Patents

Literature

59results about How to "Improve mineralization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorite ore sorting device and method

InactiveCN104289323AFast mineralization efficiencyFast flotation device mineralization efficiency High mineralization efficiencyFlotationMaceralEngineering

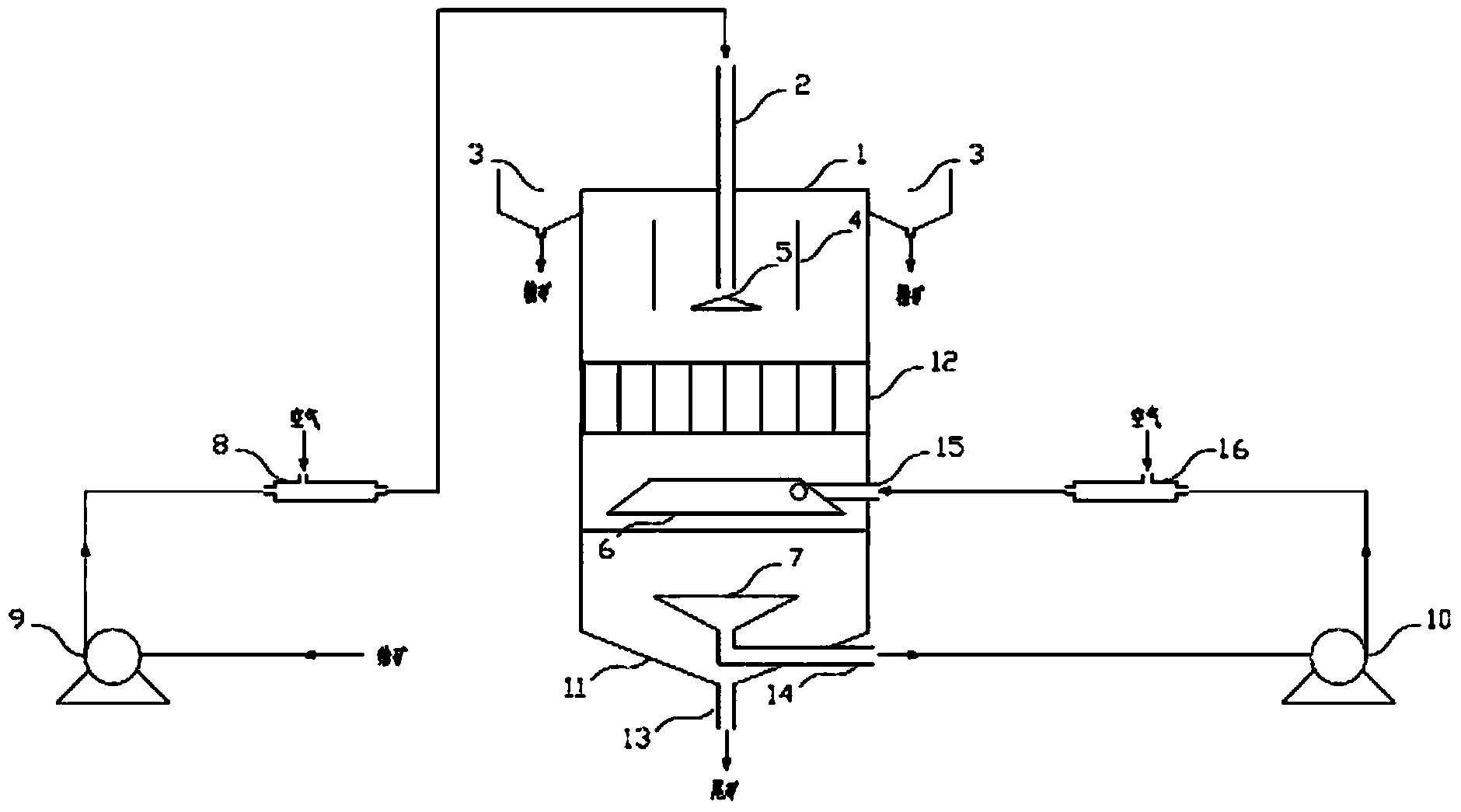

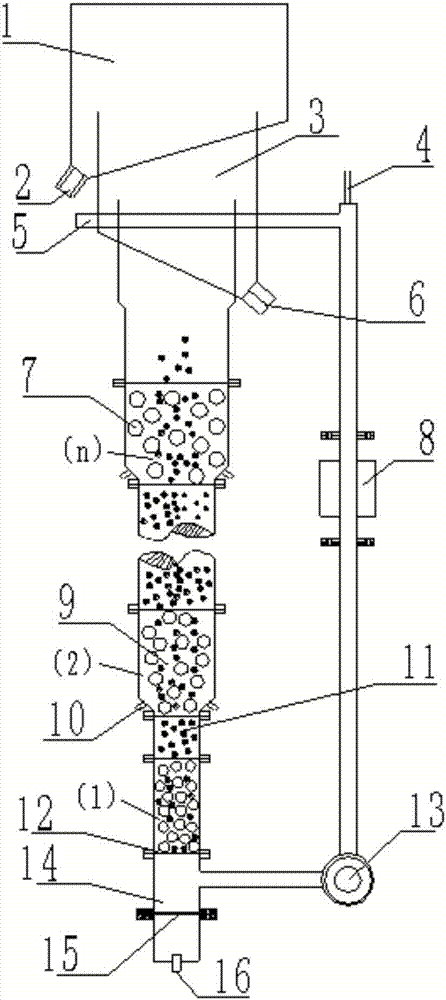

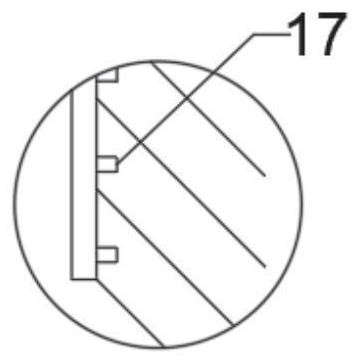

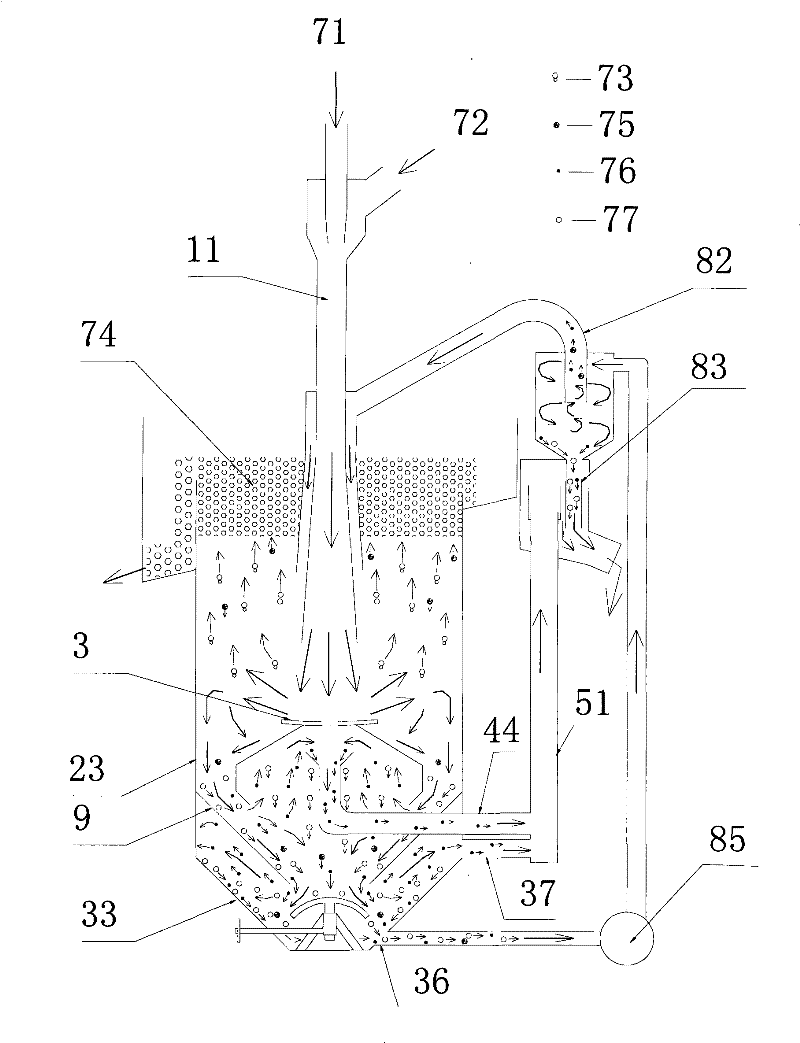

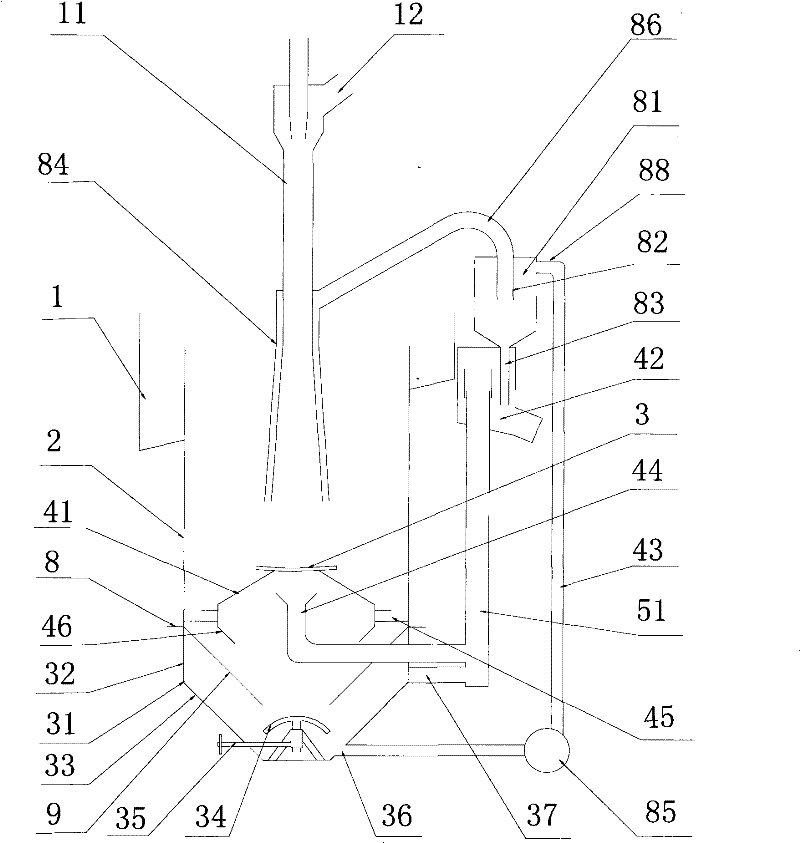

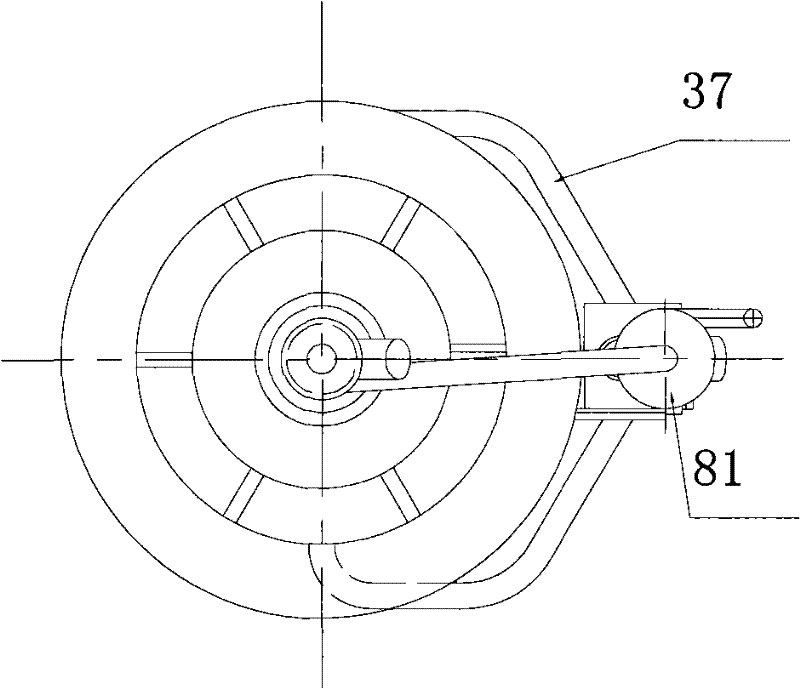

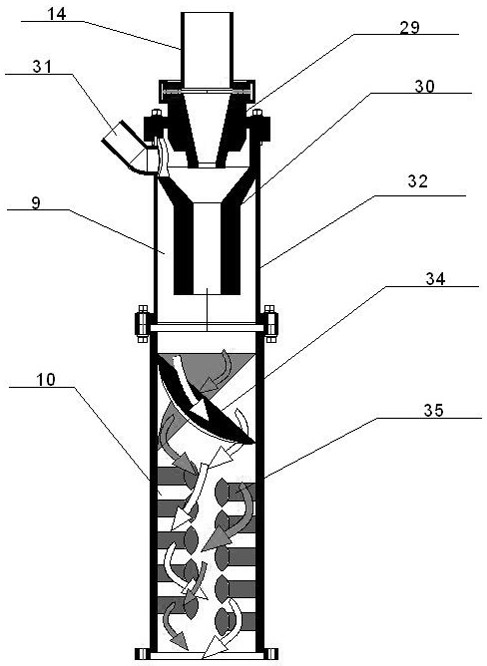

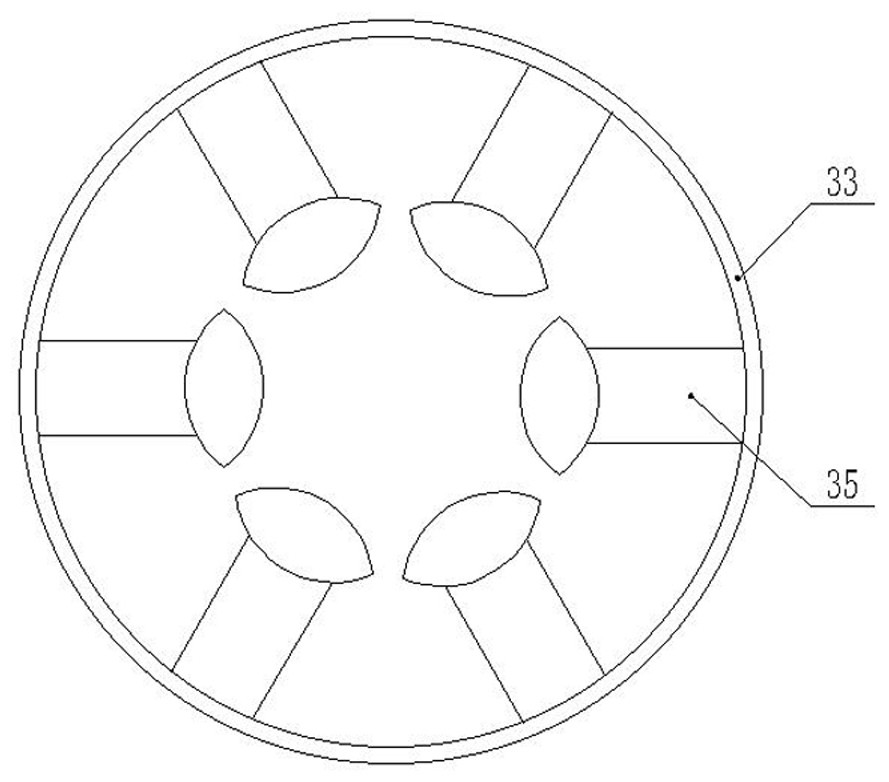

The invention relates to a fluorite ore sorting device and method and belongs to ore sorting devices and methods. The device comprises a coarse grain easy flotation ore rapid flotation device, a filling flotation device and a fine grain hard flotation ore strengthening collection device. The rapid flotation device comprises a flotation column, a lower guide pipe, a reflection false bottom, an annular sleeve, a foam collection tank and a bubble generator. The strengthening collection device comprises a cone, an inverted cone, a bubble generator, an ore pulp circulation pump and a lower inverted cone. The filling flotation device is a column segment between the rapid flotation device and the strengthening collection device and is provided with filler. The method includes the steps that feed ore is pressurized through a feed pump, subjected to the reaction in the bubble generator and the coarse grain easy flotation ore rapid flotation in the flotation column through the lower guide pipe, medium floatable ore is placed in the filling flotation device for further flotation sorting, and fine grain hard flotation ore is placed in the strengthening collection device for further sorting. The fluorite ore sorting device and method is high in mineralization efficiency, flotation speed and sorting efficiency and solves the problem that how to integrate the sorting of coarse grain easy flotation ore and fine grain hard flotation ore in one.

