Patents

Literature

56 results about "Time of concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Time of concentration is a concept used in hydrology to measure the response of a watershed to a rain event. It is defined as the time needed for water to flow from the most remote point in a watershed to the watershed outlet. It is a function of the topography, geology, and land use within the watershed. We can find time of concentration from the KIRPICH EQ.(1940). Time of concentration is useful in predicting flow rates that would result from hypothetical storms, which are based on statistically derived return periods through IDF curves. For many (often economic) reasons, it is important for engineers and hydrologists to be able to accurately predict the response of a watershed to a given rain event. This can be important for infrastructure development (design of bridges, culverts, etc.) and management, as well as to assess flood risk such as the ARkStorm-scenario.

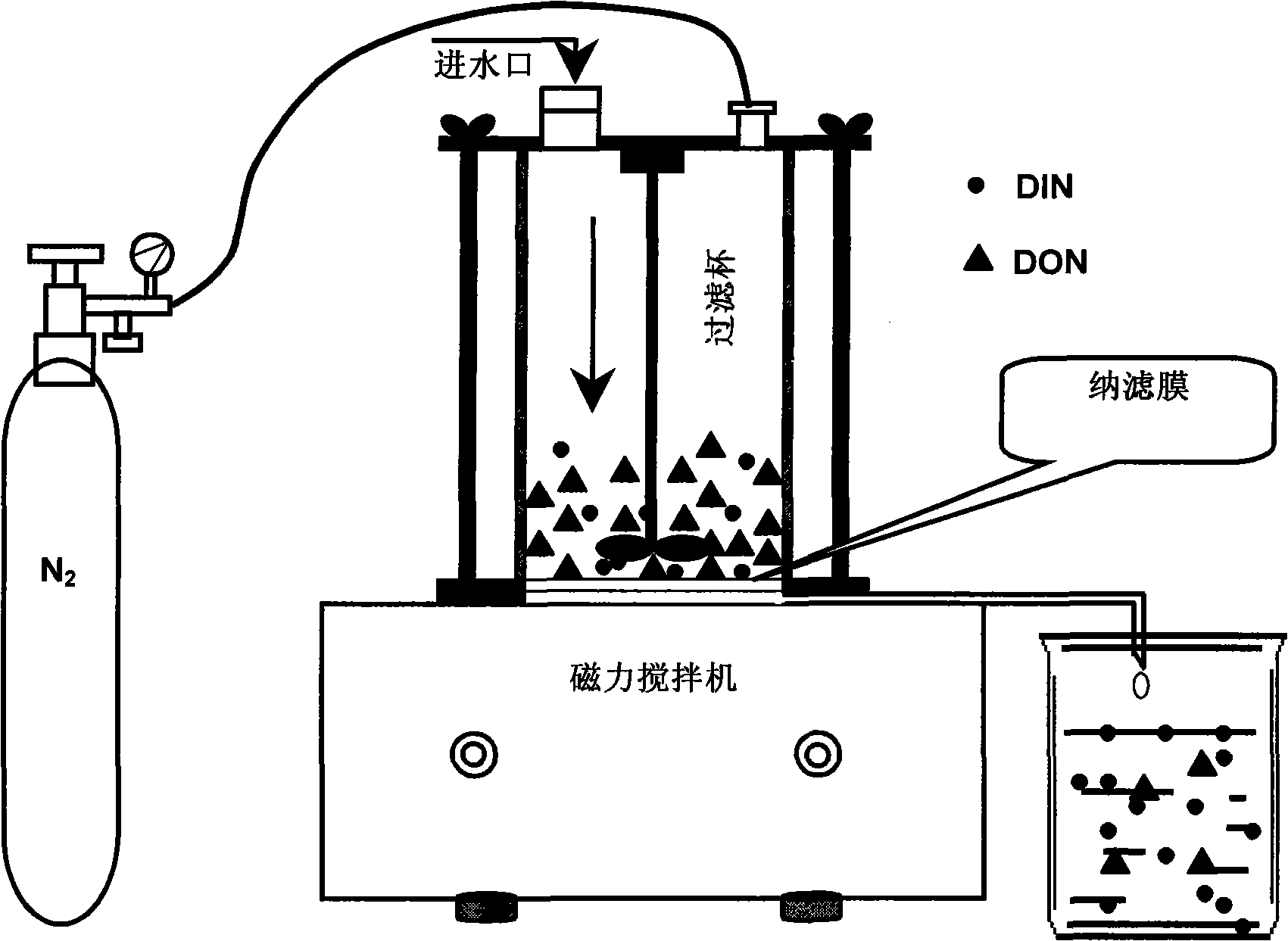

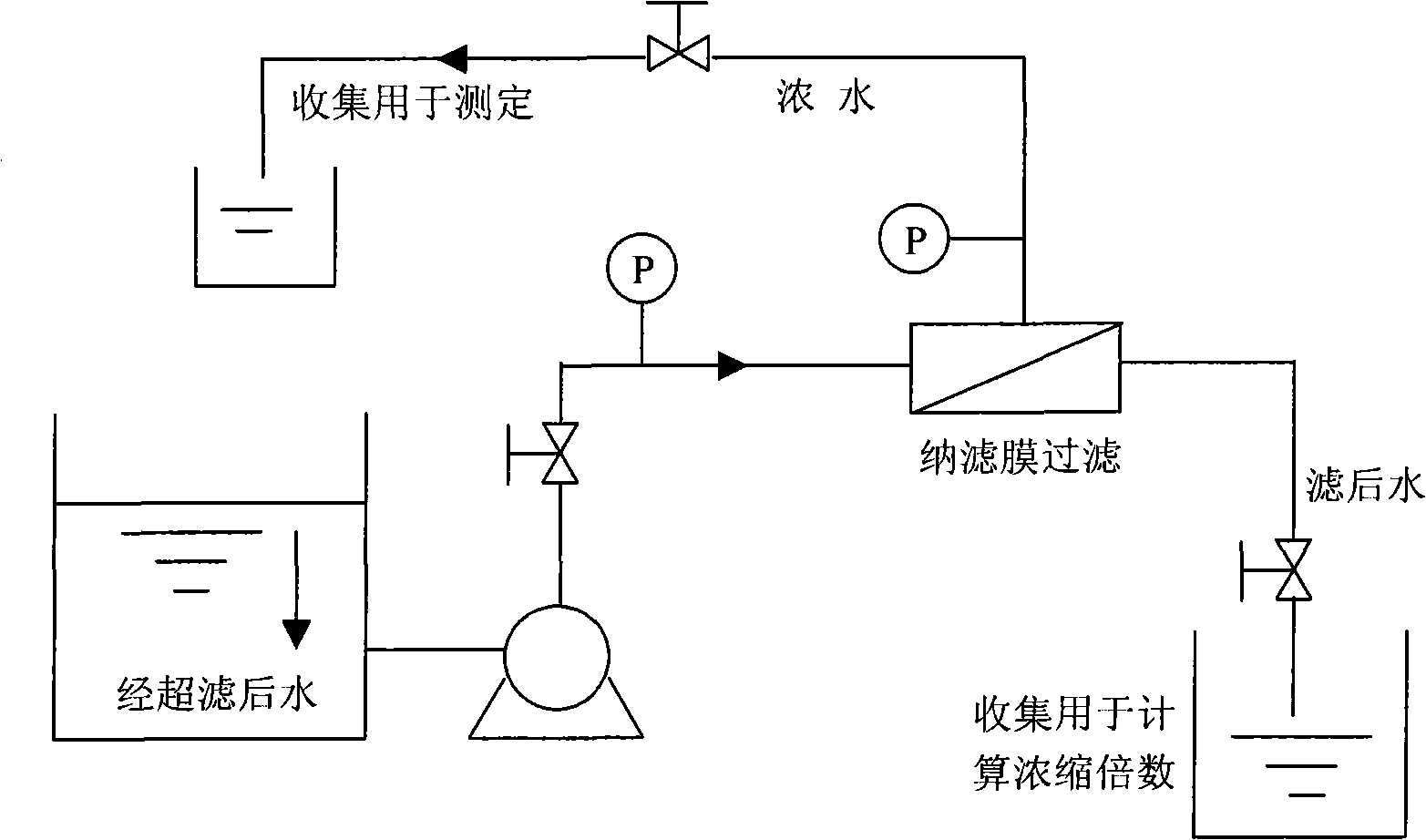

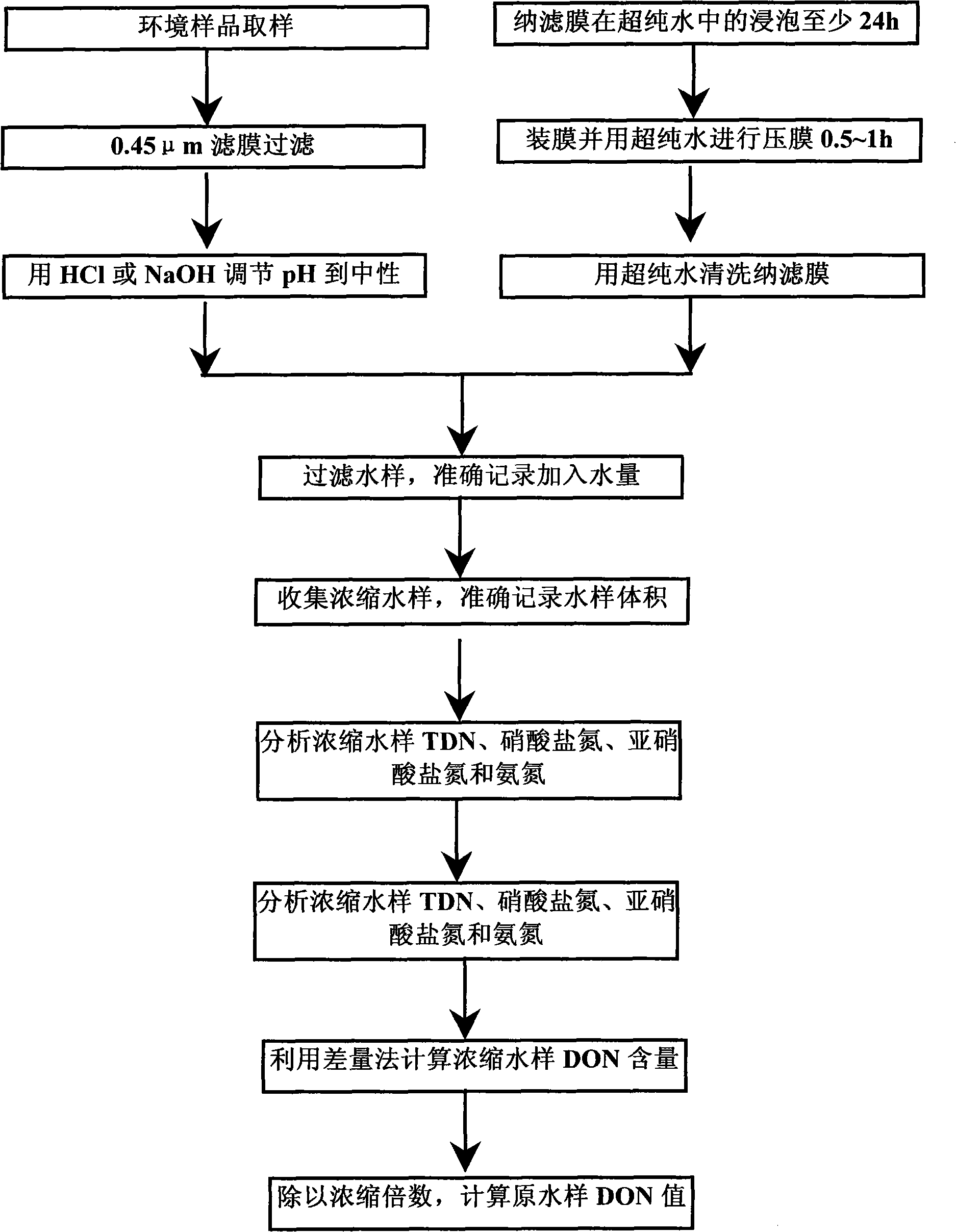

Method for measuring concentration of low-concentration soluble organic nitrogen in water

ActiveCN101782566AReduce the ratioIncrease contentComponent separationPreparing sample for investigationSolubilityFiltration membrane

The invention relates to a method for measuring concentration of low-concentration soluble organic nitrogen in water, in which the nano filtration membrane separation technology is employed to accurately measure concentration of soluble organic nitrogen. In the preparation process before pretreatment, membrane with a pore diameter being more than or equal to 0.22mu m and less than or equal to 0.45mu m is employed to remove particle impurities of a water sample.300-500mL of filtered water sample is taken, pH value is adjusted to 6.0-9.0; in the process of pretreatment, selective nano filtration membrane with a cut-off molecular weight being 150-500 Dalton is adopted for dead-end or cross flow filtration; so that 6-15 times of concentration and enrichment of DON in the water sample can be achieved; the DON content is obtained by using the total nitrogen to reduce other forms of nitrogen content of other measurements and then dividing actual concentration times. In the invention, accuracy and precision of DON measurement are greatly improved, so that the problems that negative values often appear in the direct water sample determination method and concentration standard deviation is large are solved; in addition, the whole measurement process of the measurement method is simple and effective, easy to operate, low in cost, so that the measurement method can be widely applied to surface water and ground watermonitoring and monitoring and analysis of small, medium and large waterplants.

