Patents

Literature

34results about How to "Reduce the amount of slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

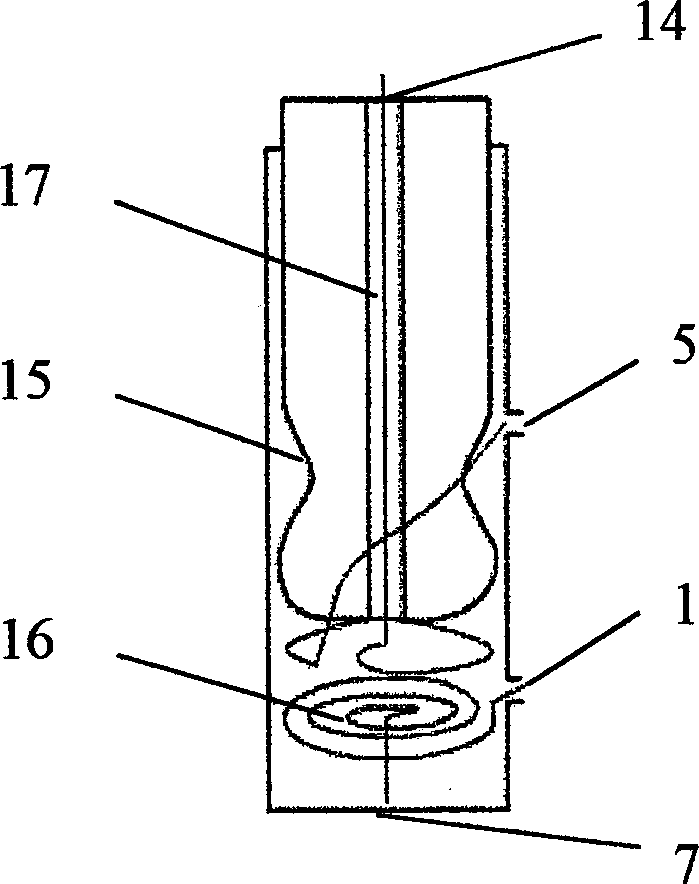

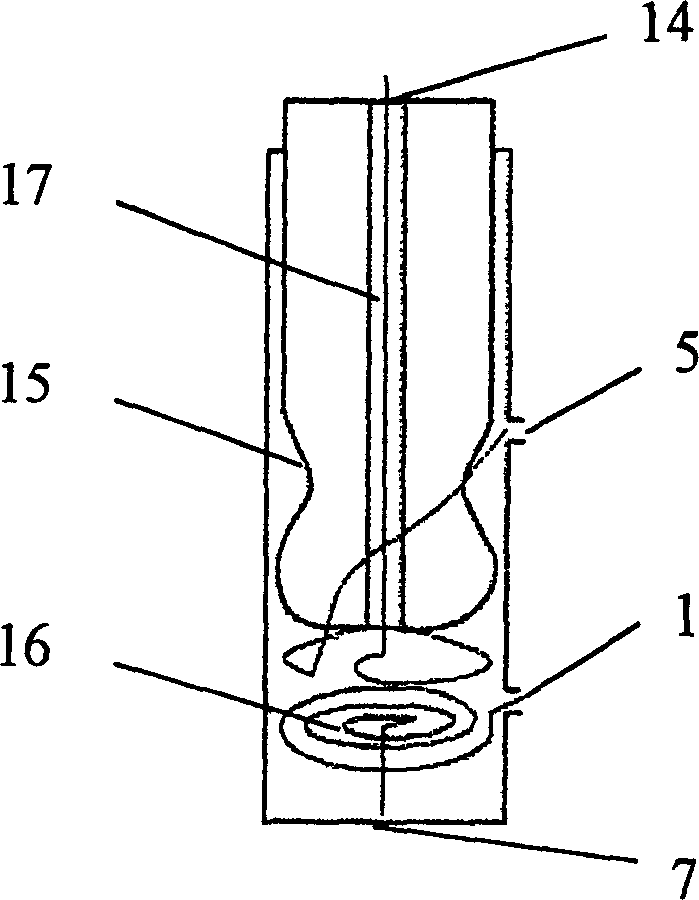

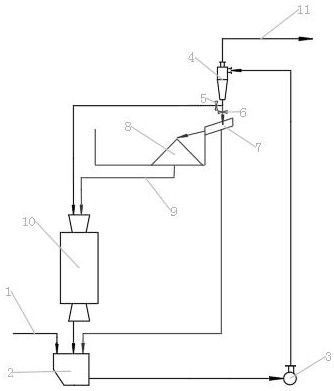

Complex twisting device for air-jet eddy-current spinning

InactiveCN1388278ANo suction phenomenonImprove production rateContinuous wound-up machinesOpen-end spinning machinesYarnFiber

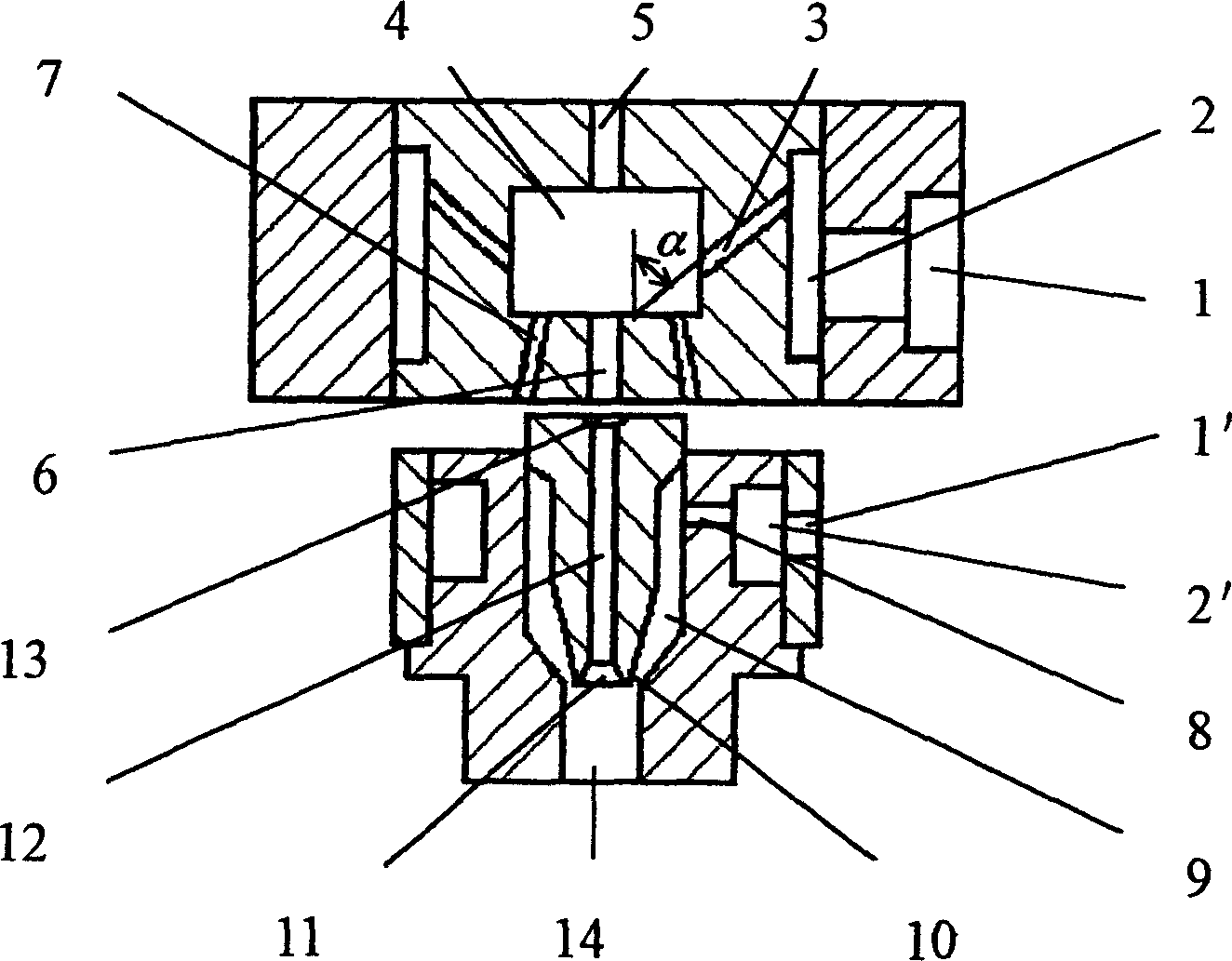

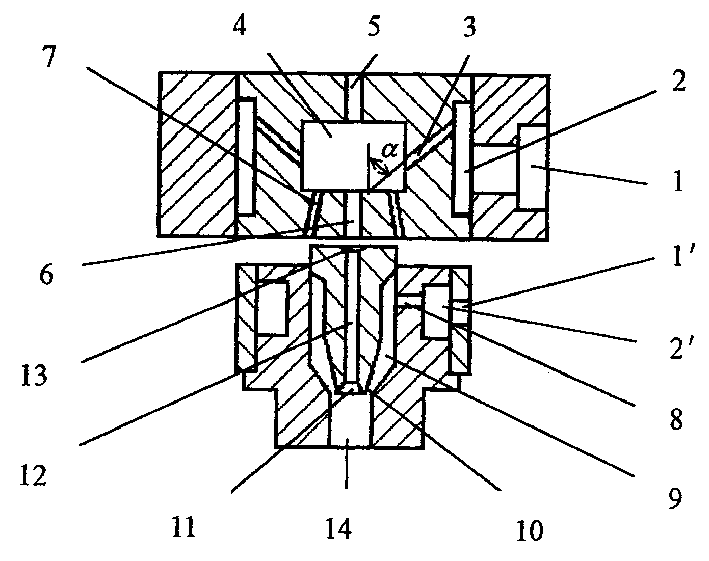

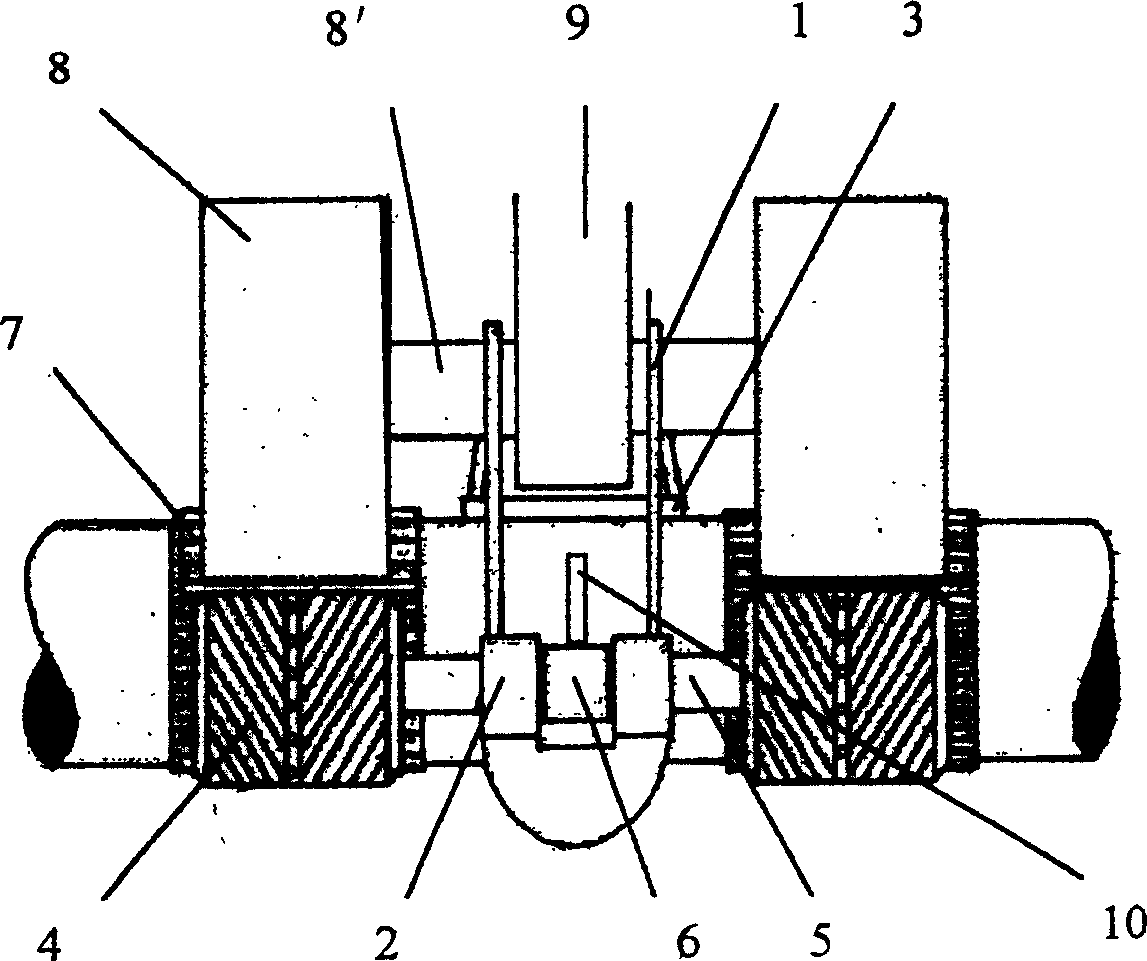

The complex twisting device for air-jet eddyc-current spining to twist fiber strand consists of the upper twisting unit and the lowr twisting unit. Positive pressure air flow is utilized to produce eddy-current field and pipe flow and the fiber is fed to the eddy-current field via the conveying pipe. Fiber strand rotates with the high-speed rotating air flow while the pipe flow protects and guides the twisted fiber strand to leave from the eddy-current field. During the process, fiber strand is twisted to produce twisted yarn in high speed. The present invention makes it possible to produce high-quality yarn at low cost and high speed.