Owner:CHINA UNIV OF MINING & TECH

Double tail-removing gravity-flotation combined sorting method and device

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is low and the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a central ore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

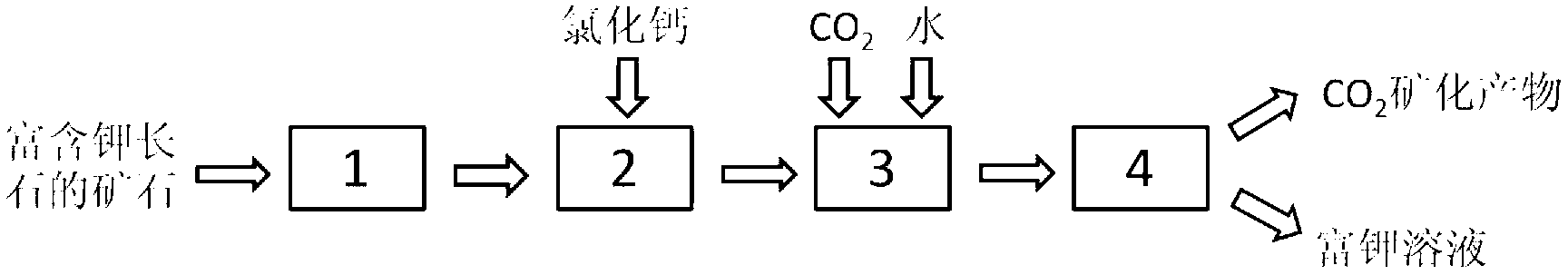

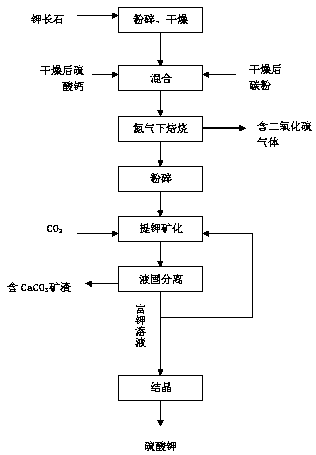

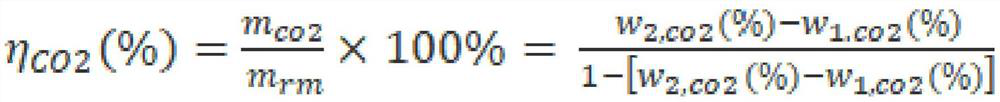

CO2 mineralization method capable of co-producing potassium-enriched solution by high temperature method

InactiveCN102701253AMineralization achievedImplement extractionCalcium/strontium/barium carbonatesPotassium fertilisersPotassium ionsChloride

The invention discloses a CO2 mineralization method capable of co-producing potassium-enriched solution by a high temperature method, which mainly comprises the following steps of: adequately and evenly mixing smashed potash feldspar-enriched ore power and calcium chloride, and carrying out conversion reaction under the condition that the temperature is not lower than 600 DEG C; putting material which is adequately converted into a reactor, adding water, charging CO2, and carrying out mineralization reaction under the condition that the CO2 partial pressure is 0.3-15MPa, and the temperature is 50-350 DEG C; and charging material liquid which is adequately mineralized into separation equipment to separate the solid from the liquid, wherein the liquid phase is the potassium ion-enriched potassium-enriched solution, and the solid phase is the calcium carbonate-containing mineralized product. The CO2 is mineralized by the technical method disclosed by the invention, and the conversion rate of the potash feldspar component in the ore reaches 96%, so that compared with the highest conversion rate 13% of the existing CO2 mineralization method capable of co-producing the potassium-enriched solution, the conversion rate of the CO2 mineralization method is improved by over 6.3 times.

Owner:SICHUAN UNIV

Jet atomization device and flotation device with same

ActiveCN111570099AMicrobubble System EquilibriumImprove mineralization efficiencyRotating receptacle mixersFlow mixersPhysicsElectric machinery

The invention discloses a jet atomization device and a flotation device with the same. The jet atomization device comprises a jet atomization device; the jet atomization device further comprises a double-connection-wheel jet agitation mechanism and a shearing emulsification device; the jet atomization device comprises an atomization cylinder, a rotating shaft, a laminar flow guide disc, a conicalflow guide cover and a flow guide cover chassis. The double-connection-wheel jet agitation mechanism comprises a flotation tank, a supporting frame, a pretreatment bin, a rotary connecting rod, a driving impeller, an agitation impeller, a flow guide cylinder and a circulating pump. The shearing emulsification device comprises an emulsification tank, a medicament spray head, a fixed fluted disc, arotary fluted disc and a speed compensation motor. Foaming agent atomization, collecting agent emulsification, size pre-mixing and flotation are integrated, and therefore, equipment size and occupiedarea are greatly reduced; and meanwhile, the energy consumption of ore pulp is decreased; the equipment has a foaming agent atomization function, a collecting agent emulsification function and a jet air suction drive stirring flotation function, and therefore, mineral separation efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

Turbulent flow regulating and controlling external particle fluidized bed mineralizing and floating device uniform in turbulence degree

ActiveCN106944264ASize balanceHigh kinetic energy utilization efficiencyFlotationFluidized bedEngineering

The invention discloses a turbulent flow regulating and controlling external particle fluidized bed uniform in turbulence degree and belongs to a mineral separation device. The device comprises a column floating area, a concentrate overflow groove in the upper portion of the column floating area and a middling ore circulating port outside the column floating area; the lower portion of the column floating area is provided with a gas and liquid mixing area; a fluidized bed mineralizing and floating area is arranged between the column floating area and the gas and liquid mixing area; the fluidized bed mineralizing and floating area is provided with a mineralizing area 1, a mineralizing area 2,... and a mineralizing area n; and the interiors of the mineralizing area 1, the mineralizing area 2,...and the mineralizing area n are filled with turbulent flow regulating and controlling particles. According to the turbulent flow regulating and controlling external particle fluidized bed uniform in turbulence degree, mineralizing and floating are totally separated, and are different from current integration of mineralizing and floating; the mineralizing time can be achieved by adjusting the mineralizing area segment number of the fluidized bed mineralizing and floating area, and therefore the kinetic energy utilizing efficiency is very high; the energy dissipating rate is high, the bubble size balance and stable retention of high-pressure gas are guaranteed, and the floating recovery rate is increased; and upper, middle and lower mineralizing fluidized bed layers are provided with different turbulence degrees, and the mineralizing efficiency is high.

Owner:CHINA UNIV OF MINING & TECH

Desalinated seawater mineralization system and manufacturing method for desalinated seawater mineralization

ActiveCN106904716AShort hydraulic retention timeImprove mineralization efficiencySeawater treatmentWater aerationNitrogen dioxideEngineering