Owner:TONGJI UNIV

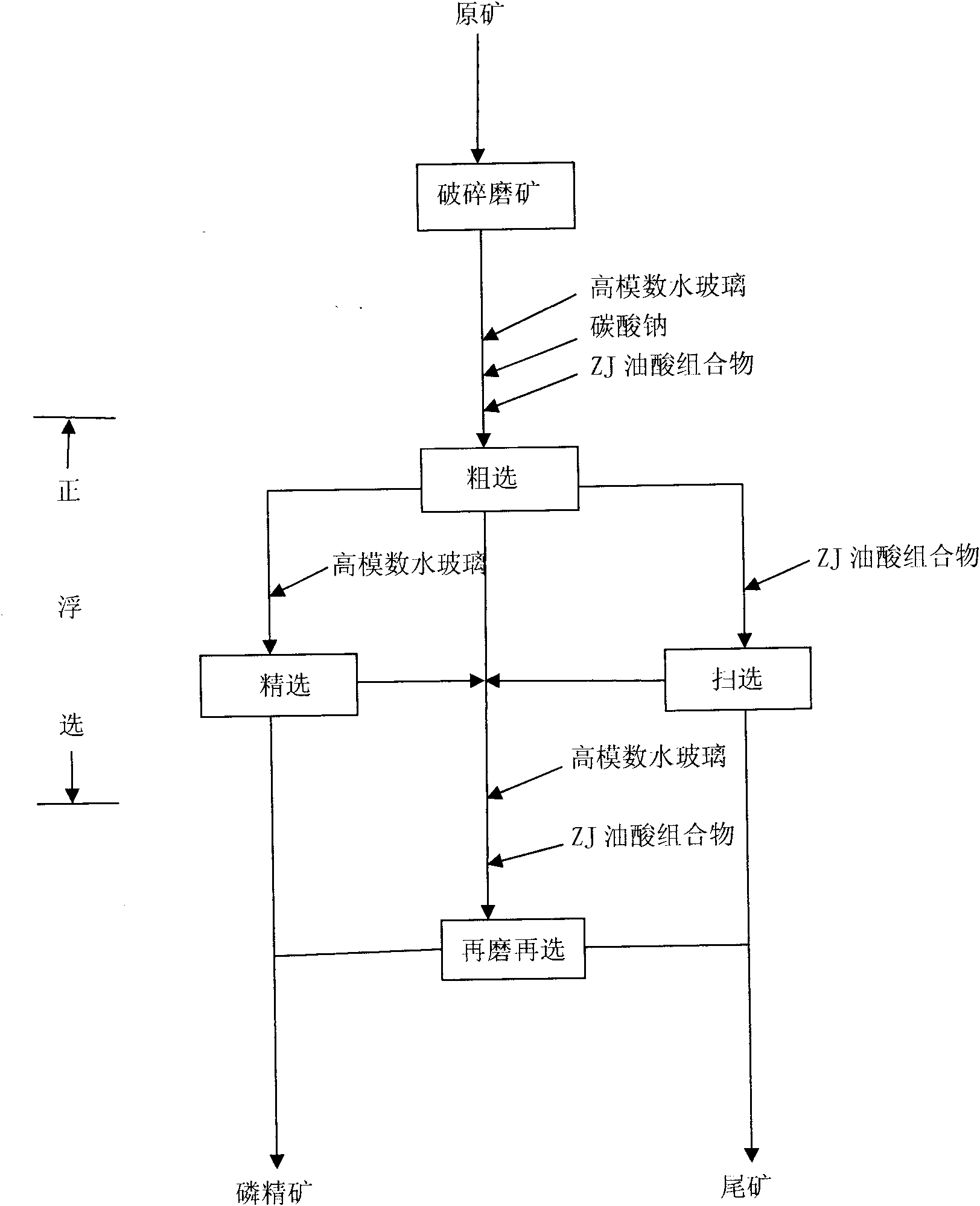

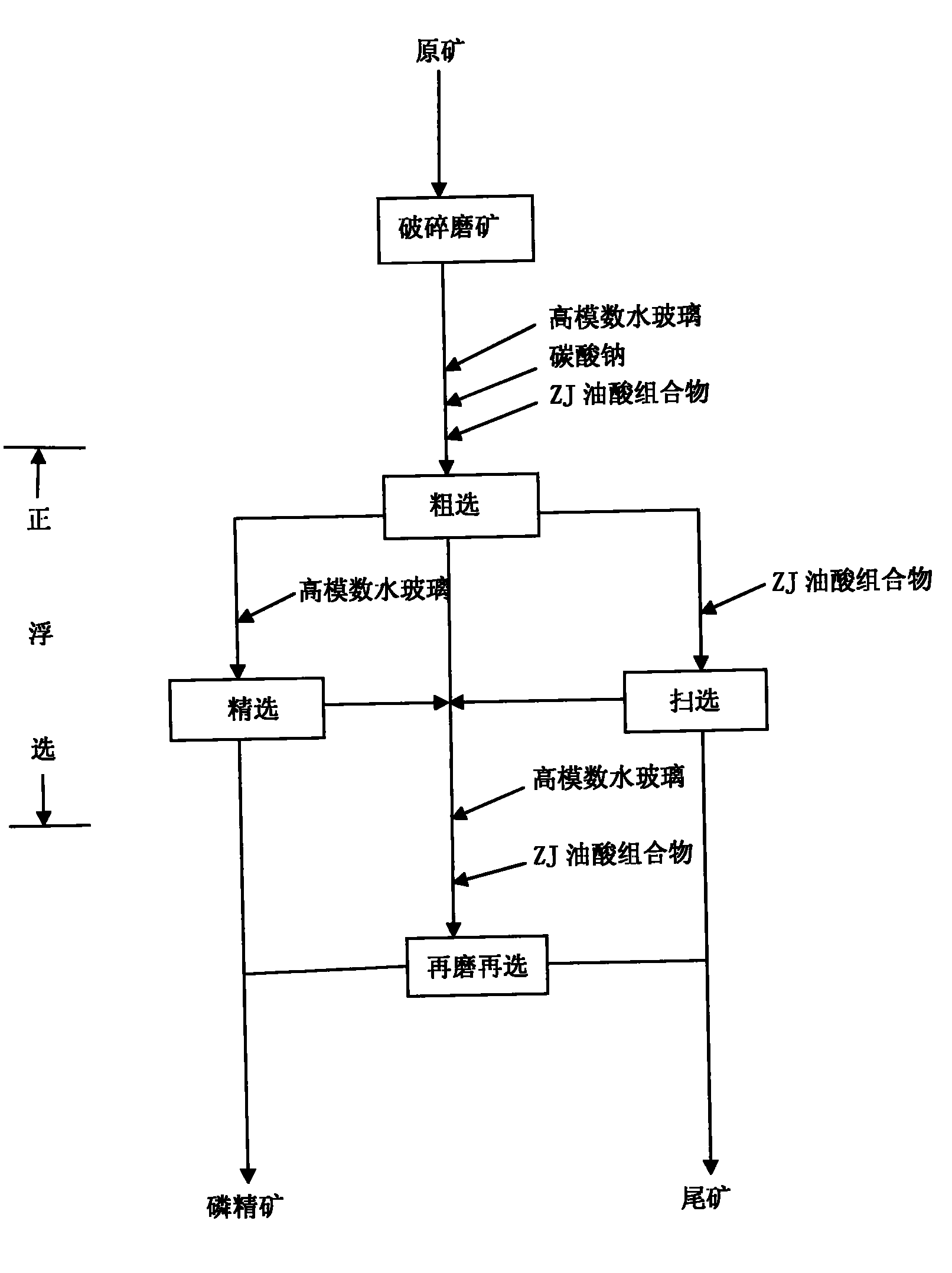

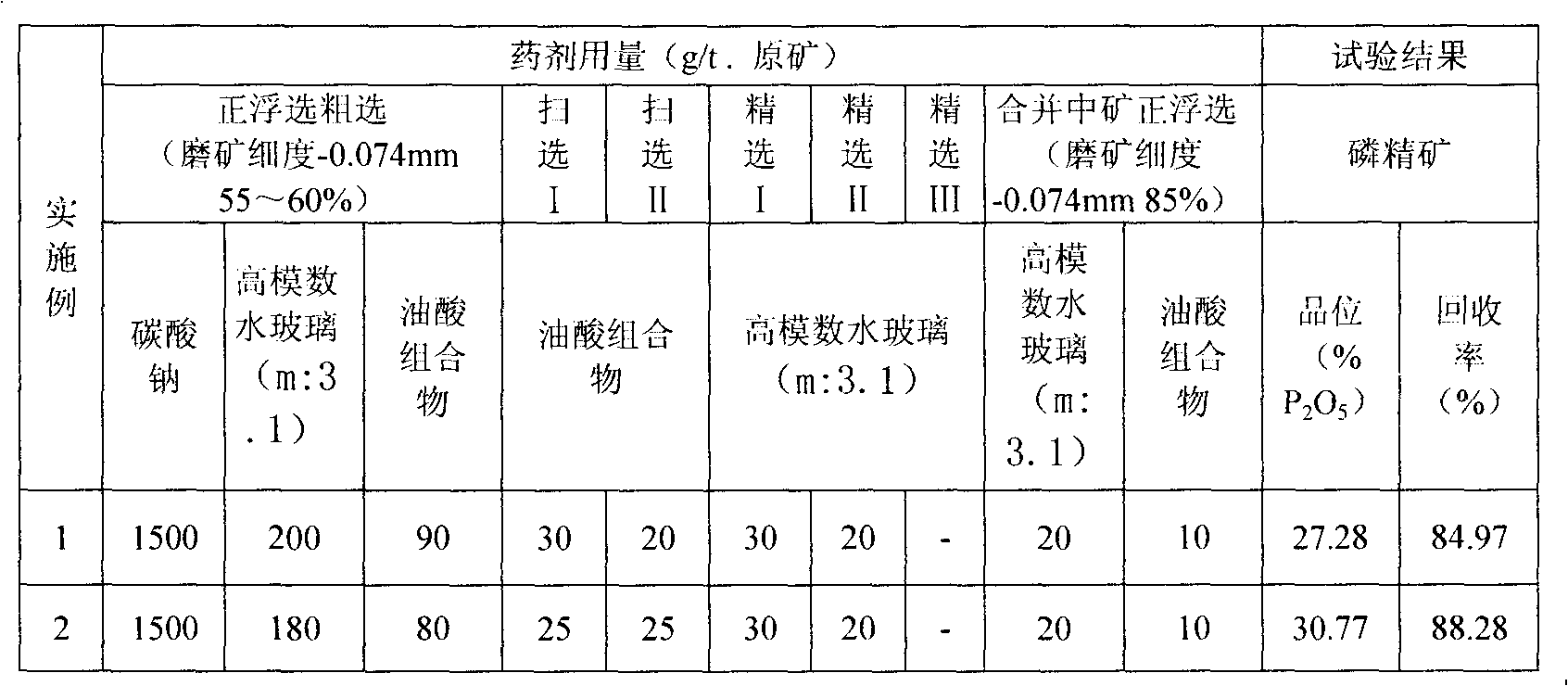

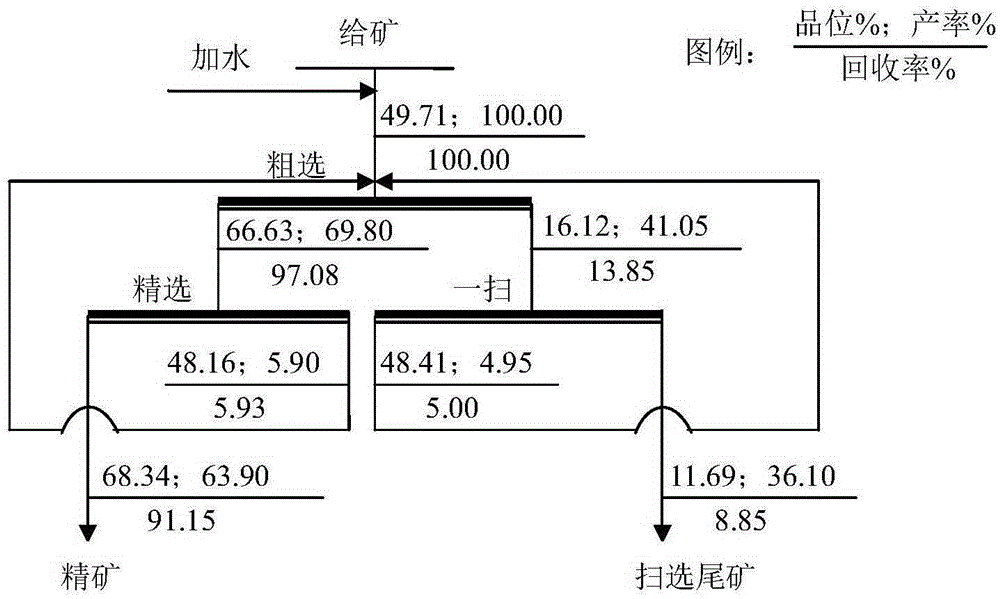

Positive flotation method of low grade refractory phosphate ores

The invention relates to a positive flotation method of low grade refractory phosphate ores. The method comprises the following specific steps: 1. crushing and grinding ores: grinding raw ore according to the grinding density of 1:1 to -0.074mm of 55-60% tailings discarding fineness; 2. performing positive flotation: firstly, roughing, namely adding depressant sodium carbonate, big modulus sodiumsilicate and collector ZJ oleic acid composite, stirring to obtain roughing concentrate, roughing middlings and roughing tailings; secondly, concentrating, namely adding big modulus sodium silicate in the roughing concentrate to perform 3-4 times of concentrations and obtain concentrating middlings and phosphorus product concentrate; thirdly, scavenging, namely adding ZJ oleic acid composite in the roughing tailings to perform 2-3 times of scavengings and obtain scavenging middlings and tailings; and 3. regrinding and reprocessing, namely further dissociating ores, and reprocessing to obtain tailings and residual phosphorus concentrate. The invention is characterized in that the ore grinding cost is low, the dosage of reagents is low, the ZJ oleic acid composite is easy to prepare and is convenient to use, the separating effect of phosphorus ores and gangue mineral is obvious, the separation indexes are good, etc; and the method is especially suitable to be used in the flotation of silicon-poor deposition-calcium phosphorite type phosphate ores with a concentration of P2O5 of less than 20%.