Owner:DONGHUA UNIV

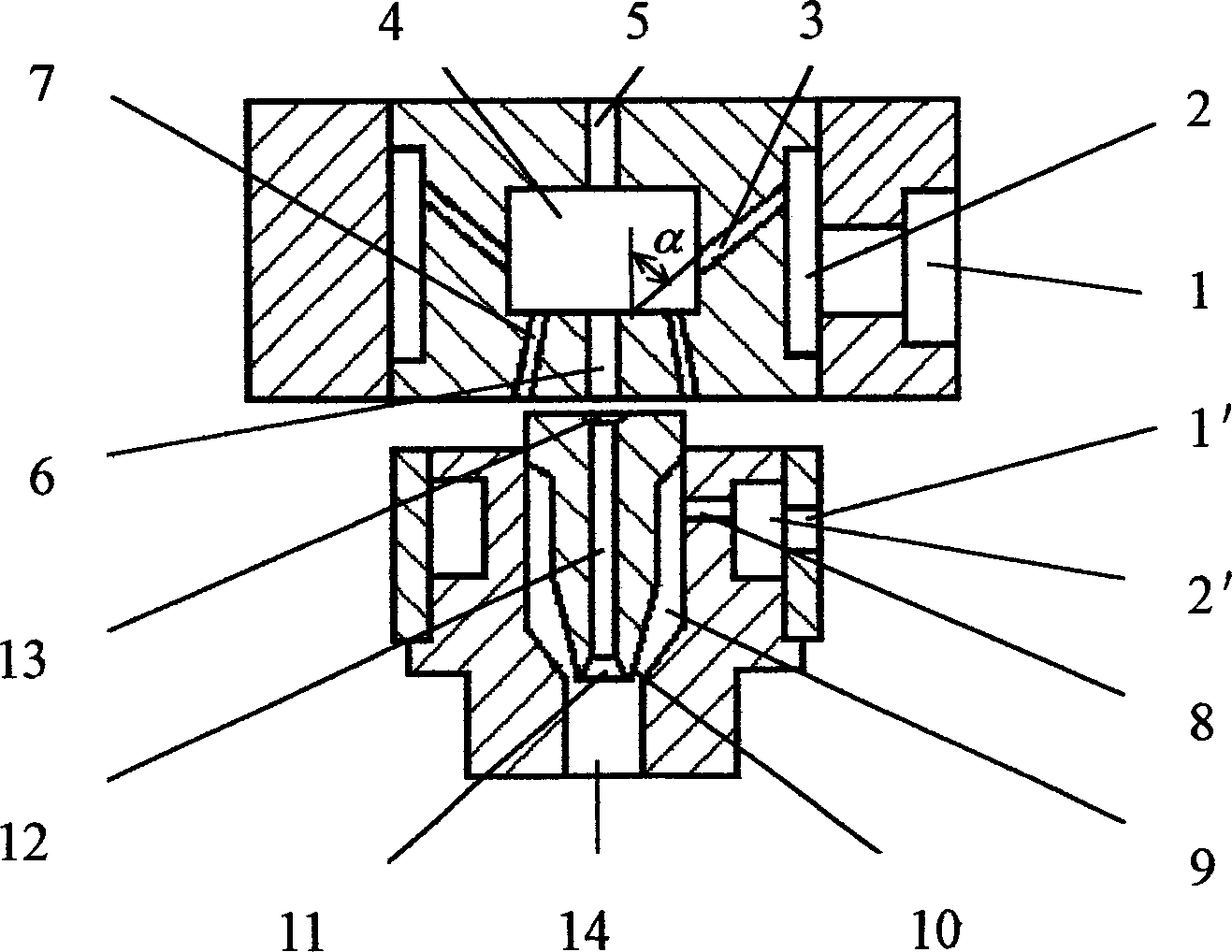

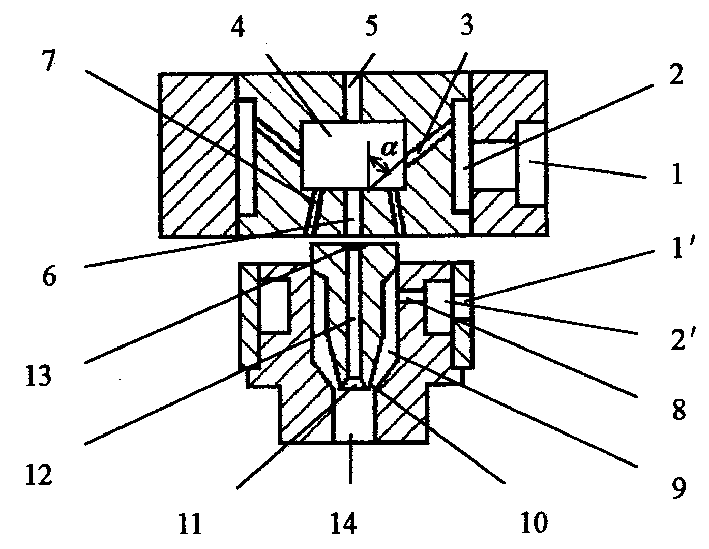

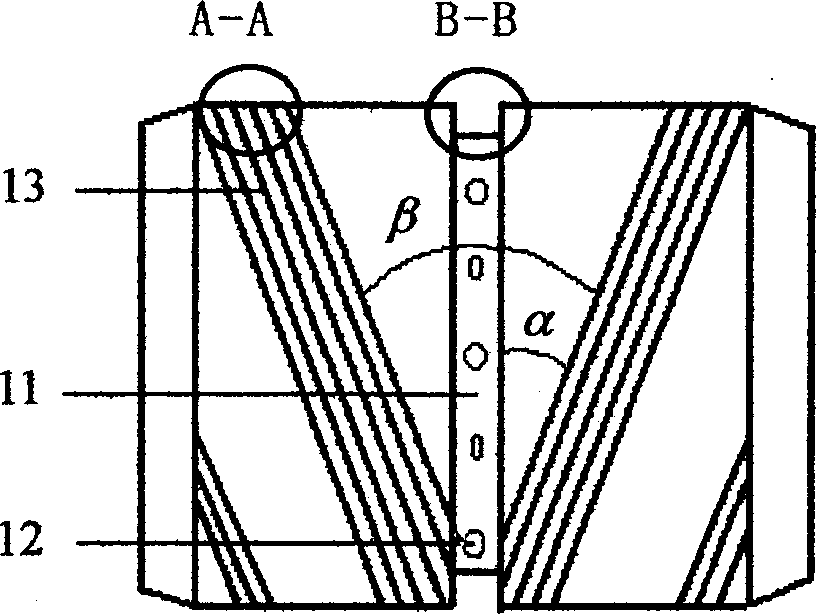

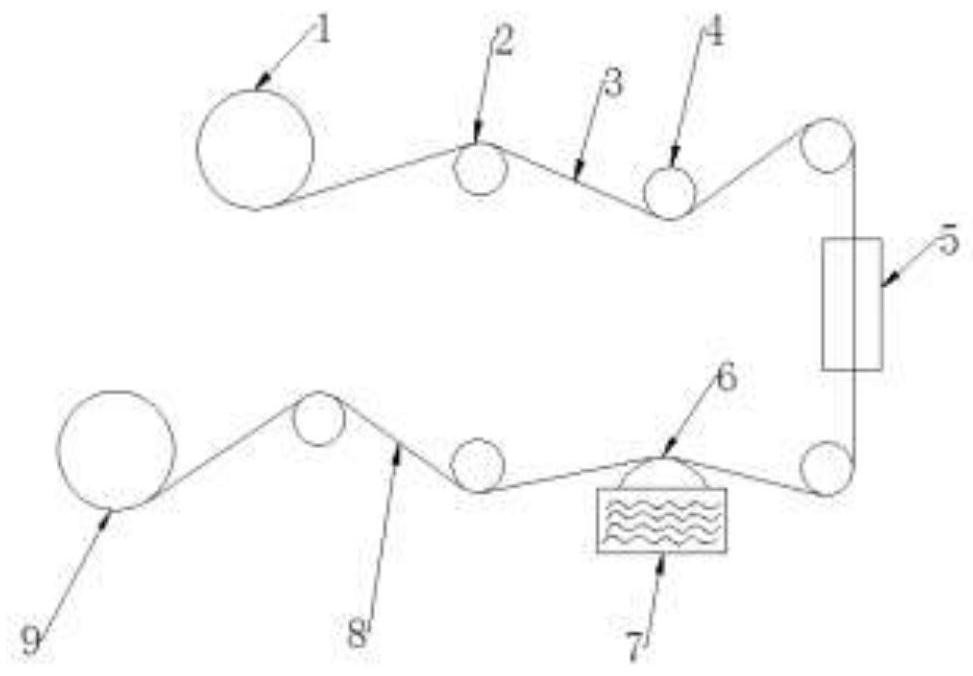

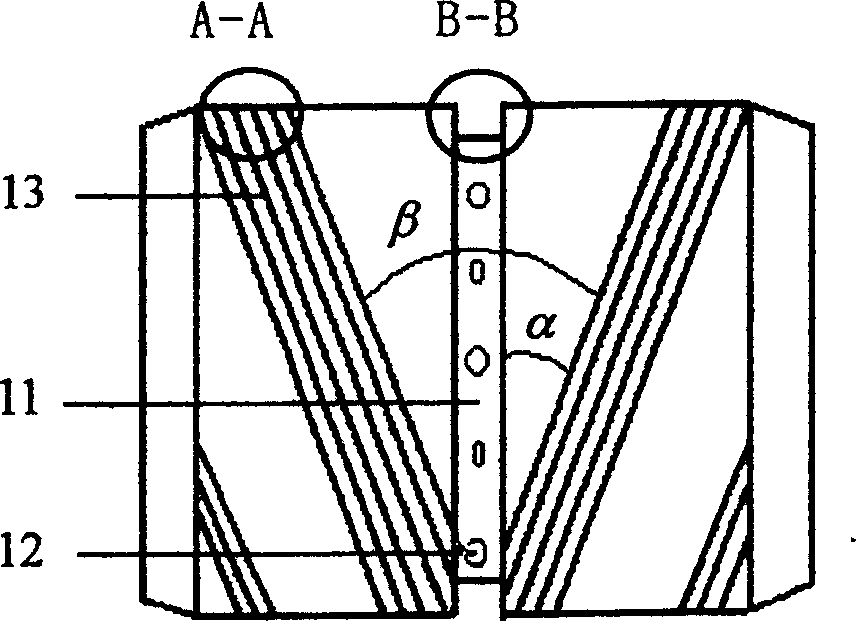

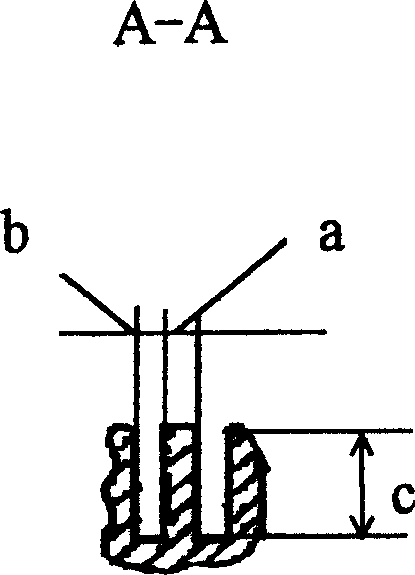

Fiber strand aggregating device for air slide

InactiveCN1388279AHigh glossImprove wear resistanceDrafting machinesContinuous wound-up machinesEngineeringHigh intensity

The present invention is fiber strand aggregating device for air slide, and its novel design is its aggregating roller with new splitting guide flute and porous aggregating flute. It is installed between the front jaw and the spinning section in the drawing area of spinnin frame, and the air slide fiber strand aggregating device and the front roller form one fiber jaw. By means of the additional aggregating air flows, one flow field for fiber inside the guide flute and the aggregating flute is provided. By means of splitting and guide of the guide flute and the aggregating flute and the aggregation of fiber strand in the aggregating flute, the fiber strand is twisted closely in the aggregating flute. The yarn of the present invention has improved axial parallel degree, decreased hairy feather amount outside the yarn and raised yarn strength.

