Separation device for coal and waste rocks and separation method thereof

A sorting device and waste rock technology, applied in sorting, instruments, character and pattern recognition, etc., can solve the problems of easy wear and tear of equipment, pollution of the environment, high energy consumption and noise, and physical injury of workers, so as to improve the sorting accuracy and The effect of automation degree, low cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The coal and gangue sorting device of the present invention is illustrated below with examples.

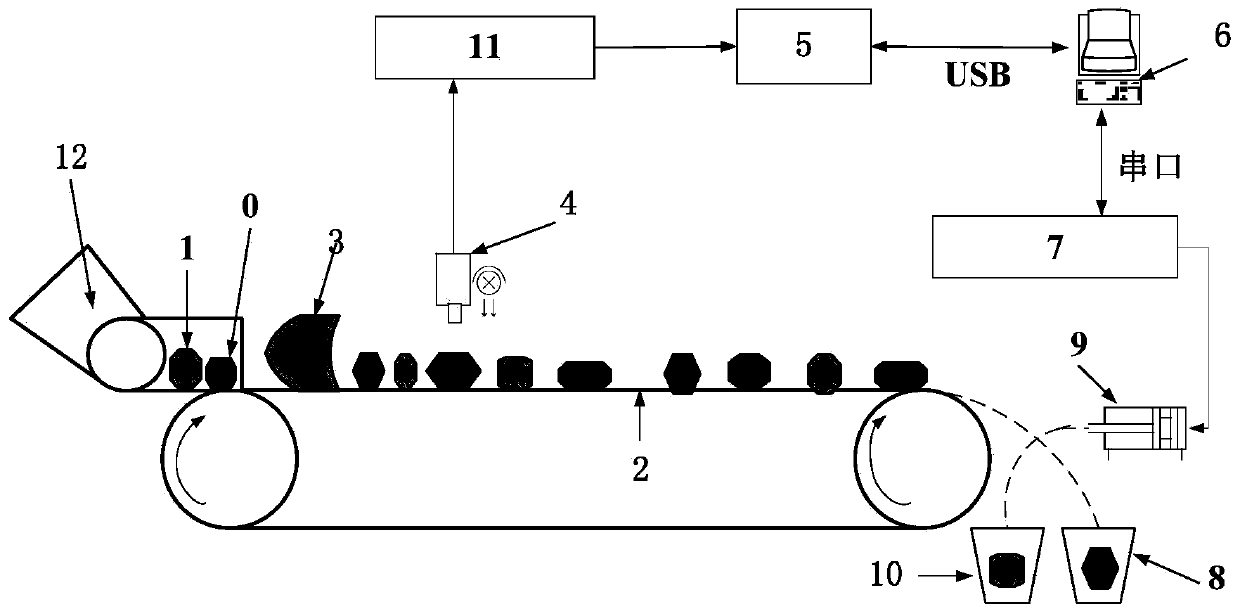

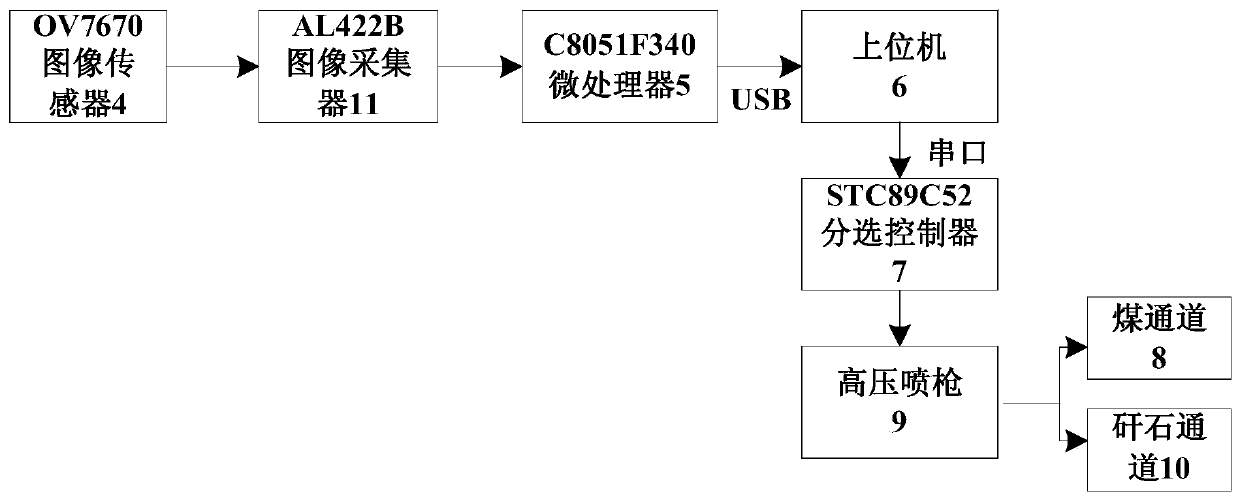

[0027] refer to figure 1 The coal and gangue sorting device of the present invention includes a vibrating coal feeder 1, a conveyor belt 2, a queuing device 3, an image sensor 4, an image collector 11, a microprocessor 5, a host computer 6, a sorting controller 7, and a high-pressure spray gun 9 , coal block channel 8 and gangue channel 10.

[0028] Image sensor 4 adopts a CMOS image sensitive device model OV7670, which is powered by a 3.3V voltage, integrates an image sensitive array and A / D conversion elements, and can directly provide 8-bit RGB / YUV format video digital signals, with the highest image output The speed can reach 30FPS, with automatic exposure control, automatic gain control, gamma correction and other control functions.

[0029] Since the clock frequency of the image sensor 4 can reach 24MHz, an image collector 11 composed of a FIFO module using AL422B a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com