Owner:ZIJIN MINING GROUP

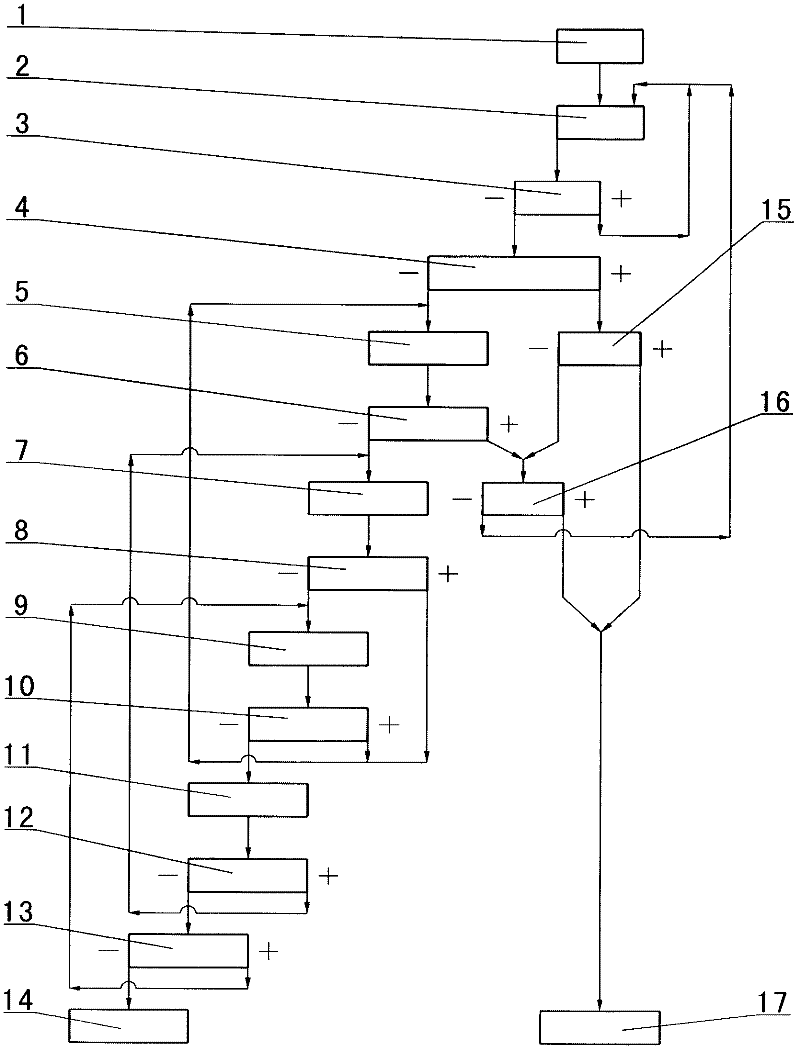

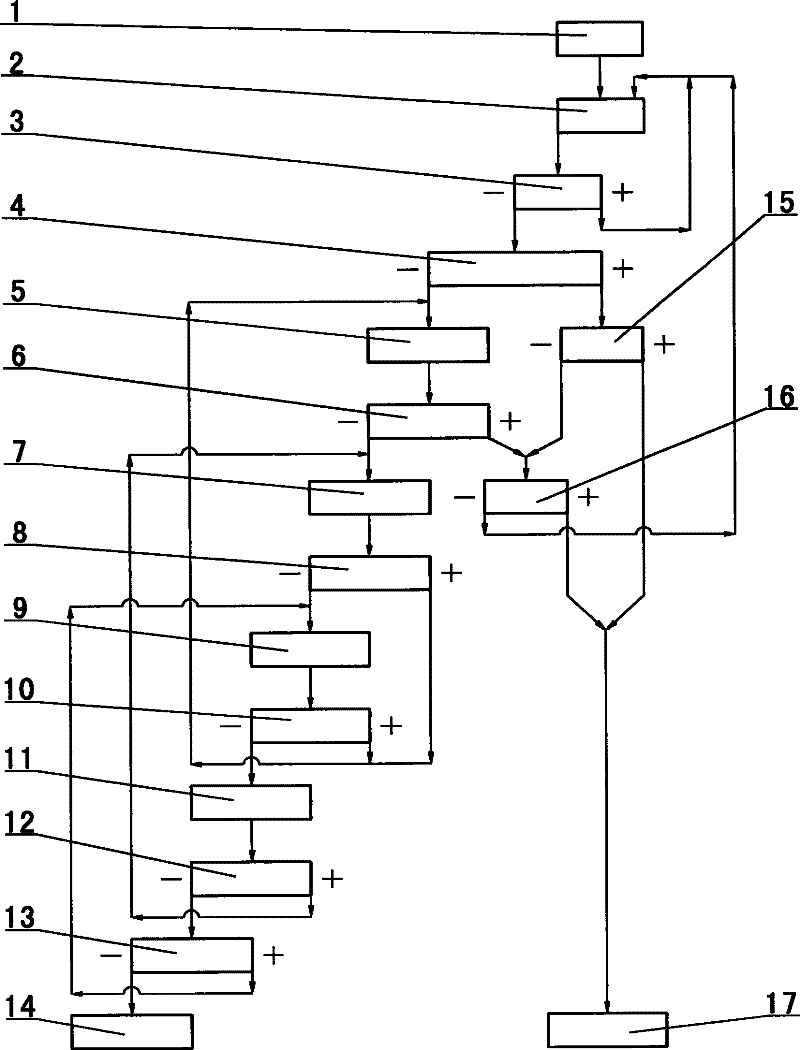

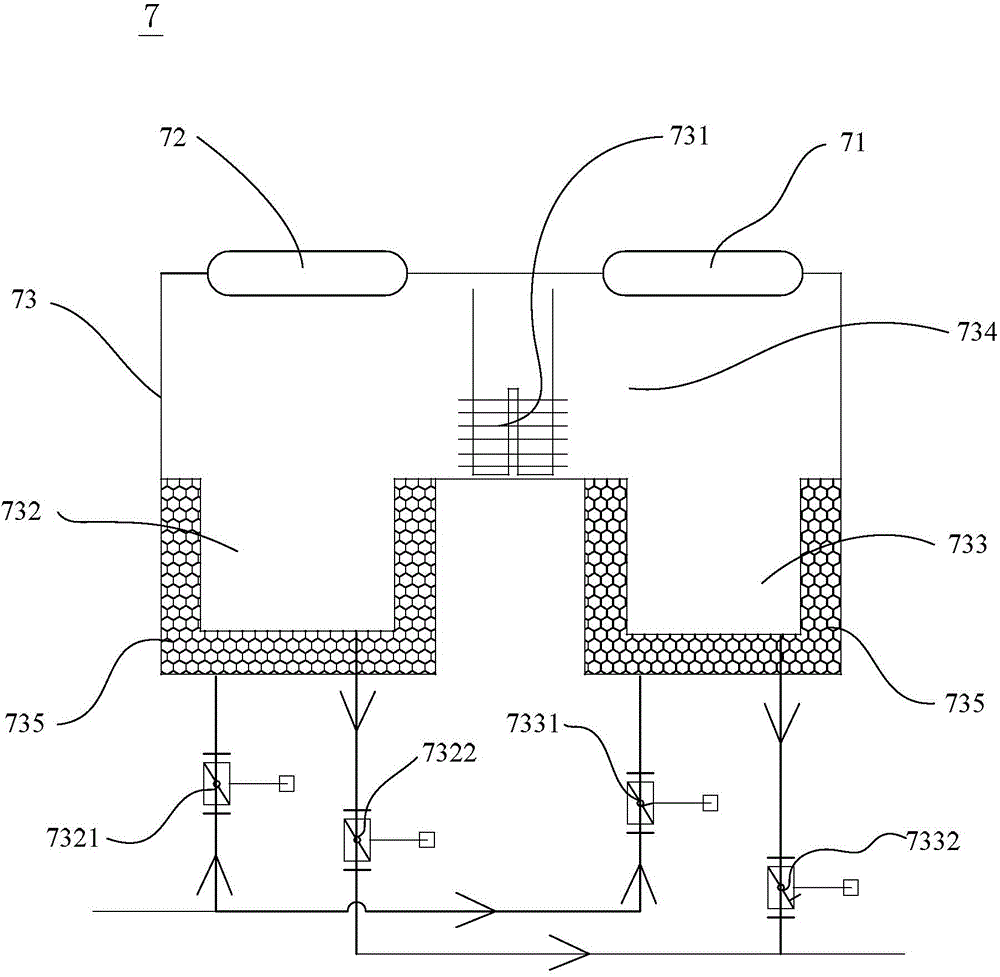

Equipment combination for fine flake graphite flotation technology

InactiveCN102649100AImprove efficiencyReduce energy consumptionWet separationEnergy consumptionMaterials science

The invention relates to equipment combination for fine flake graphite flotation technology, and belongs to a graphite separation technique. The fine flake graphite flotation technology provided by the invention adopts the scheme as follows: graphite mine arrow coarse grinding arrow classification arrow rougher floatation and two times of scavenging arrow four times of regrinding and five times of concentration for rough concentrate. The equipment combination for fine flake graphite flotation technology adopts the scheme as follows: the main equipment comprises a rod mill, a hydrocyclone, flotation columns I,II,III,IV,IV,V,VI,VIIand VIII, and regrind mills I,II,III and IV. The equipment combination has the following benefits: 1) the regrind mills are adopted as regrind equipment so that the efficiency is high and the energy consumption is low; 2) the flotation columns are adopted as flotation equipment so that the efficiency is high, the energy consumption is low and the floatation effect is good; and 3) the graphite concentrate as the final product is high in grade and high in recovery rate.