Owner:DONGHUA UNIV

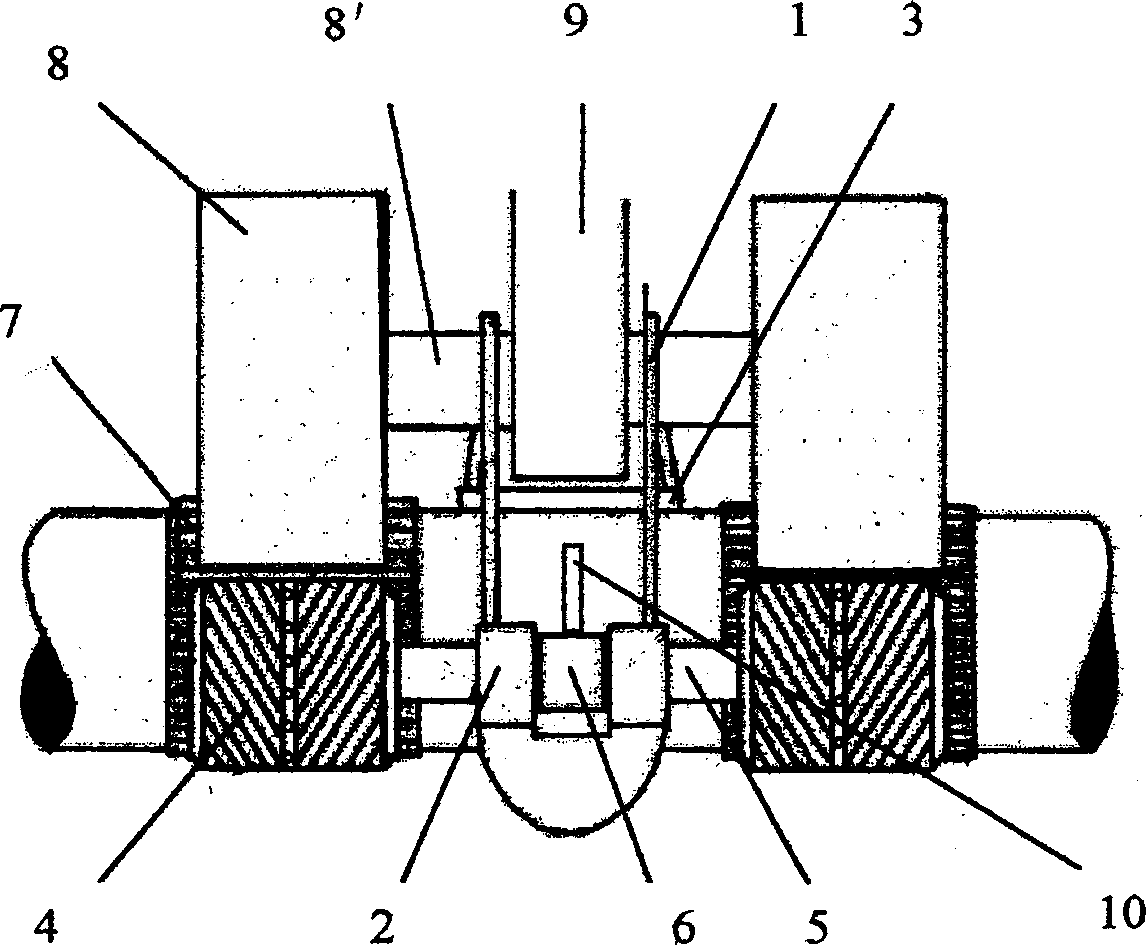

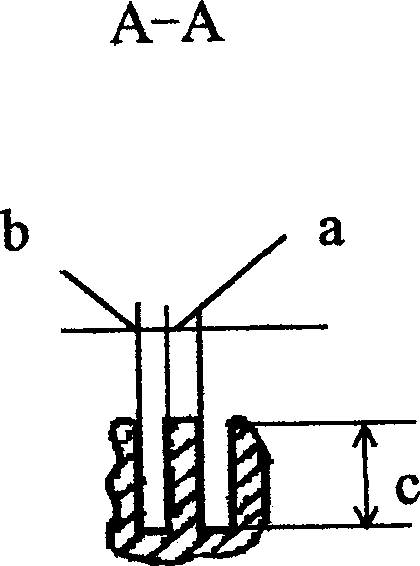

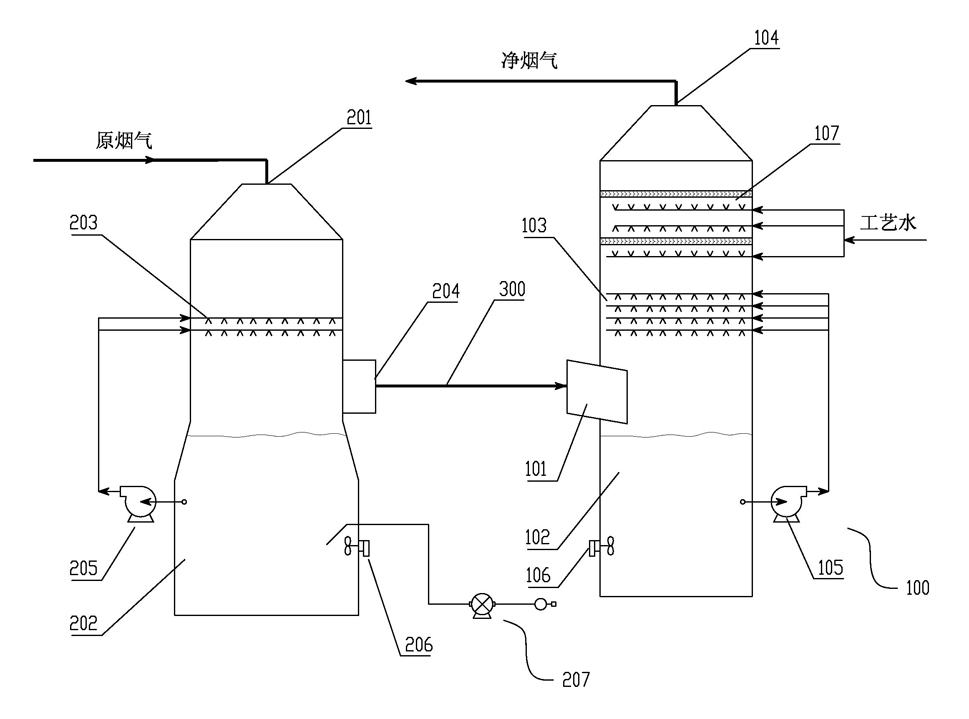

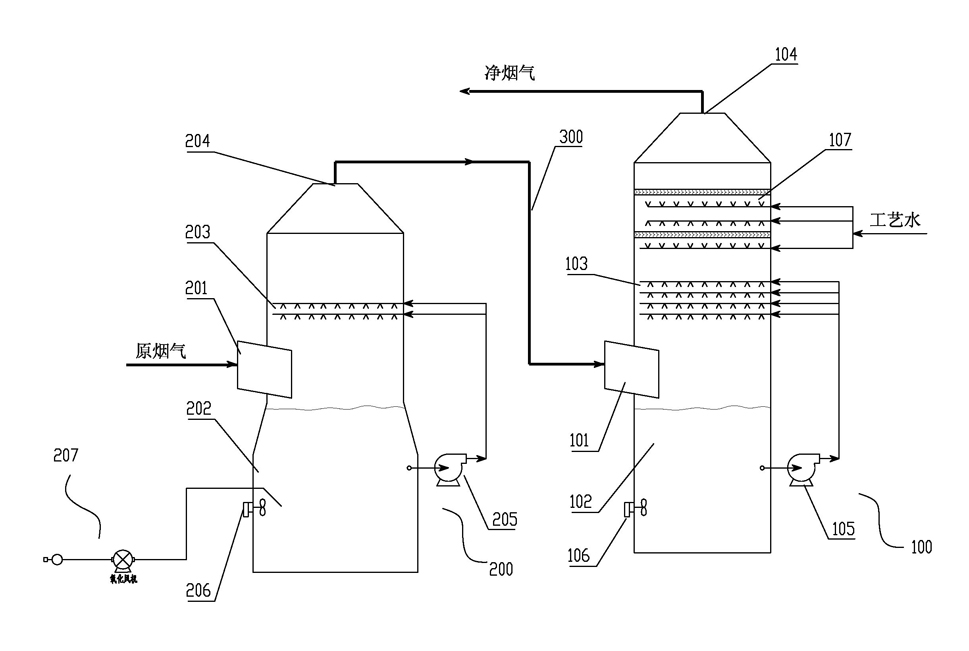

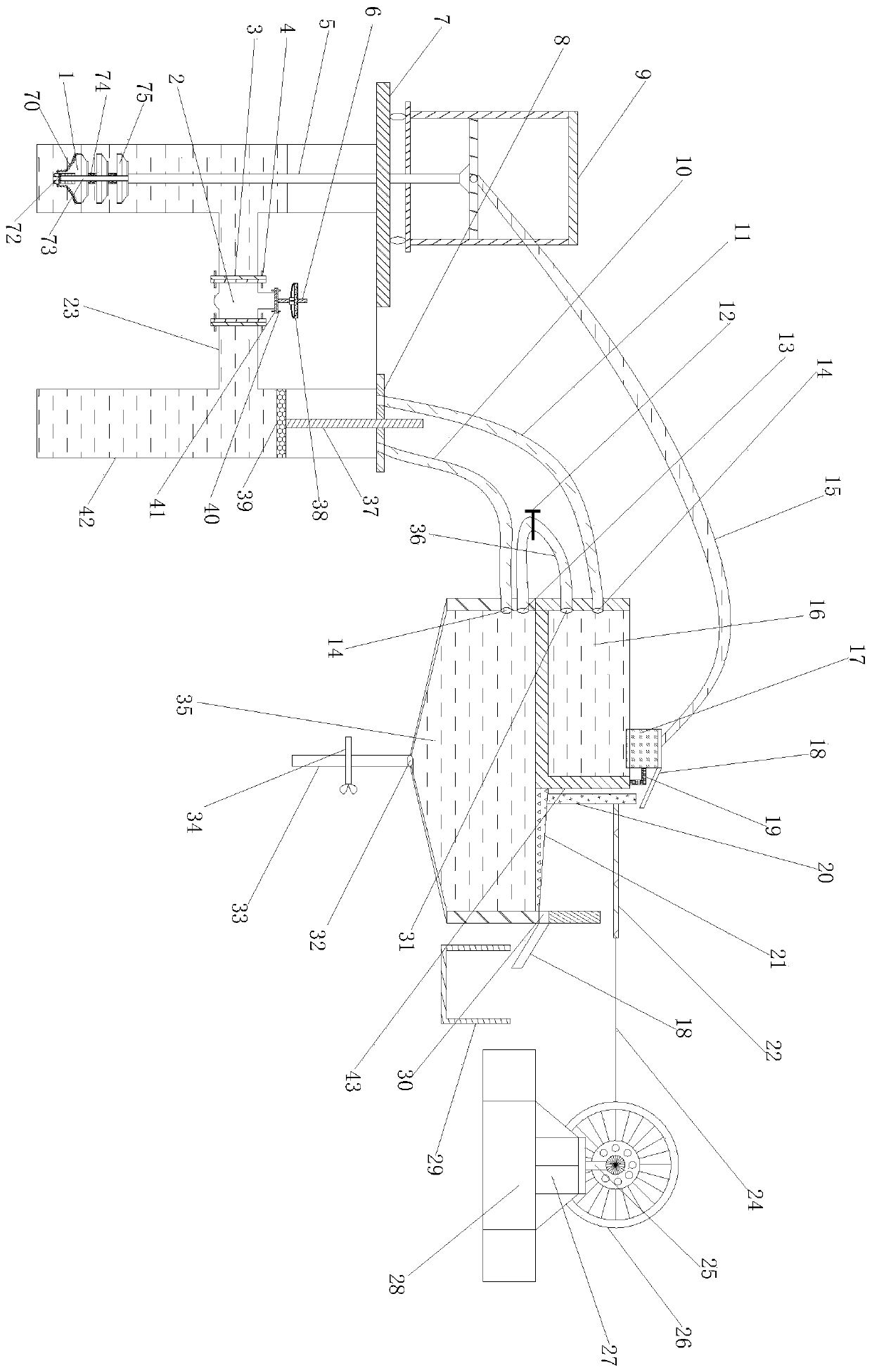

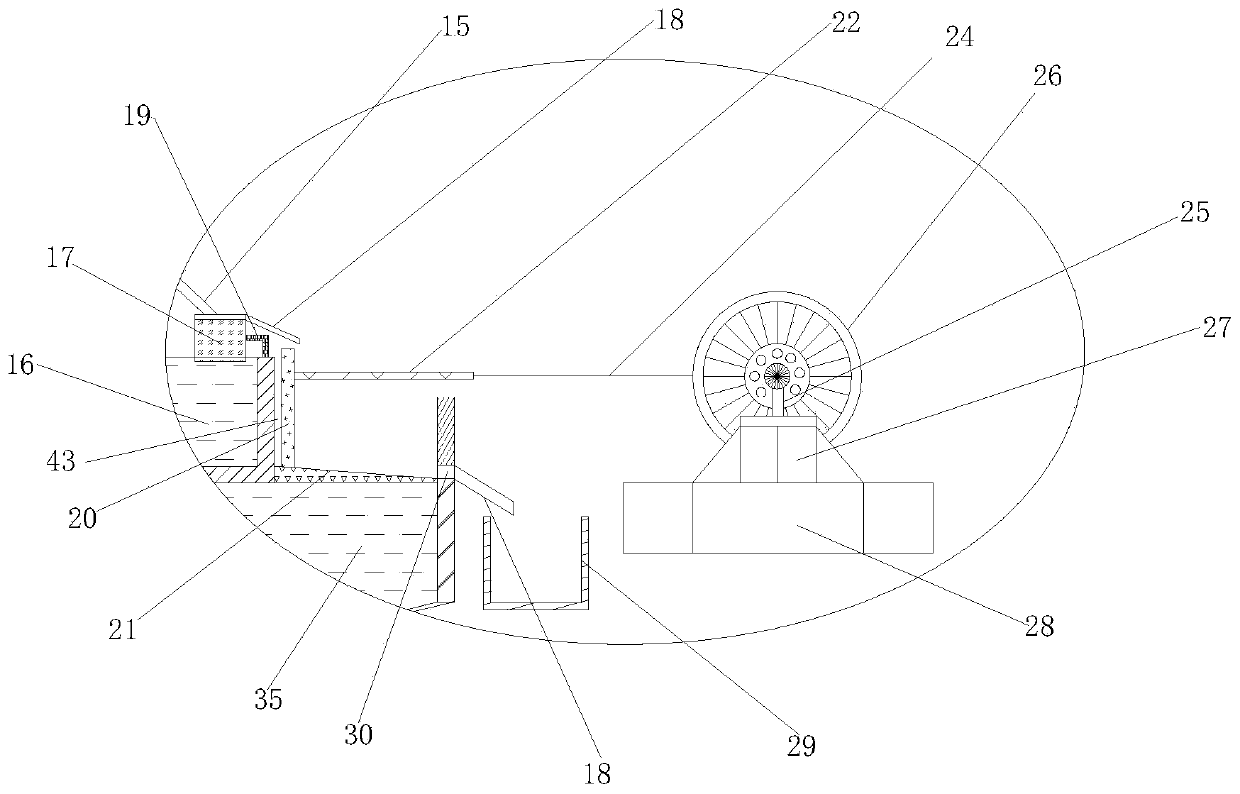

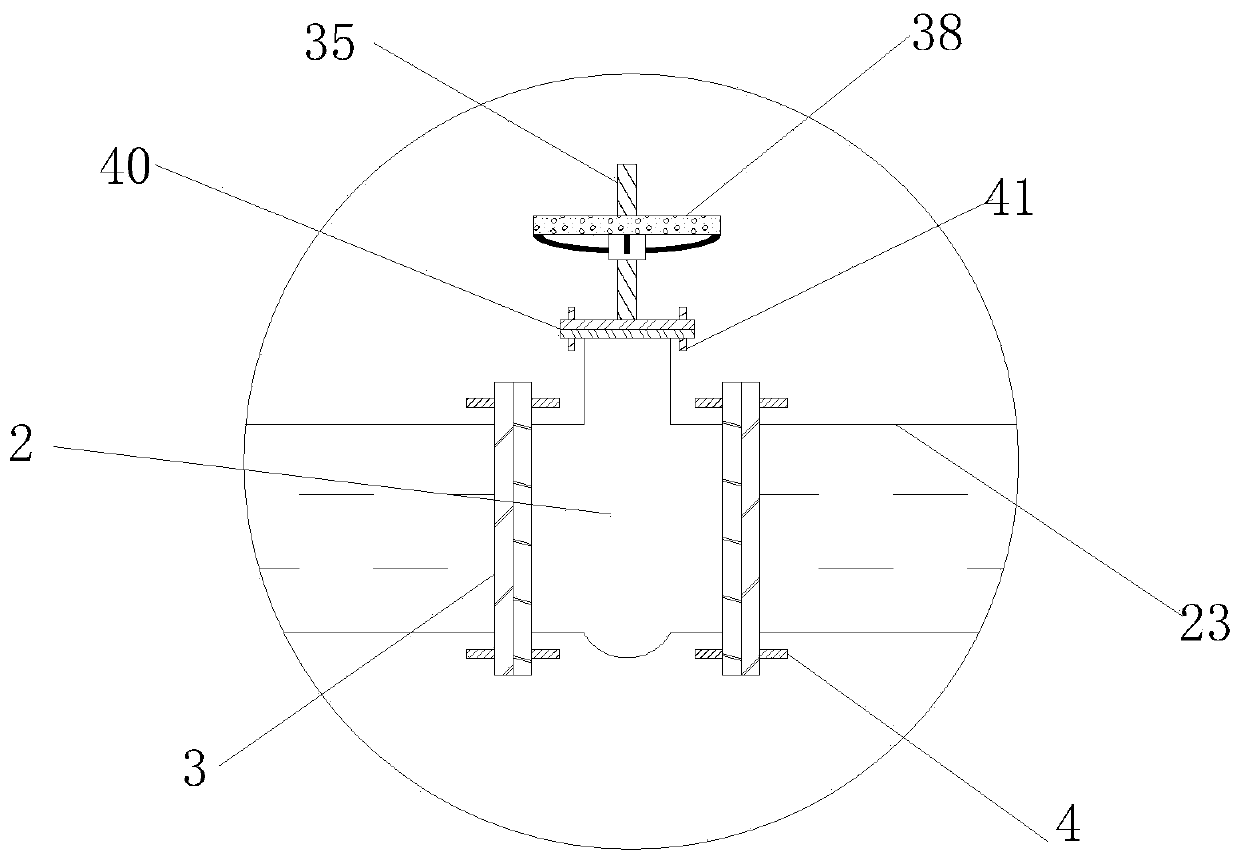

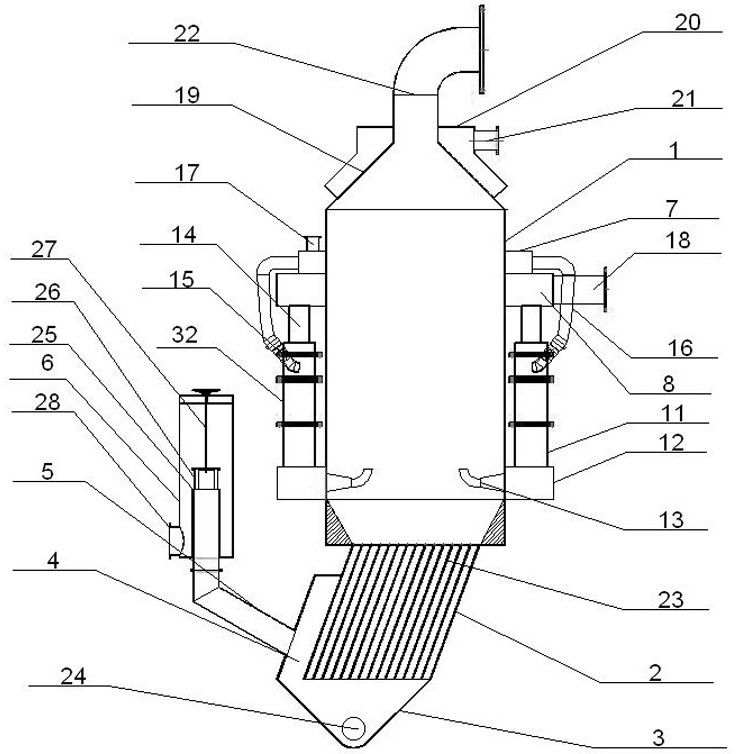

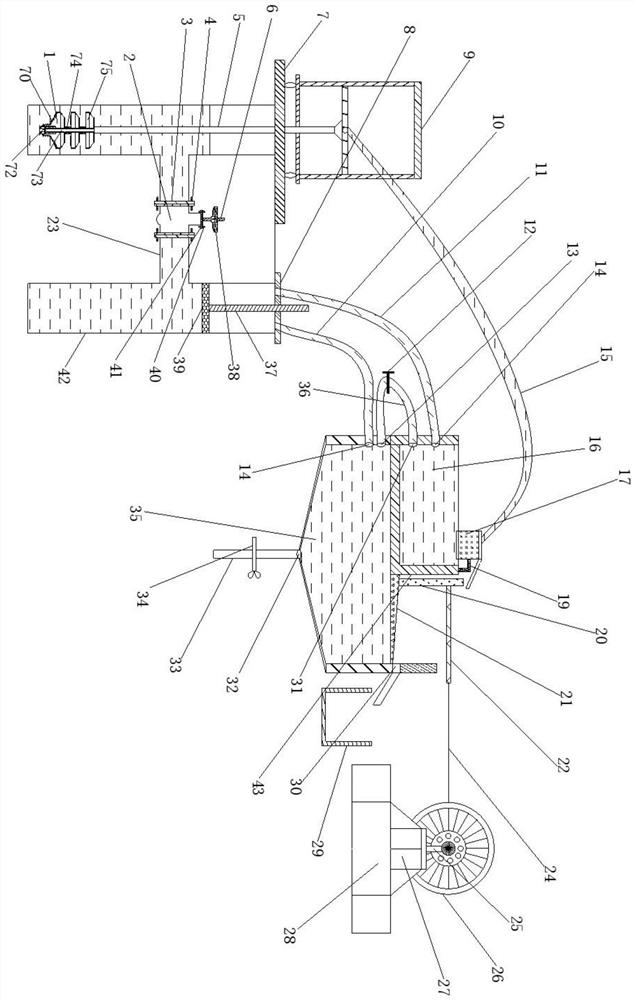

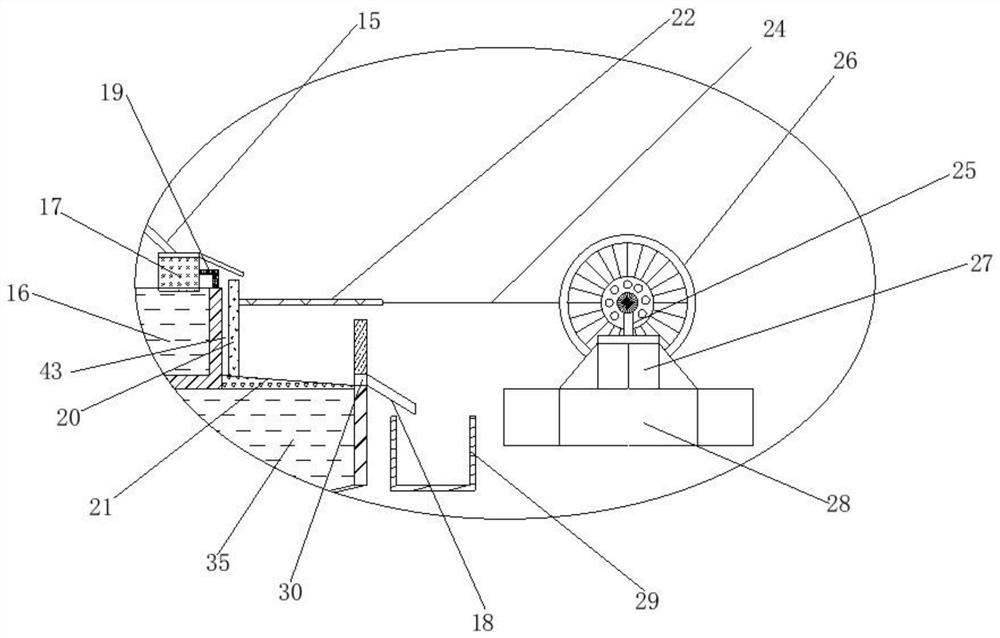

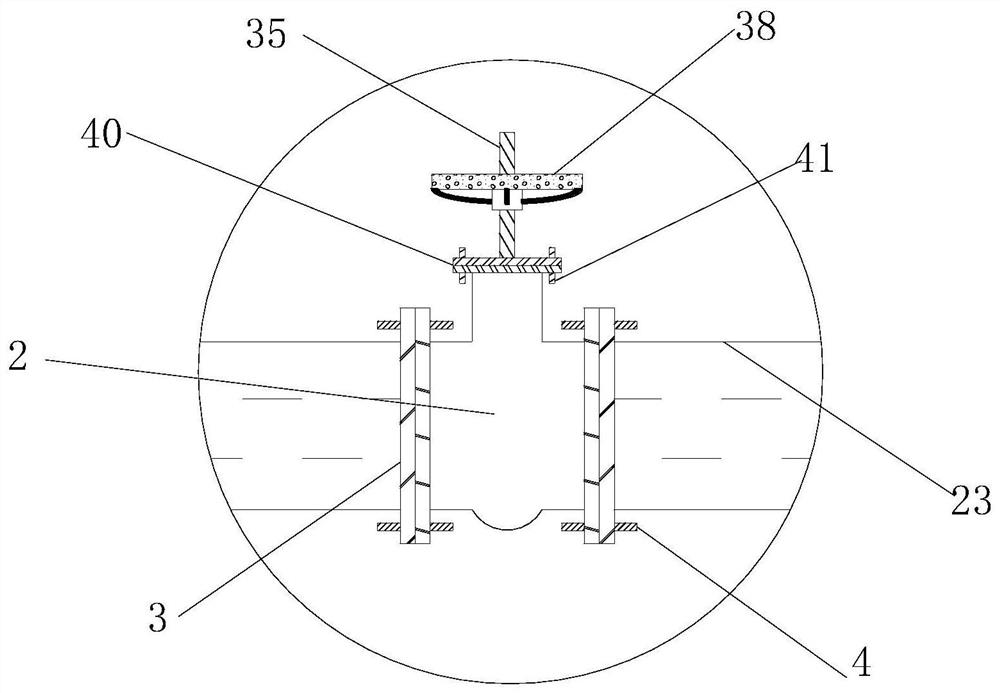

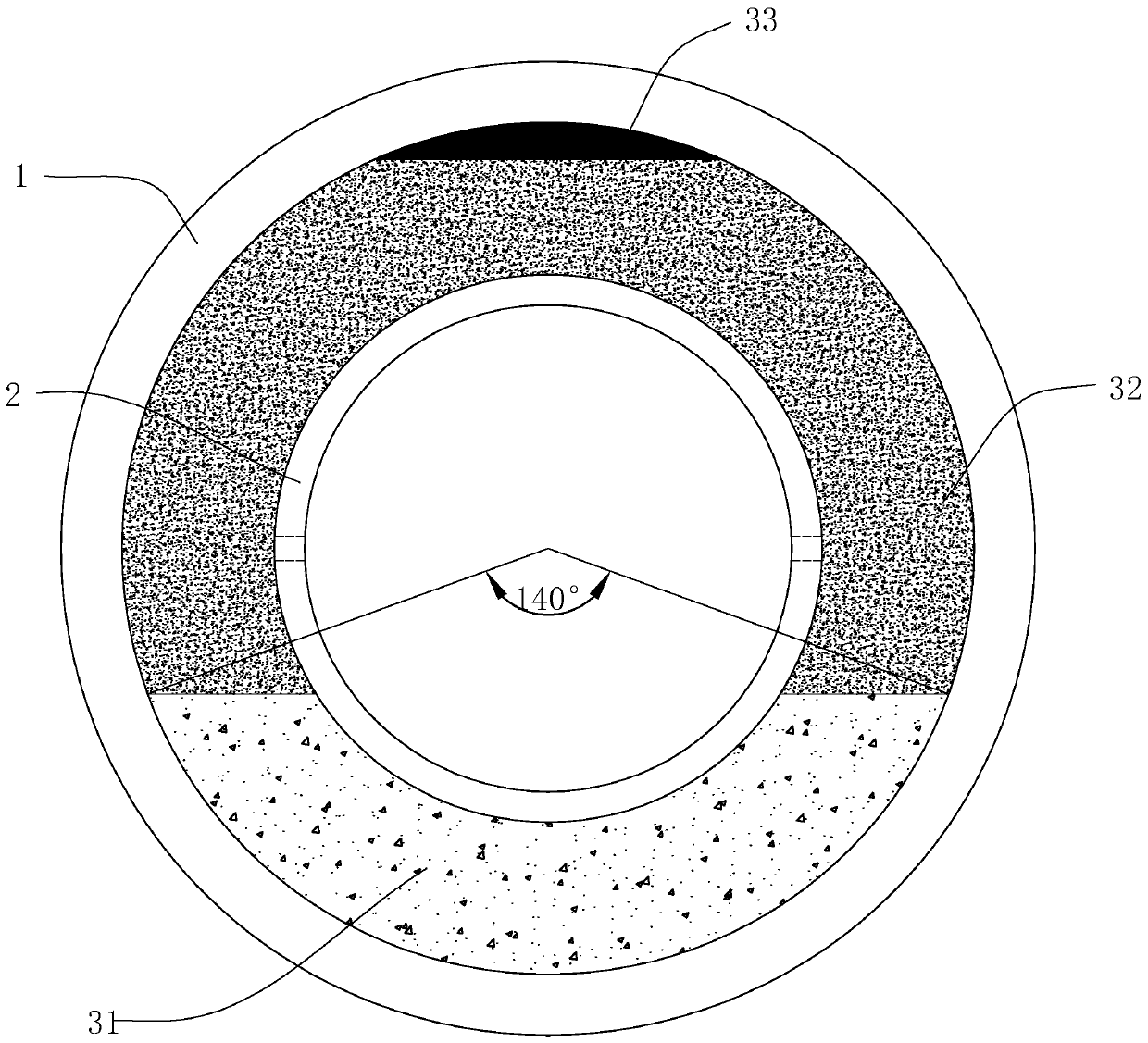

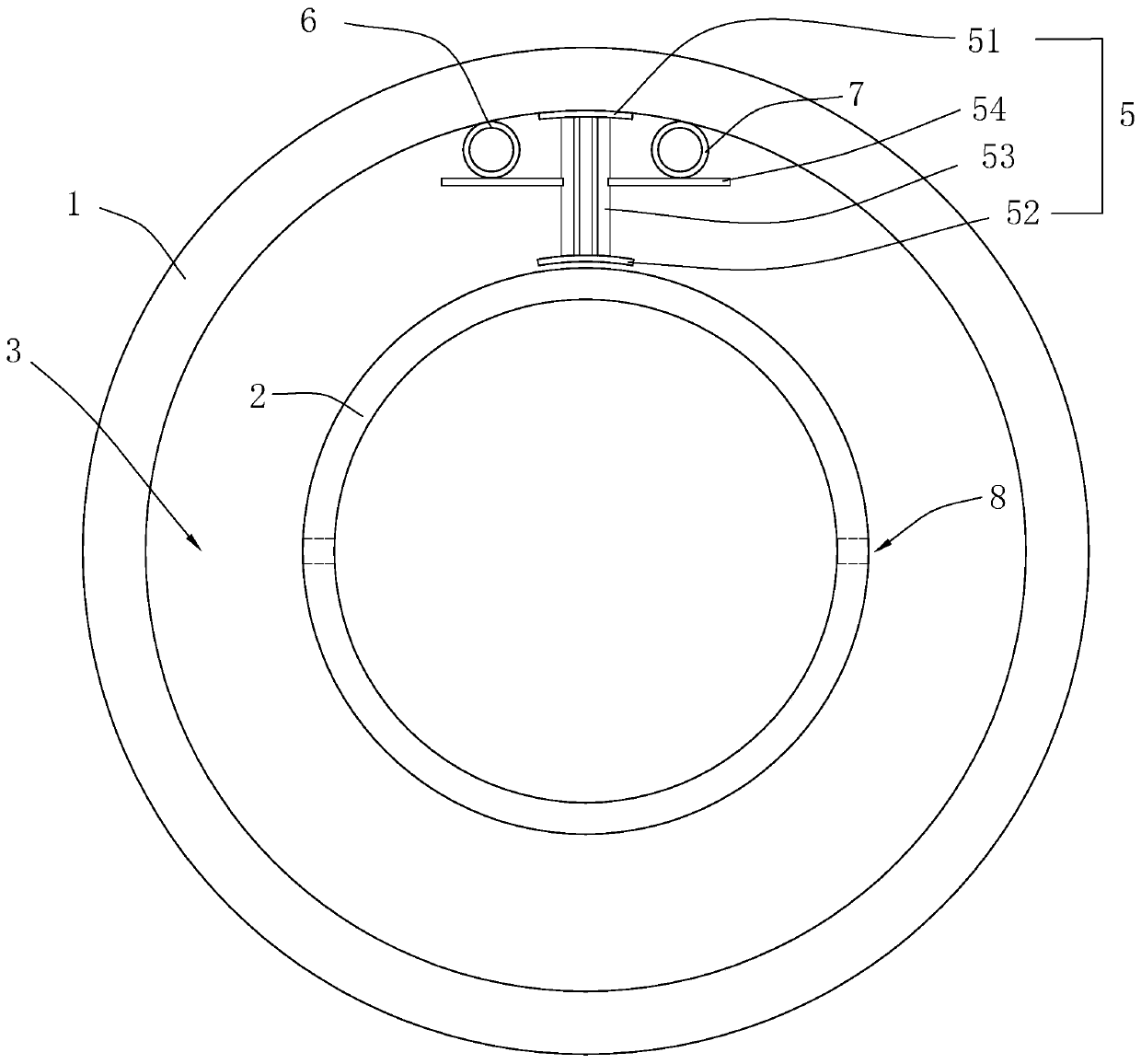

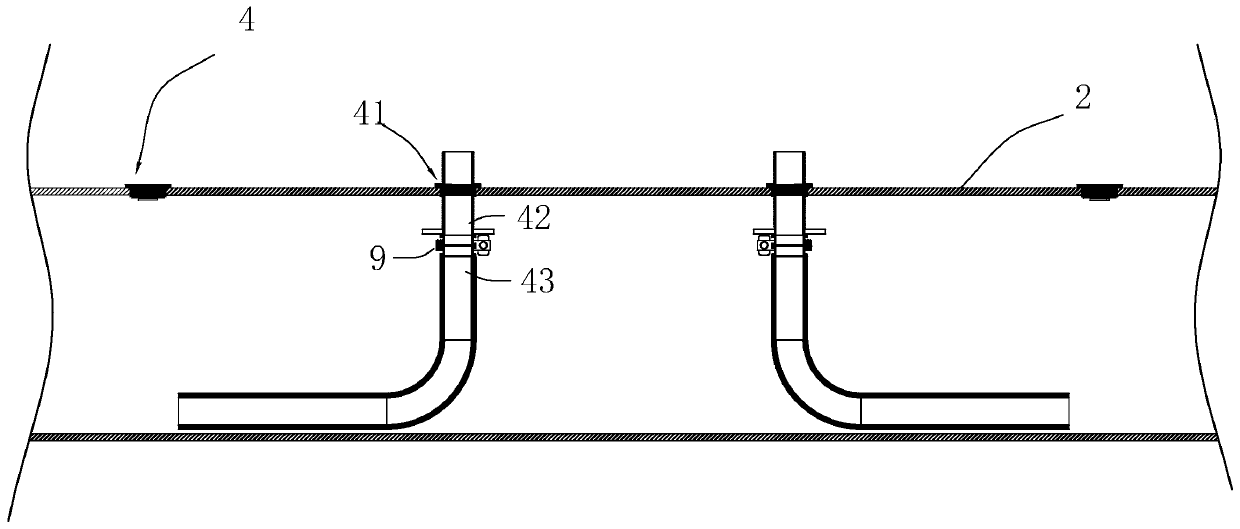

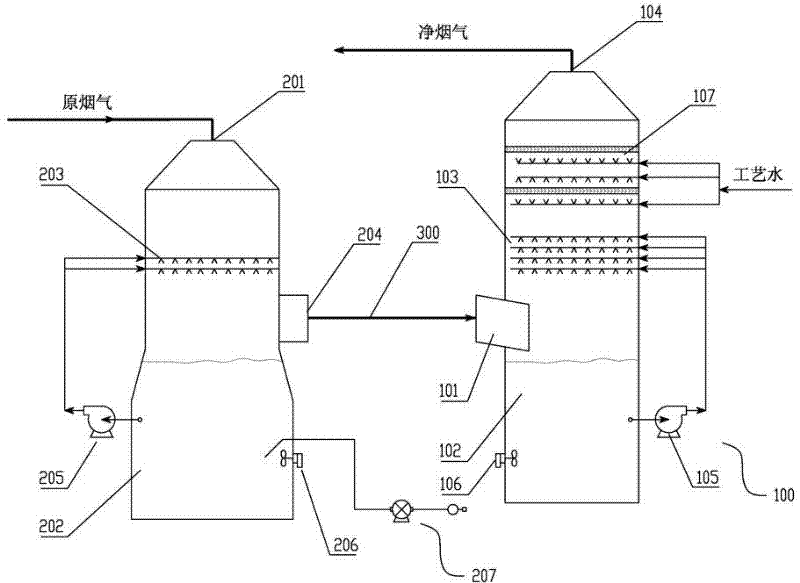

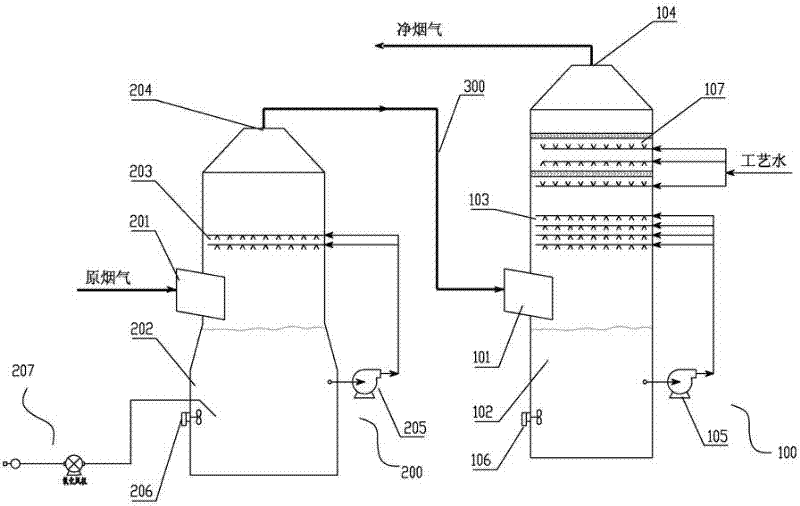

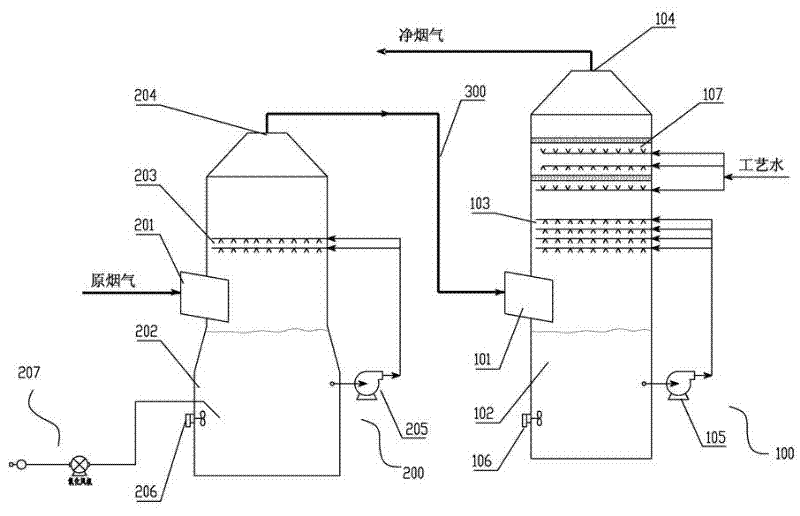

Dual-circulation absorption tower

ActiveCN101927125AImprove the operating environmentImprove desulfurization efficiencyUsing liquid separation agentDual loopEngineering

The invention discloses a dual-circulation wet absorption tower. The tower comprises a front absorption tower and a main absorption tower, wherein the main absorption tower comprises a first fume inlet and a first fume outlet; the front absorption tower comprises a second fume inlet and a second fume outlet; an inter-tower fume passage is formed between the second fume outlet and the first fume inlet; the main absorption tower and the front absorption tower are both provided with circulating pumps capable of pumping the grout from a grout tank; and an outlet pipe and a spraying layer of the circulating pump are connected with each other. The dual-circulation absorption tower of the invention can effectively improve the desulfurization efficiency and increase the operation stability, is environmentally-friendly and energy-saving and can reduce the using amount of a chemical additive.