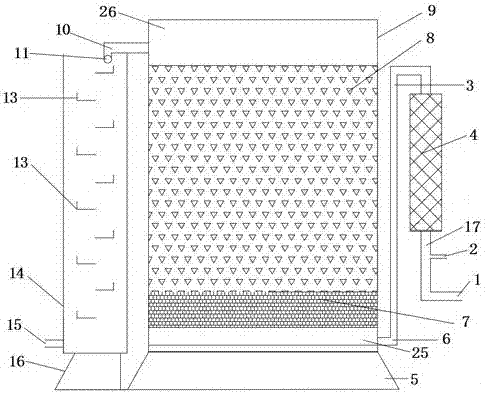

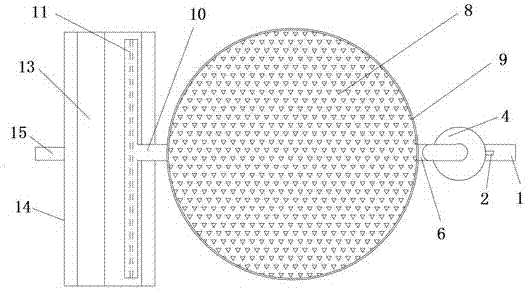

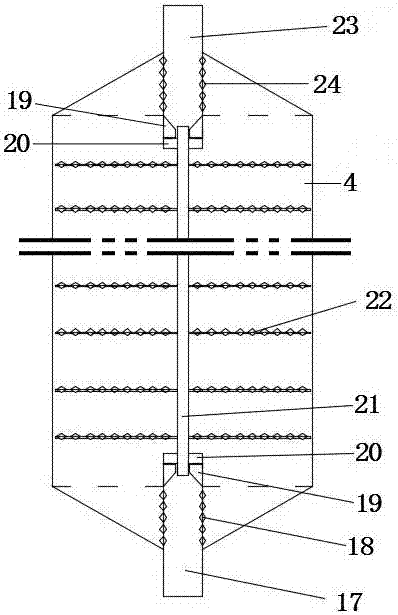

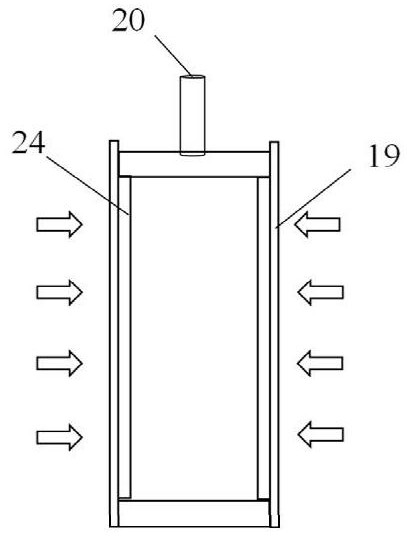

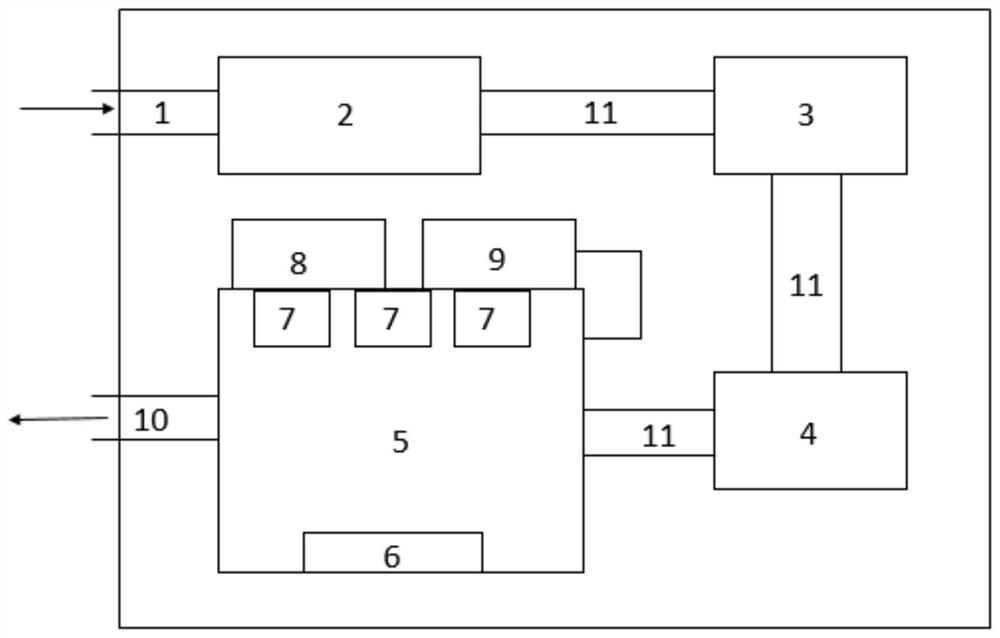

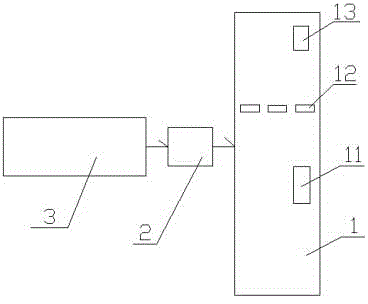

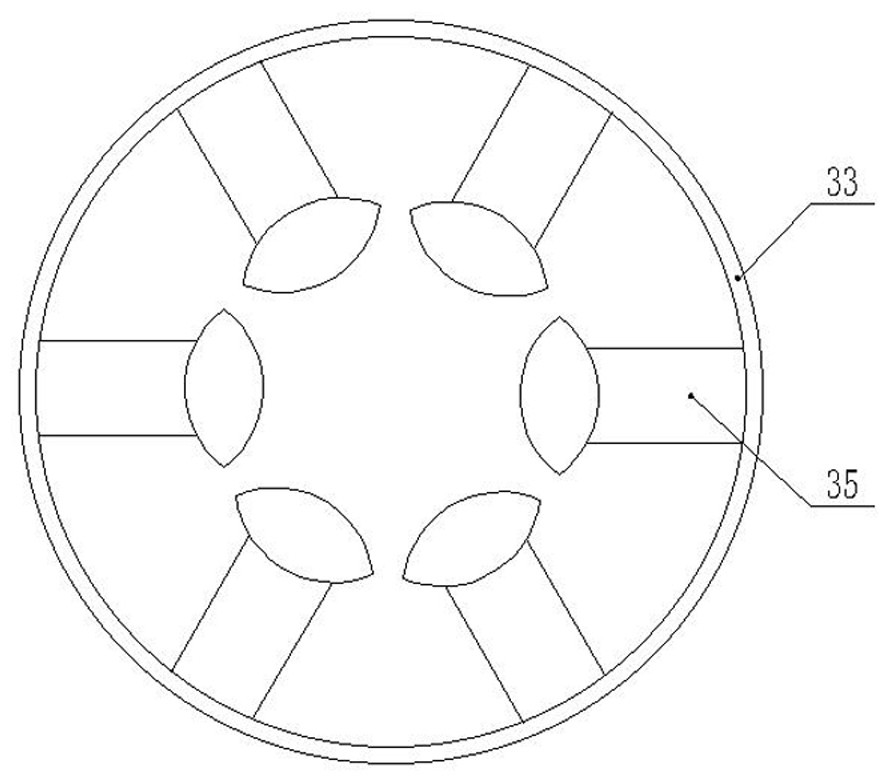

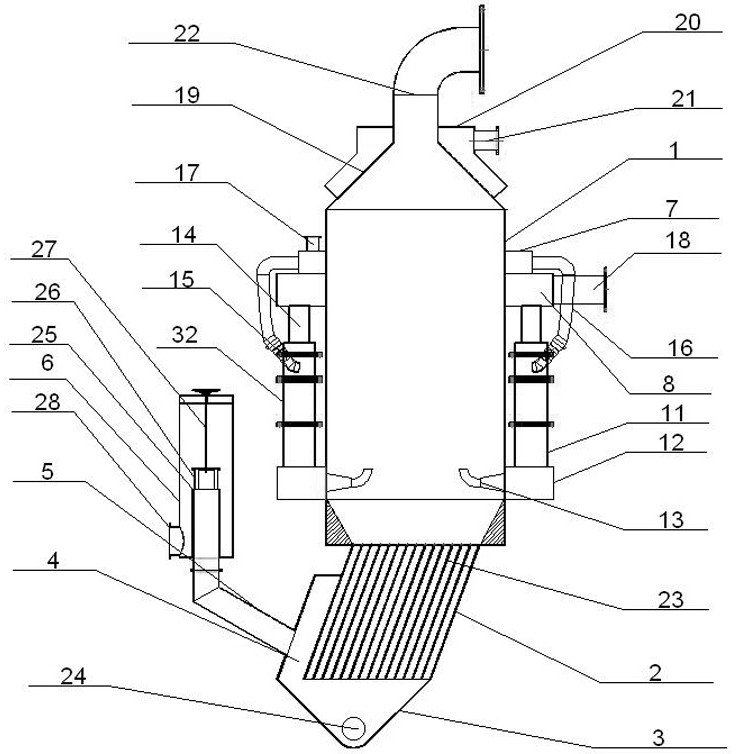

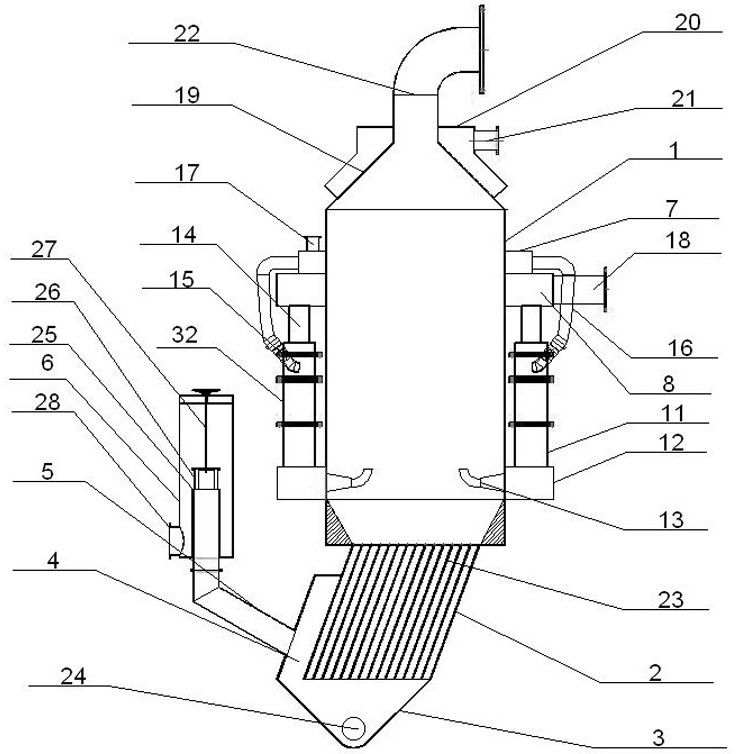

The invention relates to a desalinated seawater mineralization system and a manufacturing method for desalinated seawater mineralization. The system of the invention is composed of a gas-liquid mixer (4), a mineralization tower (9) and a fluctuation chamber (14). The gas-liquid mixer (4) reinforces desalinated seawater mineralization by the nitrogen dioxide pipeline aeration mode. The mineralization tower (9) enables carbon dioxide and a calcite filler to fully react so as to enhance desalinated seawater mineralization. The fluctuation chamber (14) enables unreacted carbon dioxide to be dissolved out so as to increase oxygen content, raise pH value and enhance safety of desalinated seawater. The gas-liquid mixer (4) is composed of a main body of the gas-liquid mixer (4), a water through hole (18), a rotary locking groove (19), a separation blade (20), a center shaft (21), a water inlet opening (24) and a rotary wheel plate (22). The system has a reasonable structure, is scientifically designed, is convenient to use, is simple to manufacture, and solves disadvantages of a traditional mineralization device. By the system, mineralization effect of desalinated seawater is raised, and mineralization time of desalinated seawater is shortened.

Owner:TIANJIN WATER RESOURCES RES INST

Method for reducing phosphogypsum by using hot carbon, heat activating potassium feldspar, mineralizing CO2 and co-producing SiO2 and potassium sulfate

InactiveCN107902631AHigh purityLow reaction temperatureChemical industrySulfur compoundsWater insolublePhosphogypsum

The invention discloses a novel mineralization method for utilizing CO2. The method comprises the following steps: firstly, uniformly mixing potassium feldspar ore powder, calcium sulfate and carbon powder, forming through a tabletting or agglomerating method; roasting the formed material under nitrogen gas atmosphere, recycling and applying the generated SO2 to sulfuric acid industry; grinding and sieving the roasted product, subjecting the sieved product to mineralization reaction with CO2; filtering and separating the mineralized liquid-solid mixture, and evaporating the filtrate and performing crystallization to prepare potassium sulfate, and the filter residue comprises CaCO3, CaSiO3, aluminosilicate and the like and can be used as a cement material. According to the invention, industrial solid waste phosphogypsum can be reduced, so that the product can be applied to the sulfuric acid industry, and meanwhile, the environment problem can be solved; the CO2 carbonation characteristic is fully utilized, and mineralization and carbon reduction are carried out; the water-insoluble potassium feldspar ore is processed into a water-soluble potassium sulfate fertilizer; a co-melt is formed in the reaction process of reactants, the temperature required by reaction is reduced, and the energy consumption is reduced. The method has the triple effects of saving energy, reducing carbon,protecting environment and producing a chemical, and has a very good industrial application prospect.

Owner:SICHUAN UNIV

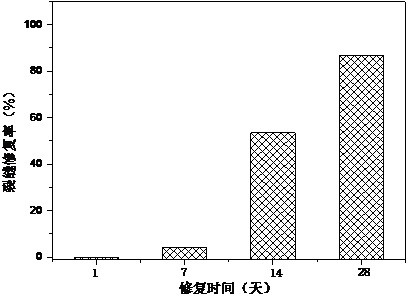

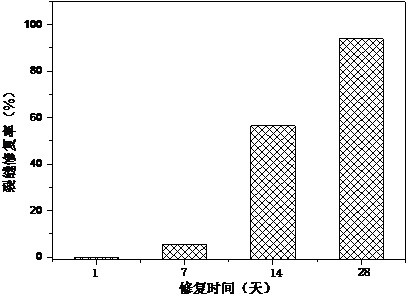

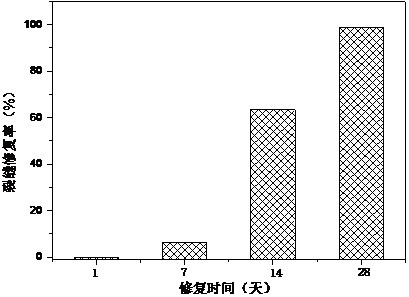

Preparation method and application of cement-based material additive

ActiveCN111718144ARealize intelligent crackingReduce dosageCalcium/strontium/barium carbonatesBiotechnologySodium bicarbonate

The invention discloses a preparation method and application of a cement-based material additive. The preparation method comprises the following steps: preparing a calcium chloride solution and a sodium bicarbonate solution with equal mass to prepare porous calcium carbonate microspheres; inoculating bacillus lysine into a culture medium, and adding a spore efficient transforming agent into a culture solution; putting the calcium carbonate microspheres into a lysine bacillus spore culture solution, and fully standing until the concentration of the spore culture solution tends to be stable so as to obtain calcium carbonate microspheres loaded with microbial spores; dissolving the calcium carbonate microspheres loaded with the microbial spores into a mixed solution of sodium alginate and barium silver, uniformly stirring, and coating the surface layers of the calcium carbonate microspheres through spray drying. Results show that the cement-based material additive prepared by the method is suitable for maritime work environments, can effectively fill and block cracks of cement-based materials, improves the durability of engineering and prolongs the service life of the engineering.

Owner:JIANGSU UNIV OF SCI & TECH

Concrete self-repairing material, and preparation method thereof and concrete with concrete self-repairing material

InactiveCN113149496AIncreased durabilityExtended service lifeCalcium/strontium/barium carbonatesMicroorganismInorganic particle

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing ozone catalyst for removal of antibiotics in water by using cheap material as carrier

InactiveCN108404913AEasy to makeEasy to operateNature of treatment waterMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

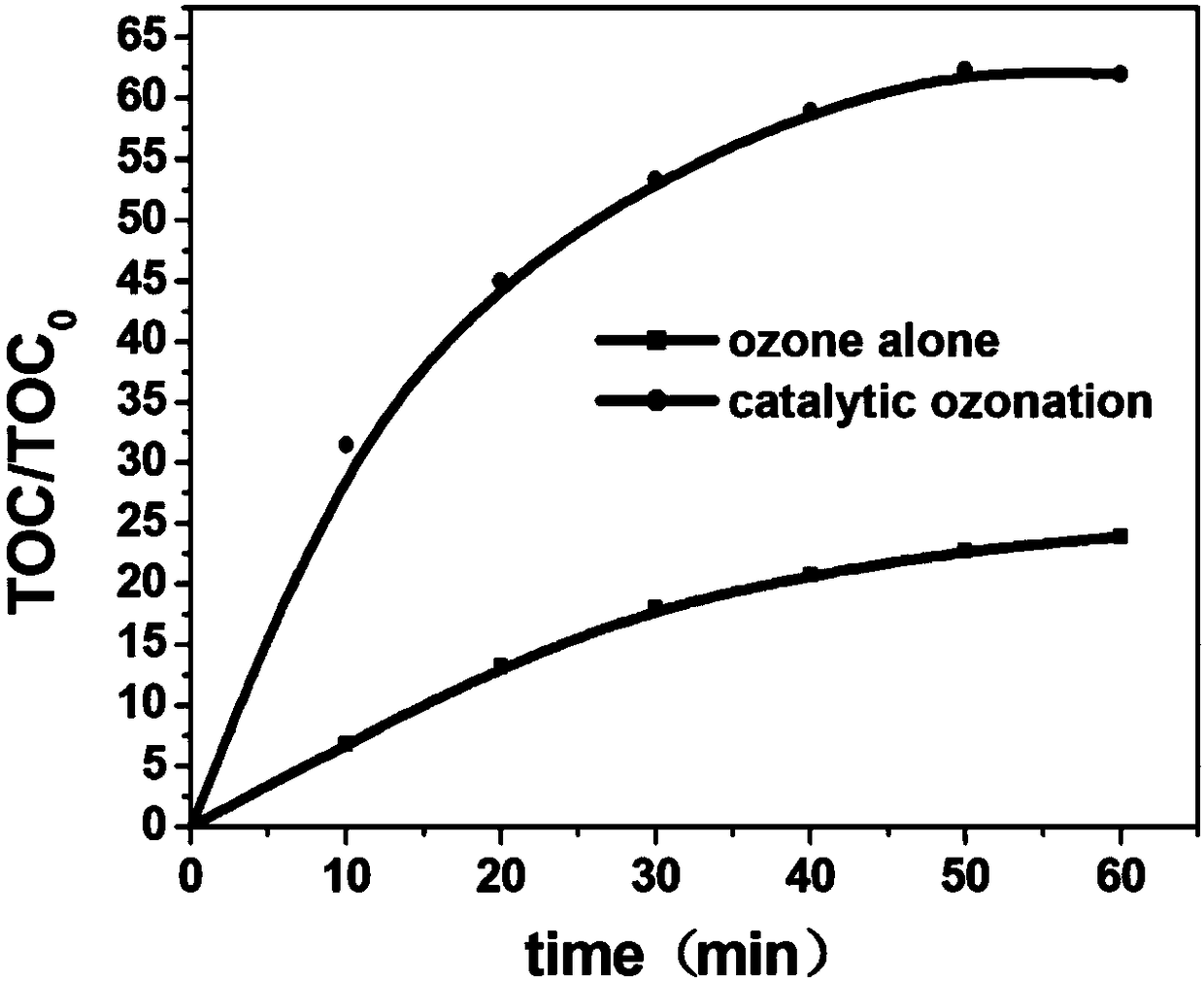

The invention belongs to the technical fields of preparation of novel materials and wastewater treatment with an advanced oxidation technology, and relates to a method for preparing an ozone catalystfor removal of antibiotics in water by using a cheap material as a carrier. The method comprises the following steps: selecting a cheap material namely oyster shells as a catalyst carrier, impregnating oyster shell powder into an impregnating solution through a wet impregnation method, and after completion of impregnation, carrying out drying, calcining and screening so as to obtain a metallic oxide loaded ozone catalyst, wherein the metallic oxide loaded ozone catalyst is applied to a system of ozone catalytic oxidation and degradation of antibiotic wastewater, significantly improves the mineralization efficiency of the antibiotics, and shows good catalytic performance. The method provided by the invention has the advantages of simple process, convenient operation, cheap and easily-available oyster shell, safety and environmental protection, significantly reduces the cost of water treatment by ozone catalytic oxidation, and facilitates extensive application of an ozone catalytic oxidation technology.

Owner:DALIAN UNIV OF TECH

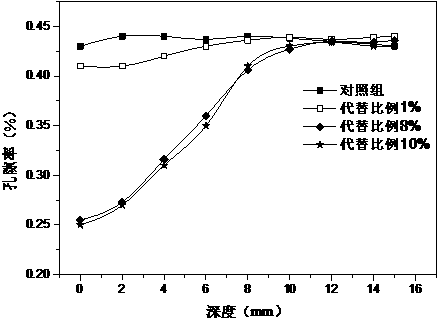

Organo-mineral biochar complex formula fertilizer and preparation method thereof

InactiveCN106431568ARaise the ratioReduce the relative proportionBio-organic fraction processingExcrement fertilisersNitrogenPlant Sources

The invention discloses organo-mineral biochar complex formula fertilizer and a preparation method thereof. The preparation method of the organo-mineral biochar complex formula fertilizer comprises the following steps: (1) a premix is obtained by mixing organic matter with biochar; (2) the premix obtained in the step (1) is subjected to composting fermentation; (3) the organo-mineral biochar complex formula fertilizer is obtained by adding chemical fertilizer to a fermentation product obtained in the step (2). According to the complex formula fertilizer, plant-sourced organic matter and animal-sourced organic matter are subjected to mixed fermentation, raw materials are subjected to biosafety disposal, the biochar is formed and plays an adsorption role, and clean organic fertilizer is produced; a balanced and reasonable NPK formula is realized according to the organic matter with difference sources, and maximization of the fertilizer efficiency is realized.