Owner:SHANDONG LAIWU COAL MINING MACHINERY

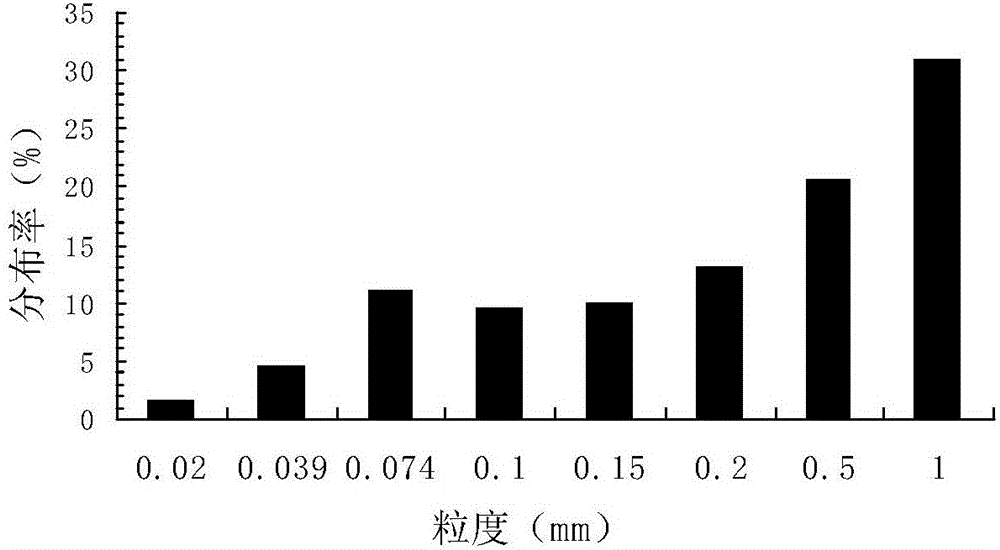

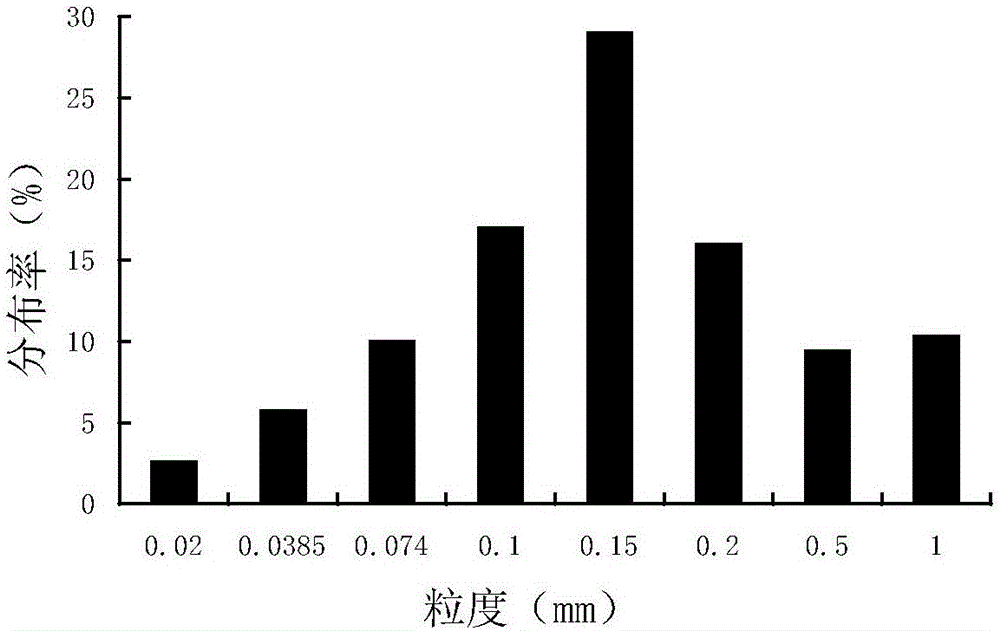

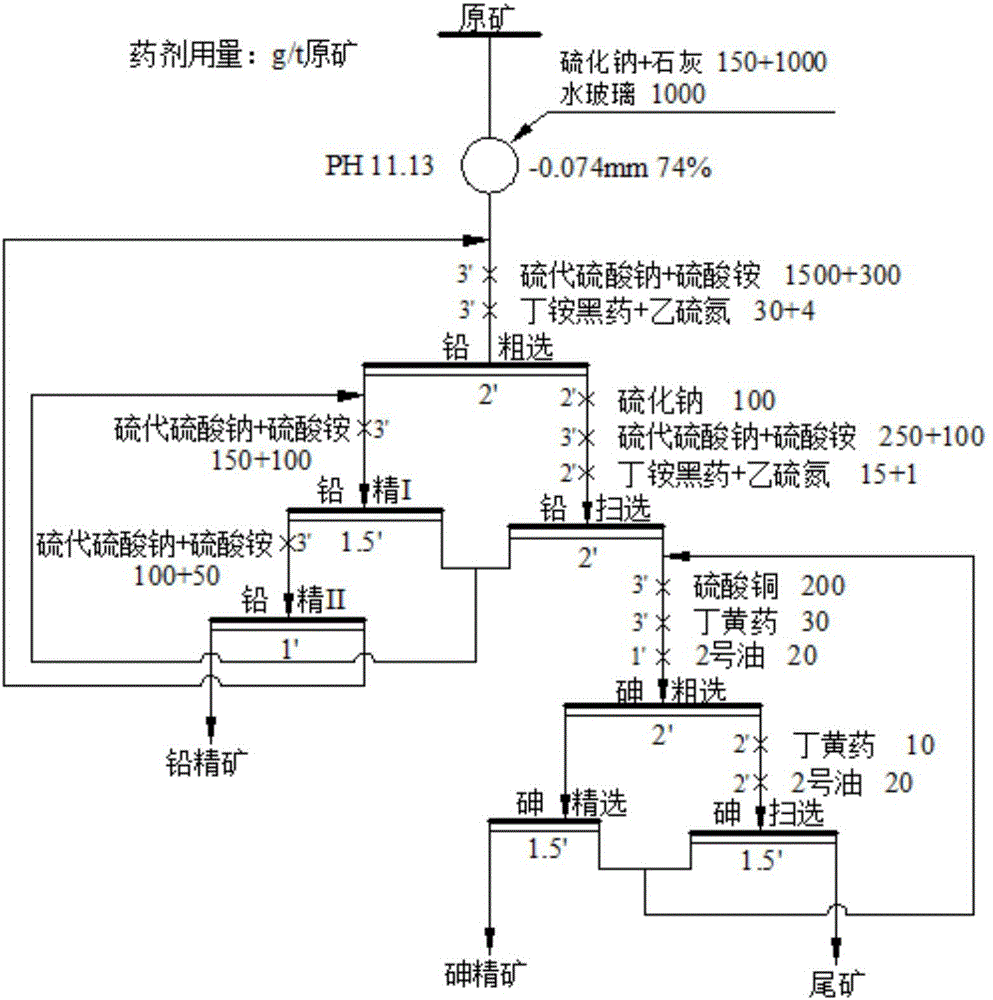

Beneficiation method for arsenic-containing lead sulfide ore

Provided is a beneficiation method for arsenic-containing lead sulfide ore. The method comprises the steps that 1, raw ore is ground; 2, ore powder obtained through grinding is subjected to flotation, one time of roughing, two times of scavenging and two times of concentration, so that lead concentrate is obtained; and 3, tailings obtained through scavenging are