Owner:浙江博众数智科技创新集团有限公司

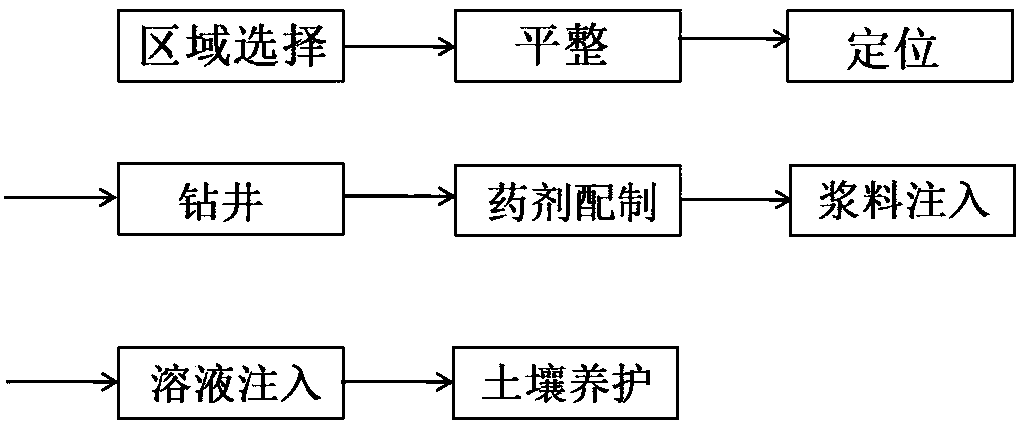

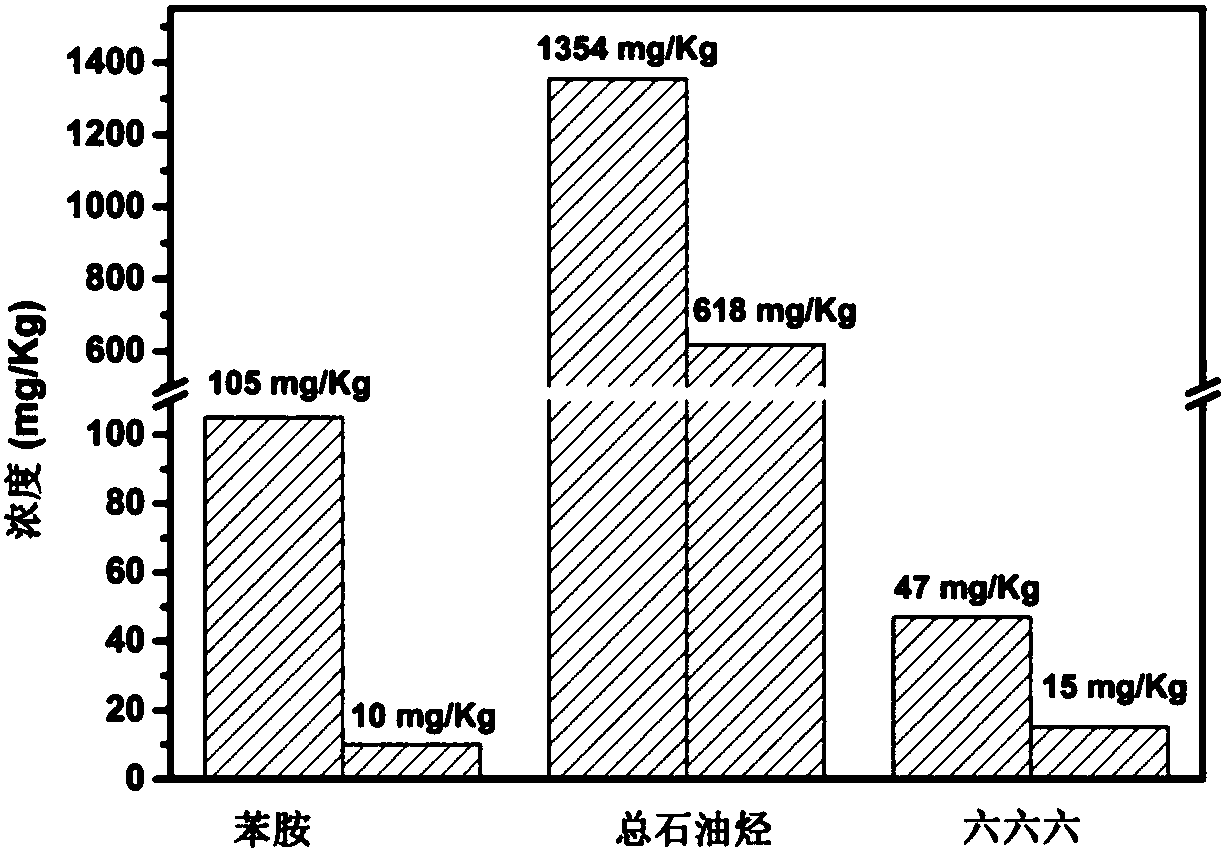

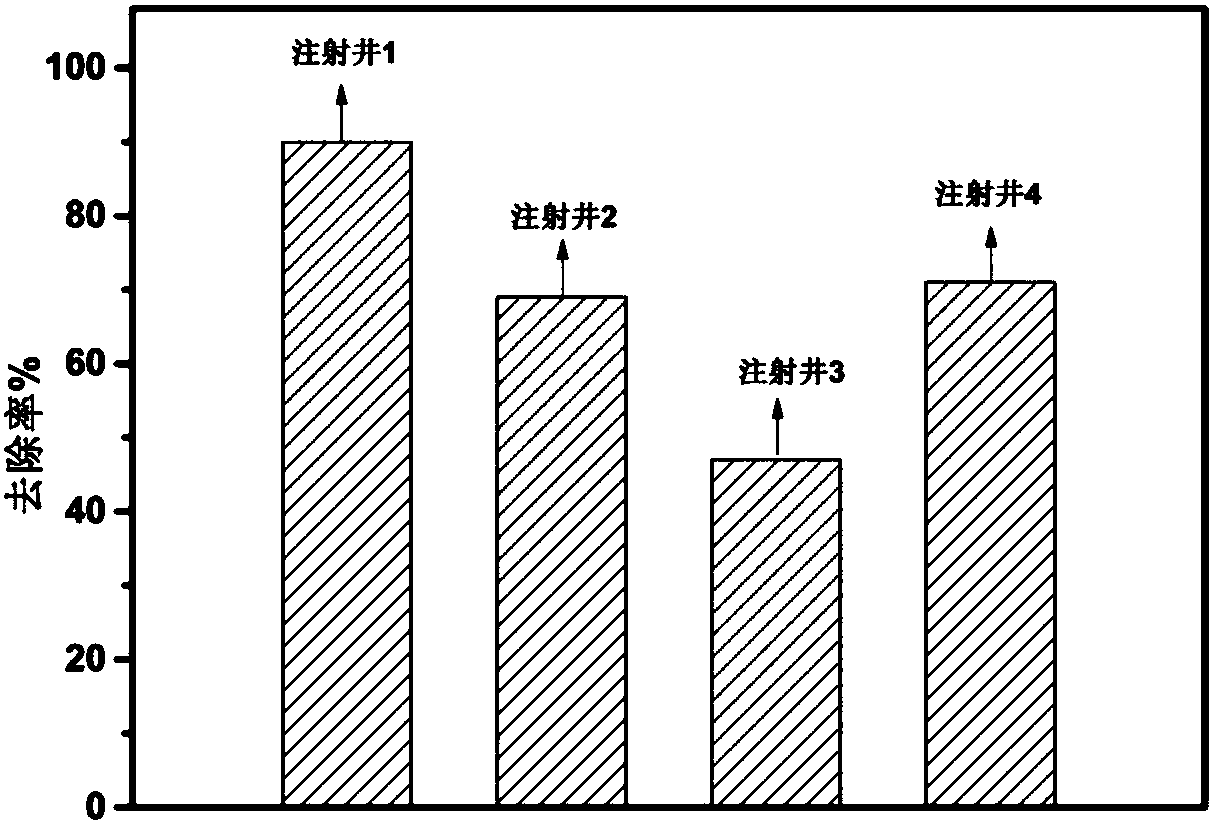

Method for in-situ repairing of organic pollutant soil by sodium persulfate and hydrogen peroxide compounded system

InactiveCN108405600AThermally activatedEfficient decompositionContaminated soil reclamationSulfateCompound system

The invention provides a method for in-situ repairing of organic pollutant soil by a persulfate and hydrogen peroxide compounded system. Iron-containing mineral and sodium persulfate paste is firstlyinjected into the soil in an in-situ injecting manner; and then a hydrogen peroxide and natural small-molecular acid solution is injected, and organic pollutant removing is performed. The method is good in repairing effect, and has the beneficial effects that manual heating for activating persulfate is not needed, manual pH value adjusting is not needed, cost is saved, and no secondary pollution is generated. The problems that in the process that a traditional singular sodium persulfate oxidizing system and a singular Fenton oxidizing system perform in-situ oxidizing repairing on the soil, efficiency is low, cost is high, it is needed to add a pH adjusting agent, and secondary pollution is caused easily are solved.

Owner:HUAZHONG NORMAL UNIV

Ground pregrouting material prepared from waste drilling slurry

ActiveCN101696352AEmission reductionReduce the amount of slurryDrilling compositionWell drillingChloride

The invention discloses a ground pregrouting material prepared from waste drilling slurry. The ground pregrouting material consists of a ground pregrouting solution prepared from the waste drilling slurry and a calcium chloride solution; the ground pregrouting solution consists of the waste drilling slurry, cement and a structural additive, the volume of the structural additive accounts for 1 to 3 percent of that of the ground pregrouting solution, the concentration of the cement is between 0.1 and 0.2g / mL, and the balance is the drilling slurry; and the volume ratio of the ground pregrouting solution to the calcium chloride solution is 1,000:(5-17). The ground pregrouting material has the advantages of reducing the emission of the waste slurry and reducing the slurry yield of clay suspension during the grouting.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