Owner:CHINA AGRI UNIV

Rhizo-spherical beneficial microorganism-charcoal composite organic fertilizer and preparation method thereof

InactiveCN106631335AImprove mineralization efficiencyPromote degradationBio-organic fraction processingNitrogenous fertilisersOrganic matter mineralizationPhosphate

The invention discloses a rhizo-spherical beneficial microorganism-charcoal composite organic fertilizer and a preparation method thereof. The rhizo-spherical beneficial microorganism-charcoal composite organic fertilizer comprises the following steps that 1, organic matter and charcoal are mixed to obtain a premix; 2, composting fermentation the premix in the step 1; 3, rhizo-spherical microorganisms are added in the fermentation product in the step 2 to obtain the rhizo-spherical beneficial microorganism-charcoal composite organic fertilizer. Plant sourced and animal sourced organic matter are subjected to mixed fermentation, the raw materials are innocently treated to form charcoal, the charcoal effect of the charcoal is played, and the clean organic fertilizer is produced. The rhizo-spherical microorganisms promoting plant growth are added in the fermentation product, the organic matter degradation and mineralization process is catalyzed, the fertilizer still has activity after being applied to soil, and the organic matter mineralization efficiency and soil phosphate degradation are improved.

Owner:CHINA AGRI UNIV

Mine pit backfill material as well as preparation method and application thereof

ActiveCN114133170AHigh extraction rateImprove mineralization efficiencySolid waste managementMaterial fill-upHydration reactionSoil science

The invention discloses a pit backfill material, a preparation method and application thereof, and the pit backfill material is composed of the following raw materials in parts by weight: 25-30 parts of industrial solid waste, 170-210 parts of water, 1-3 parts of sodium dodecyl benzene sulfonate, 1-5 parts of polyvinyl alcohol and 8-12 parts of cement. The preparation method comprises the following steps: S1, carrying out pulverization treatment on industrial solid waste; s2, carrying out hydration calcination on the raw material obtained in the step S1 and part of water; s3, stirring the sample obtained in the step S2 with sodium dodecyl benzene sulfonate, polyvinyl alcohol and the rest of water to form slurry, and injecting carbon dioxide for mineralization; and S4, mixing the mineralized sample obtained in the step S3 with cement. The filler disclosed by the invention can be used for backfilling a coal mine pit, the backfilling cost is reduced, and meanwhile, the filler has the dual advantages of reducing carbon dioxide emission and solving the problem of industrial waste emission.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

High-specific-surface-area super-hydrophilic gradient boron-doped diamond electrode and preparation method and application thereof

ActiveCN111593316AImprove electrocatalytic activityImprove degradation efficiencyWater treatment compoundsSpecific water treatment objectivesDiamond electrodesPhysical chemistry

The invention discloses a high-specific-surface-area super-hydrophilic gradient boron-doped diamond electrode and a preparation method and application thereof. According to the gradient boron-doped diamond electrode, a substrate is directly taken as an electrode base; or the surface of the substrate is provided with a transition layer, and then the substrate is taken as the electrode base, a gradient boron-doped diamond layer is arranged on the surface of the electrode base, and the wetting angle theta of the gradient boron-doped diamond electrode is smaller than 40 degrees; and the gradient boron-doped diamond layer sequentially comprises a gradient boron-doped diamond bottom layer, a gradient boron-doped diamond middle layer and a gradient boron-doped diamond top layer with the boron contents increased in a gradient mode from bottom to top. Therefore, the gradient boron-doped diamond layer has high attraction force, high corrosion resistance and high catalytic activity at the same time, high-boron content of the top layer is combined with one-time high-temperature treatment, so that the gradient boron-doped diamond electrode has the high specific surface area and superhydrophilicity, and the mineralization degradation efficiency of the gradient boron-doped diamond electrode can be greatly improved.

Owner:NANJING DAIMONTE TECH CO LTD

Batch type photocatalytic energy collection reactor and method for wastewater treatment by same

ActiveCN105836842ASimple structureLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionProton

The invention relates to a photocatalytic reactor and a method for wastewater treatment by the photocatalytic reactor, in particular to a batch type photocatalytic energy collection reactor and a method for wastewater treatment by the batch type photocatalytic energy collection reactor and aims to solve the problem of low photocatalytic organism degradation efficiency of existing photocatalytic wastewater treatment methods. The reactor comprises a shell, an anode chamber, a cathode chamber, a proton exchange membrane, a photoanode, guartz glass, a stirring device, a counter electrode, a capacitor and a converter. The proton exchange membrane is arranged in the middle of the shell, the shell is provided with the photoanode at one end of the anode chamber and provided with the counter electrode at one end of the cathode chamber, and the photoanode and the counter electrode are connected through an external circuit. The method includes: feeding wastewater into the reactor through a water inlet of the anode chamber, starting the stirring device, subjecting the photoanode to ultraviolet irradiation, and discharging the treated water through a water inlet hole of the anode chamber. The batch type photocatalytic energy collection reactor and the method for wastewater treatment by the batch type photocatalytic energy collection reactor are applied to the field of wastewater treatment, improve efficiency in separation of photogenerated holes and electrons and effectively and synchronously improve system production capacity and efficiency in degradation and mineralization of refractory organics in wastewater.

Owner:HARBIN INST OF TECH

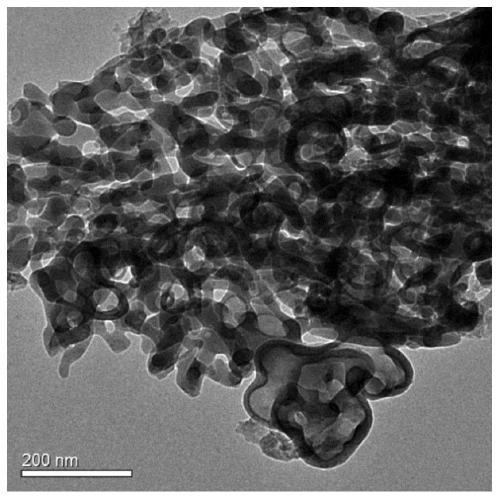

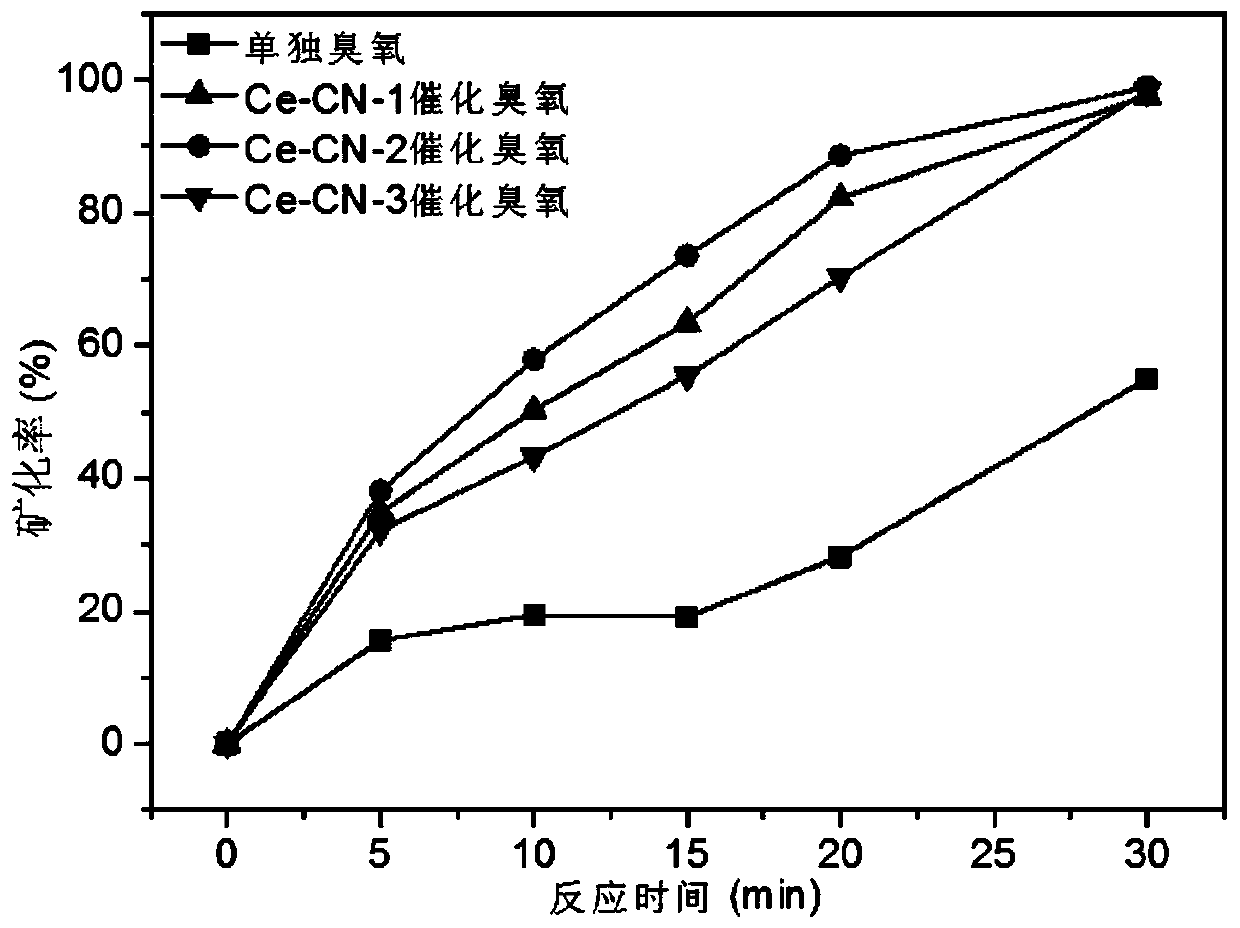

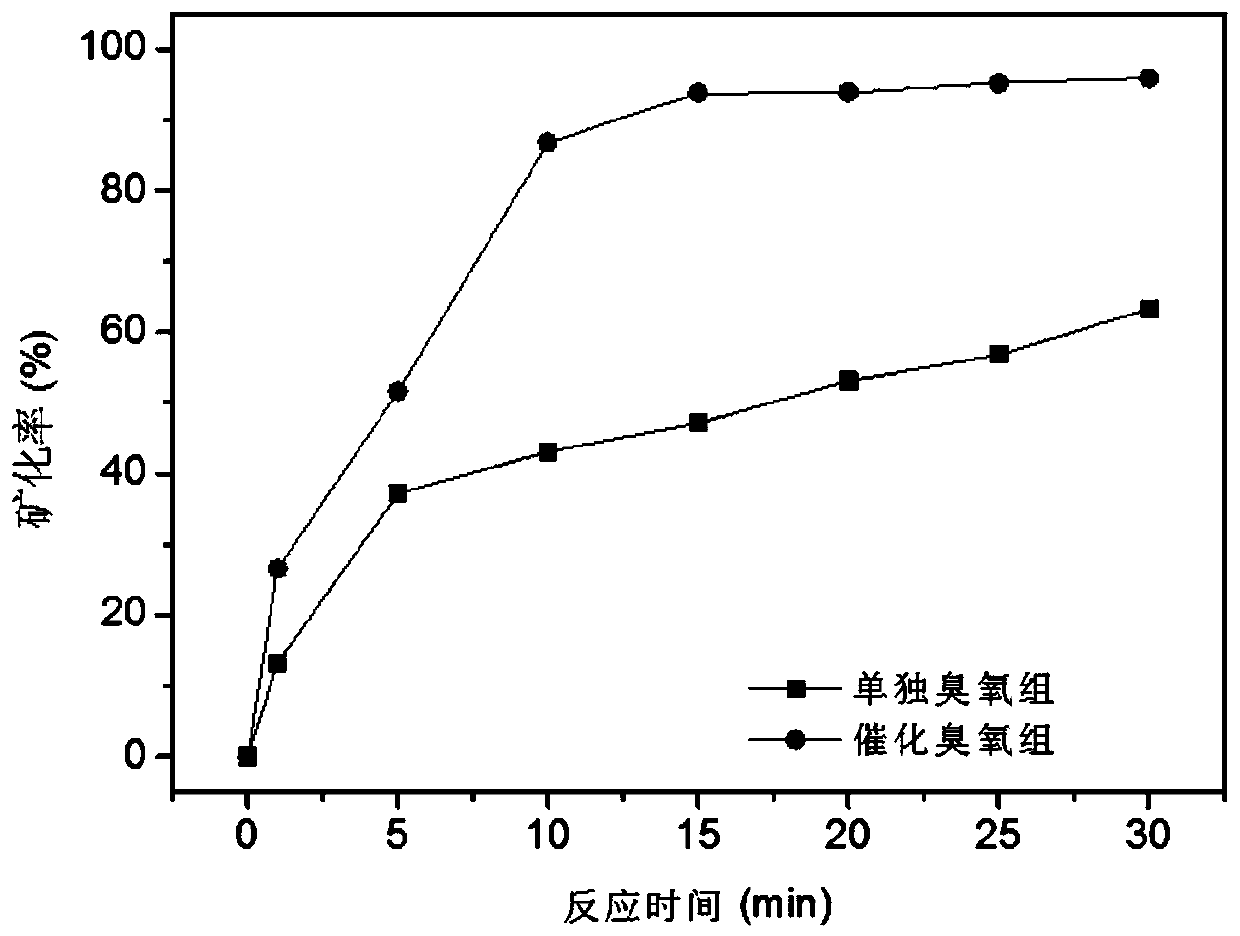

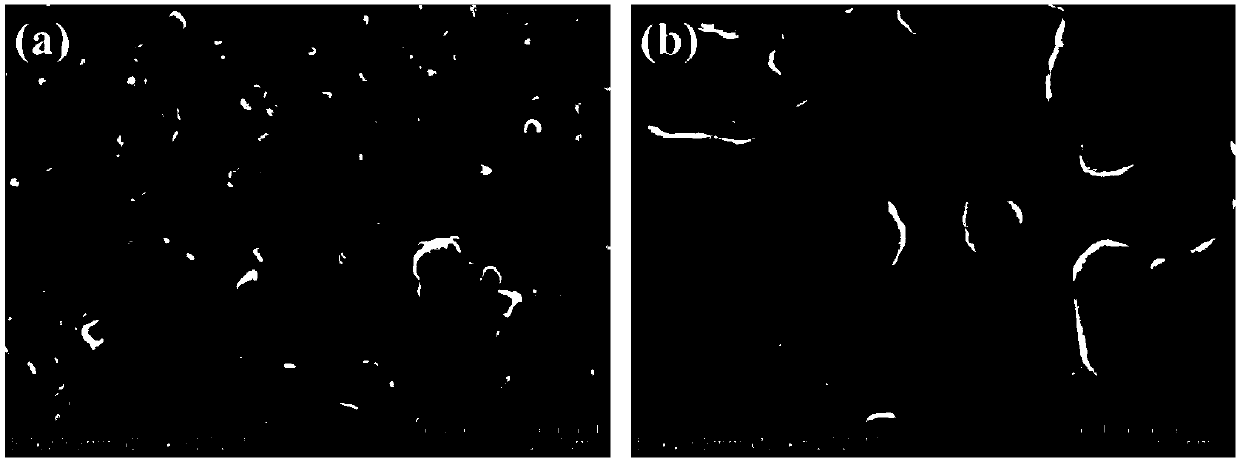

Cerium-based ozone catalyst containing double active sites as well as preparation method and application thereof

PendingCN111151280AImprove mineralization efficiencyEasy to makeWater treatment compoundsWater contaminantsPtru catalystIndustrial effluent

The invention relates to a cerium-based ozone catalyst containing double active sites as well as a preparation method and application thereof, and belongs to the technical field of advanced wastewatertreatment and environmental catalysis. The preparation method of the cerium-based ozone catalyst comprises the following steps: 1) preparing a melamine solution; 2) adding cerium salt into the melamine solution in the step 1), then adding a polyhydroxyl carboxylic acid auxiliary agent and hydrochloric acid, and stirring to obtain a mixture; and 3) drying the mixture, and calcining to obtain a Ce-g-C3N4 catalyst, which is used for degrading organic pollutants in wastewater. Compared with the prior art, the Ce-g-C3N4 catalyst has the advantages that the preparation process is simple, the raw materials are cheap and easy to obtain, and the Ce-g-C3N4 catalyst is insoluble in acid, alkali and an organic solvent, has high catalytic activity and stability, low dosage, a wide pH application rangeand good reusability, has a good mineralization promotion effect on various refractory organic pollutants, and has a wide prospect in advanced treatment of industrial wastewater.