subjected to flotation grading including one time of roughing, one time of scavenging and one time of concentration, so that arsenic concentrate is obtained. Through the process grading, the lead grade of the lead concentrate is 66.30%, the lead recovery rate is 85.04%, the arsenic grade of the arsenic concentrate is 8.48%, and the arsenic recovery rate is 79.84%.

Owner:青海省地质矿产测试应用中心

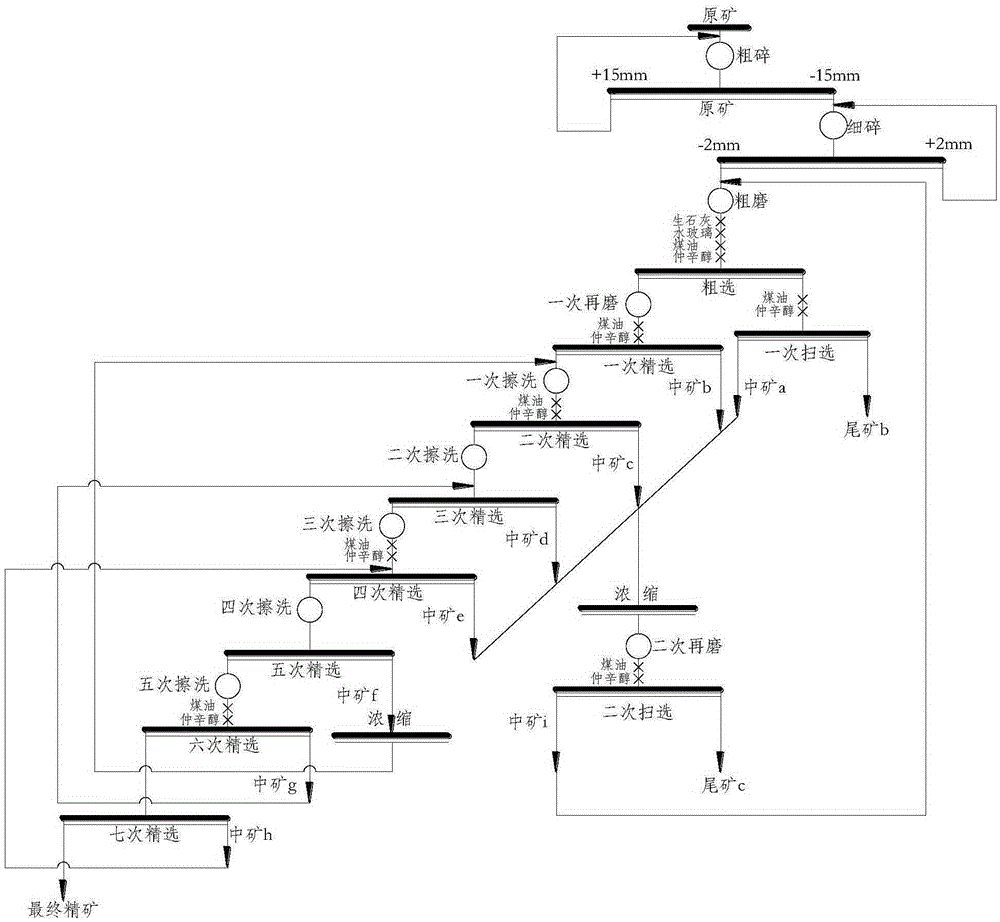

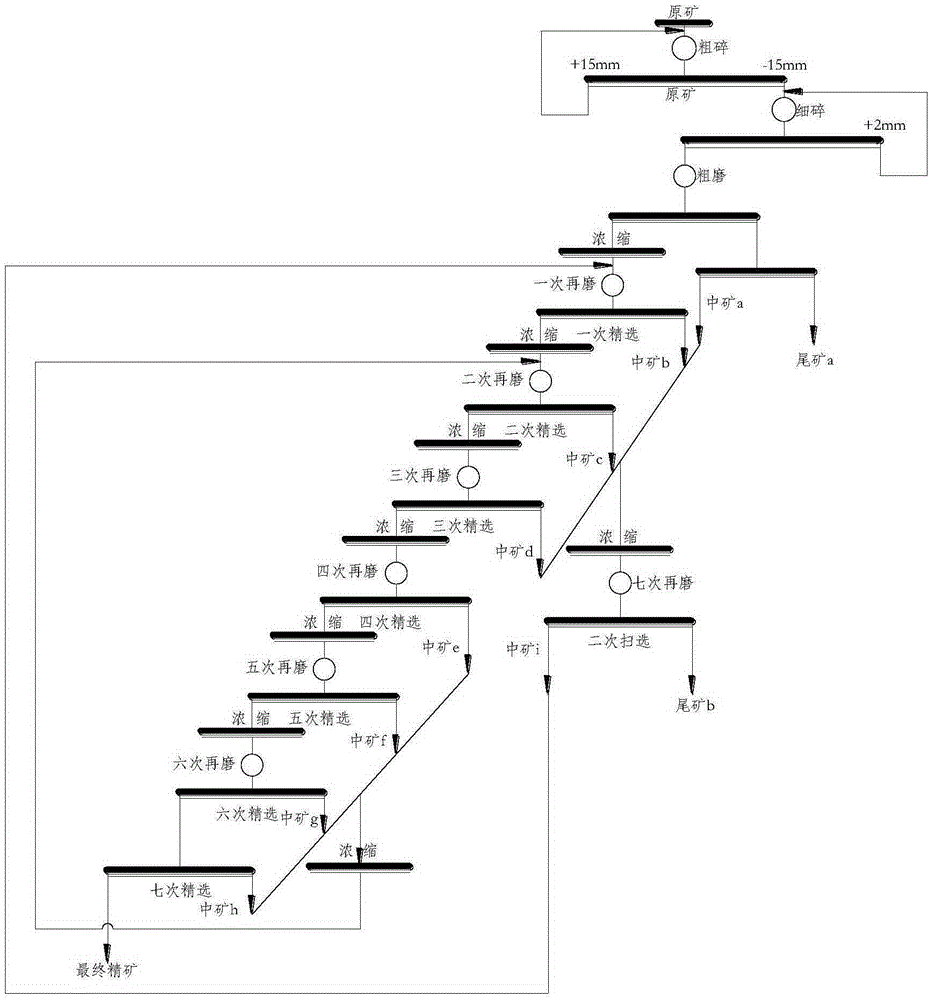

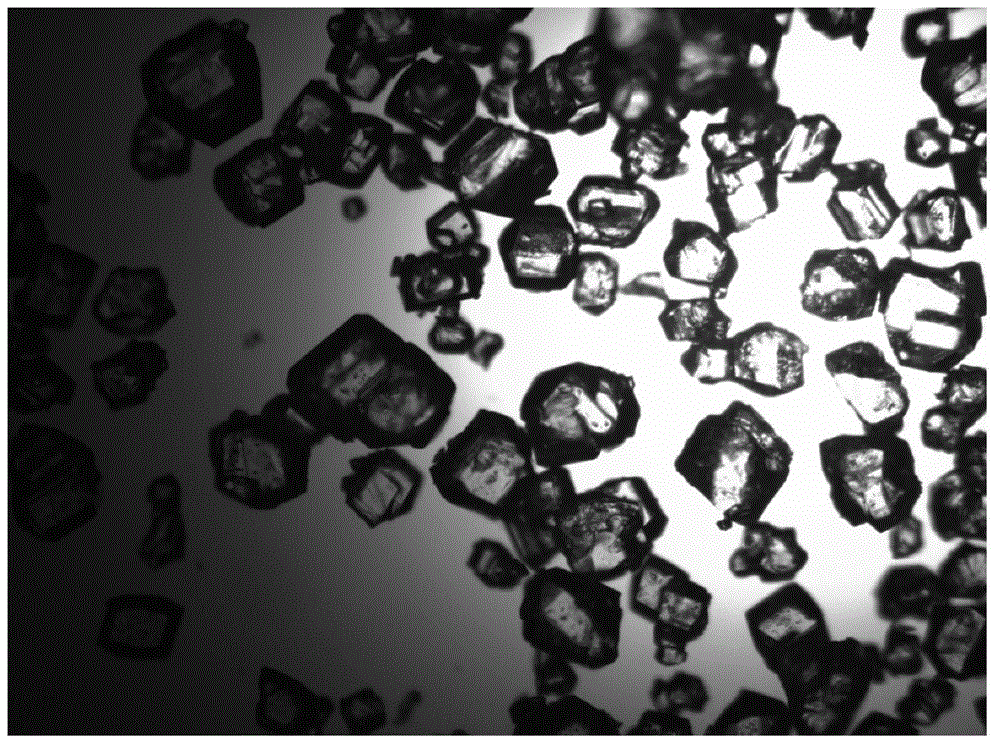

Purification technique for mineral separation of low-grade fine crystalline flake graphite

