Machine-column-machine rapid and efficient zinc flotation method and system

A column machine and fast technology, applied in the field of fast and efficient zinc separation method and system of column machine, can solve the problems of high resource recovery rate, high beneficiation cost, high reagent consumption, etc., achieve smooth process, prolong flotation time, and operate Reliable and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method of fast and efficient zinc selection by the column machine of this machine includes the following steps:

[0035]A. The slurry of lead tailings (concentration is about 40%) is sucked into the No. 1 lifting mixing tank, adding copper sulfate 300-400g / t to activate zinc minerals, adding lime 3000-4000g / t (pH=11.0-11.5), adjusting pH, Inhibit pyrite, add pine oil 10-20g / t for foaming, stir for 10 minutes, then enter No. 2 stirring, add butyl xanthate 150-200g / t as zinc mineral collector, stir for 10 minutes, pass through the pipeline Enter the fast selection flotation machine for a fast roughing, and then pass through the first selection flotation machine and the second selection flotation machine for two fast selections to obtain zinc concentrates containing 55-57% zinc , The recovery rate of zinc operation is about 60%. Add lime 1000-1500g / t and pH =12.0-12.2 to the secondary selection flotation machine to adjust the pH and further suppress pyrite. The tailing...

Embodiment 2

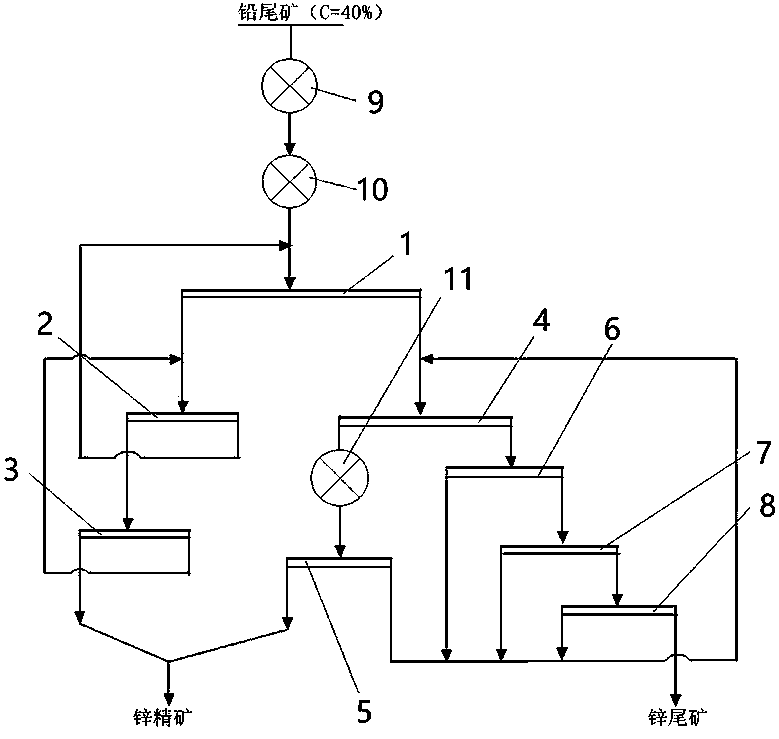

[0039] The column machine of this machine is a fast and efficient zinc separation system, including fast separation flotation machine 1, first selection flotation machine 2, second selection flotation machine 3, rough selection flotation column 4, selection flotation column 5, The first scavenging flotation machine 6, the second scavenging flotation machine 7, the third scavenging flotation machine 8;

[0040] The concentrate outlet of the quick separation flotation machine 1 is connected with the pulp inlet of the first concentration flotation machine 2, and the tailings outlet is connected with the pulp inlet of the rougher flotation machine 4;

[0041] The concentrate outlet of the first concentration flotation machine 2 is connected to the pulp inlet of the second concentration flotation machine 3, and the tailings outlet is connected to the pulp inlet of the quick separation flotation machine 1;

[0042] The concentrate outlet of the second concentration flotation machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com