Owner:TONGJI UNIV

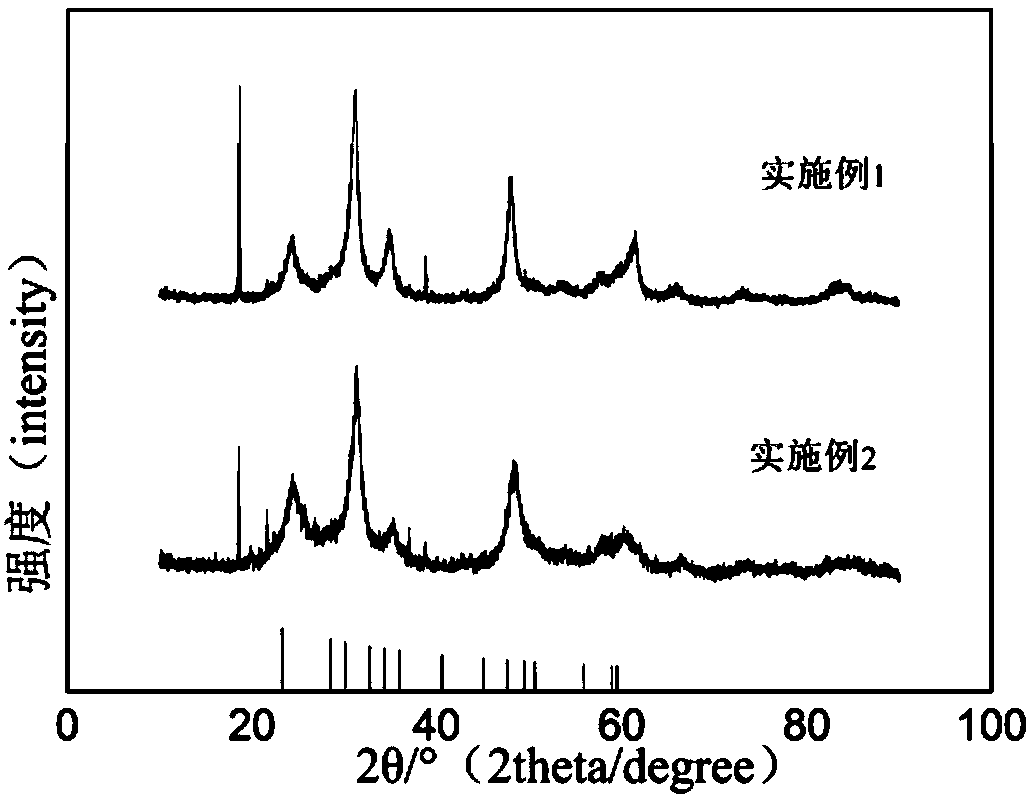

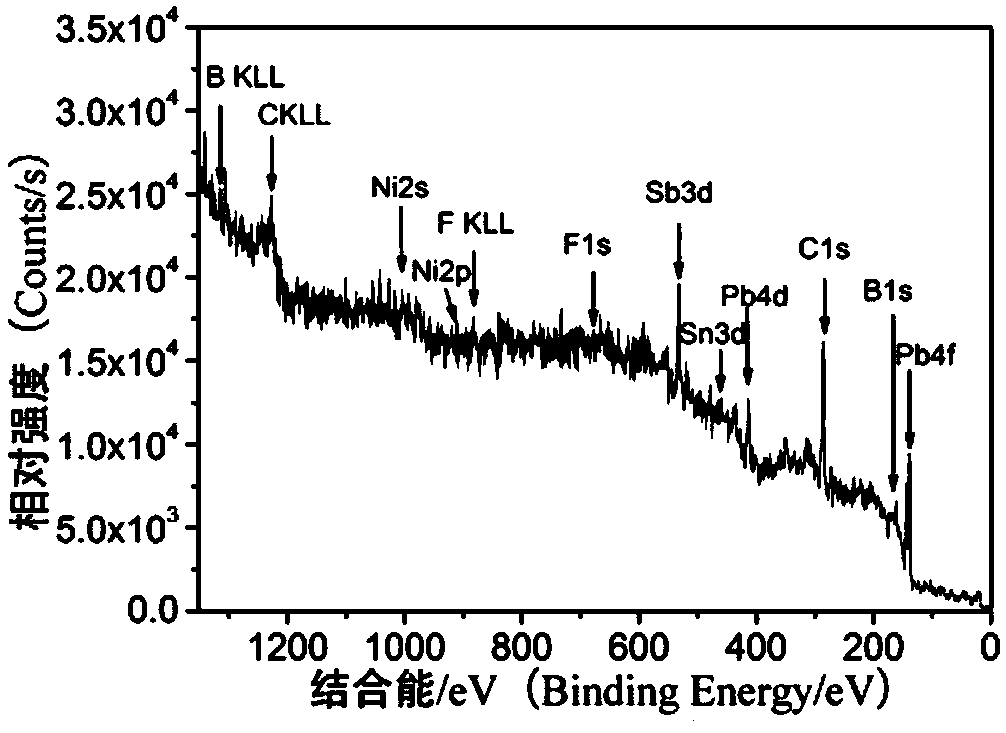

Nickel-boron-fluorine codoped lead dioxide positive pole and preparation method and application thereof

ActiveCN107902731ALarge specific surface areaStable mechanical propertiesWater contaminantsWater/sewage treatment by oxidationLead dioxideAntimony trichloride

The invention belongs to the technical field of electrochemical water treatment and specifically relates to a nickel-boron-fluorine codoped lead dioxide positive pole and a preparation method and application thereof. The preparation method disclosed by the invention comprises the following steps: mixing citric acid, ethylene glycol, stannic chloride and antimony trichloride and heating and stirring to obtain fused sol; then coating a pretreated matrix, drying, calcining and cooling; repeatedly coating-drying-calcining-cooling for many times; finally calcining to obtain a tin-antimony bottom layer; putting the tin-antimony bottom layer in a lead oxide alkaline solution to perform electrolytic deposition to obtain an alpha-lead dioxide intermediate layer; putting the alpha-lead dioxide intermediate layer into a beta-lead dioxide deposition solution to perform electrolytic deposition to obtain the nickel-boron-fluorine codoped lead dioxide positive pole. As the nickel is added, catalysisof the pole is improved; as the boron and the fluorine are added, stability of the pole is improved; the fluorine is favorable for improving an oxidation rate of Pb<2+>. By means of nickel-boron-fluorine codoping, stability of the lead dioxide pole is effectively improved, catalytic activity of the pole is improved, and the pole can be applied to treating of waste water.

Owner:河南省宗祥环保工程有限公司

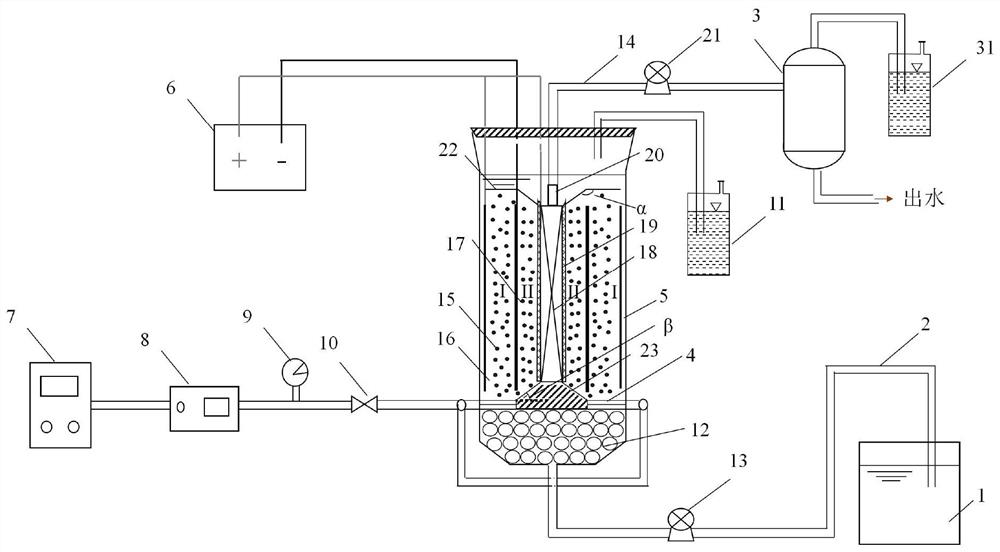

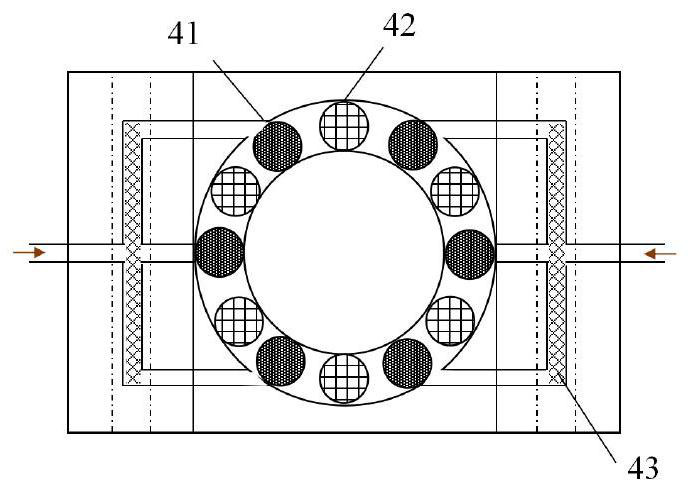

Organic wastewater deep degradation reaction device and application

ActiveCN113336373AIncrease profitFast circulationTreatment involving filtrationLoose filtering material filtersFluidized bedThree dimensional electrode

The invention relates to the field of organic wastewater degradation, in particular to a three-dimensional electrode-ozone oxidation-electro-catalytic membrane coupled wastewater treatment device and process based on a circulating fluidized bed. A fluidized bed reaction tank internally comprises a funnel-shaped inner component, a frustum, a fiber filter ball, a gas-liquid distribution plate and three coaxial inner, middle and outer cylinders; wherein the inner cylinder is an electro-catalysis membrane assembly, the middle cylinder is a gas diffusion electrode, and the outer cylinder is a stainless steel mesh; the space between the middle cylinder and the outer cylinder and the space between the middle cylinder and the inner cylinder are filled with particle electrodes; the middle cylinder is connected to the negative electrode; the inner cylinder and the outer cylinder are connected with the positive electrode; when the organic wastewater passes through the fluidized bed reactor, the mass transfer performance is good, the utilization rate of O3 and O2 is high, and the mineralization efficiency and the deep degradation effect of pollutants are greatly improved.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Ultraviolet-assisted ultrasonic coupling electrocatalytic oxidation water treatment system and water treatment method

ActiveCN111635067AImprove conductivityHigh purityWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsDiamond electrodesElectrochemical degradation

The invention discloses an ultraviolet-assisted ultrasonic coupling electrocatalytic oxidation water treatment system. The system is characterized by comprising a pH regulating tank, a particle filtering module, a microorganism desalting module and an electrochemical degradation module; the electrochemical degradation module comprises an ultrasonic generator, an ultraviolet lamp and a plurality ofprocessing units; any processing unit comprises an anode and a cathode, and the anode is a boron-doped diamond electrode. The invention provides an ultraviolet-assisted ultrasonic coupling electrocatalytic oxidation water high-efficiency energy-saving treatment system. The electrochemical degradation module with the boron-doped diamond electrode as the anode serves as a main body, an ultrasonic generator and an ultraviolet lamp are arranged in the electrochemical degradation module, ozone is generated through the ultraviolet lamp, and coupling linkage of an electrochemical degradation technology, an ultrasonic degradation technology, an ozone degradation technology and an ultraviolet catalytic degradation technology is achieved. Compared with the same type of water treatment technology, the coupling of the four technologies enables the degradation efficiency to be higher, the energy consumption to be reduced, and the system can be widely applied to the treatment of various types of water.

Owner:NANJING DAIMONTE TECH CO LTD

Marine concrete reinforcing material as well as preparation method and application thereof

InactiveCN111592258ARealize intelligent crackingReduce dosageCalcium/strontium/barium carbonatesSodium bicarbonateMicrosphere

The invention discloses a marine concrete reinforcing material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing a calcium chloride solution and a sodium bicarbonate solution with equal mole to prepare porous calcium carbonate microspheres; inoculating lysinibacillus sp. into a culture medium, and adding a spore efficient transforming agent into a culture solution; putting the calcium carbonate microspheres into the lysinibacillus sp. spore culture solution, and fully standing until the concentration of the spore culture solution tends to be stable, so as to obtain calcium carbonate microspheres loaded with microbial spores; dissolving the calcium carbonate microspheres loaded with the microbial spores into a mixed solution of sodium alginate and a barium-silver compound, uniformly stirring, and coating the surface layers of the calcium carbonate microspheres through spray drying. Results show that the material canachieve concrete surface pore filling and plugging, improve compactness, prevent invasion of corrosive substances, improve engineering durability and prolong the service lifetime.