ActiveCN105289835AReduce enrichment workReduce the cost of beneficiationWet separationPrillMineral particles

The invention relates to a purification technique for mineral separation of low-grade fine crystalline flake graphite. The purification technique comprises a coarse-grinding roughing-separation process, a regrinding five-scrubbing seven-concentration process and a middling treating process. According to the regrinding fineness in the step of regrinding, the -0.045 mm content is 95%-98%, graphite and gangue mineral single bodies are fully dissociated, and the fixed carbon content and the recovery rate of concentrate are guaranteed; after regrinding, final concentrate is obtained after one time of concentration and five-scrubbing and six-concentration of the concentrate, the fixed carbon content of the final concentrate is 92%-94%, and the concentrate recovery rate reaches 90%-95%. According to the purification technique, the graphite and the gangue mineral single bodies are fully dissociated through one time of regrinding, scrubbing replaces regrinding in subsequent procedures, and the effects of diffusing concentrate foams and cleaning mineral particle surfaces can be achieved through the step of scrubbing. The purification technique has the advantages of being low in energy consumption, small in medium abrasion, simple and the like; the graphite mineral separation cost can be effectively lowered, and low-grade fine crystalline flake graphite minerals are utilized efficiently, economically and reasonably.

Owner:鸡西市普晨石墨有限责任公司

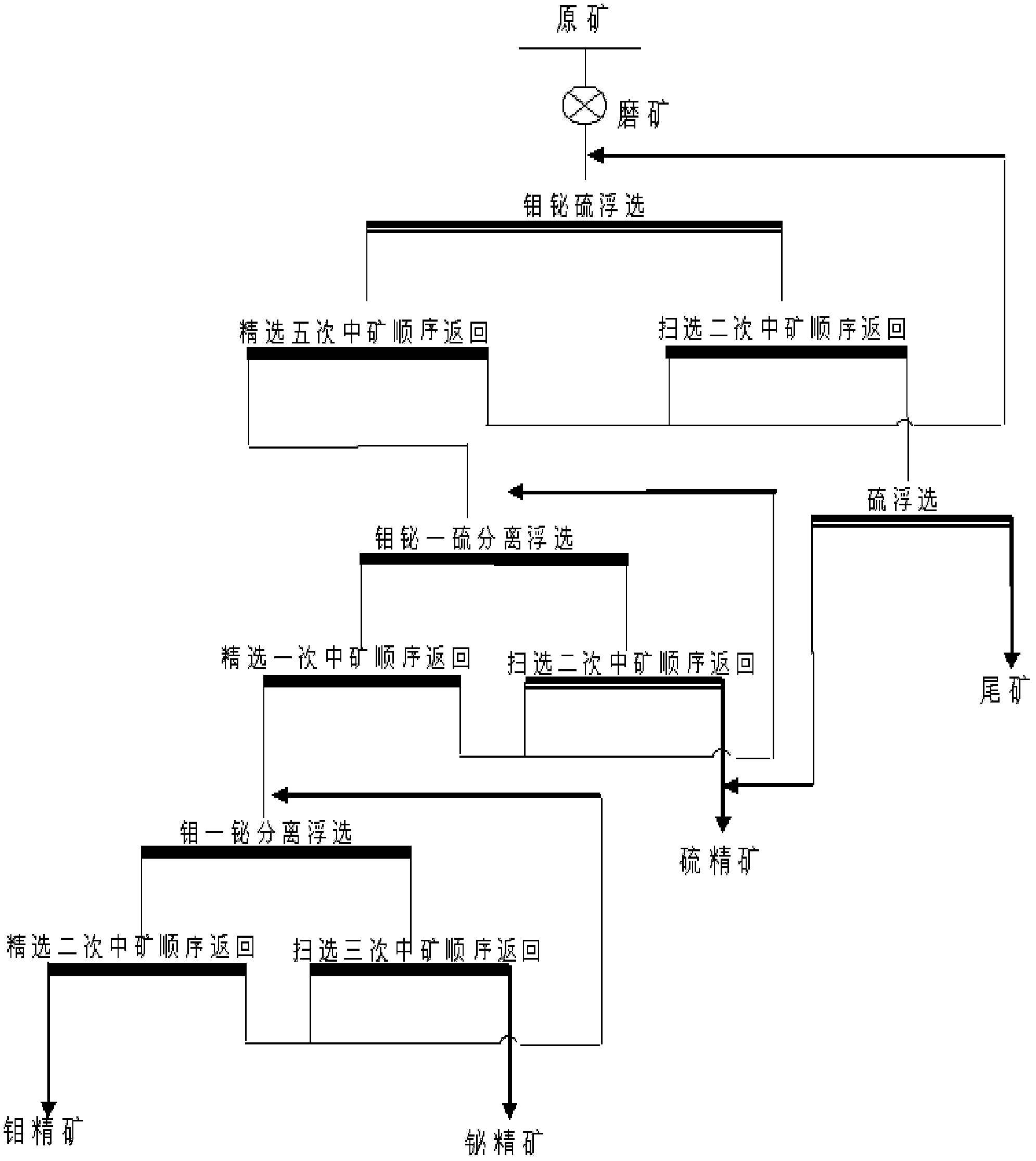

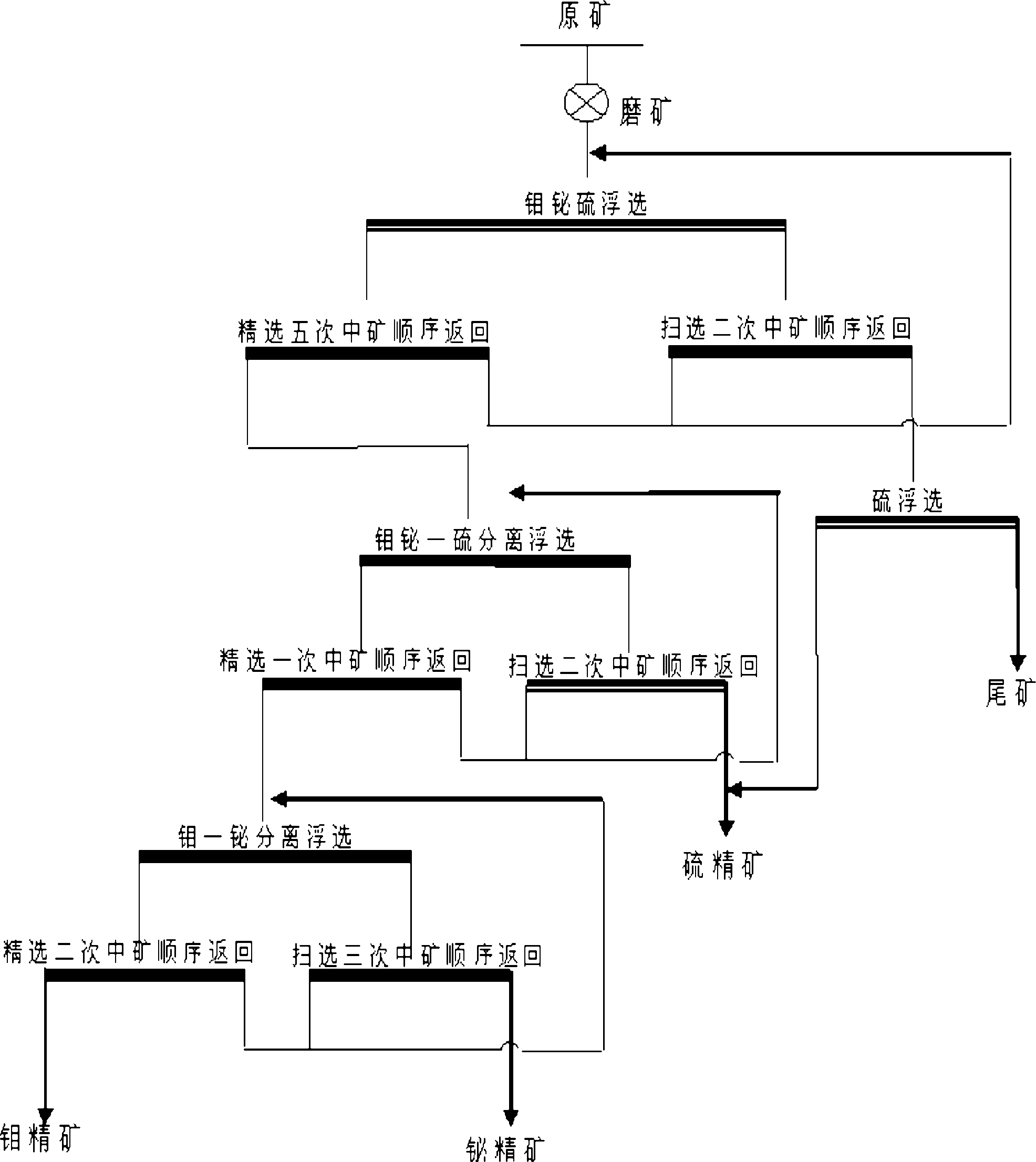

Concentration method of low-content molybdenum and bismuth in polymetallic ore

The invention discloses a concentration method of low-content molybdenum and bismuth in polymetallic ore. The method comprises the steps of grinding feed, adding a regulator, a collector and a foaming agent for mixed flotation of molybdenum, bismuth and sulfur, and carrying out once rough concentration, 1-8 times of concentration and 1-4 times of scavenging to obtain the molybdenum, bismuth and sulfur mixed concentrate; adding the regulator and the collector to the mixed concentrate for separated floatation of molybdenum and bismuth-sulfur, and carrying out once separated rough concentration, 1-8 times of concentration and 1-4 times of scavenging to obtain the molybdenum and bismuth concentrate and the sulfur concentrate; and adding the regulator and the collector to the molybdenum and bismuth concentrate for separated floatation of molybdenum-bismuth, separating molybdenum and bismuth, and carrying out once rough concentration, 1-8 times of concentration and 1-4 times of scavenging to obtain the molybdenum concentrate and the bismuth concentrate. By adopting the process technology, the valuable minerals molybdenum and bismuth in the polymetallic ore can be effectively and comprehensively recovered, poisonous sodium cyanide is not needed, the environmental pollution is reduced, the traditional production process is simplified and the comprehensive utilization rate of the resources is improved.

