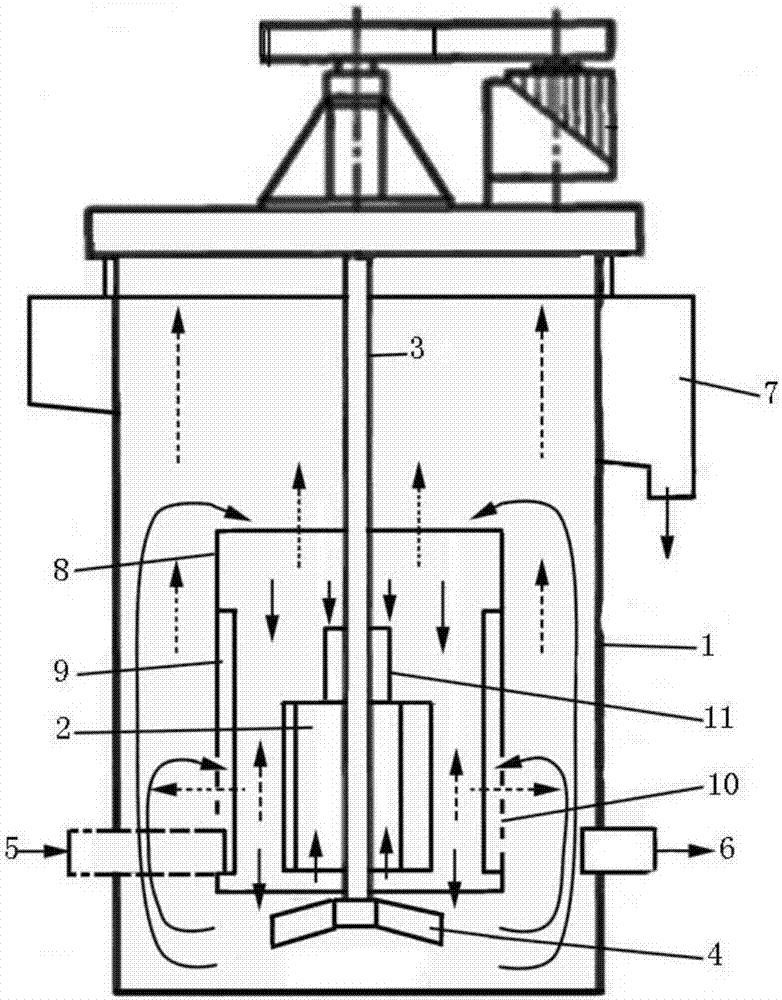

Double-impeller mechanical stirring self-suction flotation machine and flotation method

A mechanical stirring and self-priming technology, which is applied in flotation, solid separation, etc., can solve the problems of reduced negative pressure intensity, little chance of breaking through the adhesion of hydration film, and inconvenient maintenance and maintenance, etc. The probability of mineralization, the effect of improving the mineralization effect of air bubbles, and the effect of excellent aerated foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

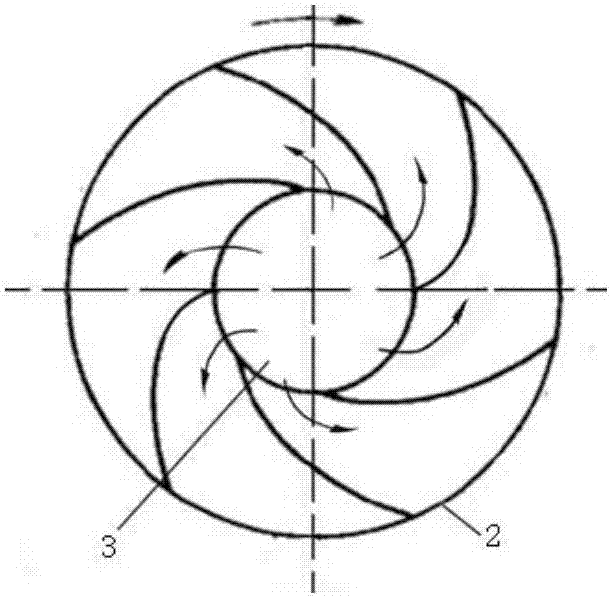

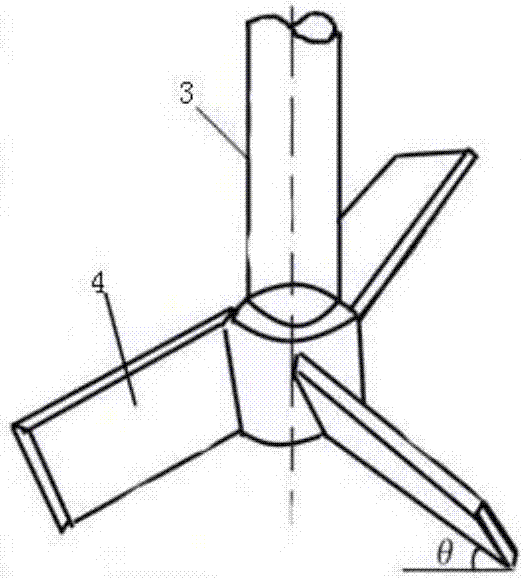

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The ore sample used in the test is Hubei Yuan'an phosphate rock, and the main chemical composition is (w / %): P 2 o 5 22.16, MgO3.15, SiO 2 25.41, Al 2 o 3 7.39, CaO 29.85, Fe 2 o 3 1.69, K 2 O 2.31, TiO 2 0.63. The positive flotation roughing comparison test was carried out under the same reagent conditions, that is, the flotation foam product was phosphorus concentrate, and the tank bottom product was impurity tailings. The best flotation results obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com