Owner:JIANGSU UNIV OF SCI & TECH

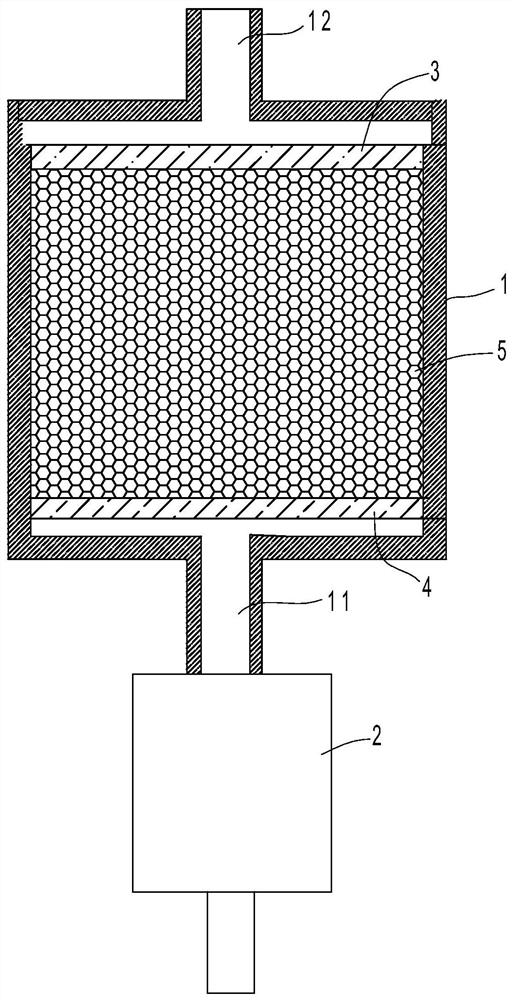

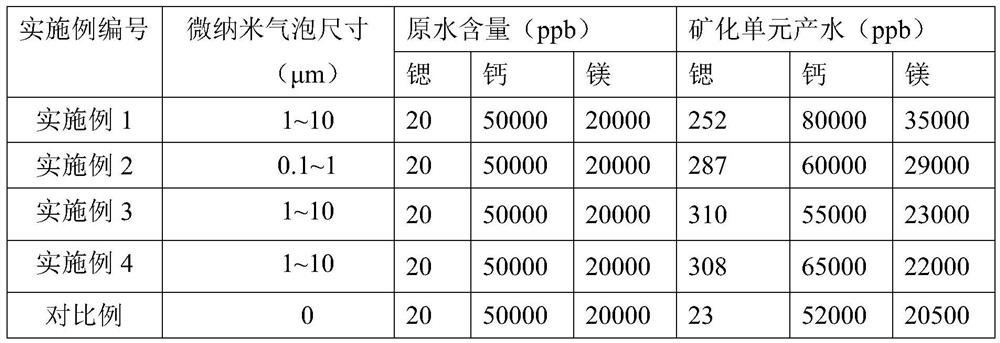

Mineral filter material, preparation method thereof, filter element with mineral filter material and water quality mineralization method of filter element

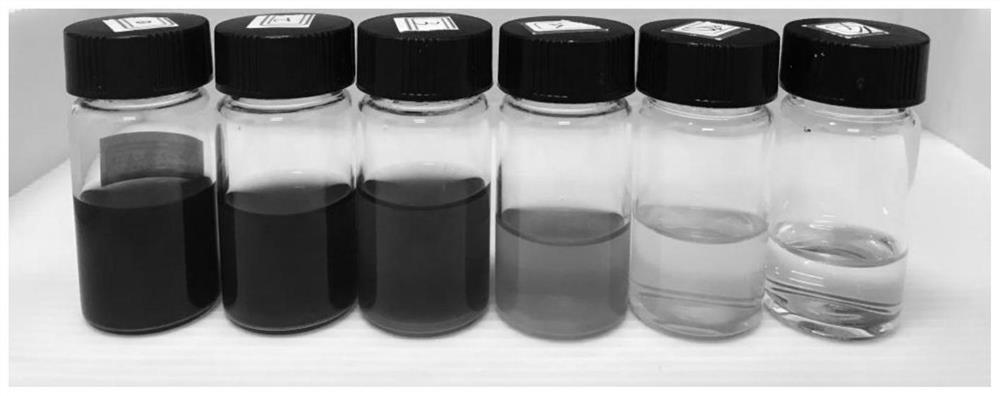

ActiveCN112320916ATo achieve the purpose of controlled releaseImprove mineralization efficiencyTreatment involving filtrationWater/sewage treatment by substance additionMicro nanoChemical reaction

The invention relates to a mineral filter material, which is characterized by comprising a mineralization material and an embedding material coated on the periphery of the mineralization material. Theembedding material is at least one of zeolite, calcium carbonate and magnesium carbonate. The invention also discloses a preparation method of the mineral filter material, a filter element with the mineral filter material and a water quality mineralization method of the filter element. In the dissolving process of the embedding material, the mineralizing material can be gradually exposed, so thatthe purpose of slowly releasing mineral substances is achieved. Meanwhile, the mineralizing material is combined with the micro-nano bubbles, so that the mineralizing efficiency of the raw water is improved. The embedding material and carbon dioxide can generate chemical reaction, so that the dissolution rate is increased.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Preparation method of electrostatic spinning fibrous membrane

InactiveCN112516806AHigh porosityLarge specific surface areaSemi-permeable membranesElectro-spinningFiberPolymer science

The invention discloses a preparation method of an electrostatic spinning fibrous membrane. The preparation method is characterized by comprising the following steps: (1) preparing a spinning solution, namely dissolving polymer resin, an additive and a mineralizing material into a solvent to prepare the spinning solution; and (2) preparing an electrostatic spinning mineralized nanofiber membrane,namely mounting a substrate on a receiving device of electrostatic spinning equipment, defoaming the spinning solution obtained in the step (1), injecting the defoamed spinning solution into an electrostatic spinning device, carrying out electrostatic spinning and air curing, and carrying out curing forming in a coagulating bath to obtain the mineralized electrostatic spinning nanofiber membrane.The mineralization material is combined with the electrostatic spinning nanofibers, the specific surface area is increased, inflow water can be fully mineralized when passing through the membrane, andthe mineralization efficiency is improved; and the mineralized material is fixed on the nanofibers, so that the risk of falling off is avoided, and the drinking water is safer.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Three-product flotation column and method suitable for high-ash fine-fraction coal slime

ActiveCN112337655AImprove mineralization efficiencyImprove clean coal qualityFlotationEngineeringCoal product

The invention relates to a three-product flotation column and method suitable for high-ash fine-fraction coal slime recovery, and belongs to the technical field of coal recovery. The three-product flotation column comprises an inner-layer column body and an outer-layer column body, the top of the inner-layer column body is provided with a clean coal collecting tank a and a feeding pipe, the periphery of the top of the outer-layer column body is provided with a clean coal collecting tank b, the bottom end of a feeding pipe is provided with a stepped jet device, and a flow baffle is arranged under the stepped jet device and in the inner-layer column body; the upper opening of the inner-layer column body is provided with a plurality of upper water spraying devices around the feeding pipe, thebottom of the inner-layer column body is provided with an L-shaped coarse grain recycling channel which is communicated with the outside of the inner-layer column body, and the clean coal collectingtank b and an outer-layer top water spraying device are arranged around the opening of the outer-layer column body; and a foam layer vibrating mechanism is arranged at the position below the clean coal collecting tank b on the same horizontal plane of the inner-layer column body and the outer-layer column body, an inclined flow distribution plate of an annular structure is arranged in the outer-layer column body, and an annular middling coal product collecting tank is reserved between the inclined flow distribution plate and the inner-layer column body. The three-product flotation column is high in recovery capacity, coal quality adaptability and separation precision.

Owner:CHINA UNIV OF MINING & TECH

Flotation device and method for coal slime

InactiveCN104668108AImprove sorting efficiencyOvercoming the disadvantages of poor recycling abilityVortex flow apparatusFlotationThermodynamicsCoal

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE

Improved double-cathode aeration-free electro-Fenton sewage treatment device and method

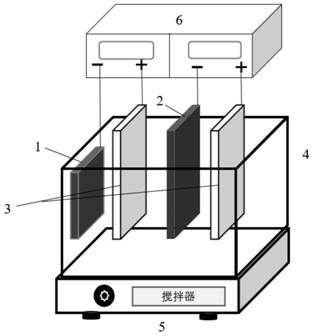

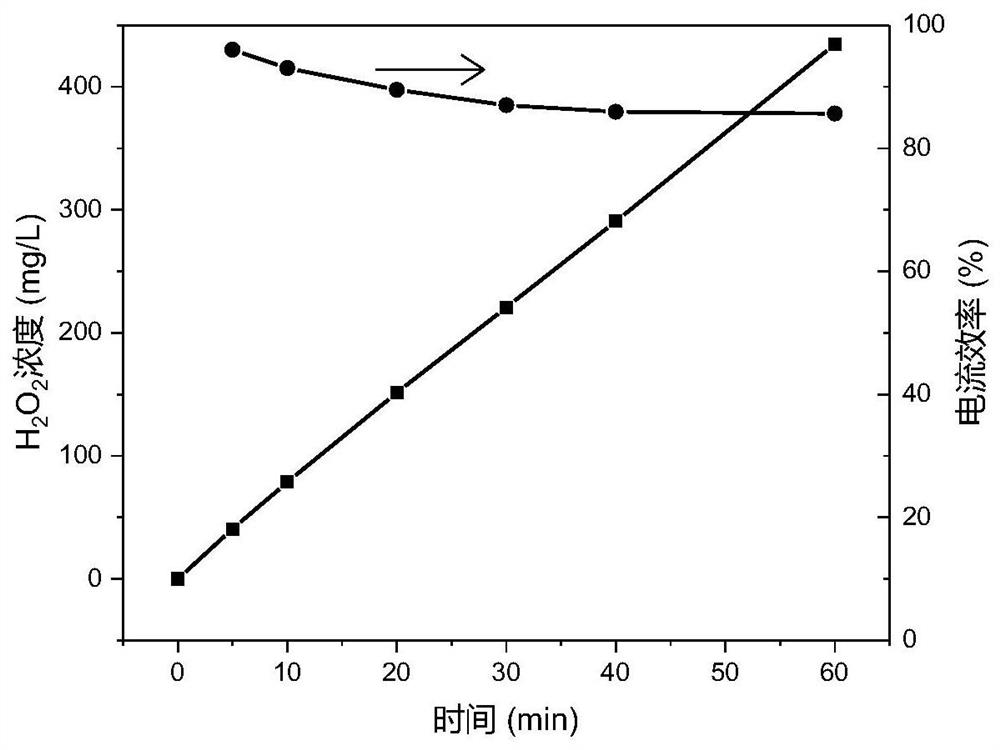

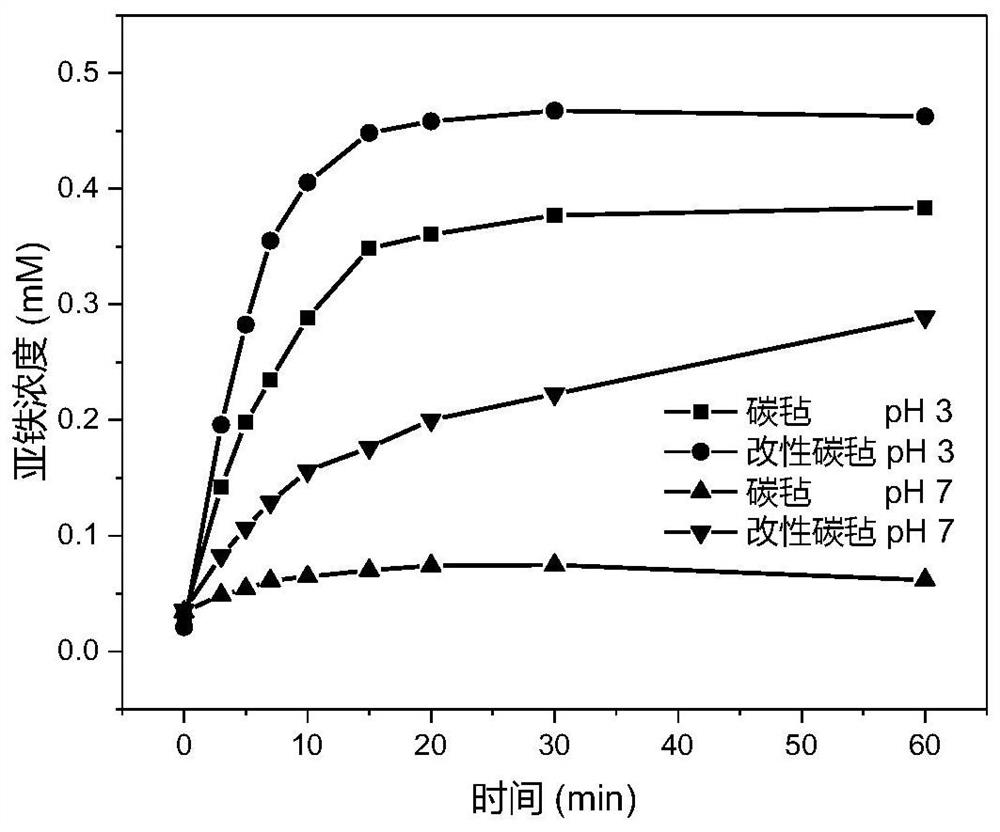

ActiveCN112811678AImprovement of ferrous recycling capacityEasy to handleWater treatment parameter controlWater treatment compoundsModified carbonWastewater

The invention belongs to the technical field of sewage treatment, and particularly provides an improved double-cathode aeration-free electro-Fenton sewage treatment method and device. According to the device and the method, a large amount of H2O2 can be rapidly generated in situ without aeration, meanwhile, ferrous iron is regenerated through cathode electroreduction, efficient generation of the Fenton reaction is promoted, and the device and the method can have a good pollutant removal effect on wastewater with the pH value of 3-9. The problems that aeration is needed, the ferrous cyclic regeneration performance is poor and the applicable pH range is narrow in a conventional electro-Fenton water treatment method are solved. The novel sewage treatment device provided by the invention comprises an air active diffusion cathode, a modified carbon felt cathode, an anode, a reaction container, a direct-current power supply and a stirrer. Compared with the conventional aeration-free electro-Fenton technology, the aeration-free electro-Fenton technology can improve the mineralization efficiency of pollutants by two times or more, and can be used for treating various organic wastewater.

Owner:NANKAI UNIV

A high bubble surface flux flotation machine and particle bubble mineralizer

The invention belongs to the technical field of coal slime flotation machines, and specifically relates to a high-bubble surface flux flotation machine and a particle bubble mineralizer. A jet aerator and a slurry gas mixer, the slurry gas mixer includes guide vanes and protruding rods, the bubble mineralization efficiency of the particle bubble mineralizer is improved by setting the slurry gas mixer, the flotation machine includes a sorting bucket, The lower barrel and the tailings chamber, the upper end of the sorting barrel is provided with a fluidized water chamber, the outer side is provided with a particle bubble mineralizer, and an inclined plate is arranged on the lower barrel, then the present invention can achieve high air bubble surface flux and washing water flux Working under the same conditions to achieve flotation without free foam layer, the lower end of the flotation machine adopts inclined plate channel to strengthen the segregation of mineralized air bubbles and pulp, ensuring that the foam area is maintained in the vertical area of the upper part of the equipment, and carries the lowest amount of pulp, which improves the separation Choose an effect.