Owner:HUNAN RES INST FOR NONFERROUS METALS

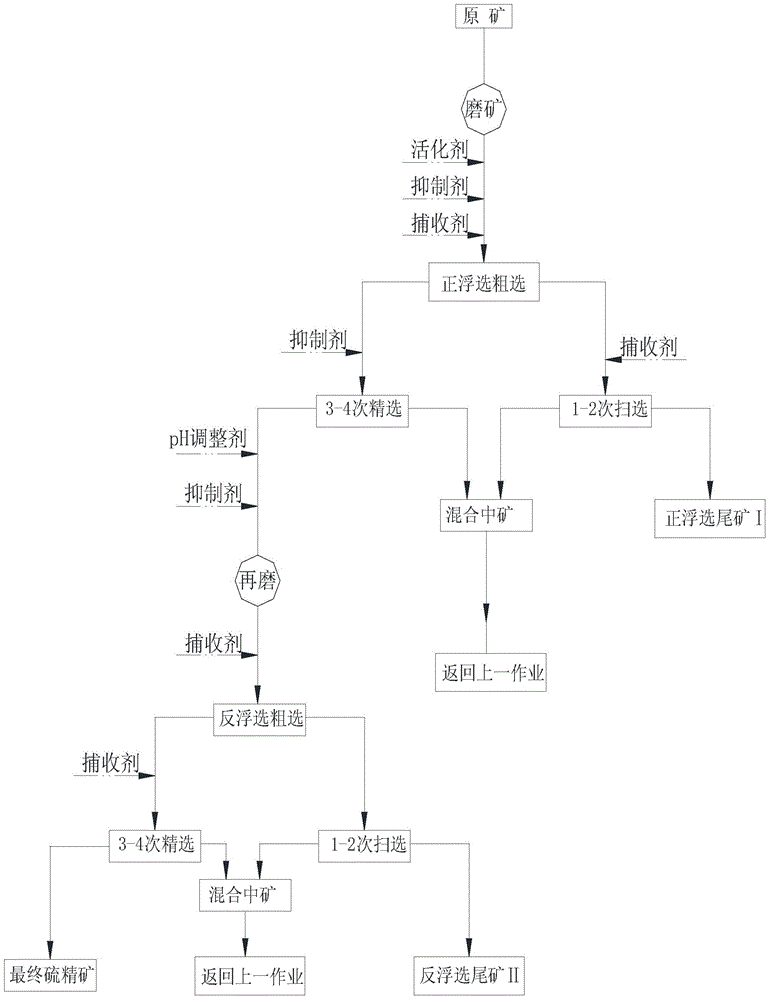

Direct-reverse flotation process for preparing high-purity sulfur concentrate

The invention provides a direct-reverse flotation process for preparing high-purity sulfur concentrate, and belongs to the technical field of mineral machining. The process includes the following steps that 1, iron pyrite raw ore is grinded to reach the grinding fitness required by the flotation work; 2, activating agents, inhibitor sodium silicate, xanthate type anion collecting agents are added to the grinded ore pulp to conduct sulfur concentrate direct flotation work; 3, one-time rough flotation, one or two times of scavenging and three to five times of concentration are conducted in the direct flotation work to obtain rough sulfur concentrate; 4, PH regulators and strong oxidants are added to the rough sulfur concentrate, and grinding is conducted; 5, positive ion collecting agents are added to the grinded ore pulp to conduct sulfur concentrate reverse flotation work; 6, one-time rough flotation, two or three times of concentration and one or two times of scavenging are conducted in the reverse flotation work to finally obtain the qualified high-purity sulfur concentrate. The finally-obtained sulfur concentrate is high in grade, the concentrate is filtered easily, and industrialization is achieved easily.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Method for producing xylose by sugarcane leaves

The invention relates to a method for producing xylose by sugarcane leaves, which comprises the following steps: carrying out fore treatment and pretreatment on the raw material sugarcane leaves to decontaminate, acid hydrolyzing the raw material by a high-temperature cooking and steaming manner, and filtering to obtain a hydrolysate; carrying out three times of concentration and three times of ion-exchange and decoloration on the hydrolysate to obtain a low-concentration xylose solution; concentrating the low-concentration xylose solution to obtain a high-concentration xylose syrup; and crystallizing or spray drying the syrup so as to obtain powdered sugar. The process is simple; multistage ion-exchange and decoloration are carried out, deacidification is not needed in the process; the quality of product is good, the production cost is low, the salt content of discharge of sewage is less, and less three wastes are generated.

Owner:GUANGXI UNIV

High-mud high secondary copper ore mineral dressing method and combined modifier applied to method

ActiveCN107350083AEliminate the effects ofInhibition effectFlotationMineral flotationMaterials science

The invention belongs to the technical field of the ore flotation process and particularly relates to a high-mud high secondary copper ore mineral dressing method and a combined modifier applied to the method. The combined modifier comprises, by weight, sodium sulfide, sodium metabisulfite, sodium hydrosulfite and sodium carbonate dry powder in proportion of 4-5:1:1-2:1-2. The combined modifier is applied to the high-mud high secondary copper ore mineral dressing method. Lime, the combined modifier and water with the same mass as raw ores are added into the raw ores and then are subjected to grinding and flotation. Copper concentrates and flotation tailings are obtained after two times of concentration and two times of scavenging. The combined modifier effectively eliminates flotation environment deterioration caused by secondary copper ions in flotation pulp through full utilization of the synergic effect of chemicals. The use amount of flotation collectors is reduced. The ore dressing cost is saved. Floating of floatable gangue minerals is effectively suppressed. The electric potential of copper ore flotation pulp is optimized. The flotation speed of copper ores is increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Atmospheric particulate collecting and analyzing device and atmospheric particulate collecting and analyzing method

InactiveCN104677975APollution controlHigh sensitivityMaterial analysis by electric/magnetic meansParticulatesFilling materials

The invention provides an atmospheric particulate collecting and analyzing device; the atmospheric particulate collecting and analyzing device comprises a switch valve, an eluant access pipe, an analyzer, two adapters and a sampling analysis column, wherein the eluant access pipe, the analyzer and the two adapters are connected with the switch valve; the sampling analysis column is connected between the two adapters; and the sampling analysis column is composed of a tubular hollow cylinder and a fibrous filler material. The invention further discloses an atmospheric particulate collecting and analyzing method. The atmospheric particulate collecting and analyzing method disclosed by the invention is high in test sensitivity; for collecting same amount of particulates, the concentration rate of the atmospheric particulate collecting and analyzing method is 50-100 times higher than that of the traditional method; 50 times of concentration rate is achieved; a sample is collected for two days in the traditional method; but, the sample is collected and tested within about 1 hour in the atmospheric particulate collecting and analyzing method disclosed by the invention; therefore, the sampling efficiency is greatly increased; furthermore, the fibrous filter material is not damaged in the eluting process; collected particulate components are analyzed after being eluted; and thus, pollution of the sampling analysis column due to component sources is effectively controlled.

Owner:QINGDAO UNIV OF SCI & TECH +1

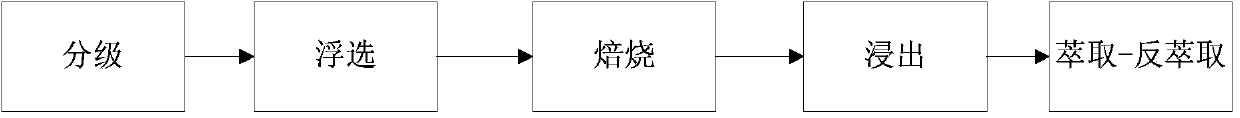

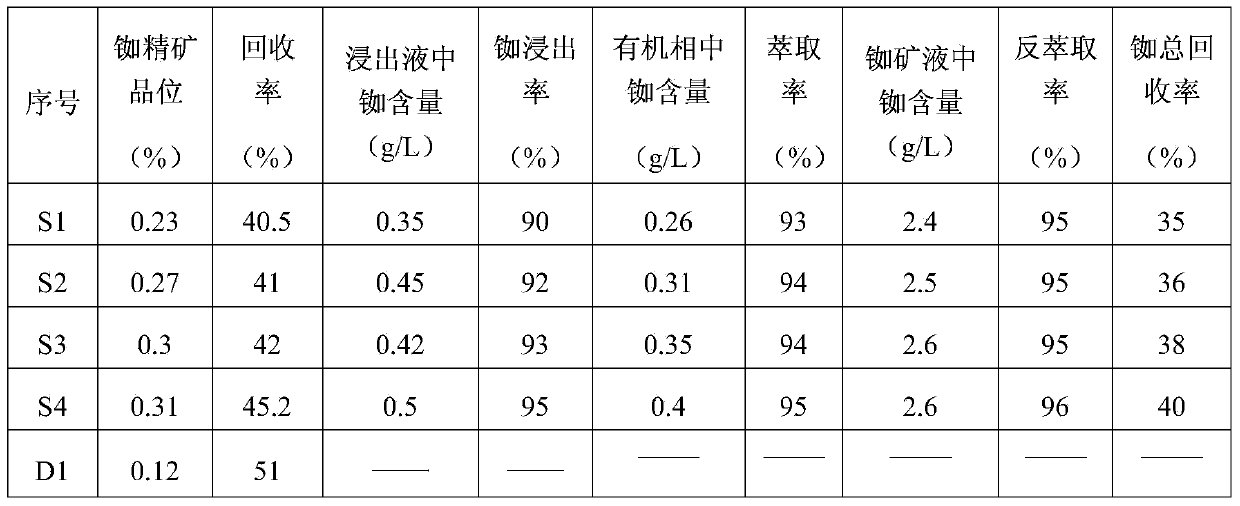

Method for recycling rubidium from iron tailings

InactiveCN104178644AAchieve enrichmentEasy to separate and purifyProcess efficiency improvementSulfurMaceral

The invention provides a method for recycling rubidium chloride from iron tailings. The method comprises the following steps of: classification: the iron tailings are classified to obtain a first mineral of +10 microns; flotation: the flotation is performed for the first mineral to obtain rubidium concentrate; roasting: the rubidium concentrate is roasted to obtain a roasting product; the leaching and the extraction-back extraction are performed for the roasting product in sequence to obtain a water phase as a rubidium ore solution. The flotation at least comprises sulfur removal flotation and recycling flotation which are performed in sequence; and each of the sulfur removal flotation and the recovery flotation comprises one time of rough concentration, two times of scavenging and four times of concentration. The method, through classification of the iron tailings, can obtain the mineral with the particle size of +10 microns, and the rubidium accumulates in the mineral with the particle size; and the content of the rubidium is 8-10 times higher than that of the rubidium in the raw material of iron tailings, so that the subsequent separation and purification treatment is facilitated.