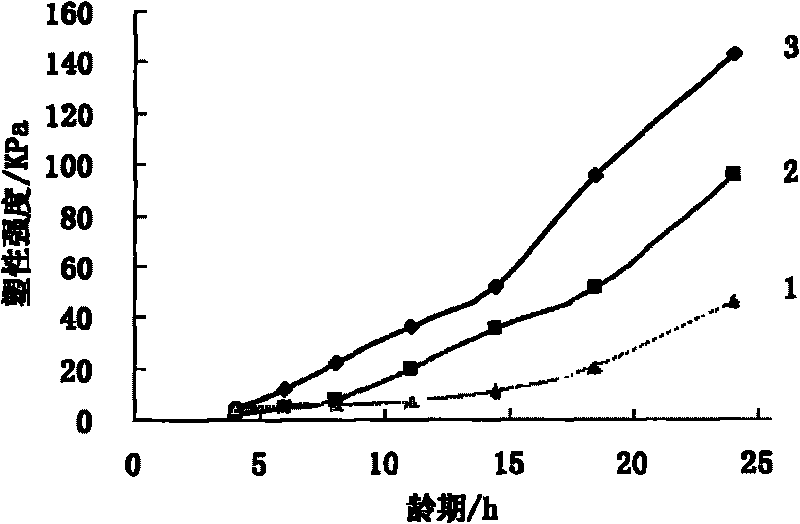

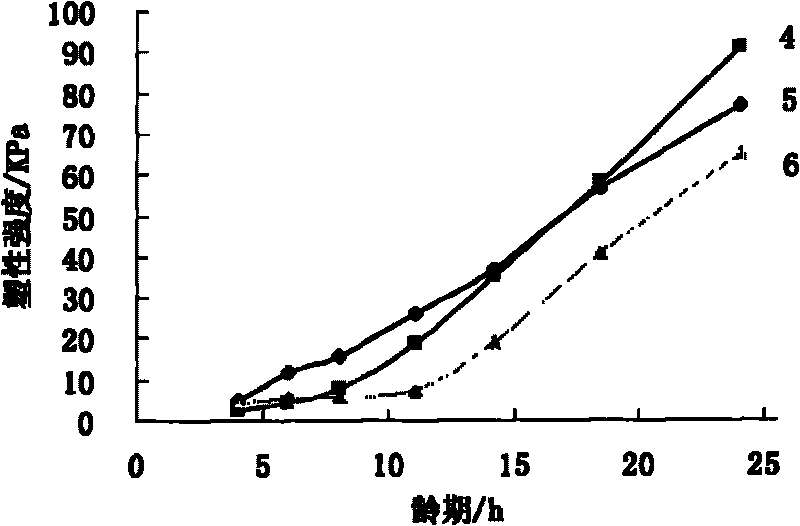

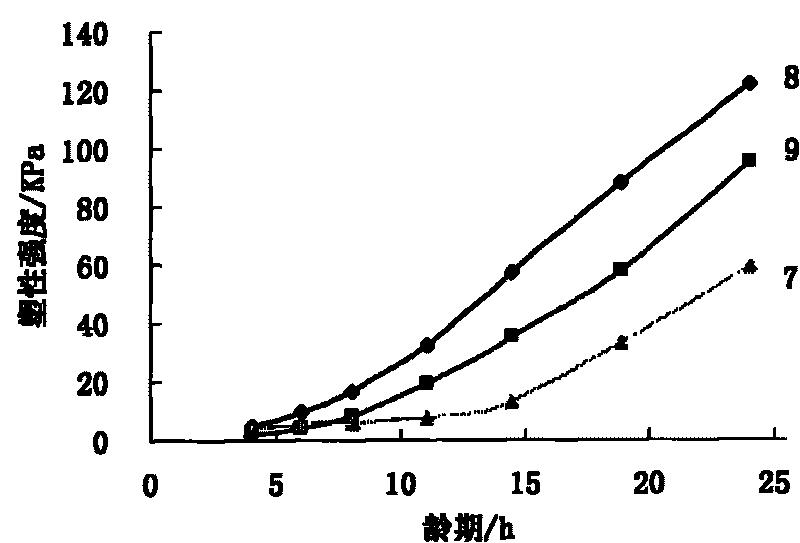

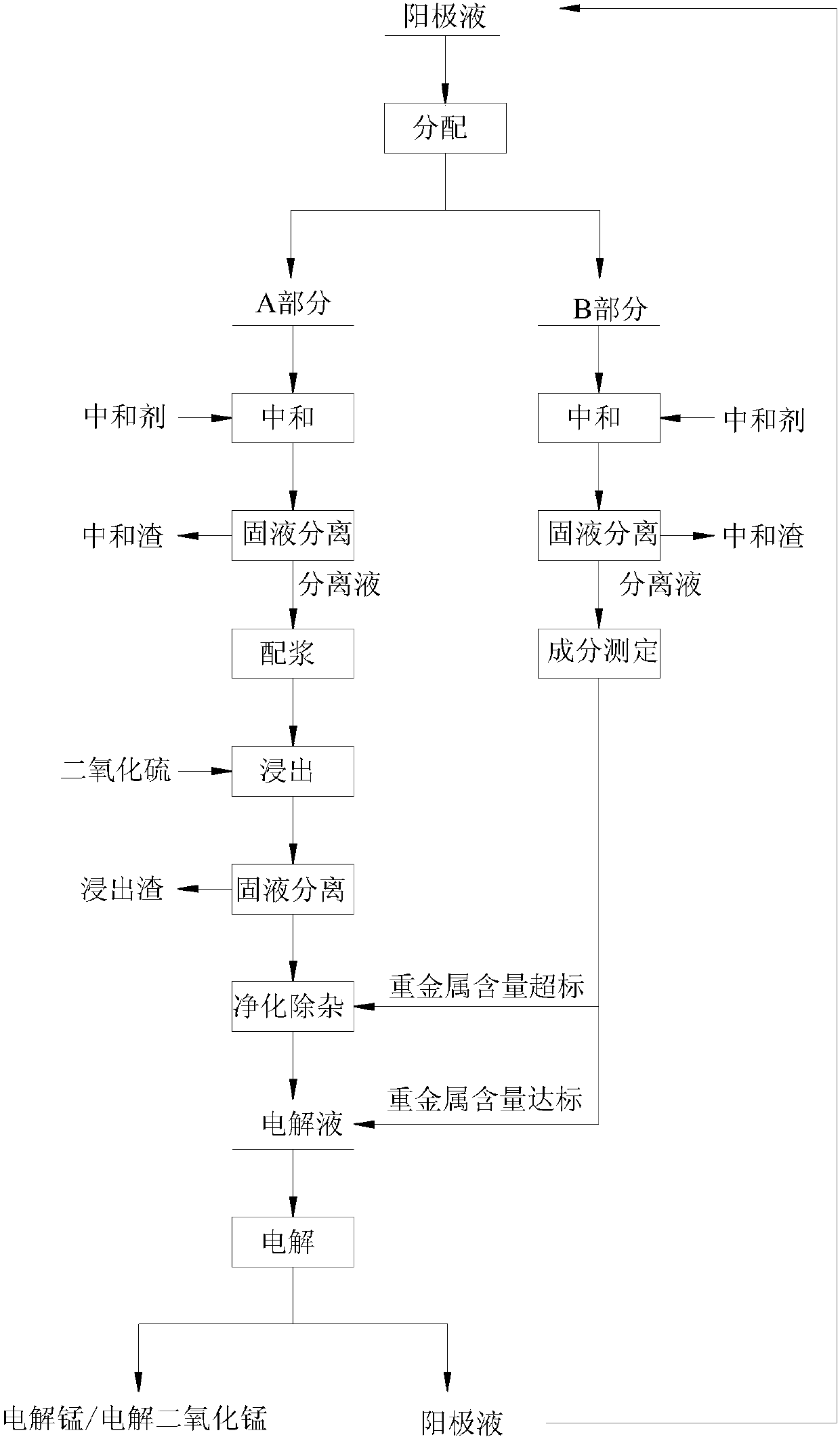

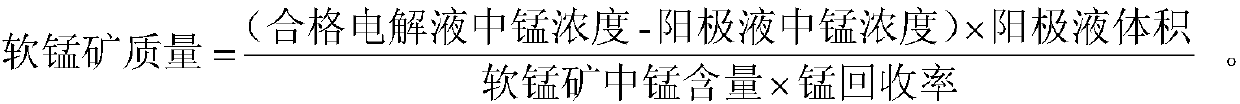

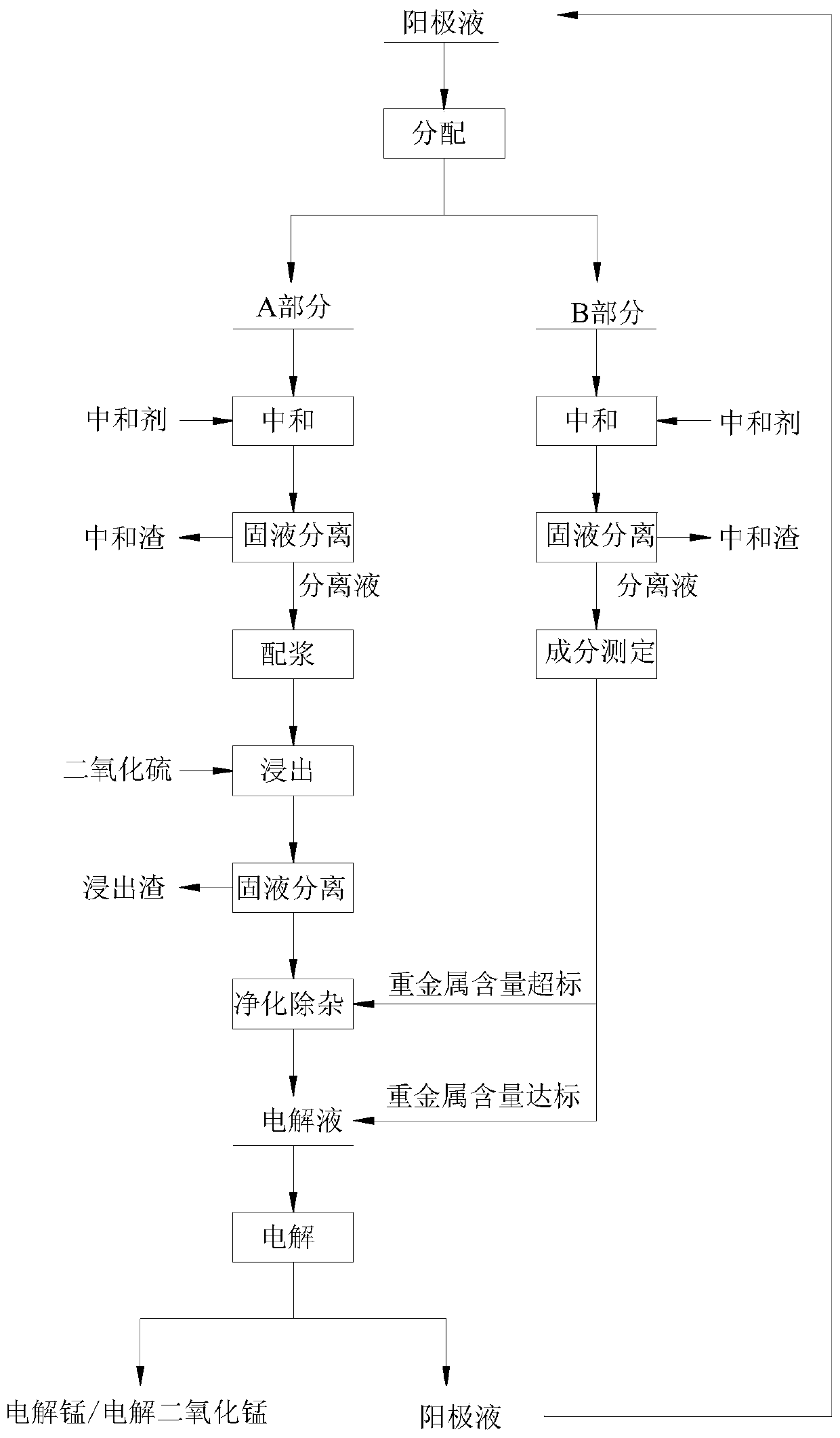

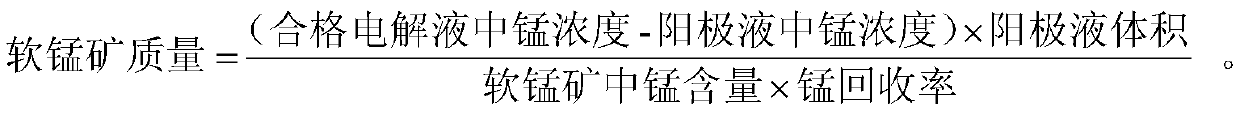

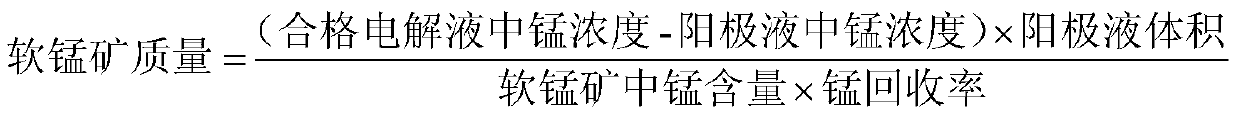

Method for preparing manganese sulfate electrolyte by leaching pyrolusite through sulfur dioxide

ActiveCN107699714AIncrease the solid-to-liquid ratioIncrease profitHigh concentrationPregnant leach solution

The invention provides a method for preparing a manganese sulfate electrolyte by leaching pyrolusite through sulfur dioxide. According to the main concept, the method comprises the steps that only a part of an anolyte and whole-process pyrolusite are used for preparing a fluid, and after the fluid reacts with the sulfur dioxide, a high-concentration manganese sulfate solution is obtained; after the other part of the anolyte is neutralized and subjected to liquid-solid separation, a low-concentration manganese sulfate solution with the manganese sulfate concentration being identical to that ofthe prior anolyte is obtained; and the two manganese sulfate solutions are blended to obtain the qualified electrolyte with the manganese sulfate concentration meeting electrolysis requirements. By adopting the method, the utilization efficiency of the sulfur dioxide and the pyrolusite in the leaching process can be improved, and the capital construction cost and operation cost of a leaching technology and a leachate impurity removing technology are lowered.

Owner:SICHUAN UNIV

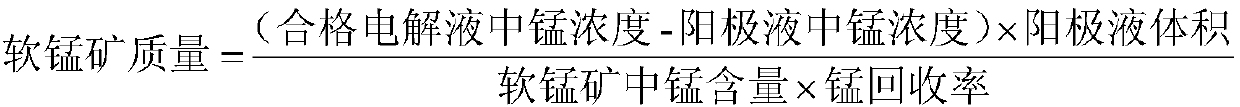

Coarse-size separation technique

The invention discloses a rough particle separation process comprising the following steps: (1) after the particle size of a pulverized greenore achieves 20mm, pulverized ores are processed by the operation of wet prescreening to separate fine particle products which are smaller than or are equal to 3 mm and 3-20mm rough particle products, and the fine particle products which are smaller than or are equal to 3 mm are dehydrated to be directly led into the next step of ore benefication; (2) the 3-20mm rough particle products are led into jigging equipment; according to the composition and the distribution of the ores, light products, i.e. waste rocks, and heavy products are separated by the jigging equipment, and the heavy products are discharged from the bottom of the jigging equipment; and (3) the heavy products discharged from the bottom of the jigging equipment are dehydrated by dehydration plant and then are led into the next step of ore benefication. The invention adopts a BATAC wind pulse jigger as the jigging equipment. The rough particle separation process can greatly improve the selection level of the ores, and has the advantages of simple technological procedure, easy engineering, environmental protection and energy saving.

Owner:CINF ENG CO LTD

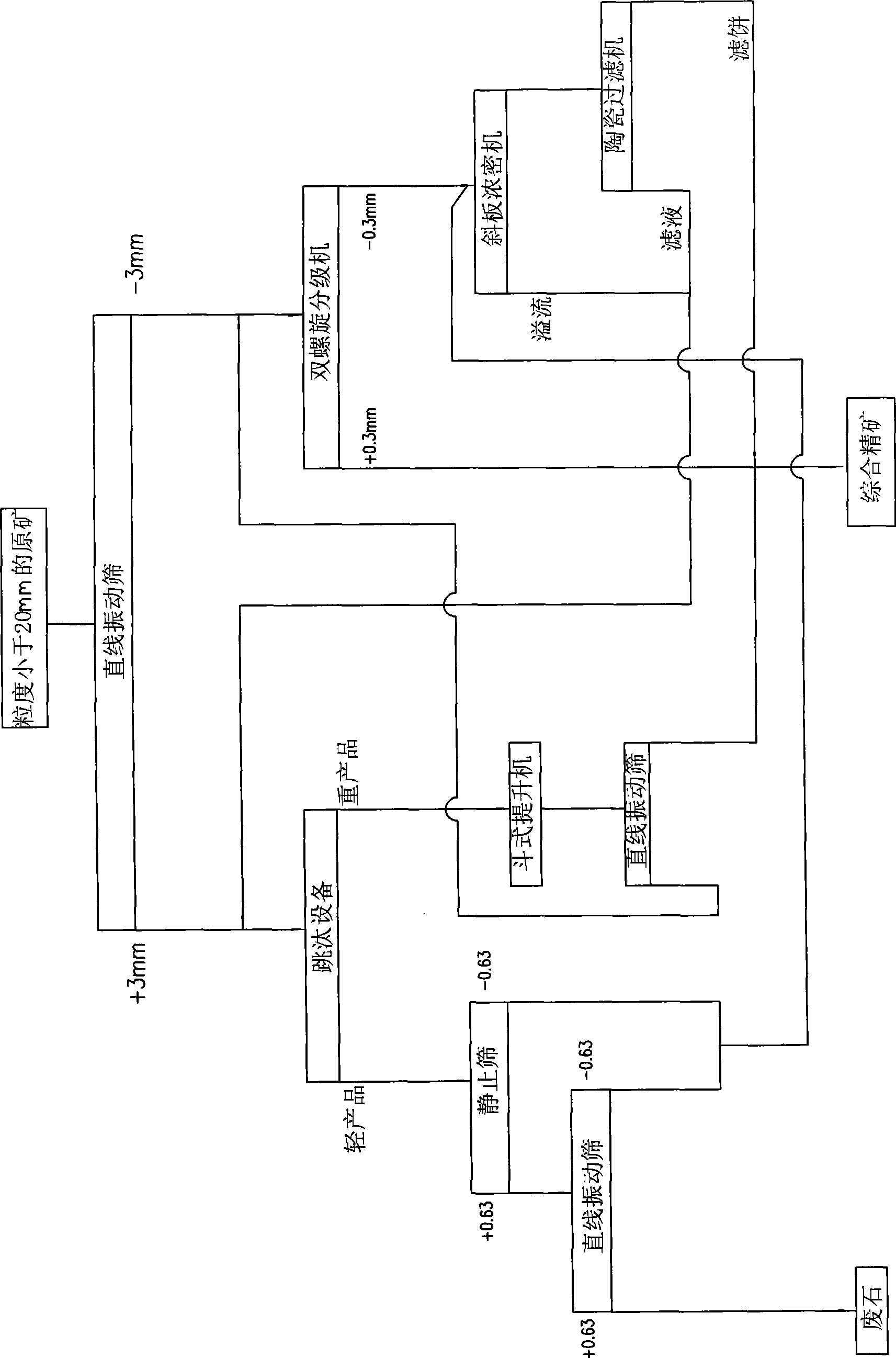

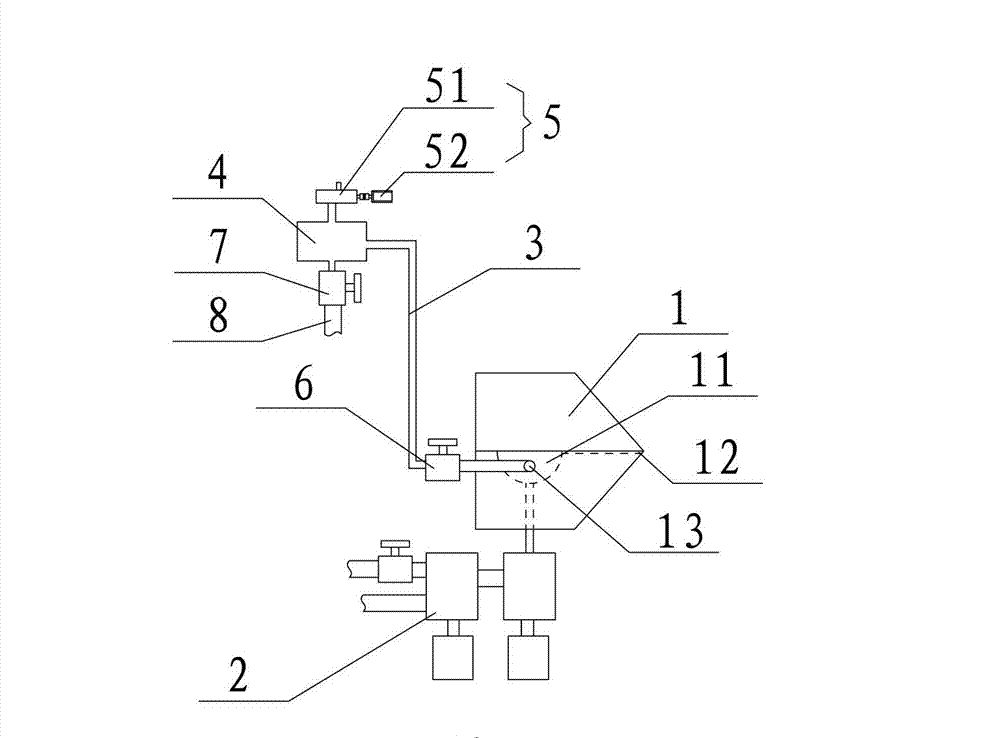

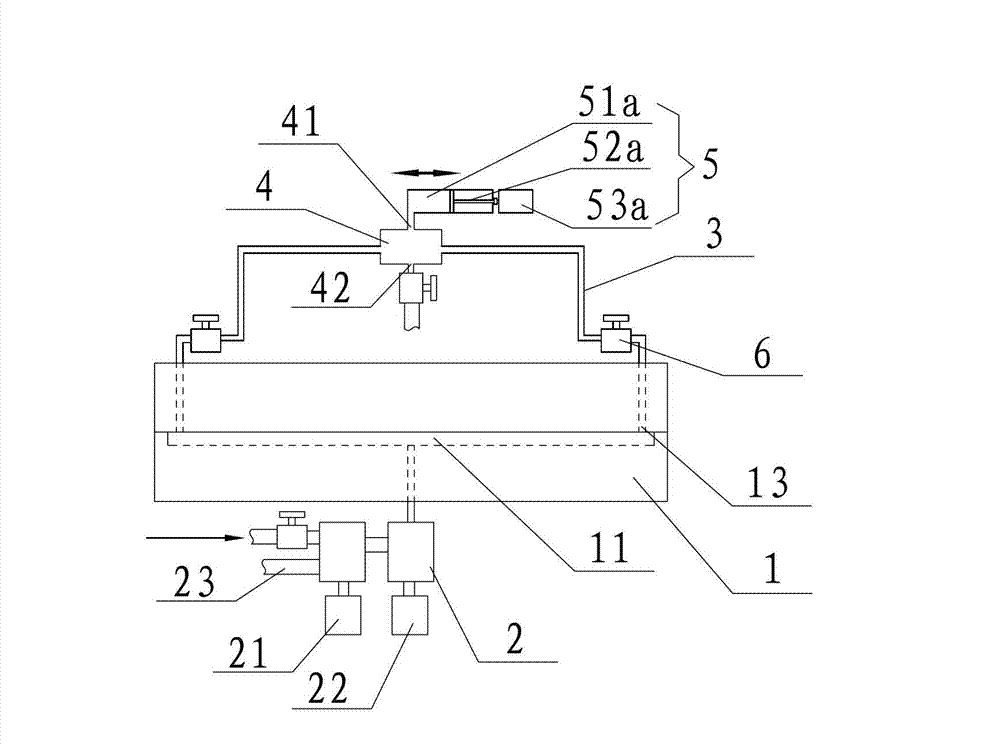

Intermittent extrusion coater

The invention discloses an intermittent extrusion coating method and an intermittent extrusion coater. According to the coating method, a matrix is coated with slurry intermittently through a seam of an extrusion head; and the coating method comprises the following steps that when the extrusion head coats the slurry on the matrix, the slurry at the seam of the extrusion head is sucked back to flow back; and when the extrusion head stops coating the slurry on the matrix, the slurry at the seam of the extrusion head is sucked back to flow back. According to the coating method, when the coating is started, the slurry in the extrusion head flows back in a trace amount at the moment of supplying, so that the slurry coated on the matrix is reduced and the thickness of the head in the intermittent coating can be effectively controlled; during intermittence, namely when the extrusion head stops coating, the slurry in the extrusion head flows back instantaneously, so that the slurry coated on the matrix can be quickly disconnected; and therefore, the uniformity of the tail during intermittence is effectively controlled.

Owner:SHENZHEN HAONENG TECH

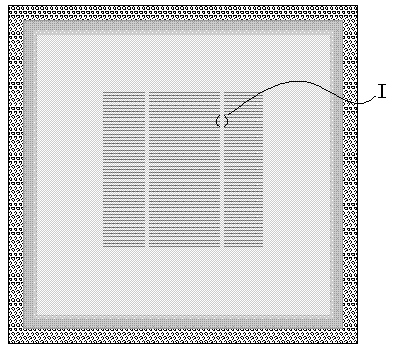

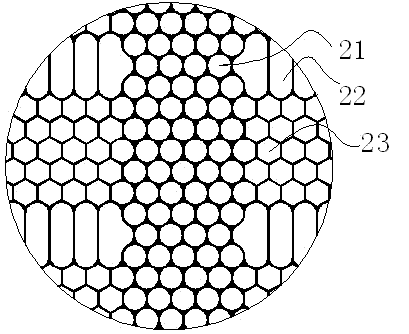

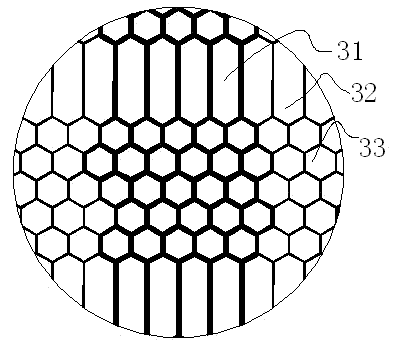

Trepanning-adjustable flat silk screen and screen printing plate comprising same

The invention relates to a trepanning-adjustable flat silk screen. The trepanning-adjustable flat silk screen mainly solves the problems that a silk screen is not stable in structure and low in mechanical strength in an existing precision printing technology. The trepanning-adjustable flat silk screen comprises a flat silk screen body, and is characterized in that the flat silk screen body is of a faveolate structure formed by mutual connection between a polygonal array or a circular array; the silk screen area of the flat silk screen body is divided into a masking area and a plot area. An array unit structure of a local area is changed, the size of an array unit is adjusted, or the two methods are combined, so that the local trepanning rate of the flat silk screen is adjusted, the problem is well solved, and therefore the trepanning-adjustable flat silk screen and the screen printing plate comprising the same can be widely used in industrial production of precision printing.

Owner:KUN SHAN POWER STENCIL

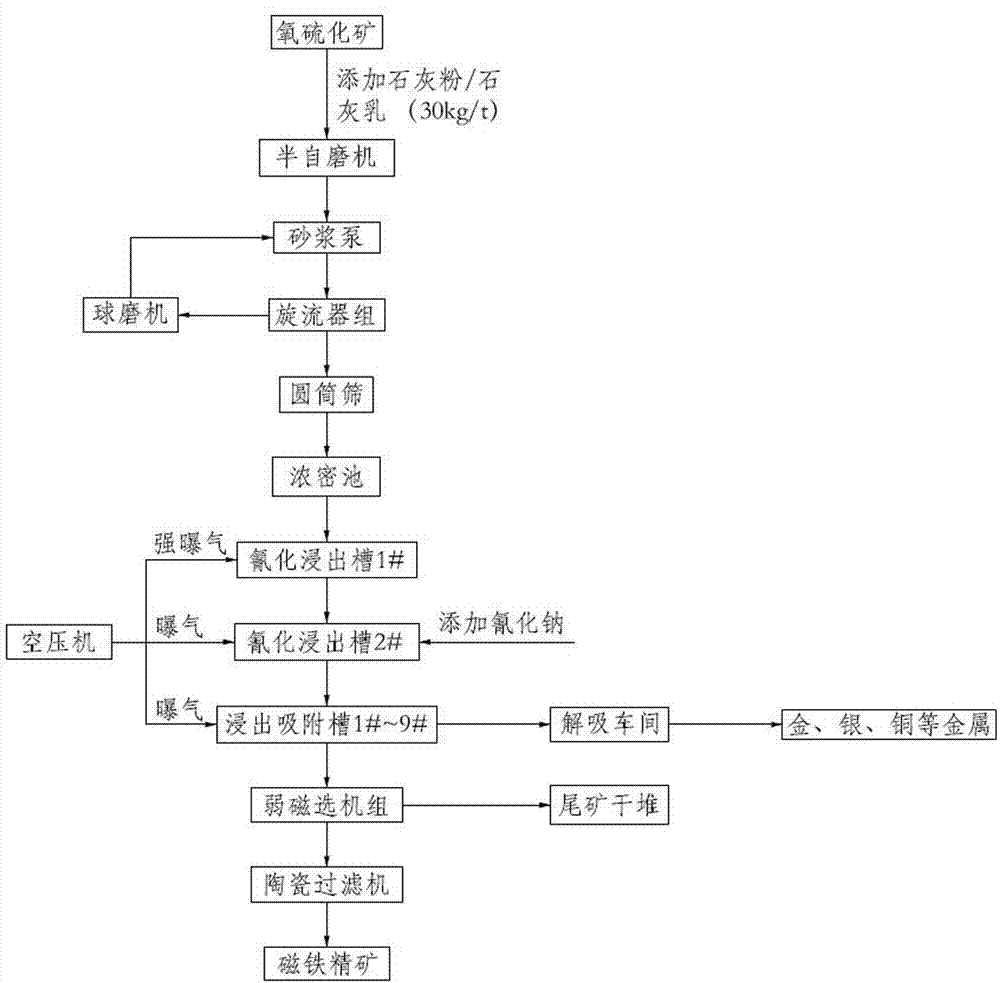

Sulfide-oxidized mixed ore treatment process

InactiveCN107297270APromote oxidationMaintain pH valueWet separationHigh concentrationMetal leaching

The invention belongs to the technical field of ore dressing and particularly relates to a sulfide-oxidized mixed ore treatment process. The sulfide-oxidized mixed ore treatment process includes three sections namely ore grinding and classification, cyanidation leaching and magnetic separation. Due to high sulfur content in treated sulfide-oxidized mixed ore, a great quantity of lime is added at the ore grinding and classification section to accelerate oxidation of sulfide ore in advance, and a PH value in ore pulp can be constantly kept in a range of 10-12 to achieved a protection alkali function; during secondary grinding, sodium cyanide is removed to avoid reaction between sodium cyanide with sulfide ore in the sulfide-oxidized mixed ore, sodium cyanide consumption is reduced, and production cost is saved; oxygen-rich leaching is adopted at the cyanidation leaching section, and an oxygen-rich environment accelerates sulfide ore oxidation to realize passivation in sodium cyanide solution, so that reaction with sodium cyanide is avoided, and unit consumption of sodium cyanide is reduced; by preparation of the oxygen-rich ore pulp high in cyanide content, the leaching rate of metals such as gold and silver is increased, pulp volume is decreased due to high-concentration leaching, and sodium cyanide consumption is reduced.