Owner:太原睿孚特选煤技术有限公司

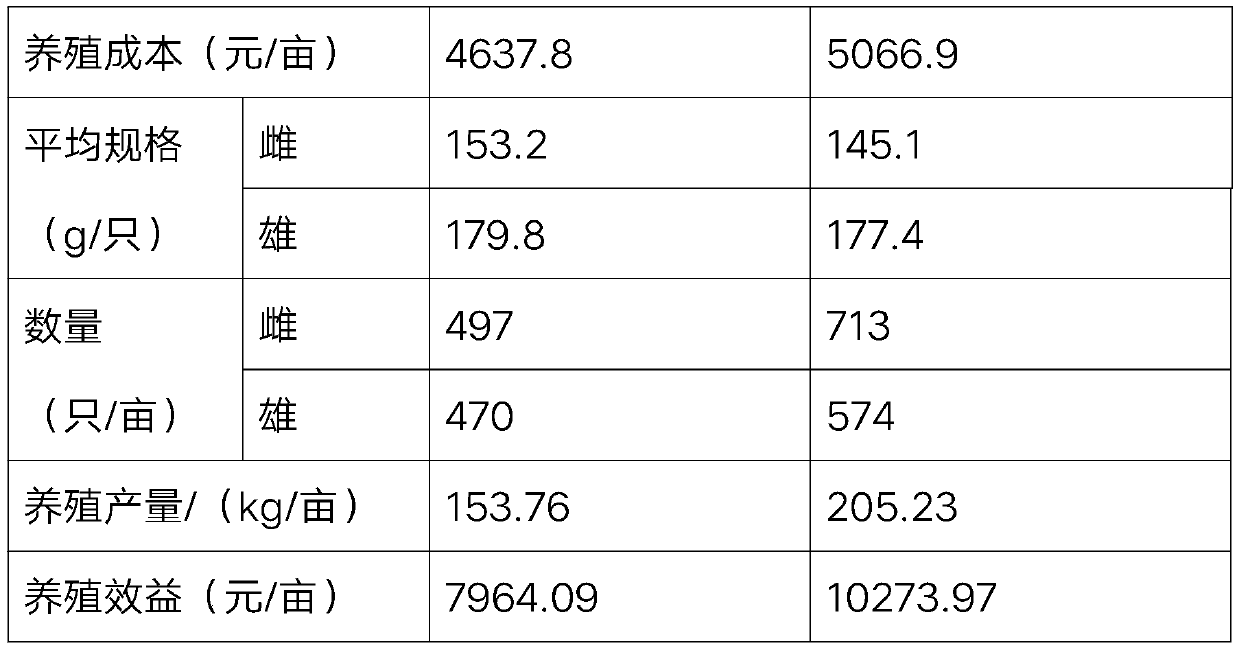

Ecological breeding method for increasing output of river crabs

InactiveCN110999835AIncrease productionImprove utilization efficiencyHops/wine cultivationClimate change adaptationFisheryTreatments water

The invention discloses an ecological breeding method for increasing the output of river crabs. The method comprises the following steps: (1) pretreating a pond; (2) planting aquatic plants; (3) making preparation before stocking; (4) stocking young crabs and snails; and (5) taking management measures. The invention aims at problems that in production, the snails are stocked too early, the pond deposit of the aquatic plants is hard to control, microecologics are poor in water purification effect, oral medicines are seriously lost, and the like in production practice, conventional river crab breeding method is improved, then effects of aquatic plant maintenance, water quality regulation and control and disease and insect prevention and control in the river crab breeding process can be improved, and the output and the breeding benefits of the river crabs can be increased.

Owner:SUQIAN AGRI SCI RES INST JIANGSU ACAD OF AGRI SCI

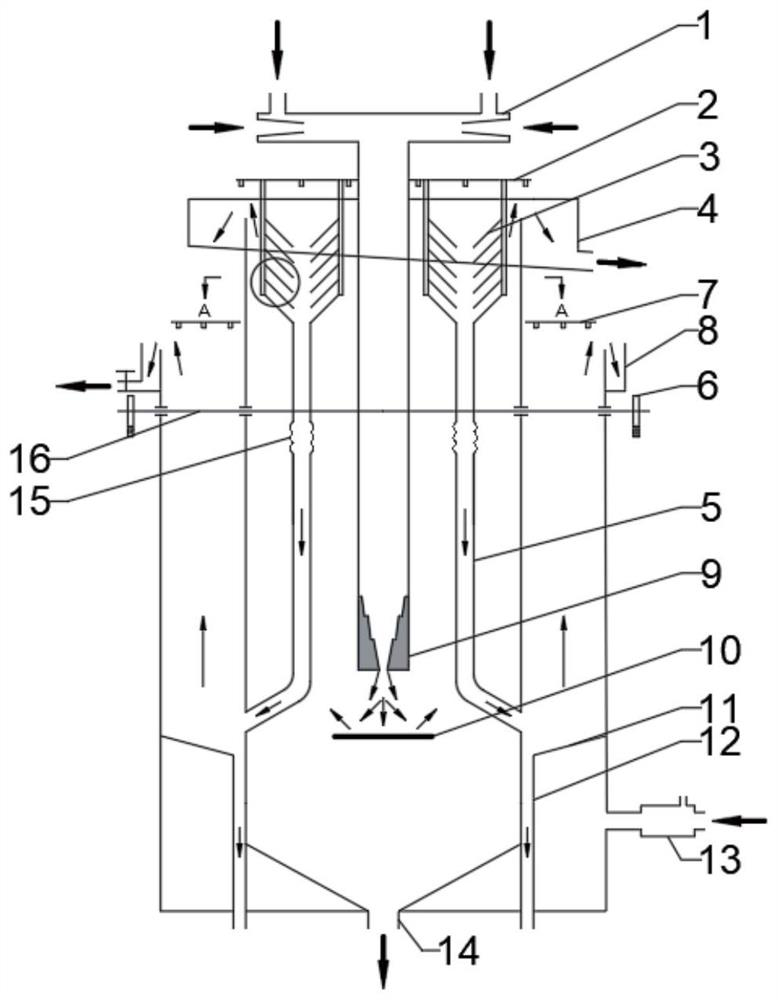

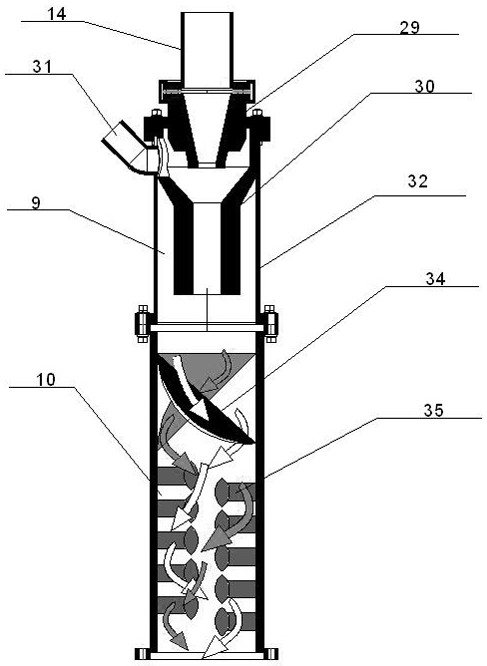

Double tail-removing gravity-flotation combined sorting method and device

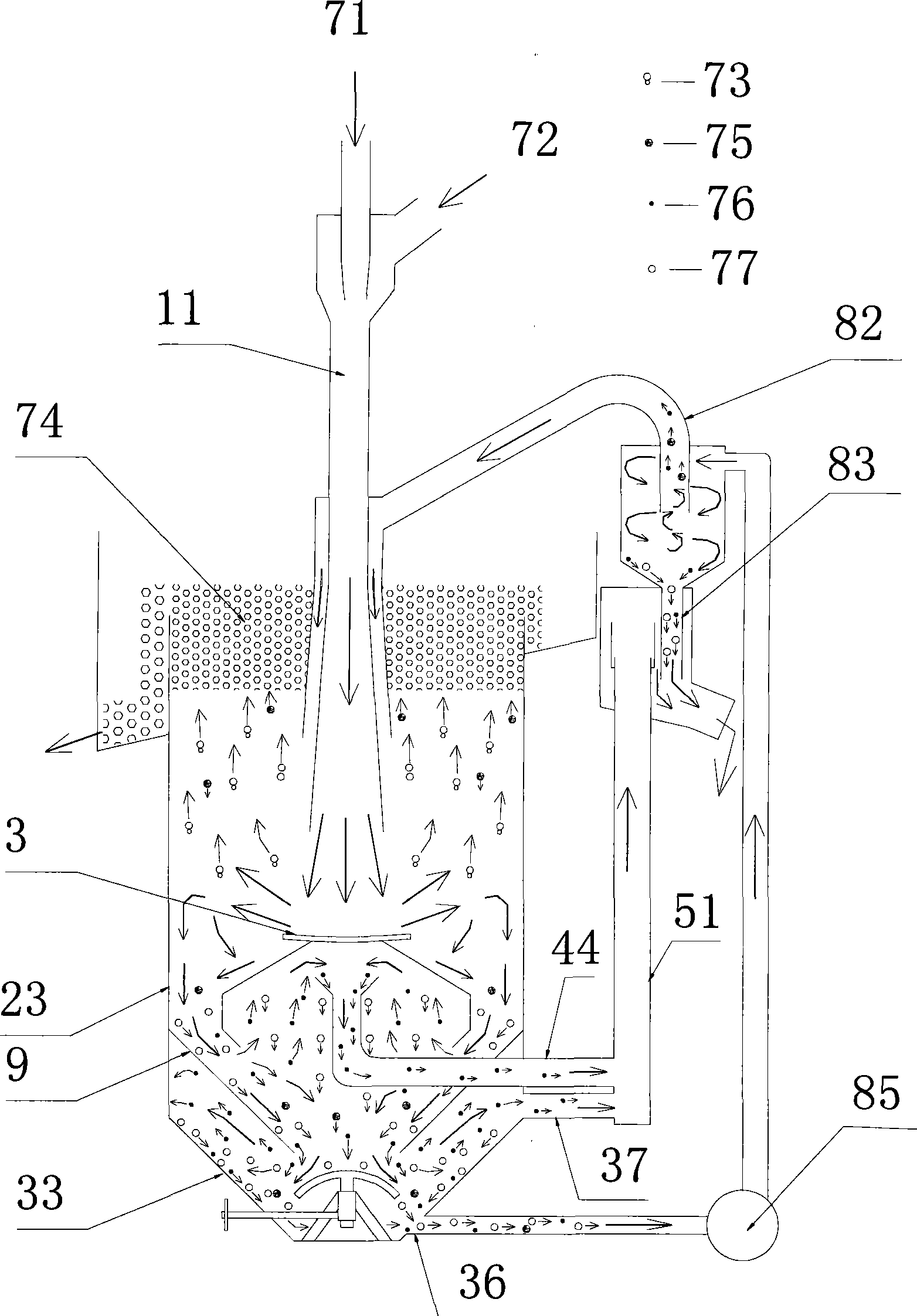

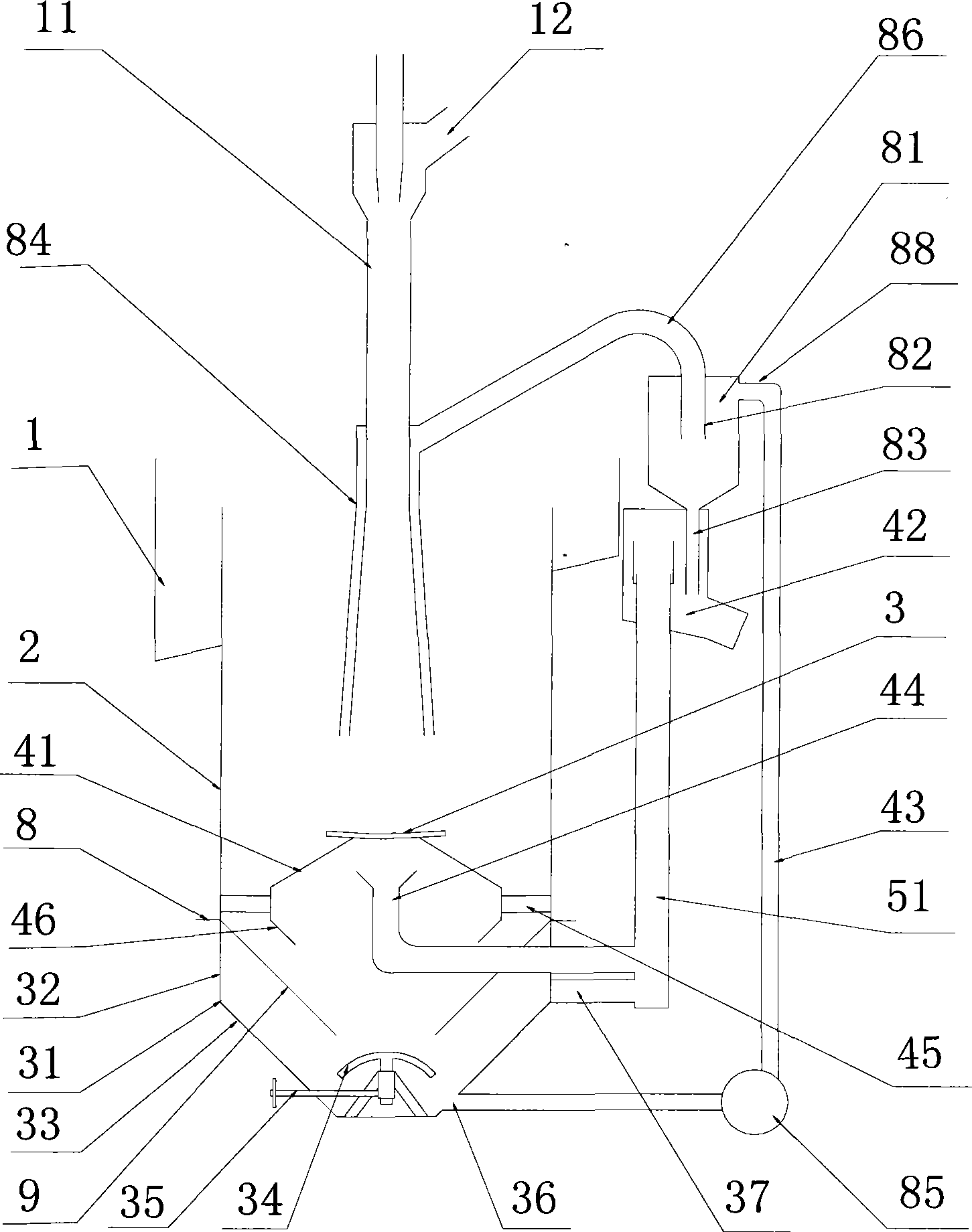

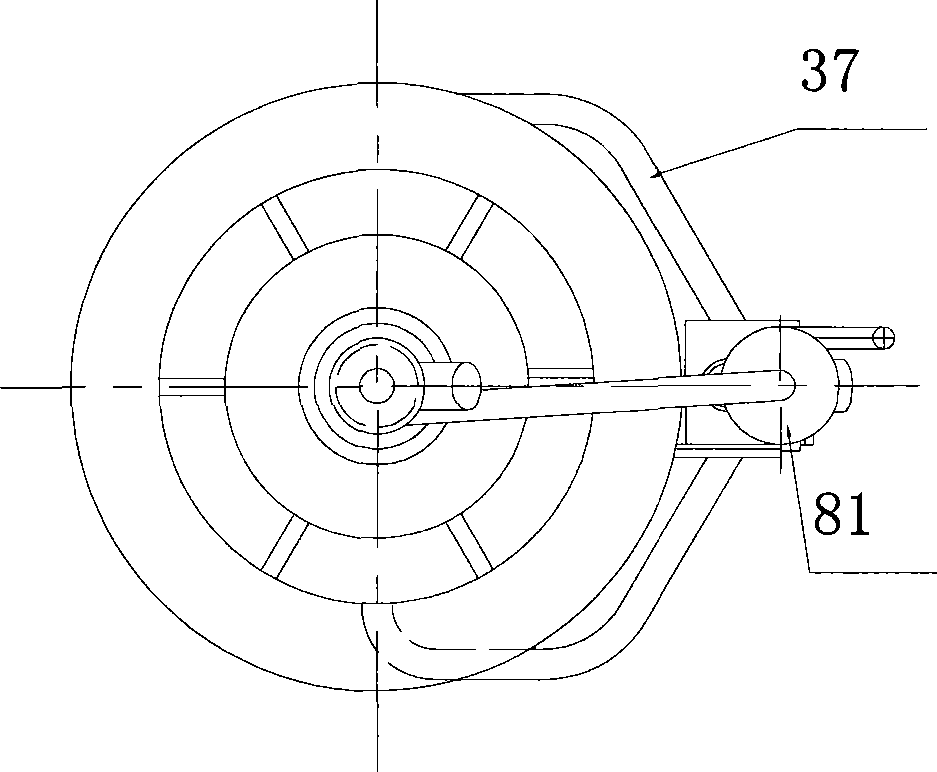

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is lowand the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a centralore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

