Transformer core pressure resistant test fixture

A technology of withstand voltage testing and transformers, which is applied in the direction of testing dielectric strength, etc., and can solve problems such as low detection efficiency, missed detection, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

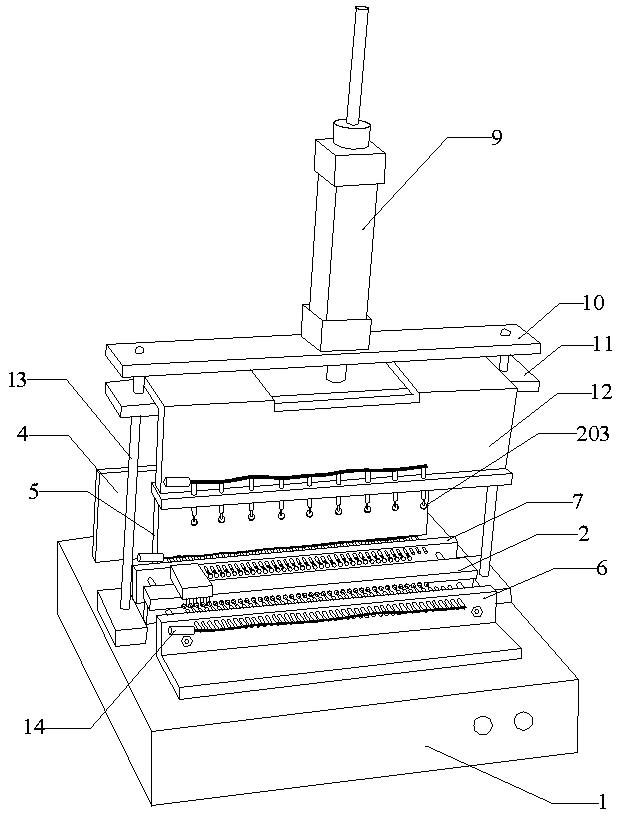

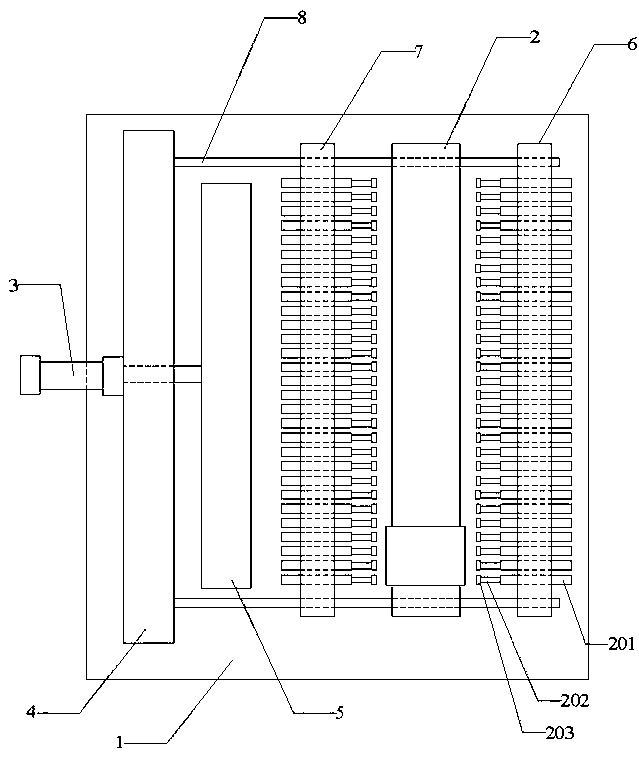

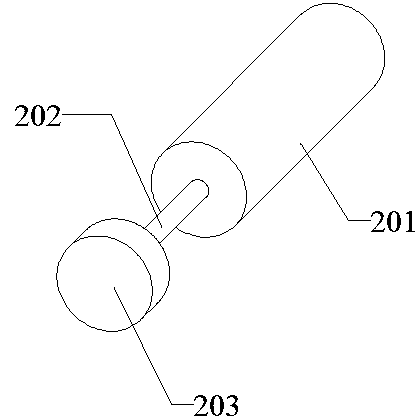

[0019] Such as figure 1 , 2 The transformer core voltage withstand test fixture shown includes a base 1, a placement board 2, a horizontal test component and a vertical test component. The base 1 is made of insulating material, and the horizontal test assembly and the vertical test assembly are used to contact the transformer magnetic core placed above the placement plate 2 from the front, rear and top respectively to achieve detection.

[0020] The level test assembly includes: a plurality of front probe units located in front of the placement board 2 and arranged side by side along the length direction of the placement board 2, a plurality of rear probe units located behind the placement board 2 and arranged side by side along the length direction of the placement board 2, The horizontal actuator for driving the front probe unit and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com