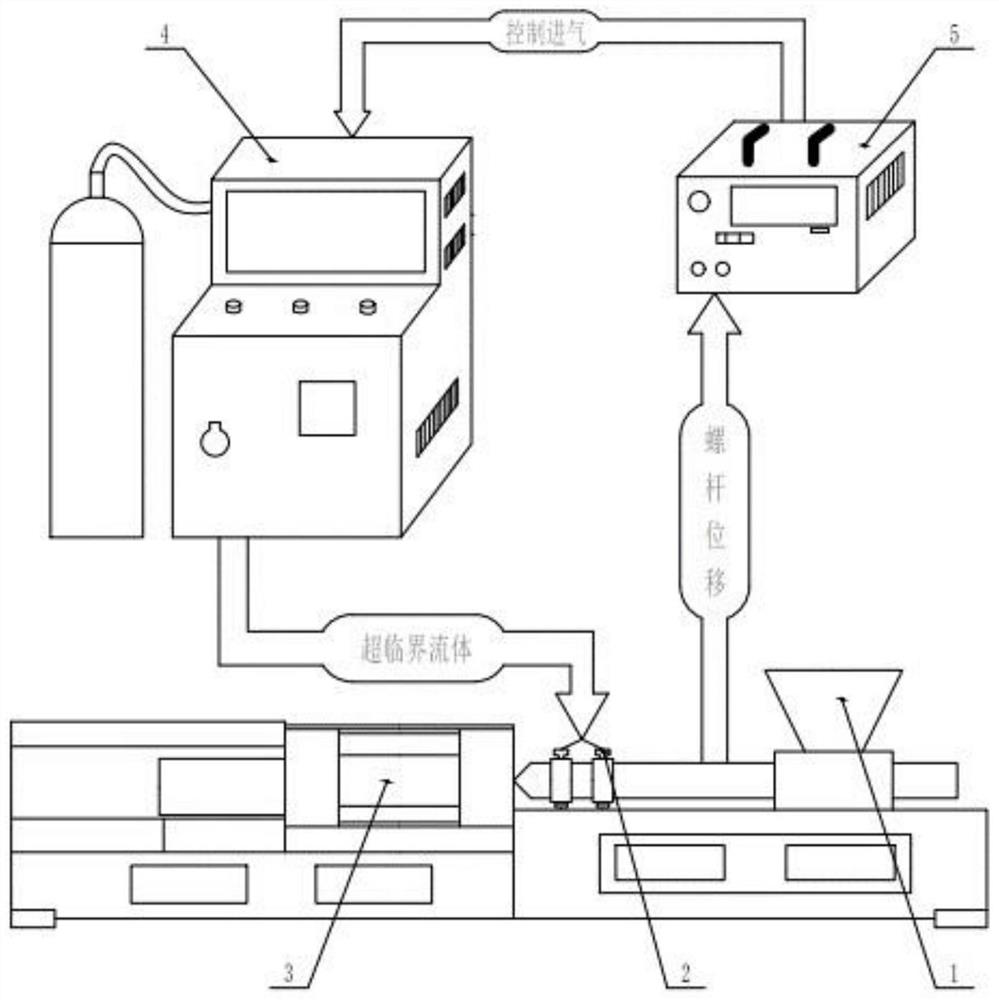

Decompression micro-foaming injection molding device and process thereof

A micro-foaming and process technology, applied in other household appliances, household components, household appliances, etc., can solve the problems of insufficient contact between materials and supercritical fluids, inability to guarantee product quality, and difficulty in screw processing. , The effect of less stress concentration area and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