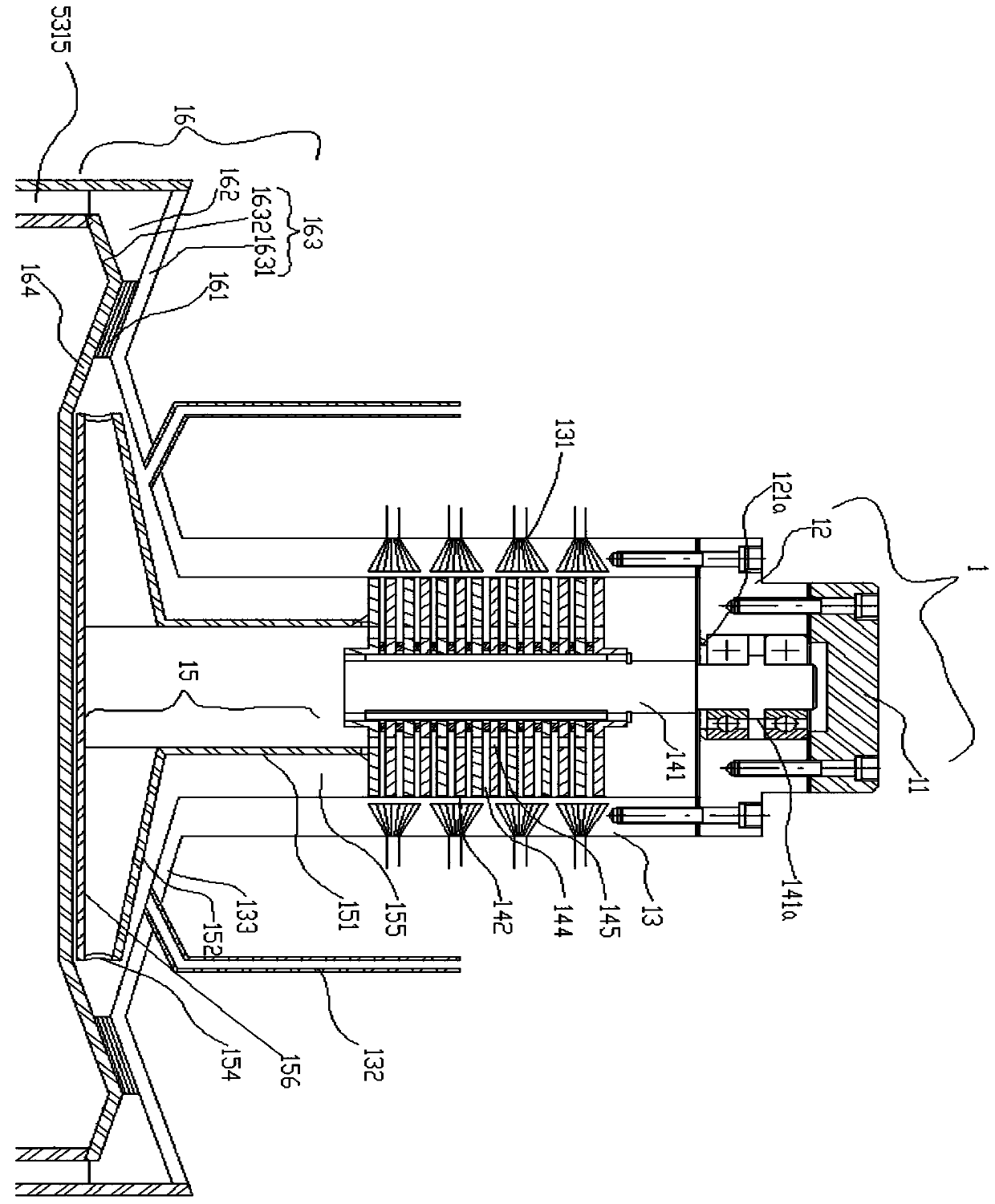

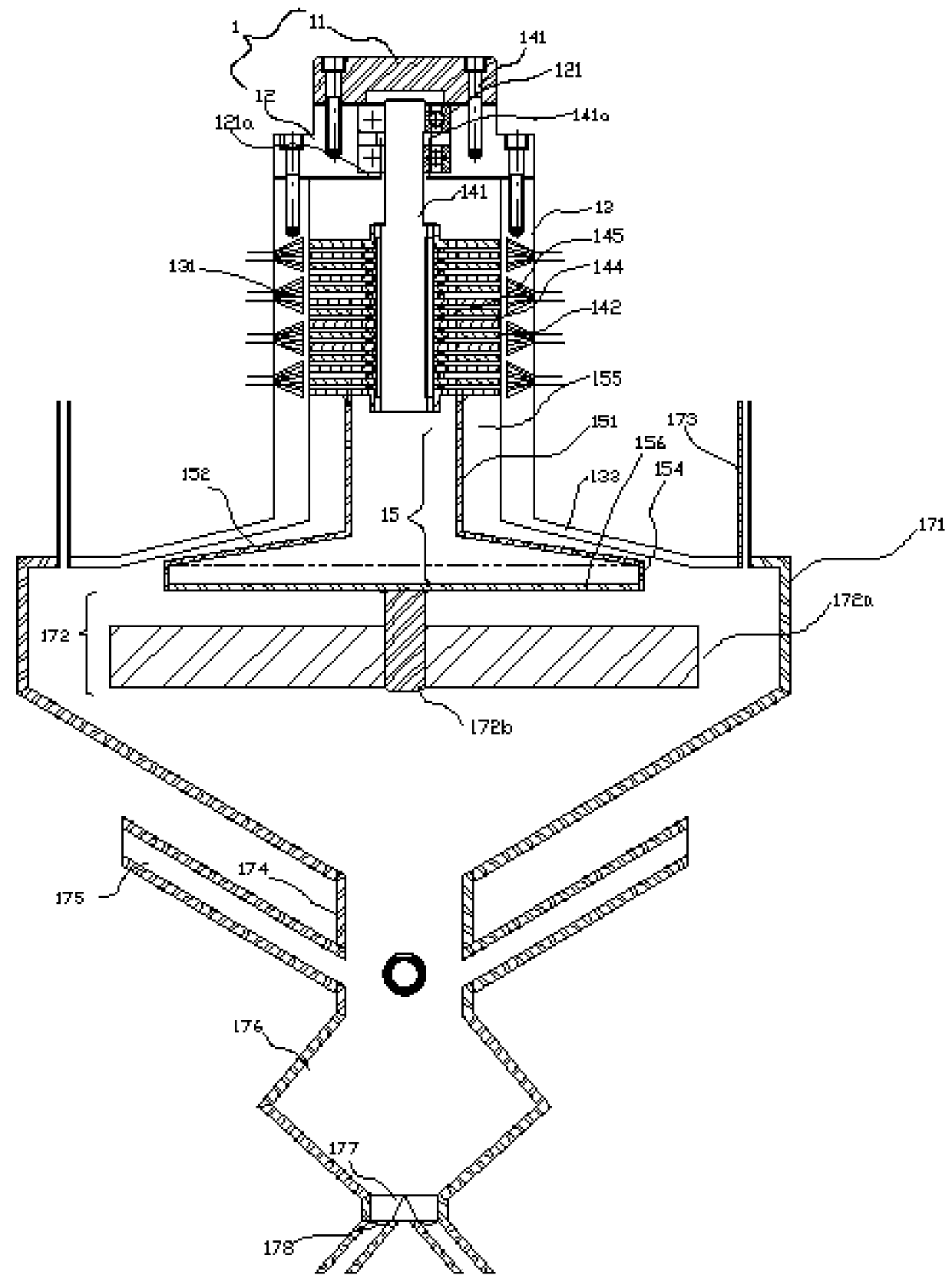

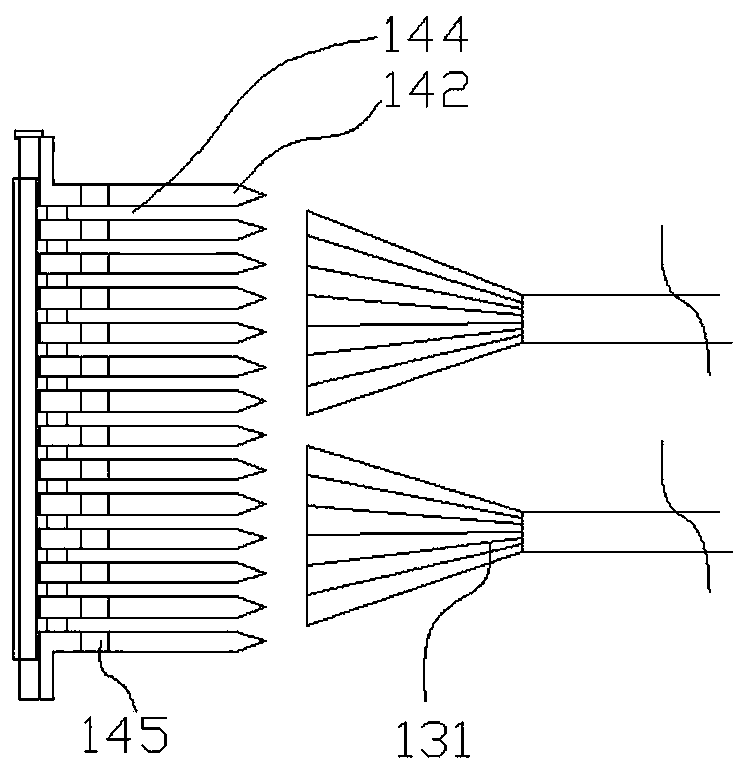

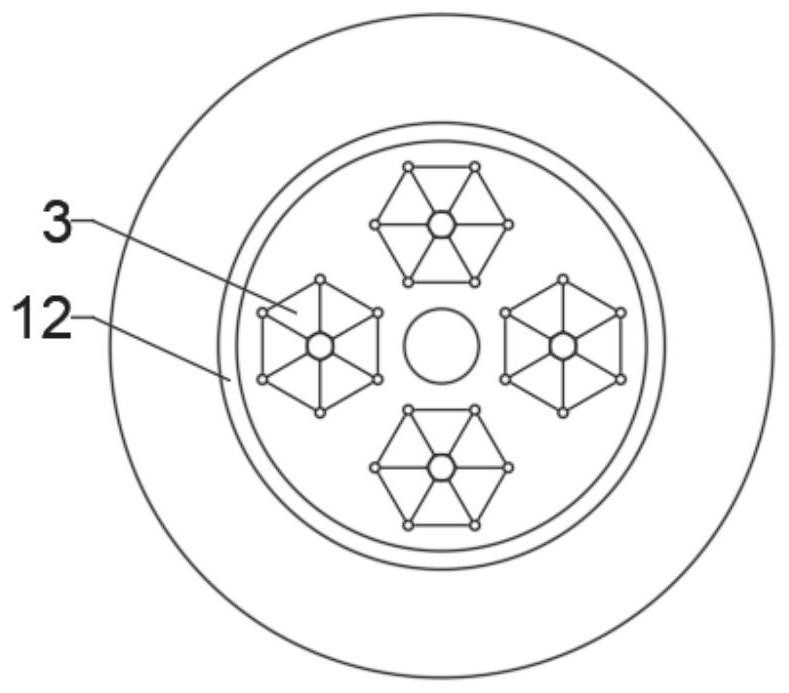

Flotation machine with high bubble surface flux and particle bubble mineralization device

The invention belongs to the technical field of coal slime flotation machines, and particularly relates to a flotation machine with high bubble surface flux and a particle bubble mineralization device. The particle bubble mineralization device comprises a mineralization device shell, a jet aerator and a slurry-gas mixer; the jet aerator and the slurry-gas mixer are arranged in the mineralization device shell, and the slurry-gas mixer comprises guide blades and protruding rods; the bubble mineralization efficiency of the particle bubble mineralization device is improved by arranging the slurry-gas mixer; the flotation machine comprises a separation barrel, a lower barrel body and a tailing chamber; a fluidization water chamber is arranged at the upper end of the separation barrel, the particle bubble mineralization device is arranged on the outer side of the separation barrel, and an inclined plate is arranged on the lower barrel body, so that the flotation machine can work under the conditions of high bubble surface flux and washing water flux, and no free foam layer flotation is achieved; an inclined plate channel is adopted at the lower end of the flotation machine to strengthen separation of mineralized bubbles and ore pulp, it is ensured that a foam area is maintained in a vertical area on the upper portion of the equipment, the lowest ore pulp amount is carried, and the separation effect is improved.

Owner:太原睿孚特选煤技术有限公司

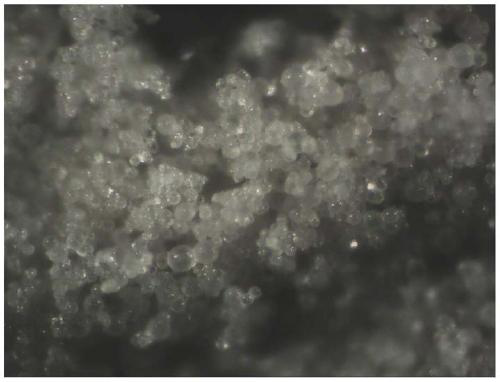

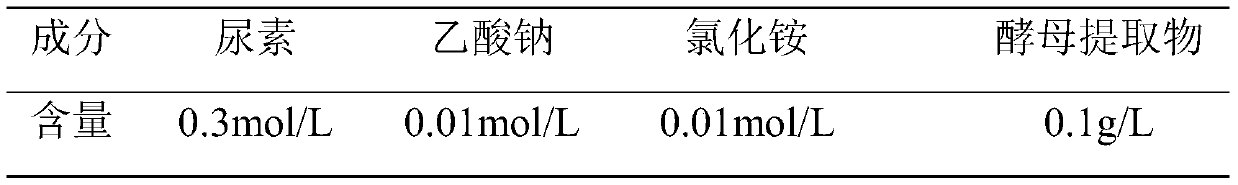

Method for preparing light calcium carbonate by using primary microorganisms

ActiveCN110438165AImprove mineralization efficiencyAchieve sustained metabolic proliferationFermentationMicroorganismGrowth promoting

The present invention discloses a method for preparing light calcium carbonate by using primary microorganisms. The method comprises the following steps: (1) collecting a soil sample; (2) preparing growth promoting liquid and cementing liquid; (3) after injecting a certain amount of the growth promoting liquid into the soil sample collected in the step (1) for a period of time, collecting effluentliquid in the soil sample; (4) inoculating the effluent liquid obtained in the step (3) into an amplification culture medium, conducting culture under a constant-temperature oscillation condition toobtain micro-organism liquid; and (5) reacting the obtained micro-organism liquid obtained in the step (4) with the cementing liquid prepared in the step (2) in an isovolumetric manner to obtain calcium carbonate. The method uses the soil treated by the growth promoting liquid to promote mass propagation of more kinds of microorganisms, then the used culture medium is mainly used for screening bacteria with urea decomposition capability, a final product of an urea decomposition reaction dependent on participation of urease microorganisms is carbonate ions, a large amount of calcium carbonate minerals can be generated by applying exogenous calcium ions, and besides, mineralization efficiency of the microorganisms can be obviously improved under synergistic effects of a plurality of the microorganisms.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com