Owner:鹤庆北衙矿业有限公司

Technological method for drilling fluid solid control circulation system

ActiveCN104499970AIncrease concentrationReduce volumeConstructionsFlushingSolid phasesConcentration effect

The invention relates to a technological method for a drilling fluid solid control circulation system, in particular to a technological method for the treatment of drilling fluid produced during oil and gas drilling. The technological method for the drilling fluid solid control circulation system adopts the following device components: a special concentration treatment device I, a special centrifugal machine, an oil field mud pump I, a special cyclone set I, a special concentration treatment device II, an oil field mud pump II, a special cyclone set II, a special concentration treatment device III, an oil field mud pump III, a storage box, an oil field mud pump IV, a special filter press (or a special stacked spirals), a solid-phase mud cake collection barrel (or a mud transfer tank), and a circulating fluid storage tank. The technological method for the drilling fluid solid control circulation system has the following benefits: desanding, mud removal, destabilization and gel breaking in a circulating and classification manner are achieved through the two-stage special cyclone sets, so that the classifying effect is remarkable; circulating concentration is achieved through the three-stage special concentration treatment devices, so that the concentration effect is remarkable; the treated drilling fluid is recycled; treated solid-phase mud cakes or highly-concentrated mud are / is directly transported away.

Owner:山东能源重装集团莱芜装备制造有限公司 +1

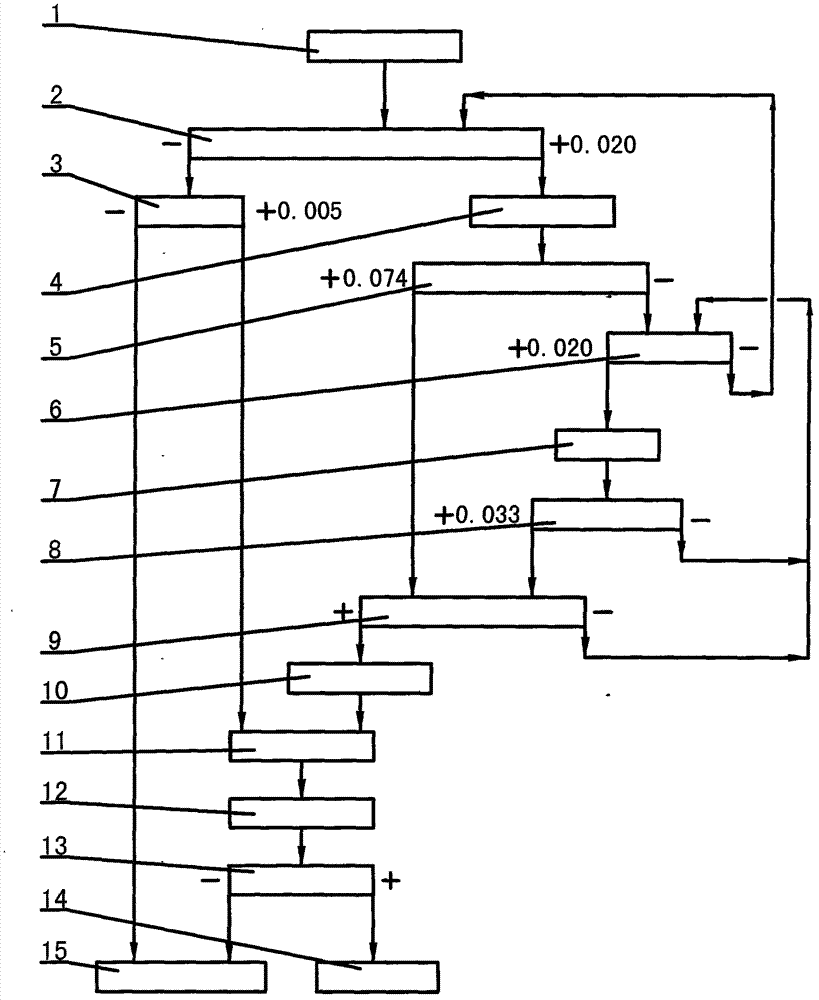

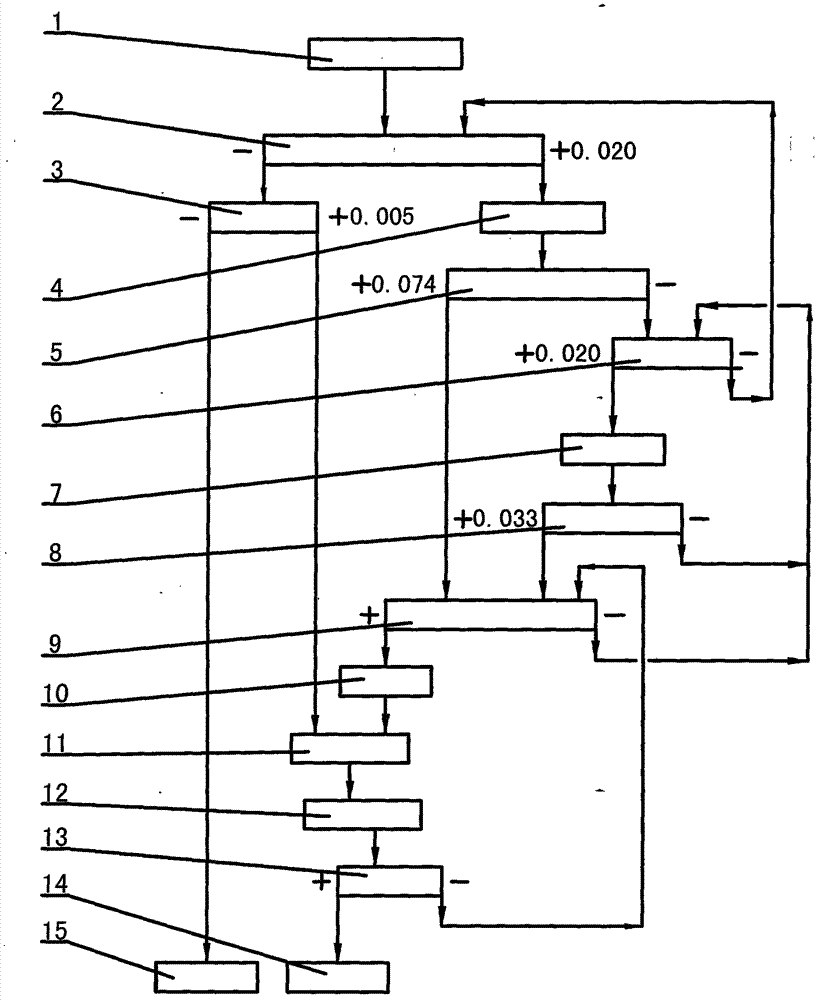

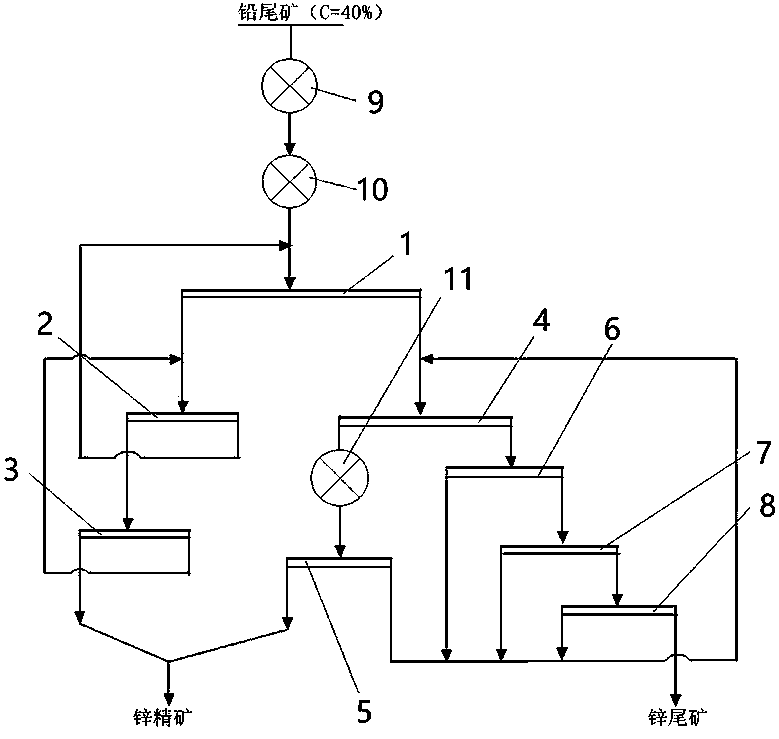

Machine-column-machine rapid and efficient zinc flotation method and system

The invention discloses a machine-column-machine rapid and efficient zinc flotation method. The method adopts the flotation procedure of one time of roughing and two times of concentration of a flotation machine, one time of roughing and one time of concentration of a flotation column and three times of sweeping of the flotation machine. Firstly, coarse particle zinc which is easy to float is rapidly produced through the flotation machine, then zinc which is floated in medium difficulty is produced in concentration of the flotation column through the flotation column, zinc which is very difficult to float is produced under synergy of the flotation column through the long-time excitation and capturing functions in the flotation machine, the floating time and procedure of the zinc minerals which are easy to float are shortened, the cyclic loss of the medium minerals is reduced, and the zinc minerals difficult to float have longer time and much chance to float. The method not only well solves the problem that the same kind of minerals have different floatability, but also solves the problem that zinc minerals of different size fractions have different floatability, achieves refine selection, remarkably improves the zinc recovery rate, achieves efficient zinc flotation, and has great importance significance for improving the zinc recovery rate and concentrate quality, saving energy, reducing consumption and achieving clean production.

Owner:南京银茂铅锌矿业有限公司

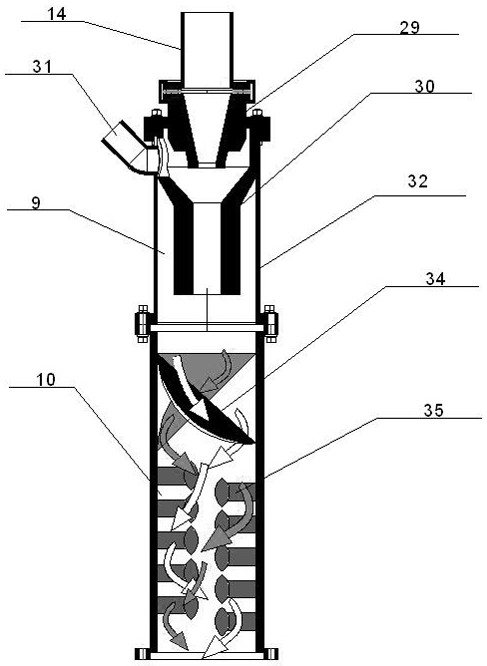

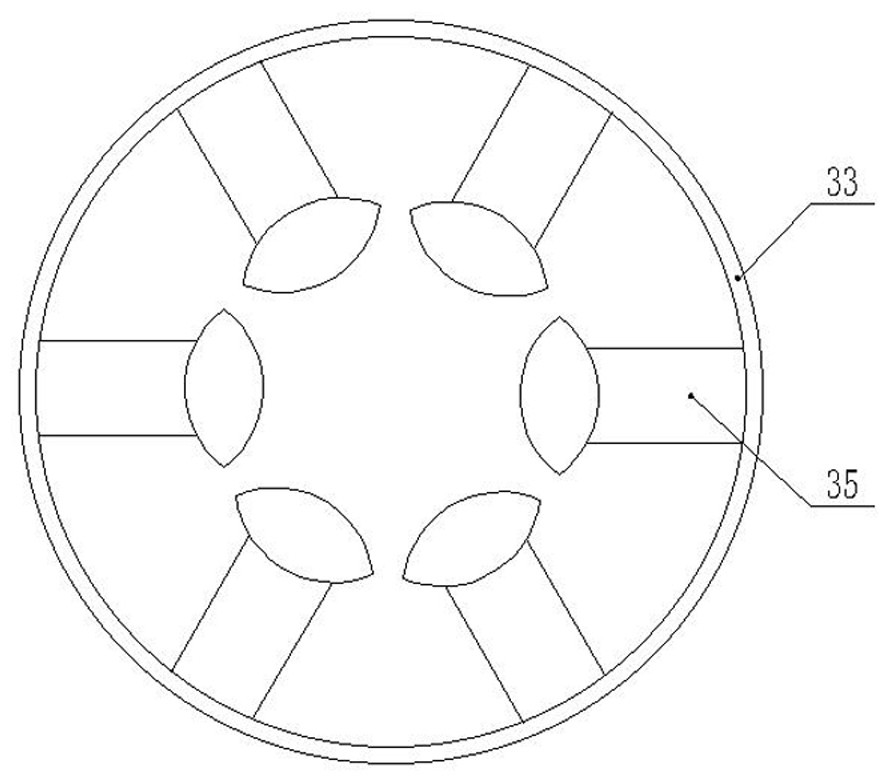

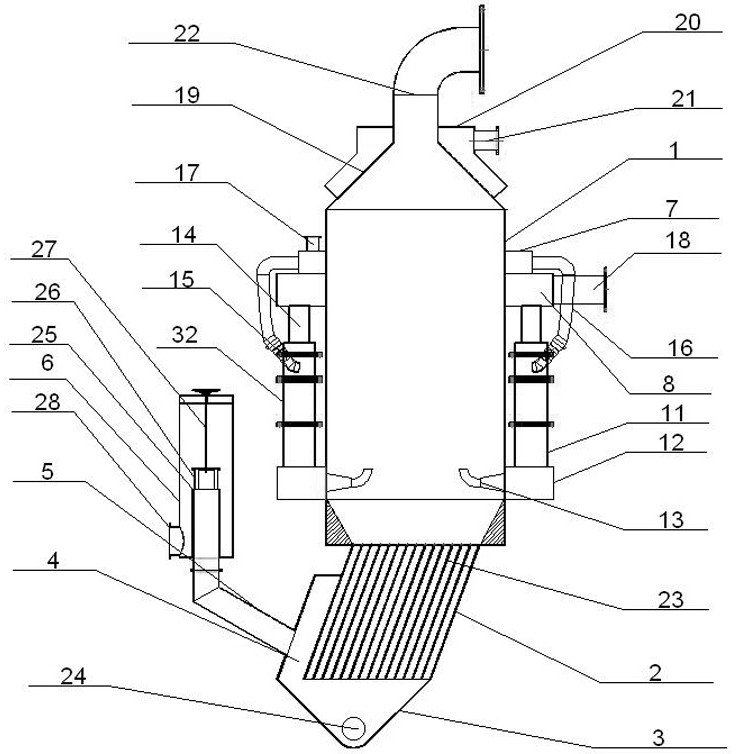

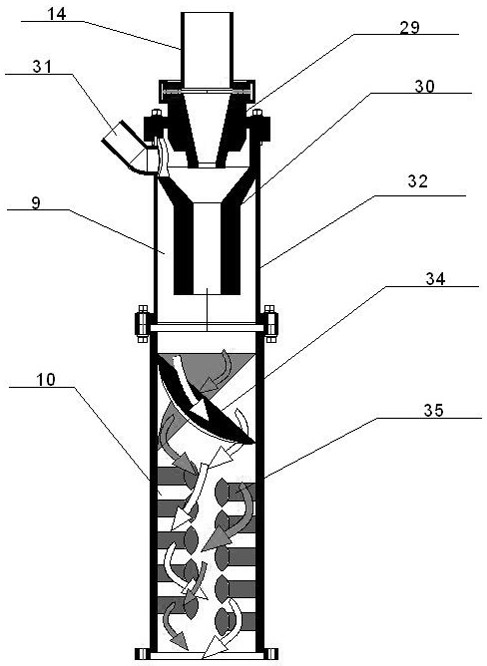

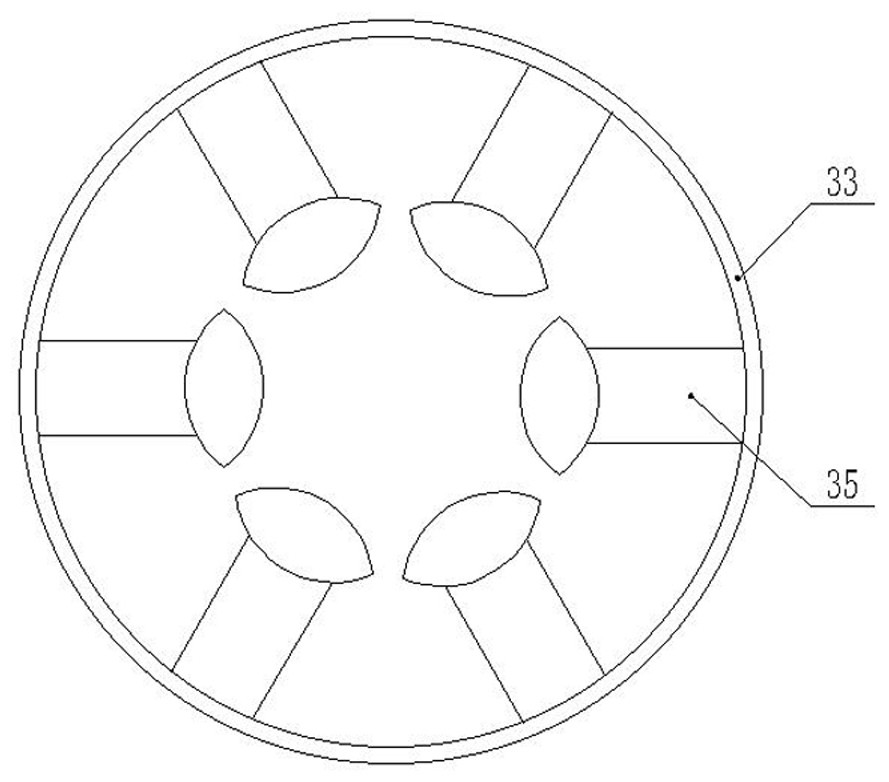

A high bubble surface flux flotation machine and particle bubble mineralizer

The invention belongs to the technical field of coal slime flotation machines, and specifically relates to a high-bubble surface flux flotation machine and a particle bubble mineralizer. A jet aerator and a slurry gas mixer, the slurry gas mixer includes guide vanes and protruding rods, the bubble mineralization efficiency of the particle bubble mineralizer is improved by setting the slurry gas mixer, the flotation machine includes a sorting bucket, The lower barrel and the tailings chamber, the upper end of the sorting barrel is provided with a fluidized water chamber, the outer side is provided with a particle bubble mineralizer, and an inclined plate is arranged on the lower barrel, then the present invention can achieve high air bubble surface flux and washing water flux Working under the same conditions to achieve flotation without free foam layer, the lower end of the flotation machine adopts inclined plate channel to strengthen the segregation of mineralized air bubbles and pulp, ensuring that the foam area is maintained in the vertical area of the upper part of the equipment, and carries the lowest amount of pulp, which improves the separation Choose an effect.

Owner:太原睿孚特选煤技术有限公司

Drilling filling pile construction method

ActiveCN110894722AEfficient dischargeClean up thoroughlyDrill bitsDerricks/mastsSocial benefitsArchitectural engineering

The invention discloses a drilling filling pile construction method, and relates to the technical field of civil engineering. The drilling filling pile construction method comprises the following steps including the first step of construction preparing, the second step of pile position lofting, the third step of protection barrel burying, the fourth step of slurry preparing and storing, the fifthstep of drilling platform construction, the sixth step of drill bit type selecting and drill tool arrangement, the seventh step of drilling, the eighth step of hole forming checking, the ninth step ofprimary hole cleaning, the tenth step of reinforcement cage hoisting placing and positioning construction, the eleventh step of secondary hole cleaning and the twelfth step of underwater concrete pouring. According to the drilling filling pile construction method, a large-diameter ultra-long drilling filling pile and a construction method are adopted, the engineering problems that under complex work conditions, drilling filling pile drilling one-time hole forming difficulty is large, hole inclining is likely to happen, perpendicularity is hard to guarantee, a coverage layer is thick, slurry leakage is likely to happen, the hole collapsing risk is large, and efficiency is low can be effectively solved, and good technical, economic and social benefits are achieved.

Owner:湖北省路桥集团有限公司

Complex twisting device for air-jet eddy-current spinning

InactiveCN1200155CIncrease spinning speedImprove labor productivityContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention belongs to the textile field and provides an air-jet vortex spinning compound twister for twisting fiber strands by using an air-jet vortex. The compound twister is composed of an upper twister and a lower twister. It uses positive pressure airflow to generate vortex field and pipe flow, and the fiber enters the vortex field through the conveying pipe. The fiber strands rotate with the high-speed rotating air flow. While the fiber strands are rotating at high speed, the pipeline flow protects and guides the fiber strands being twisted to leave the eddy current field quickly. During this process, the fiber strands are twisted and produced at high speed. There are twisted yarns. By adopting the invention, high-quality yarn can be produced at low cost and high speed.

