Cylindrical formwork fixing device and fixing method

A formwork fixing and cylinder technology, which is applied in formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve problems such as difficult fixation, deformation of cylinders, deformation of wood formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

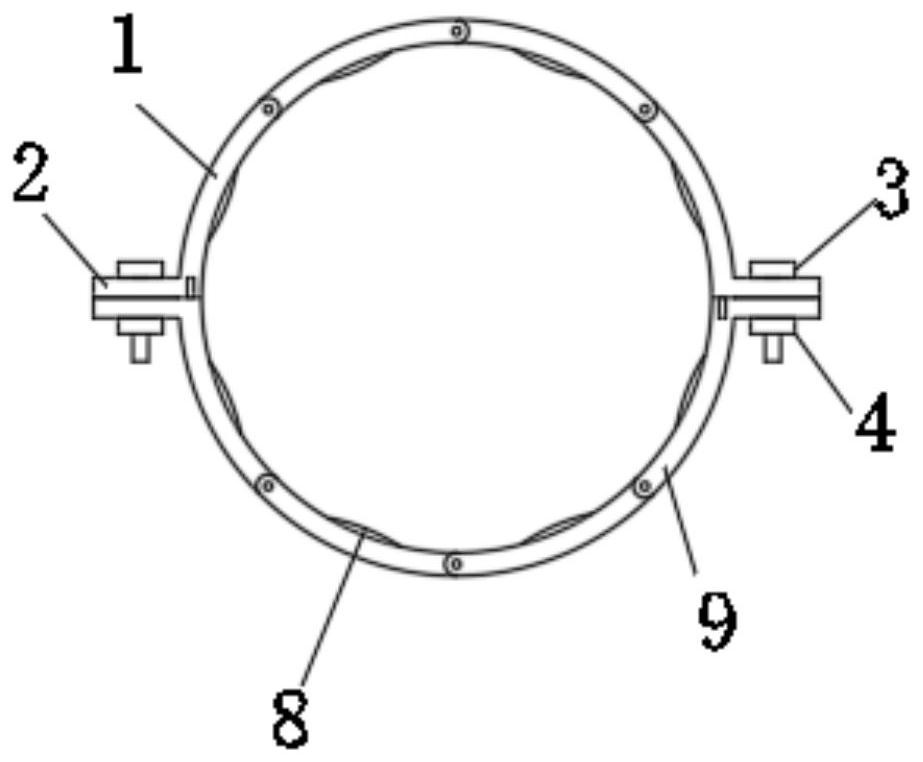

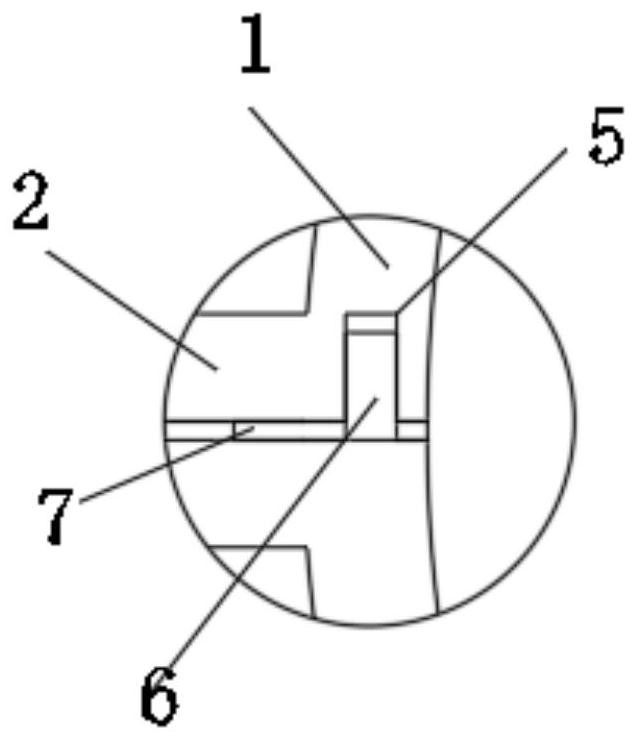

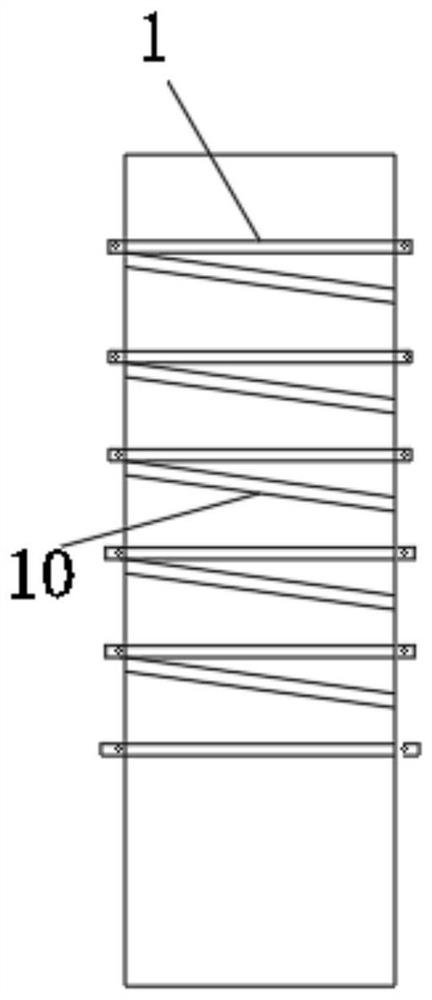

[0025] Such as figure 1 , figure 2 As shown, in this embodiment, a cylindrical formwork fixing device includes two semicircular hoops 1 and connecting plates 2 arranged at both ends of the hoops 1. On the connecting surface, one of the connecting surfaces is provided with a positioning hole 5, and the other is provided with a positioning shaft 6. The axes of the positioning hole 5 and the positioning shaft 6 are arranged symmetrically with the axis of the hoop 1, and the connecting plate 2 is provided with screws hole.

[0026] After the cylindrical formwork is built, use two hoops 1 to hold the cylindrical formwork tightly so that the connecting surfaces of the two hoops 1 are aligned, and the connecting surface of one hoop 1 with the positioning hole 5 is aligned with the other hoop 1 with the positioning hole 5. The connecting surface of the shaft 6 is corresponding, so that the positioning shaft 6 is packed into the positioning hole 5 . Then use screws 3 and nuts 4 to ...

Embodiment 2

