Intelligent mineral dry separation system based on intelligent arrayed air nozzles

An air nozzle, array type technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of low sorting accuracy, low processing capacity, no energy saving, etc., and achieve improved The effect of improving processing capacity and space utilization and lowering the lower limit of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

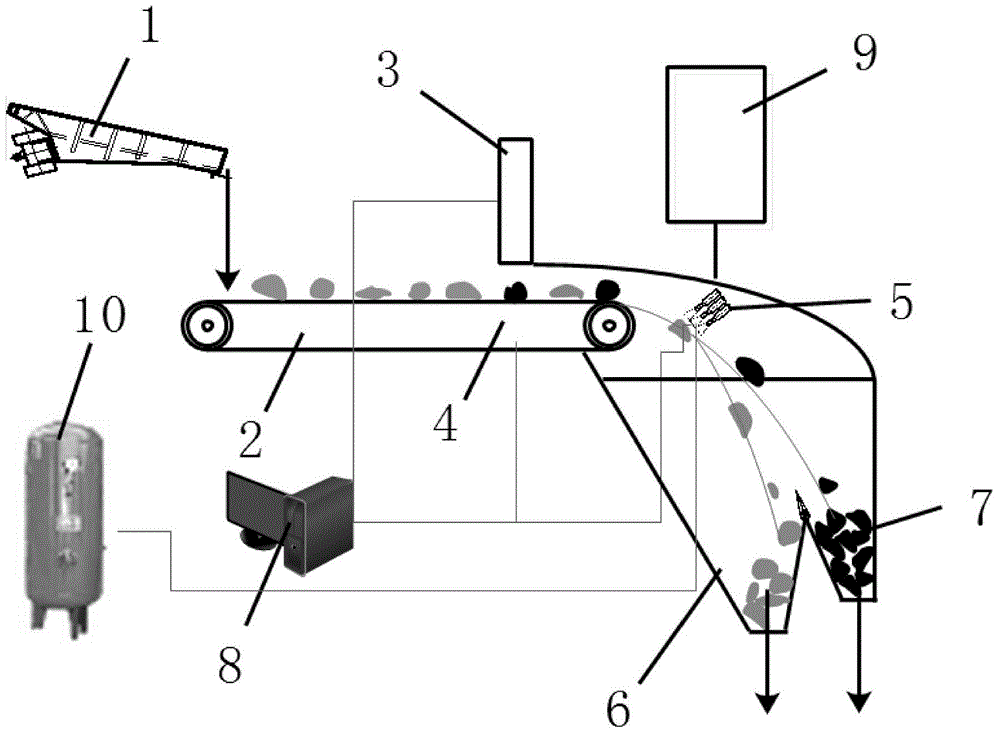

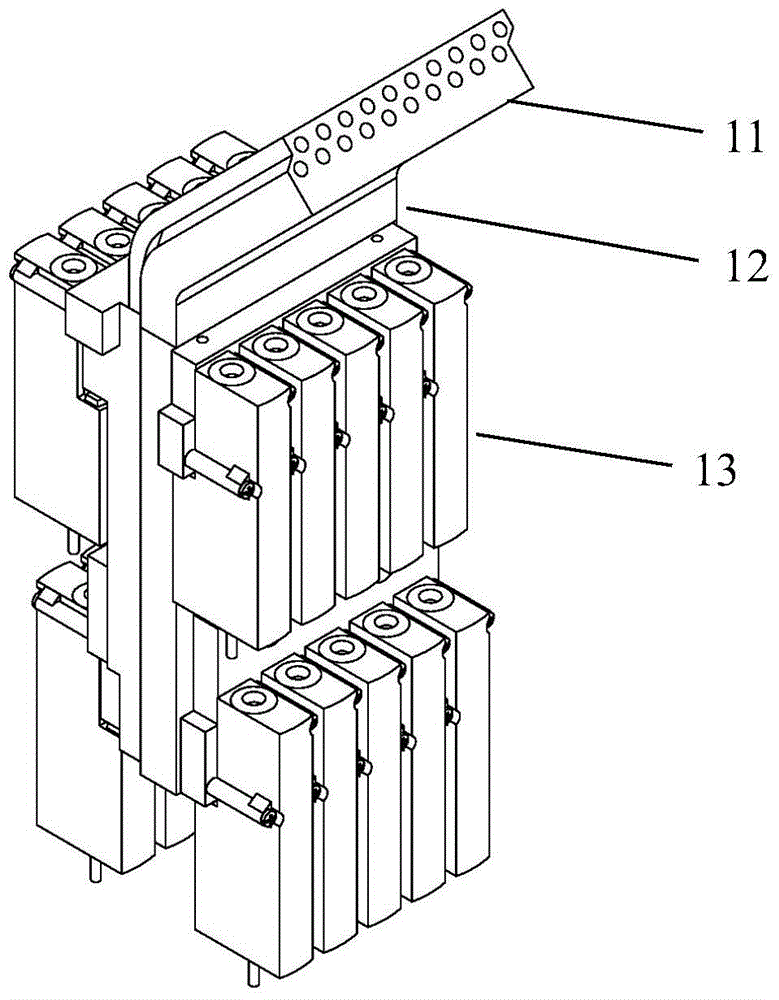

[0025] Such as figure 1 As shown, a mineral intelligent dry separation system based on intelligent array air nozzles.

[0026] The mineral intelligent dry separation system based on intelligent array air nozzles is a dry separation equipment that uses rays to intelligently identify and sort minerals. The mineral intelligent dry separation system based on intelligent array air nozzles identifies the concentrates and tailings according to the difference in the amount of radiation absorbed by the concentrates and tailings, and uses the air nozzles as the actuator, which is suitable for 300-3mm blocks , Sorting of granular minerals.

[0027] The raw materials are fed to the belt conveyor 2 through the feeding device 1, and the cloth is completed on the belt conveyor 2 to realize the single-layer arrangement of the objects, and there are gaps between each object and the front,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com