Flotation machine with high bubble surface flux and particle bubble mineralization device

A mineralizer and flotation machine technology, applied in flotation, solid separation, etc., can solve the problems of low gas-liquid mixing intensity, affecting the mineralization effect of particle bubbles, affecting the dispersion and mixing efficiency of inhaled air and jet fluid, and achieving Improvement of collision probability and attachment probability, and improvement of processing capacity per unit area of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

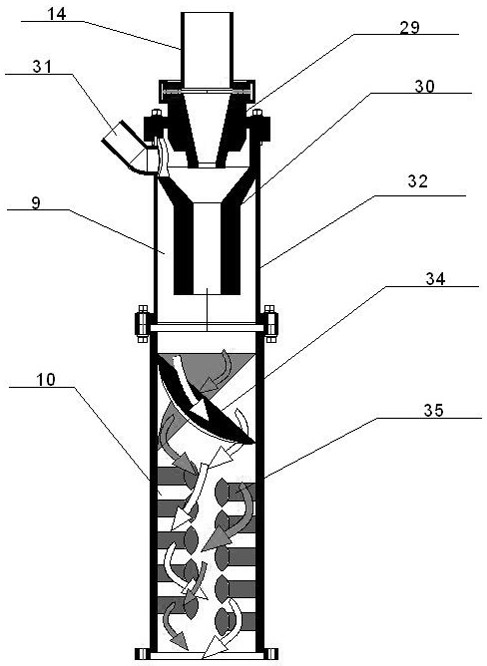

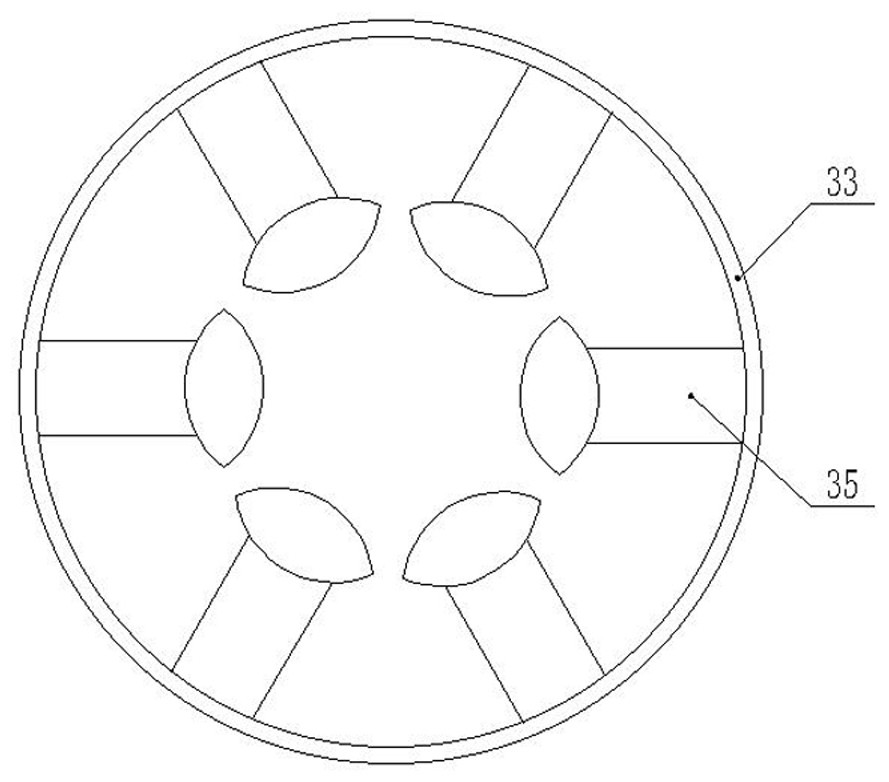

[0031] Such as figure 1As shown, Embodiment 1 of the present invention provides a particle bubble mineralizer, comprising a mineralizer housing 32 and a jet aerator 9 and a slurry gas mixer 10 arranged in the mineralizer housing 32, the jet The aerator 9 includes a nozzle 29 arranged above and a nozzle 30 arranged at the bottom of the nozzle 29, and an air suction port 31 is arranged between the nozzle 30 and the nozzle 29; the slurry gas mixer 10 includes guide vanes 34 And the protruding rod 35, the guide vane 34 is obliquely arranged below the outlet of the nozzle 30, and there are several protruding rods 35, which are arranged under the guide vane 34, and are fixedly arranged in a spiral or ring shape on the mineralizer shell 32 on the inner wall.

[0032] Further, as figure 1 As shown, in the particle bubble mineralizer described in this embodiment, the nozzle 29 is in an inverted conical shape, the nozzle pipe 30 is funnel-shaped at the upper end, and cylindrical at th...

Embodiment 2

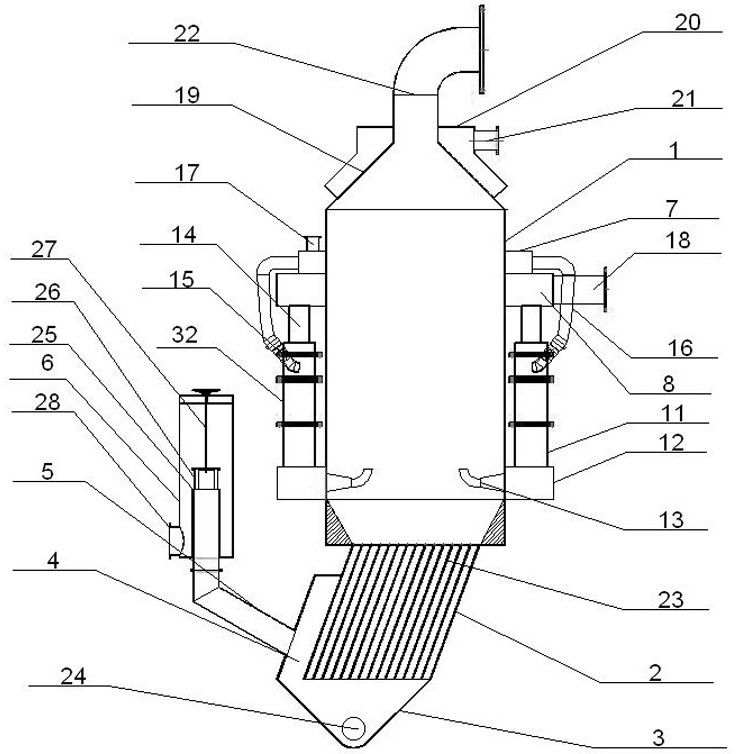

[0037] Embodiment 2 of the present invention provides a high-bubble surface flux flotation machine, including a sorting barrel 1, a lower barrel body 2, and a tailings chamber 4. A water distribution cone 19 and a concentrate are arranged above the sorting barrel 1. The foam outflow pipe 22, the fluidized water chamber 20 is arranged on the outside of the water distribution cone 19; the outer periphery of the sorting barrel 1 is provided with a pulp distribution ring 7, an inflatable distribution ring 8, an aerated pulp distribution ring 12 and a plurality of The particle bubble mineralizer, the particle bubble mineralizer is evenly distributed on the periphery of the sorting barrel 1, the pulp distribution ring 7 and the inflatable distribution ring 8 are respectively used to provide the particle bubble mineralizer with pulp and air; the particle bubble mineralizer The bottom of the mineralizer is connected to a plurality of slurry gas nozzles 13 evenly distributed inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com