, and then reacted at 130°C for 10 hours to obtain nanometer silicon hydroxide-aluminum hydroxide gel. Wash with 200ml of distilled water three times, and dry at 120°C for 8 hours to obtain nano silicon hydroxide-aluminum hydroxide SAH1.

Embodiment 2

[0043] Nanometer silicon hydroxide-aluminum hydroxide SAH1 was extracted with petroleum ether for 3 hours at a temperature of 80°C, wherein the volume ratio of petroleum ether to nanometer silicon hydroxide-aluminum hydroxide SAH1 was 2:1, and the extraction times were 2 times, and then Dry at 100° C. for 6 hours to obtain nano silicon hydroxide-aluminum hydroxide SAH2.

Embodiment 3

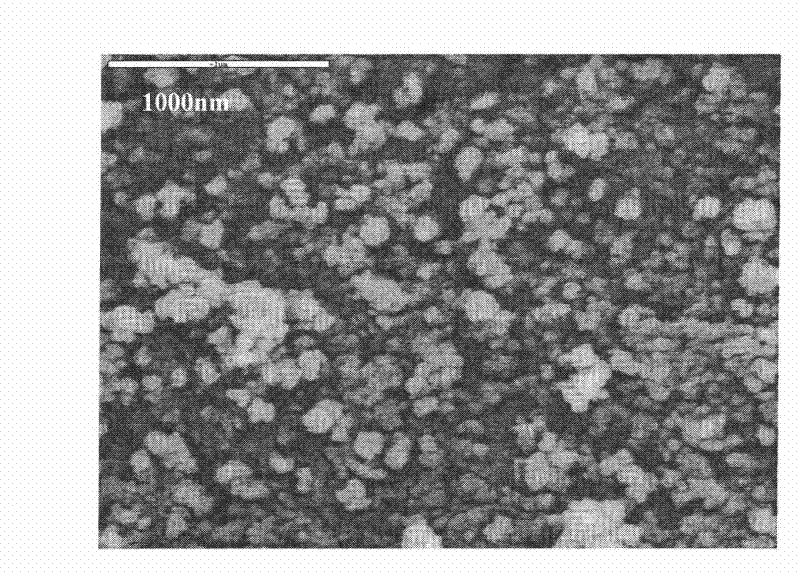

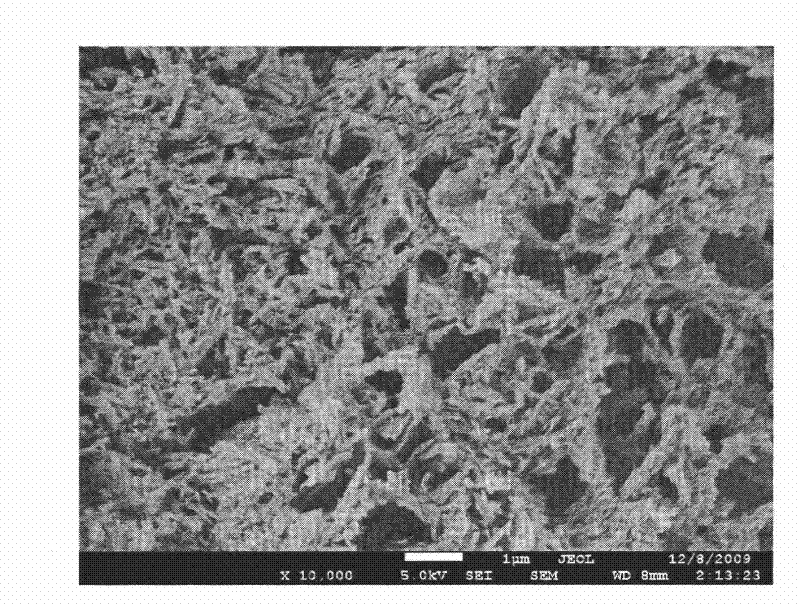

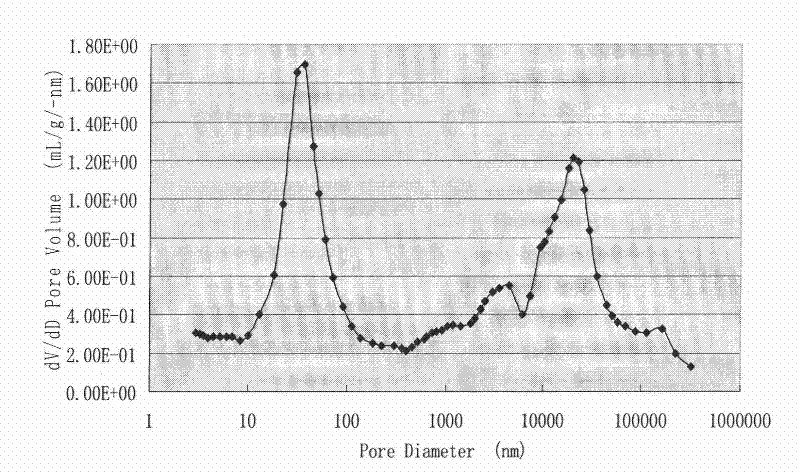

[0045] Mix nano silicon hydroxide-aluminum hydroxide 104g SAH1 with 6g dilute nitric acid (mass concentration 17%), 60g water and 10g ethanol, mix uniformly on a mixer, and then shape it in an extruder, controlling the pressure at 10MPa. The molded product was dried at 100°C for 10 hours, calcined at 240°C for 3 hours, and calcined at 850°C for 4 hours, wherein the heating rate was 5°C / min, to obtain the silica-alumina composite carrier SA1 of the present invention, Appearance see figure 2 , pore distribution see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com