Method for preparing light calcium carbonate by using primary microorganisms

A light calcium carbonate and microorganism technology, which is applied in the field of chemical materials, can solve the problems that the impact of the natural environment is difficult to ignore, and the quality of calcium carbonate is difficult to be effectively controlled, so as to achieve the effect of improving mineralization efficiency, ensuring continuous supply, and continuous metabolic proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Use a 75% alcohol-sterilized soil fetcher to collect 500 g of a sandy soil sample at a depth of 20 cm located at a certain lakeshore in the East Lake Scenic Area of Wuhan City.

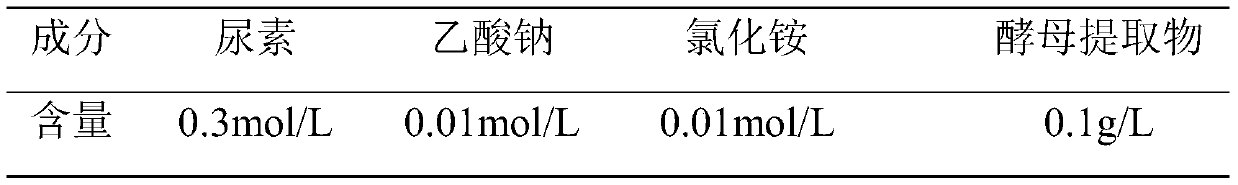

[0024] (2) Take a small amount of soil sample and put it into an opening at one end, and use a perforated rubber stopper at the other end to seal the plexiglass tube. Inject the growth-promoting solution into the collected soil samples continuously for 5 times with an interval of 24 hours. The formula of the growth-promoting solution is as follows :

[0025] Growth Booster Formula

[0026]

[0027] (3) Collect and filter the effluent after 5 times of growth promotion, inoculate 5ml of the filtrate into 100ml of expansion medium, culture at 30°C and 150r / min for 48h to obtain the bacterial solution for reaction, the formulation of the expansion medium is as follows:

[0028] Extended Medium Formulation

[0029]

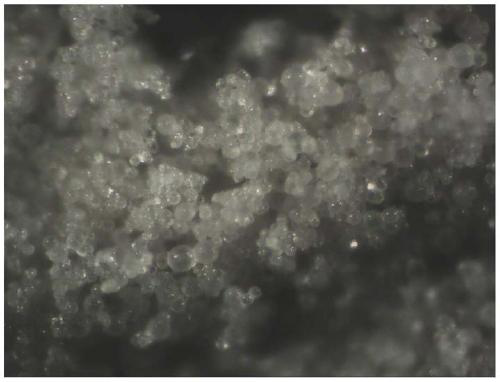

[0030] (4) Take the bacterial liquid and the cementing liquid to reac...

Embodiment 2

[0035] (1) Aseptically collect 1000 g of aeolian sand samples from the Gurbantunggut Desert in Xinjiang, and the sampling depth is 50 cm.

[0036] (2) Put the sand sample into a Buchner funnel with a geotextile cushion, inject the growth-promoting liquid into the sand sample 7 times continuously, with a time interval of 24 hours, and the formula of the growth-promoting liquid is as follows:

[0037] Growth Booster Formula

[0038]

[0039] (3) Collect and filter the effluent after 7 times of growth promotion, inoculate 5ml of the filtrate into 100ml of expansion medium, culture at 30°C and 150r / min for 36h to obtain the bacterial solution for reaction, the formulation of the expansion medium is as follows:

[0040] Extended Medium Formulation

[0041]

[0042] (4) Take the bacterial liquid and the cementing liquid to react for 10 hours in equal volumes, wash and dry the precipitated matter after the reaction to obtain calcium carbonate, and the cementing liquid formula ...

Embodiment 3

[0047] (1) 500 g of expansive soil samples at a depth of 20 cm located somewhere in Wuhan City, Hubei Province were collected using a 75% alcohol-sterilized soil fetcher.

[0048] (2) Put the soil sample into a Buchner funnel with a geotextile cushion, and continuously inject the growth-promoting solution into the soil sample 7 times with a time interval of 24 hours. The formula of the growth-promoting solution is as follows:

[0049] Growth Booster Formula

[0050]

[0051] (3) Collect and filter the effluent after 7 times of growth promotion, inoculate 5ml of the filtrate into 100ml expansion medium, culture at 30°C and 150r / min for 24 hours to obtain the bacterial solution for reaction, the formulation of the expansion medium is as follows:

[0052] Extended Medium Formulation

[0053]

[0054] (4) Take the bacterial liquid and the cementing liquid to react for 10 hours in equal volumes, wash and dry the precipitated matter after the reaction to obtain calcium carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com