Process for washing and selecting high-ash, high-water easily-argillized lignite

A muddying and washing technology, applied in the direction of solid separation, etc., can solve the problems affecting the sorting process, high concentration of washing water, easy muddying, etc., and achieve the effect of simple treatment process, cost saving, and improved washing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

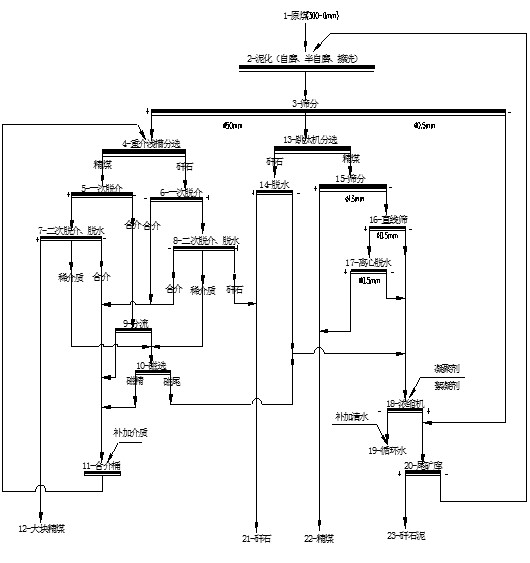

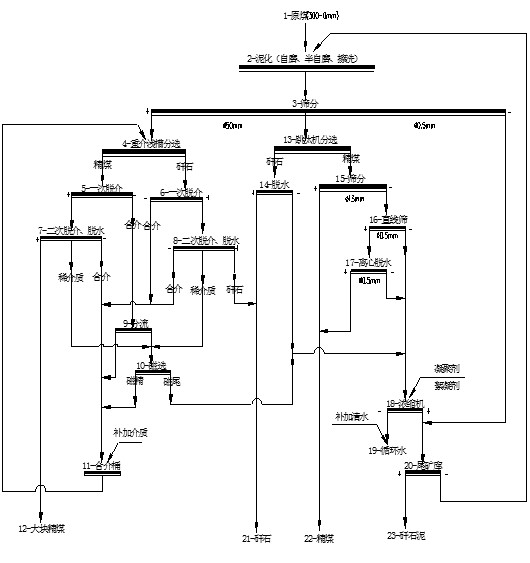

[0029] Embodiment 1: this lignite washing process step is as follows:

[0030] a. The raw coal 1 is artificially muddyed by a kind of muddy equipment 2;

[0031] b. The muddy raw coal from step a is screened and classified at 50mm and 0.5mm using a screening machine 3 to obtain three grades of >50mm, 50-0.5mm and <0.5mm;

[0032] c. Discharging the <0.5mm particle size product from step b directly to the tailings pond 20;

[0033] d. The > 50mm particle size product from step b is subjected to dense medium shallow tank 4 sorting, and the obtained clean coal and gangue products are respectively subjected to a first deintermediation 5, 6, and the underscreen product of the clean coal enters the split flow 9, part of the split flow and The under-screened gangue enters the joint barrel 11, and the over-screened product enters the next step.

[0034] e. The two products from step d are respectively subjected to secondary de-intermediation and dehydration 7, 8, wherein the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com