Owner:DONGHUA UNIV

A process method of drilling fluid solid control circulation system

The invention relates to a technological method for a drilling fluid solid control circulation system, in particular to a technological method for the treatment of drilling fluid produced during oil and gas drilling. The technological method for the drilling fluid solid control circulation system adopts the following device components: a special concentration treatment device I, a special centrifugal machine, an oil field mud pump I, a special cyclone set I, a special concentration treatment device II, an oil field mud pump II, a special cyclone set II, a special concentration treatment device III, an oil field mud pump III, a storage box, an oil field mud pump IV, a special filter press (or a special stacked spirals), a solid-phase mud cake collection barrel (or a mud transfer tank), and a circulating fluid storage tank. The technological method for the drilling fluid solid control circulation system has the following benefits: desanding, mud removal, destabilization and gel breaking in a circulating and classification manner are achieved through the two-stage special cyclone sets, so that the classifying effect is remarkable; circulating concentration is achieved through the three-stage special concentration treatment devices, so that the concentration effect is remarkable; the treated drilling fluid is recycled; treated solid-phase mud cakes or highly-concentrated mud are / is directly transported away.

Owner:山东能源装备集团莱芜装备制造有限公司 +1

A sizing method for high-strength and high-modulus silicon carbide fibers

The invention discloses a sizing method for high-strength and high-modulus silicon carbide fibers. The sizing agent is prepared as follows: deionized water, epoxy resin slurry and hydrophilic softener are mixed in a mass ratio of 26-28:4-6 : 1-3 mix and stir evenly to obtain sizing agent; pre-drying: turn on the oven, and raise the temperature to 100 ℃ ~ 130 ℃; sizing: wind the silicon carbide fiber on the yarn bobbin, enter the sizing agent through the sizing roller, and remove the sizing agent The silicon carbide fiber is poured into the sizing tank for sizing treatment to obtain the sizing fiber; after drying the sizing fiber in the oven, the sizing fiber is wound on the yarn winding drum through the tension controller and the guide roller. It solves the problems existing in the prior art that the silicon carbide fibers are prone to hairiness and breakage during the sizing process, and the sizing agent is not suitable.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

Flotation machine with high bubble surface flux and particle bubble mineralization device

The invention belongs to the technical field of coal slime flotation machines, and particularly relates to a flotation machine with high bubble surface flux and a particle bubble mineralization device. The particle bubble mineralization device comprises a mineralization device shell, a jet aerator and a slurry-gas mixer; the jet aerator and the slurry-gas mixer are arranged in the mineralization device shell, and the slurry-gas mixer comprises guide blades and protruding rods; the bubble mineralization efficiency of the particle bubble mineralization device is improved by arranging the slurry-gas mixer; the flotation machine comprises a separation barrel, a lower barrel body and a tailing chamber; a fluidization water chamber is arranged at the upper end of the separation barrel, the particle bubble mineralization device is arranged on the outer side of the separation barrel, and an inclined plate is arranged on the lower barrel body, so that the flotation machine can work under the conditions of high bubble surface flux and washing water flux, and no free foam layer flotation is achieved; an inclined plate channel is adopted at the lower end of the flotation machine to strengthen separation of mineralized bubbles and ore pulp, it is ensured that a foam area is maintained in a vertical area on the upper portion of the equipment, the lowest ore pulp amount is carried, and the separation effect is improved.

Owner:太原睿孚特选煤技术有限公司

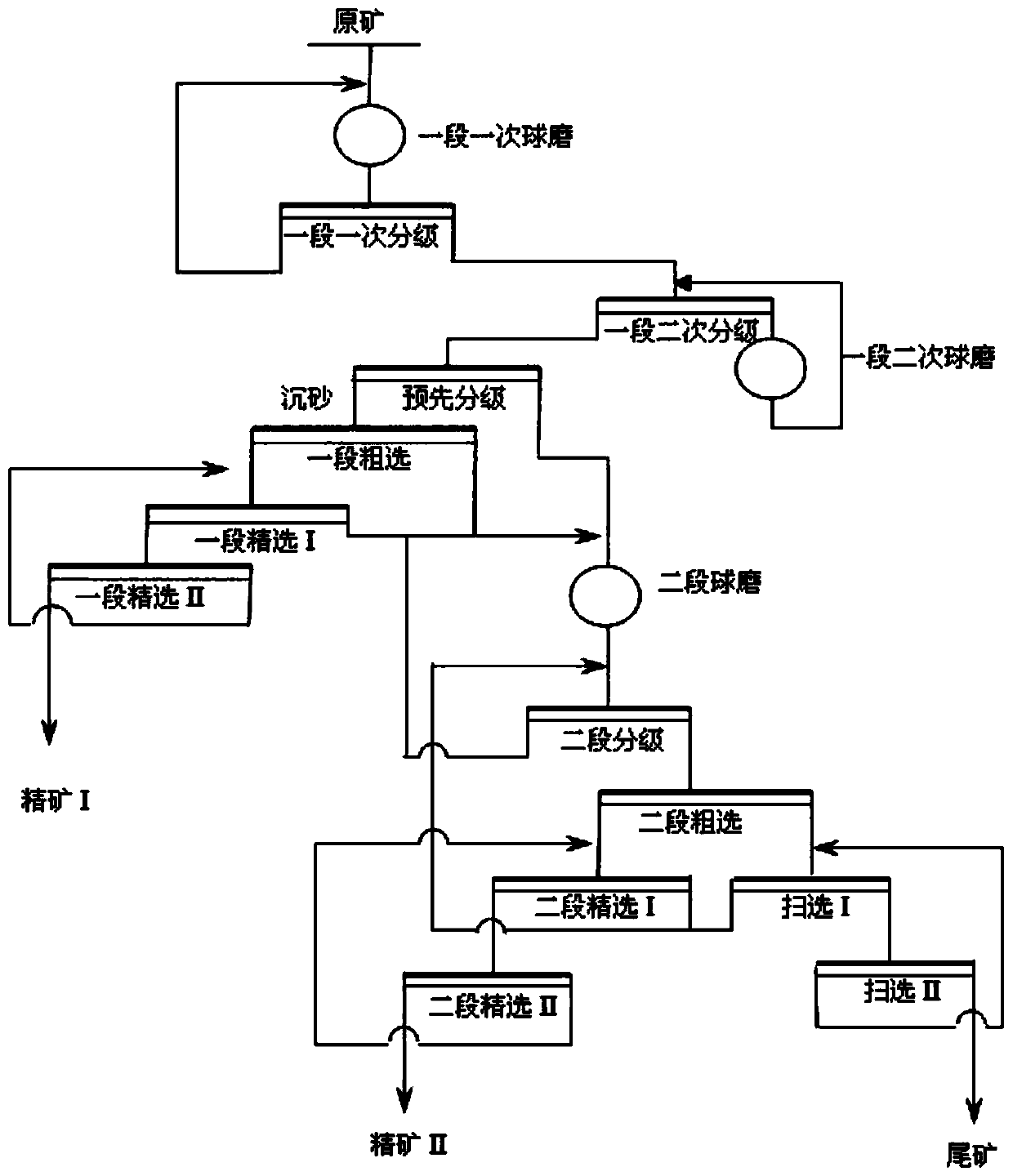

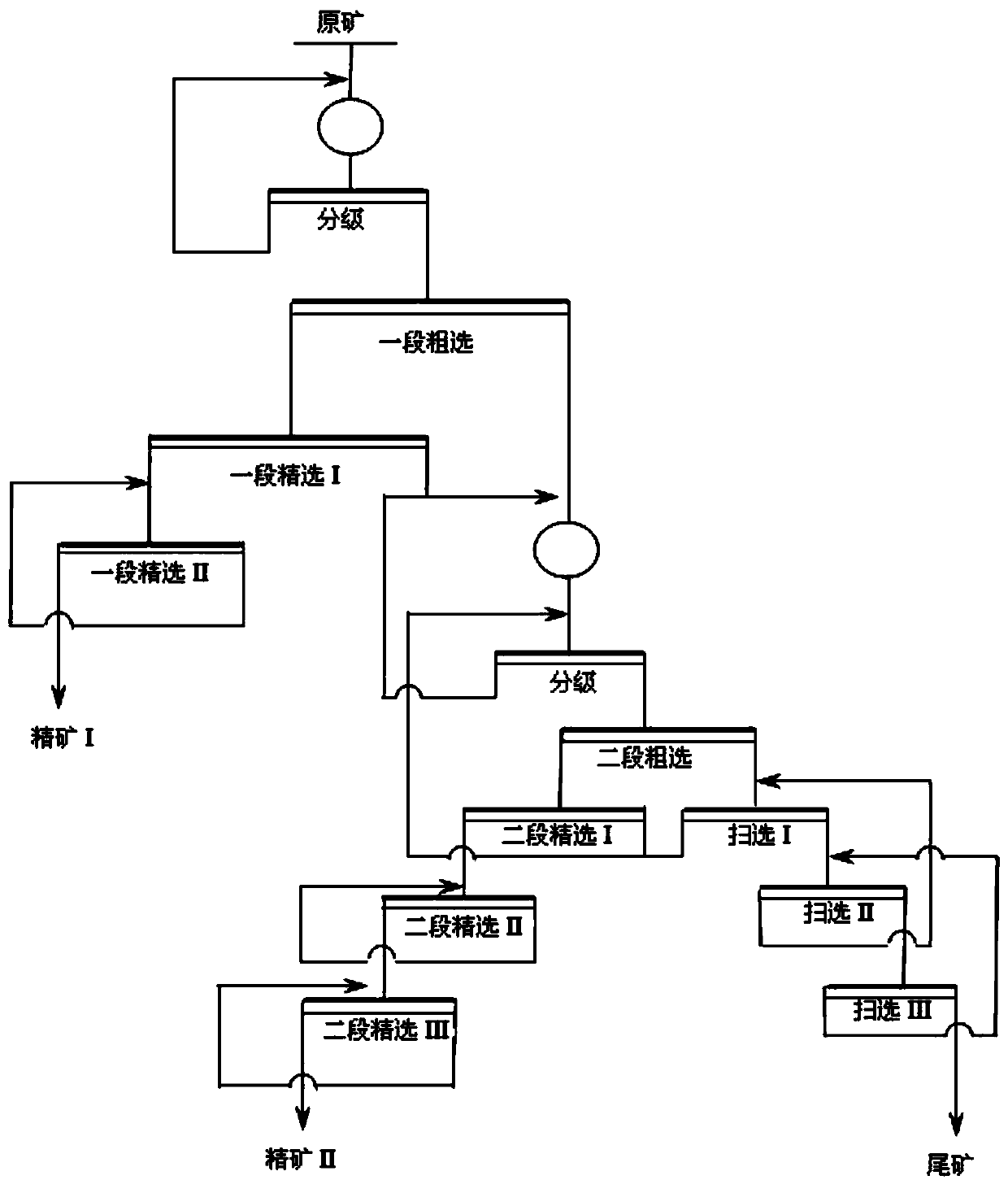

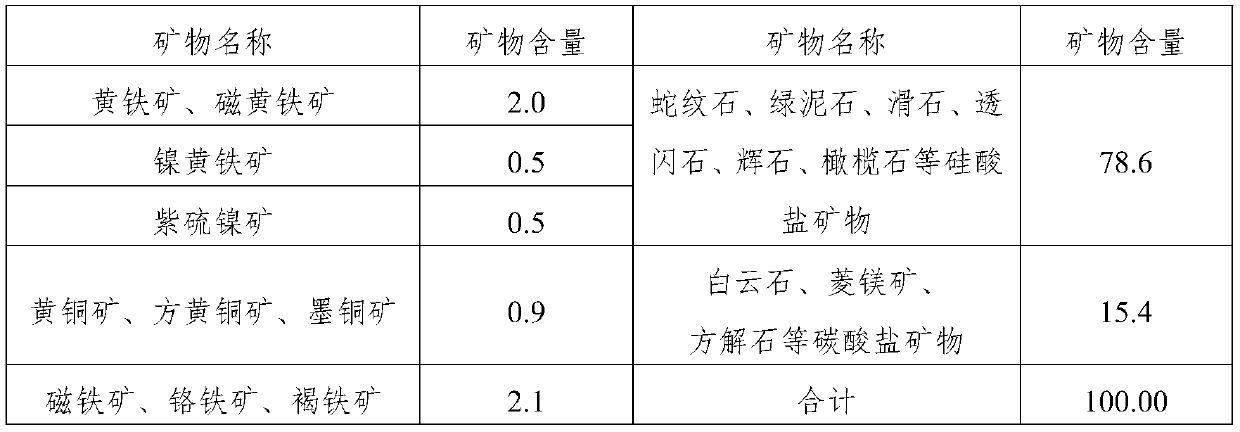

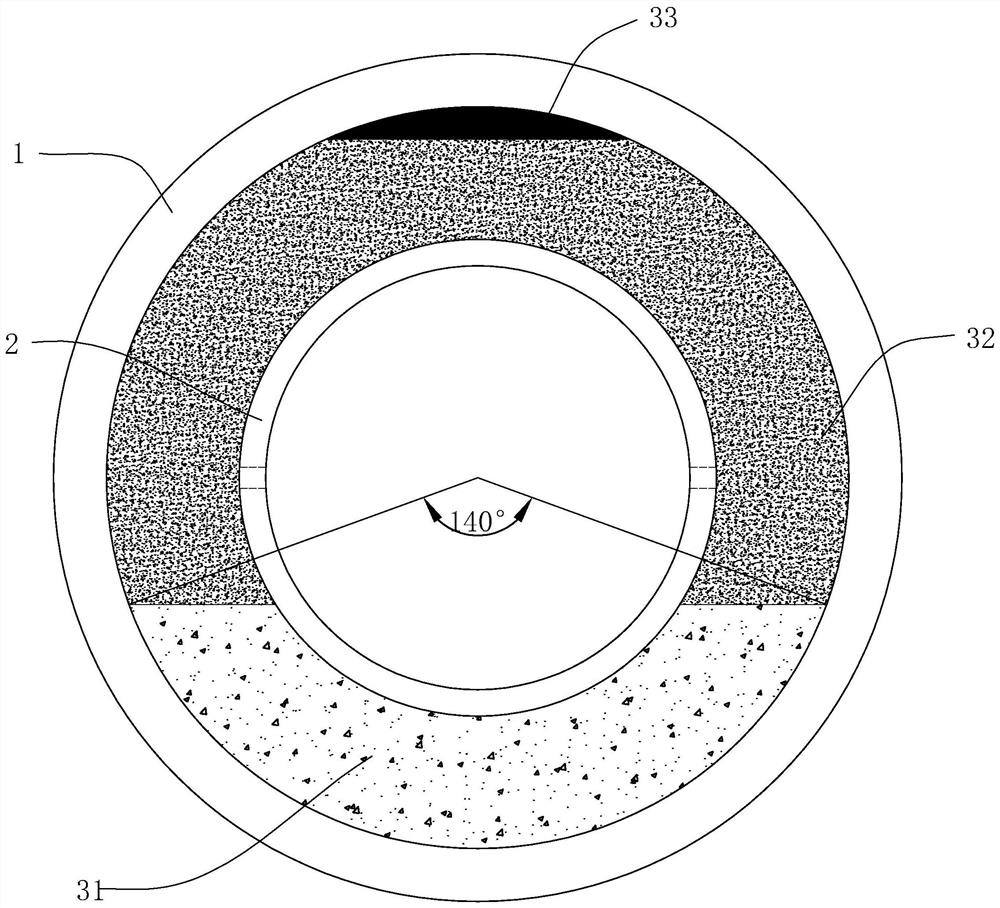

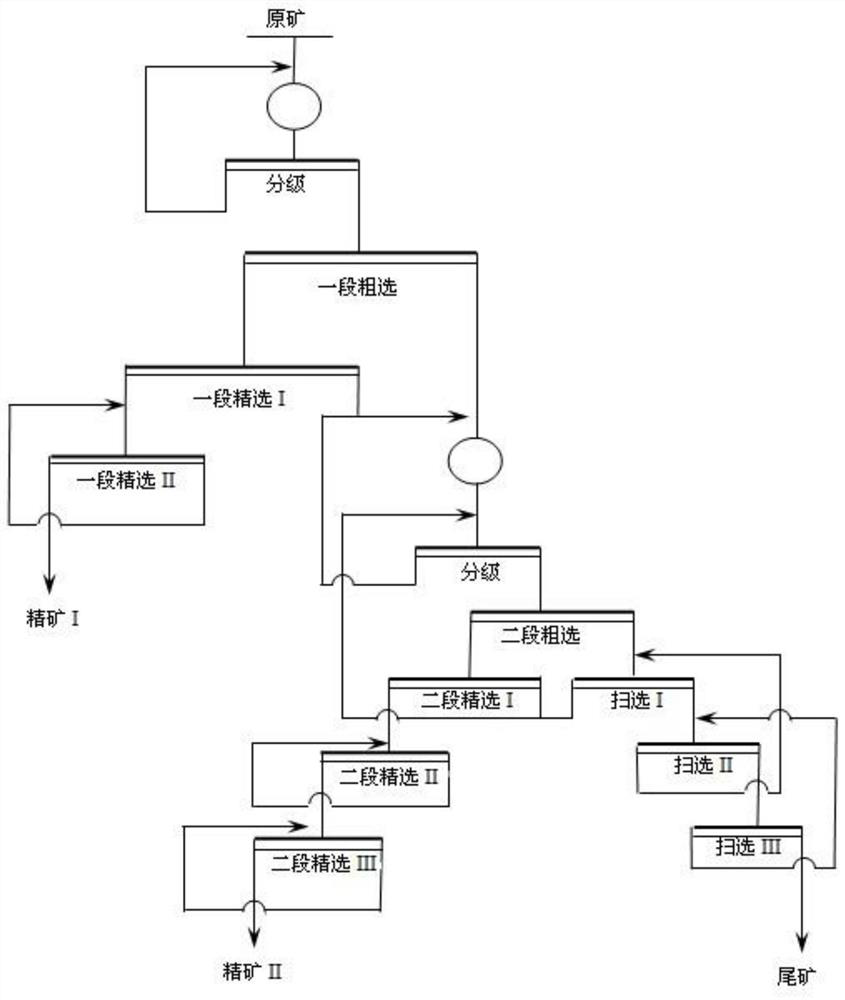

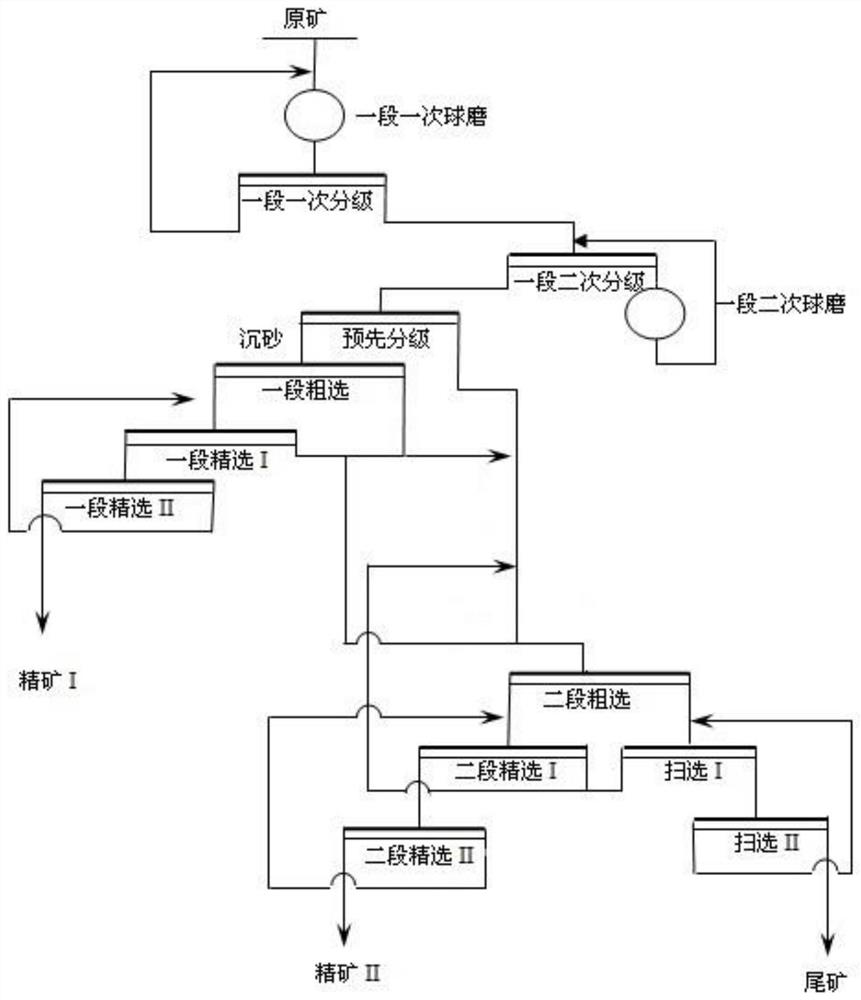

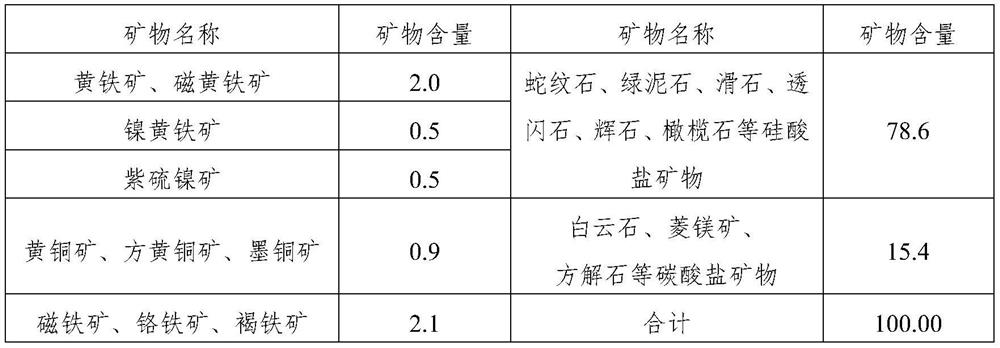

Asynchronous simultaneous separation process of poor and difficult-to-separate nickel-copper ore

ActiveCN111282710AImprove sorting indexImproving and increasing the efficiency of flotation operationsSolid separationEngineeringCopper sulfide

The invention discloses an asynchronous simultaneous separation process of poor and difficult-to-separate nickel-copper ore. A cyclone centrifugal separation beneficiation technology is adopted, a part of gangue and metal minerals with low nickel-copper grade and fine granularity and meeting secondary flotation conditions are separated in advance in an ore grinding loop before flotation of the low-grade poor and difficult-to-separate copper sulfide ore, and directly enter the secondary flotation, so that the recovery rate of nickel-copper metal and the concentrate quality are improved. According to the asynchronous simultaneous separation process of the poor and difficult-to-separate nickel-copper ore, a process for pre-grading an ore grinding product by utilizing centrifugal gravity ore beneficiation equipment is applied to the ore grinding loop of a copper-nickel ore beneficiation flow. The asynchronous simultaneous separation process of the poor and difficult-to-separate nickel-copper ore can improve the flotation operation efficiency of each section, reduces the process energy consumption, achieves the purpose of improving the final copper-nickel separation index, and is economical, applicable, simple and good in beneficiation effect.