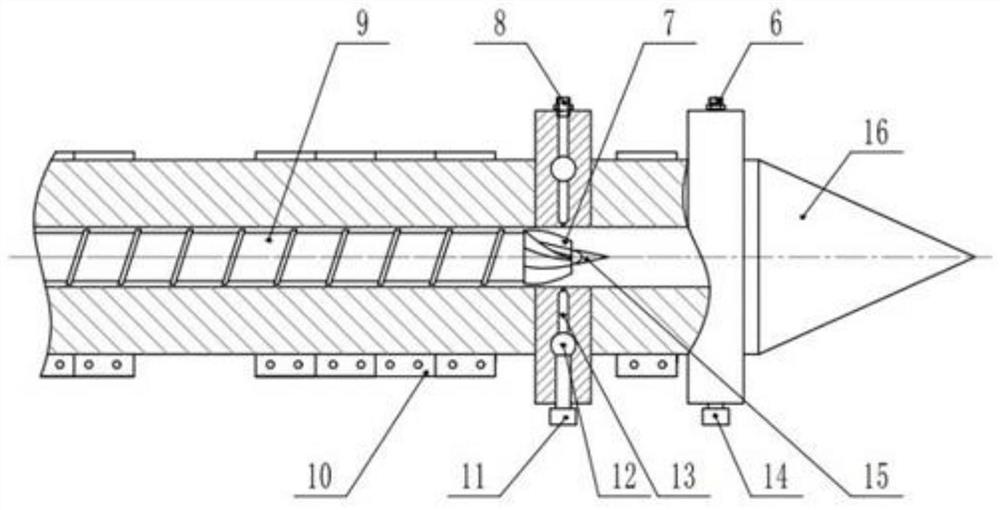

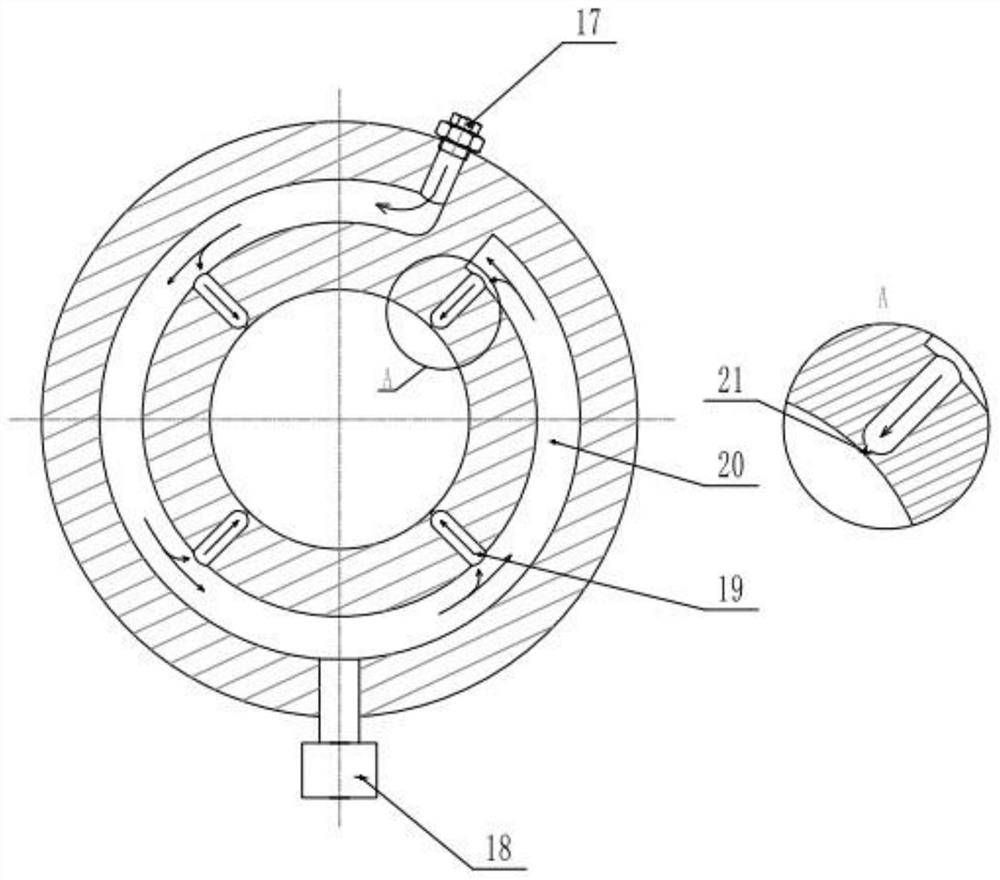

Method used

Image

Examples

Embodiment

[0043] Using supercritical carbon dioxide to prepare TPU foam soles, the operation steps are as follows:

[0044] (1) Preheat the injection molding machine first. After reaching the preset temperature, start to put in TPU pellets, and perform washing and extrusion tests;

[0045] (2) The parameter setting for injection extrusion of this material is that the injection speed is 5m / s, the injection pressure is 40bar, the three-stage temperature is 210°C, 200°C, and 190°C, the pressure is maintained, and the cooling time is 10s.

[0046] (3) The normal production cycle begins when the high-pressure gradient mixing screw head reaches the front end of the machine head. When the polymer melt completely fills the screw groove, the screw starts to retreat. The screw displacement monitoring module monitors the position of the screw. When it is close to the front end When the gas homogenizer opens the inlet valve, the supercritical fluid is injected into the gas homogenizer at a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com