[0029] On the basis of the above embodiments, in this embodiment, the hoop 1 includes several hoop units 9 hinged to each other. In this way, the diameter of the hoop 1 can be adjusted according to the diameter of the cylindrical formwork, so that the hoop 1 can be closely attached to the cylindrical formwork with different diameters, and the scope of application of the hoop 1 is increased.

[0030] After the corresponding diameter of the hoop 1 increases, the distance between the corresponding connecting plates 2 on the two hoops 1 will also increase. At this time, a gasket 7 can be added between the two connecting plates 2 to eliminate the gap between the connecting plates 2. The gap can enhance the locking effect of the screw 3 on the connecting plate 2, thereby enhancing the stability of the hoop 1 and the locking effect of the hoop 1 on the cylindrical formwork.

[0031] When the distance between the corresponding connecting plates 2 on the two hoops 1 is relatively large...

Embodiment 3

[0034] On the basis of the above embodiments, in this embodiment, the diameter of the positioning hole 5 is larger than the diameter of the positioning shaft 6 . In this way, the assembly of the positioning hole 5 and the positioning shaft 6 is facilitated, thereby facilitating rapid positioning, and avoiding the problem that the positioning hole 5 and the positioning shaft 6 cannot be aligned due to machining errors, deformation and the like. The connecting plate 2 is hinged with the hoop 1 so that the corresponding two connecting plates 2 are always kept parallel, so that the positioning hole 5 and the positioning shaft 6 can also be aligned all the time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com