Owner:JINCHUAN GROUP LIMITED

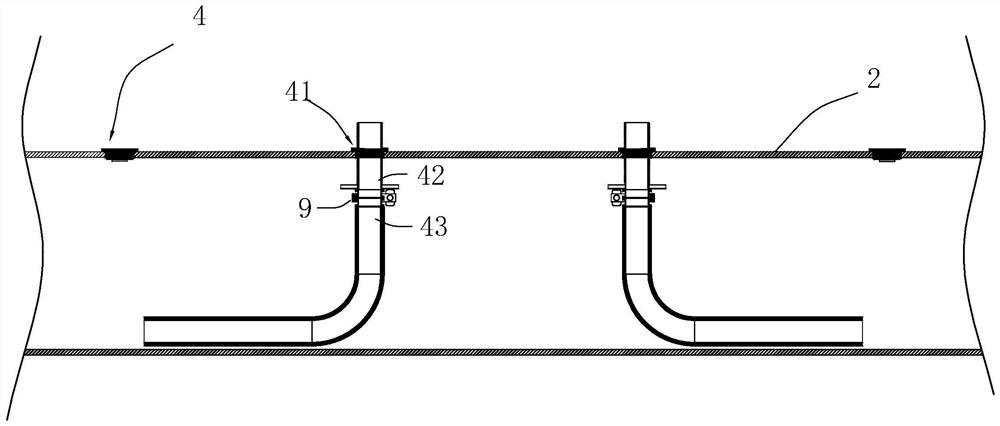

A construction method for pouring concrete through the back of the steel pipe

ActiveCN110984153BReduce height differenceGuaranteed StrengthUnderground chambersFoundation engineeringArchitectural engineeringPipe

The invention discloses a construction method for pouring concrete through the back of a steel pipe. The technical scheme includes preparation work, pouring of the first-stage concrete, pouring of the second-stage concrete, grouting construction and anti-corrosion treatment. Install exhaust pipes and grouting pipes on the top of the annular layer that penetrates the steel pipe and concrete pipe, and build walls at both ends of the annular layer to seal. A plurality of ash filling ports are opened at the top of the pierced steel pipe. The pouring pipe is connected with the ash pouring port, and the first stage concrete is poured; when the height of the concrete is close to the middle height of the pierced steel pipe, the pouring pipe is moved to the next ash pouring port, and the pouring steps are repeated. Install the pouring pipe again and start pouring the second stage concrete. When the next ash pouring port is evenly and stably leaking grout, stop pouring, the pouring pipe moves to the next ash pouring port, and the pouring ash pouring port is permanently blocked. Inject grout into the grouting pipe to fill the top cavity. Carry out anti-corrosion treatment on the ash filling port. The invention has the advantages of making poured self-tight concrete more plump and reducing the amount of grouting.

Owner:北京京水建设集团有限公司

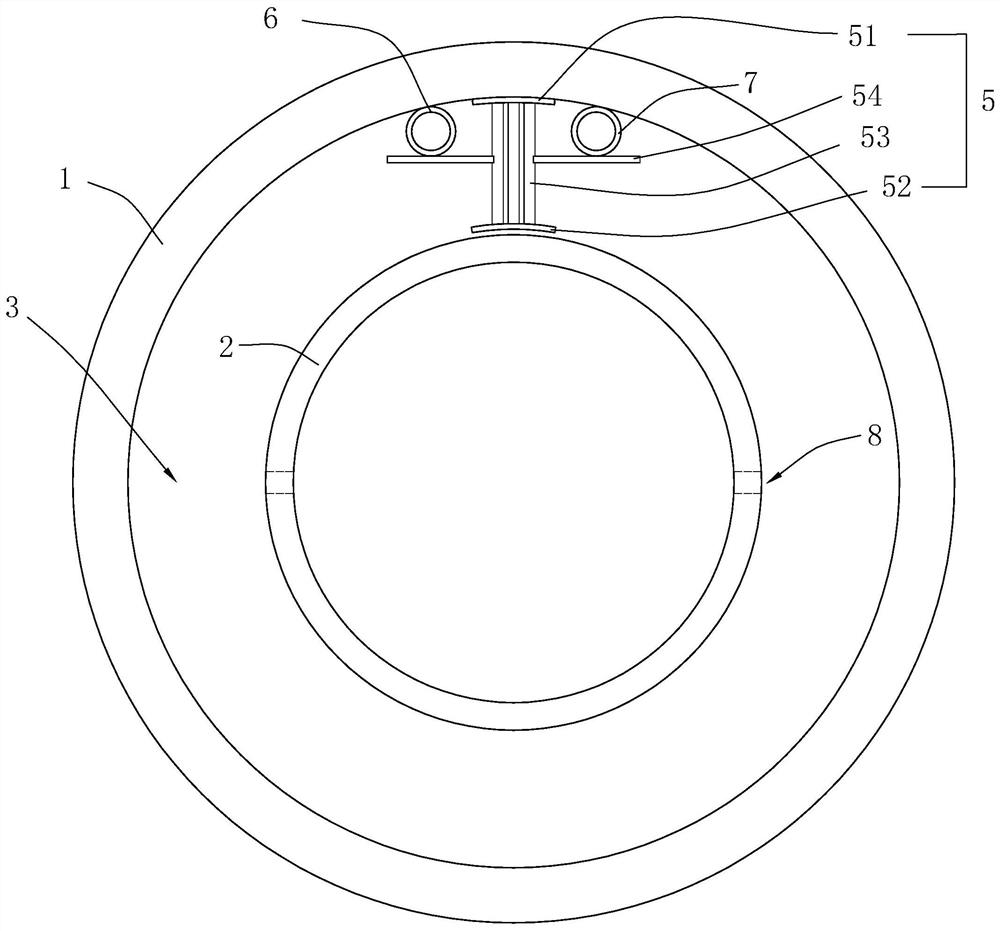

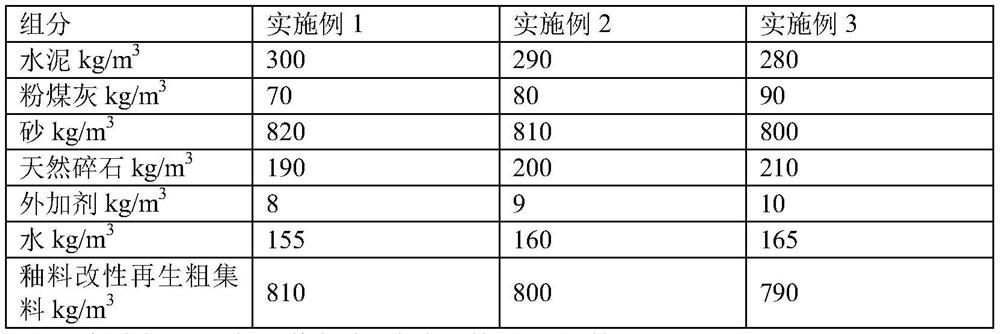

A kind of recycled concrete and its preparation method

Owner:西安顺通建材有限责任公司

Recycled concrete and preparation method thereof

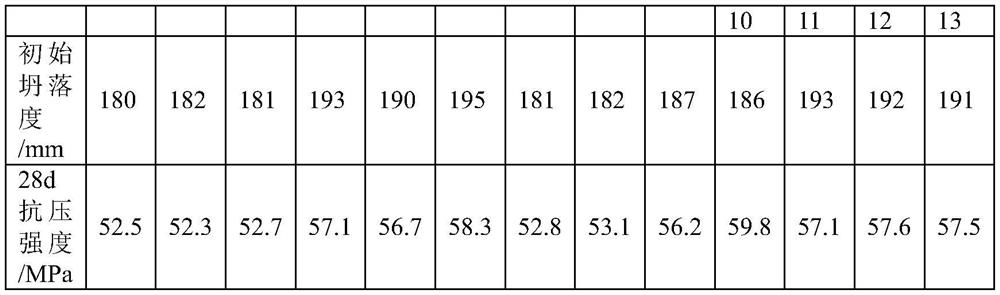

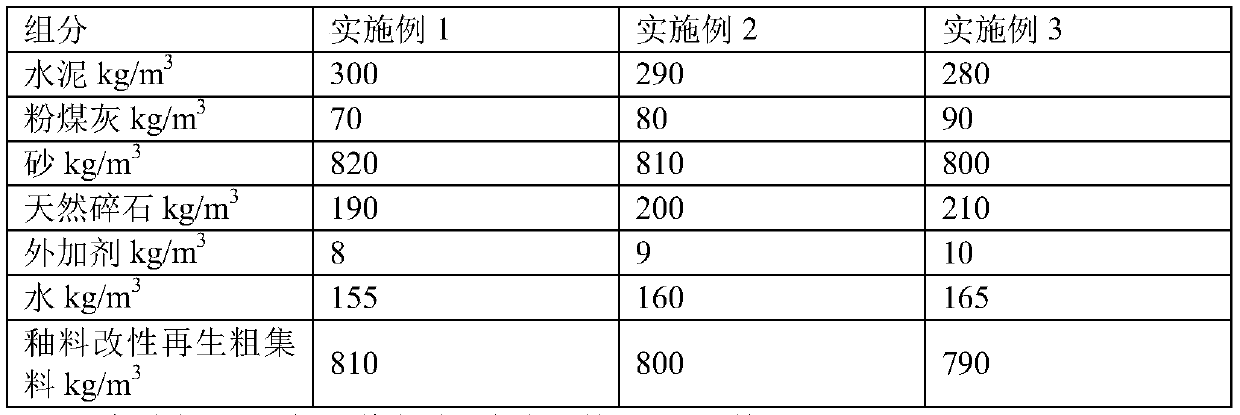

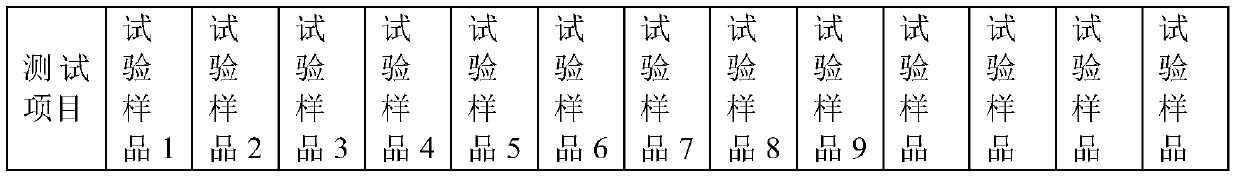

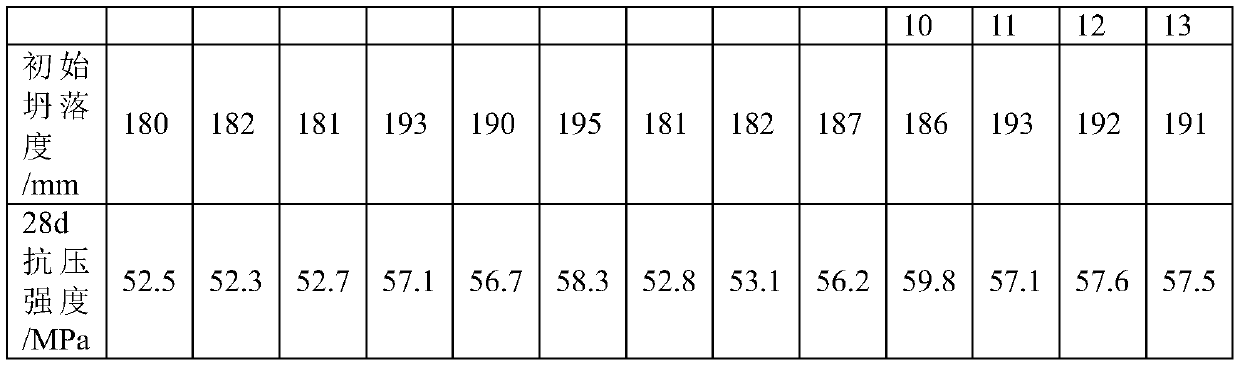

The invention discloses recycled concrete and a preparation method thereof, and relates to the technical field of concrete. The technical key points are as follows: the raw materials comprise the following components in parts by weight: 280-300 kg / m < 3 > of cement; 70-90 kg / m < 3 > of fly ash; 800 to 820 kg / m < 3 > of sand; 790 to 810 kg / m < 3 > of glaze modified recycled coarse aggregate; 190-210 kg / m < 3 > of natural gravel; 8-10 kg / m < 3 > of an additive; and 155-165k kg / m < 3 > of water. The recycled concrete provided by the invention has the advantage of improving the slump and mechanical strength of recycled concrete.

Owner:西安顺通建材有限责任公司

Construction method of bored pile

ActiveCN110894722BEfficient dischargeClean up thoroughlyDrill bitsDerricks/mastsSocial benefitsArchitectural engineering

The invention discloses a construction method for bored piles, and relates to the technical field of civil engineering. The present invention comprises the following steps: step 1: construction preparation; step 2: stake out; step 3: bury casing; step 4: mud preparation and storage; step 5: drilling platform construction; step 6: drill bit selection and Drilling tool configuration; Step 7: Drilling; Step 8: Hole inspection; Step 9: Cleaning the hole once; Step 10: Reinforcement cage hanging and positioning construction; Step 11: Secondary hole cleaning; Step 12: Water injection Lower the concrete. The present invention adopts the large-diameter super-long bored pile and its construction method, which can effectively solve the difficulty of drilling the bored pile once in complex working conditions, the holes are easy to be inclined, the verticality is difficult to guarantee, the covering layer is thick, and it is easy to leak. It has good technical, economic and social benefits.

Owner:湖北省路桥集团有限公司

Construction method for pouring concrete at back of tunnel-through steel pipe

ActiveCN110984153AReduce the amount of slurryGuaranteed StrengthFoundation engineeringSteel tubeGrout

The invention discloses a construction method for pouring concrete at the back of a tunnel-through steel pipe. The technical scheme is as follows: the construction method comprises preparatory work, pouring of first-stage concrete, pouring of second-stage concrete, grouting construction and preservative treatment. The construction method specifically comprises the following steps of mounting an exhaust pipe and a grouting pipe on the tops of annular layers of the tunnel-through steel pipe and a concrete pipe, and building walls at two ends of the annular layers to block the annular layers; forming a plurality of ash filling ports in the top end of the tunnel-through steel pipe; communicating pouring pipes to the ash filling ports, and starting pouring of the first-stage concrete; when theheight of the concrete is close to the height of the middle of the tunnel-through steel pipe, moving the pouring pipes to the next ash filling port for repeating the pouring step; mounting the pouringpipes again, and starting pouring of the second-stage concrete; during uniform and stable grout leakage of the next ash filling port, stopping pouring, and moving the pouring pipes to the next ash filling port to block the poured ash filling ports permanently; carrying out grouting to the grouting pipe to fill a top cavity fully; and carrying out preservative treatment on the ash filling ports. The construction method has the advantages that the poured self-sealed concrete is fuller and the slurry supplementing amount is reduced.

Owner:北京京水建设集团有限公司

A method suitable for preparing manganese sulfate electrolyte by leaching pyrolusite with sulfur dioxide

ActiveCN107699714BIncrease the solid-to-liquid ratioIncrease profitHigh concentrationPregnant leach solution

The invention provides a method for preparing a manganese sulfate electrolyte by leaching pyrolusite through sulfur dioxide. According to the main concept, the method comprises the steps that only a part of an anolyte and whole-process pyrolusite are used for preparing a fluid, and after the fluid reacts with the sulfur dioxide, a high-concentration manganese sulfate solution is obtained; after the other part of the anolyte is neutralized and subjected to liquid-solid separation, a low-concentration manganese sulfate solution with the manganese sulfate concentration being identical to that ofthe prior anolyte is obtained; and the two manganese sulfate solutions are blended to obtain the qualified electrolyte with the manganese sulfate concentration meeting electrolysis requirements. By adopting the method, the utilization efficiency of the sulfur dioxide and the pyrolusite in the leaching process can be improved, and the capital construction cost and operation cost of a leaching technology and a leachate impurity removing technology are lowered.

Owner:SICHUAN UNIV

A Consumption Reduction Technology of Iron Tailings Slurry Intermittent Grinding

ActiveCN113333150BReduce energy consumptionReduce consumptionMechanical material recoveryWet separationProcess engineeringSlurry

The present invention relates to a process for intermittent grinding of iron dressing tailings slurry to reduce consumption. The process includes the following steps: (1) Storage: the iron dressing tailings slurry with a slurry volume greater than 600t / h enters the pump box, and then feeds it into a hydrocyclone Classification by the filter to obtain graded grit and graded overflow pulp; graded grit is fed into the high-frequency linear vibrating screen to obtain under-screen materials and over-screen coarse-grained materials; under-screen materials enter the pump box, and over-screen coarse-grained materials are stored in Coarse material cache stacking plant; ⑵Material holding: When the slurry volume of iron ore tailings is 500~600t / h, start the wet overflow ball mill, stop the high frequency linear vibrating screen, and feed the graded grit into the wet overflow type ball mill for grinding operation, and the ore slurry A after grinding enters the pump box; (3) loss of material: when the slurry amount of the iron ore tailings slurry is less than 500t / h, the coarse material on the grading sand settling and sieve is fed into the wet overflow at the same time The flow-type ball mill performs the grinding operation, and the ore slurry B enters the pump box after grinding. The invention has remarkable effect of reducing consumption and can ensure stable production process and indicators.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Dual-circulation absorption tower

ActiveCN101927125BImprove the operating environmentImprove desulfurization efficiencyUsing liquid separation agentFlue gasTower

Owner:浙江博众数智科技创新集团有限公司

A method to effectively improve the efficiency of black tungsten beneficiation

ActiveCN104096627BRaise the gradeImprove work efficiencyGrain treatmentsMagnetic separatorMineral processing

The invention discloses a method for effectively improving the mineral processing efficiency of wolframite. The method comprises the following steps: after raw ores of the wolframite are crushed, the wolframine and impurities are fully separated through the flow of multistage grinding-size grading-strong magnetic separation; and the wolframite is enriched in quantity by a high gradient magnetic separator before being floated, so that the separation of the wolframite and the impurities is realized, tailings of the wolframite is discarded in quantity before the wolframite is floated, and efficiency of the technological process is further improved. The method has the following main characteristics that (1) the flow of multistage grinding and size grading creates conditions for the strong magnetic enrichment and the tailing discarding operation; (2) the mineral processing process is improved, and the flotation feeding index is enhanced; (3) the flotation reagent dosage and the production cost are reduced, and the efficiency of the whole technological process is improved; and (4) the full dissociation and the beforehand tailing discarding of minerals are realized through the novel process, so that the flotation flow is simplified, the efficiency of the whole technological process and the wolframite mineral processing index are enhanced, and the comprehensive utilization ratio of resources is improved.

Owner:赣州金环磁选科技装备股份有限公司

Asynchronous and simultaneous separation process of poor and difficult nickel-copper ore

ActiveCN111282710BImprove sorting indexImproving and increasing the efficiency of flotation operationsSolid separationEngineeringNickel sulfide

A kind of asynchronous co-separation process of poor and difficult nickel-copper ore of the present invention adopts cyclone centrifugal separation ore dressing technology, and selects a part of nickel in advance in the grinding circuit before flotation of low-grade poor and difficult separation copper-nickel sulfide ore The gangue and metal minerals with low copper content, fine particle size and meeting the conditions of the second-stage flotation are allowed to directly enter the second-stage flotation, so as to improve the recovery rate of nickel-copper metal and the quality of the concentrate. The present invention applies the process of pre-grading grinding products by centrifugal gravity beneficiation equipment to the ore grinding circuit of the copper-nickel ore beneficiation process. The invention can improve and enhance the flotation operation efficiency of each stage, reduce process energy consumption, achieve the purpose of improving the final copper-nickel separation index, and is economical, applicable, simple and has good beneficiation effect.

Owner:JINCHUAN GROUP LIMITED

Fiber strand aggregating device for air slide

InactiveCN1195111CLow costReduce the amount of slurryDrafting machinesContinuous wound-up machinesEngineeringHigh intensity

The present invention is fiber strand aggregating device for air slide, and its novel design is its aggregating roller with new splitting guide flute and porous aggregating flute. It is installed between the front jaw and the spinning section in the drawing area of spinnin frame, and the air slide fiber strand aggregating device and the front roller form one fiber jaw. By means of the additional aggregating air flows, one flow field for fiber inside the guide flute and the aggregating flute is provided. By means of splitting and guide of the guide flute and the aggregating flute and the aggregation of fiber strand in the aggregating flute, the fiber strand is twisted closely in the aggregating flute. The yarn of the present invention has improved axial parallel degree, decreased hairy feather amount outside the yarn and raised yarn strength.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com