A Consumption Reduction Technology of Iron Tailings Slurry Intermittent Grinding

An intermittent, pulp technology, applied in solid separation, mechanical material recovery, chemical instruments and methods, etc., can solve the waste of energy consumption in grinding and classification, large fluctuation in the amount of slurry in iron beneficiation tailings, and low cyclic load in grinding and classification, etc. problems, to achieve the effect of reducing grinding energy consumption and steel ball consumption, stable production process and technical indicators, and reducing grinding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

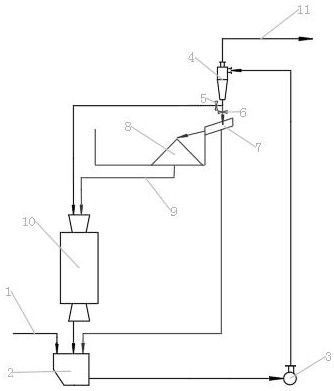

[0025] Example 1 as figure 1 As shown, a process for reducing consumption by intermittent grinding of iron dressing tailings slurry includes the following steps:

[0026] ⑴Storage:

[0027] The iron beneficiation tailings slurry 1 with a slurry volume of more than 600t / h enters the pump box 2, and then is fed into the hydrocyclone 4 through the slurry pump 3 for classification, and the proportion of the composition of the classified sand settling and the -0.074mm particle size is obtained as follows: 60%~80% of graded overflow pulp 11; graded sand settling is fed into high-frequency linear vibrating screen 7 to obtain under-screen materials and over-screen coarse-grained materials with a particle size of +0.25mm~+0.5mm; under-screen materials enter Pump box 2, the coarse-grained material on the screen is stored in the coarse-grained material buffer plant 8. The particle size composition of the classified overflow pulp 11 needs to meet the requirements of flotation, and then ...

Embodiment 2

[0034] Example 2 A process for reducing consumption by batch grinding of iron beneficiation tailings slurry is the same as that in Example 1. Among them: the hydraulic classification overflow is -0.074mm and the mass fraction of the particle size composition is 70%.

Embodiment 3

[0035] Example 3 A process for reducing consumption by batch grinding of iron beneficiation tailings slurry is the same as that in Example 1. Among them: the particle size of the coarse-grained material on the sieve is +0.375mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com