Owner:湖南鑫生矿冶废弃物综合利用科技有限公司

Method for extracting anthocyanin from fructus aroniamelanocarpae pomace

The invention discloses a method for extracting anthocyanin from fructus aroniamelanocarpae pomace, which includes the following steps: (1) fructus aroniamelanocarpae pomace and first extract are stirred and extracted under 4 DEG C to 10 DEG C and pH is equal to 3 to 4; and by filtration, first filtrate and first filter residue are obtained; (2) the first filter residue is added with second extract, and is stirred and extracted under 4 DEG C to 10 DEG C and pH is equal to 3 to 4; and by filtration, second filtrate and second filter residue are obtained; (3) by using aqueous ethanol solution, the second filter residue is stirred and extracted under 4 DEG C to 10 DEG C and pH is equal to 3 to 4; (4) the first filtrate is concentrated by reducing pressure; and filtration is carried out; (5) the filtrate is loaded onto macroporous resin, aqueous ethanol solution is used for resolution, resolved solution is collected, and after concentration and drying, an anthocyanin extract is obtained. The method is carried out under low temperature, and the degradation and physiological activity decrease of anthocyanin are prevented. Weak acid prevents the partial and complete hydrolysis of acylated anthocyanin as the result of subsequent evaporation and concentration. The use of the filtrates shortens the time of concentration, reduces energy consumption, and saves new solvent, and the yield of anthocyanin is high.

Owner:黑龙江省尚志绿野浆果有限责任公司

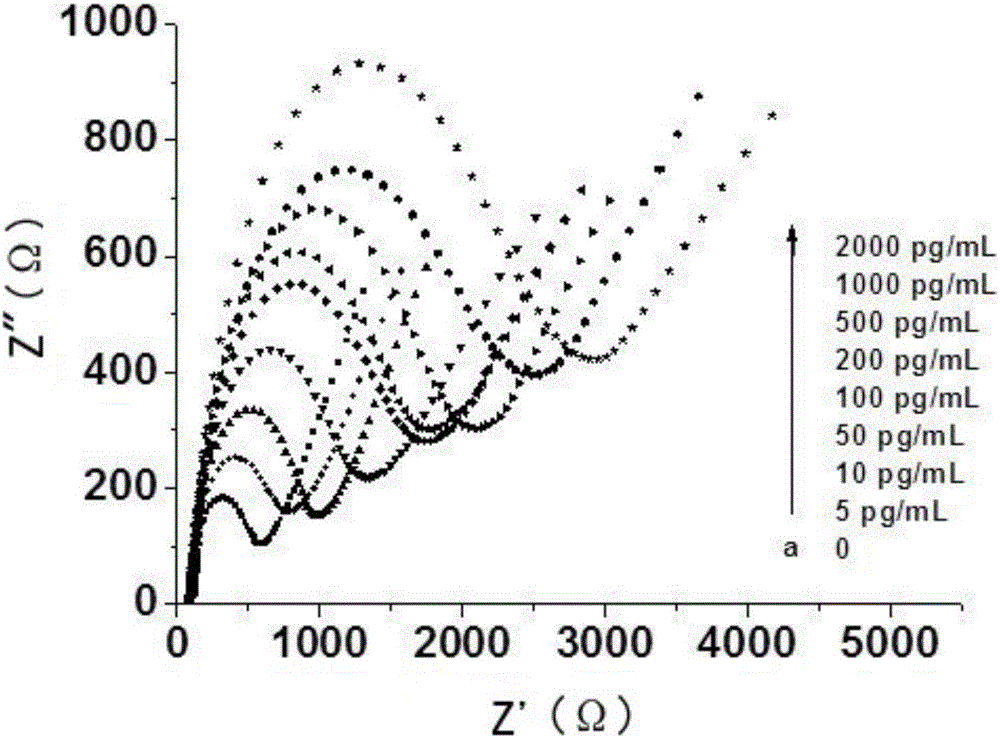

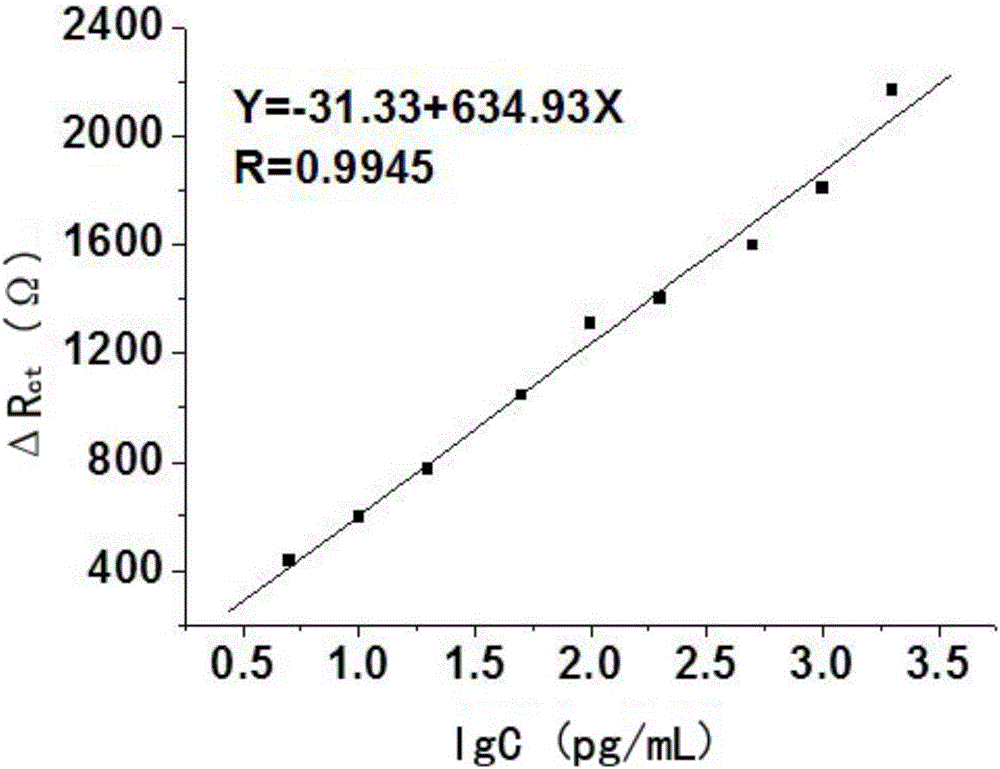

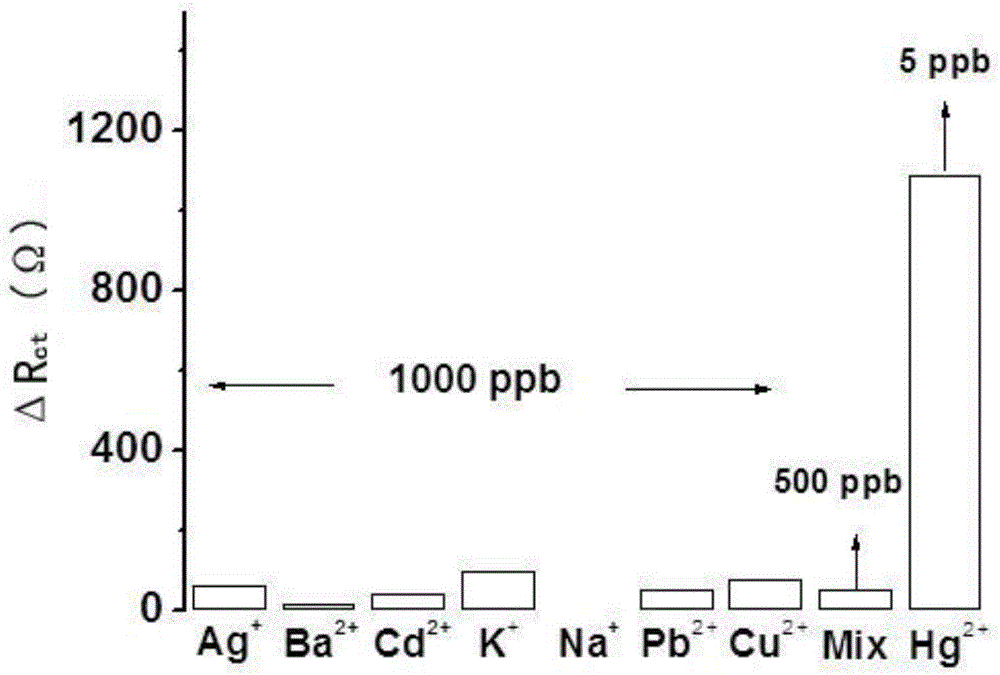

Aptamer sensor for mercury ion detection, as well as preparation method and application of aptamer sensor

InactiveCN106841349AHigh sensitivityStrong amplification effectMaterial analysis by electric/magnetic meansInterference resistanceGold particles

The invention discloses an aptamer sensor for mercury ion detection, as well as a preparation method and application of the aptamer sensor. The sensor comprises a substrate glassy carbon electrode, wherein nano-gold particles are deposited on the surface of the substrate glassy carbon electrode; the surface of nano-gold particles is modified with ethanthiol; and a nano-gold-aptamer conjugate is modified to the nano-gold particles on the surface of the electrode through the self-assembly effect of Au-S bond. The aptamer sensor has a relatively strong amplification effect by adopting dual-layer nano-gold modification, has ultrahigh sensitivity for detecting mercury ions reaching 1.1pg / mL, and has a linear range of 5-2000pg / mL; meanwhile, the aptamer has strong interference resistance due to strong specificity, and does not interfere with Ag<+>, Ba<2+>, Cd<2+>, K<+>, Na<+>, Pb<2+>, Cu<2+> and other ions with 200 times of concentration.

Owner:南京百圃环境科技有限公司

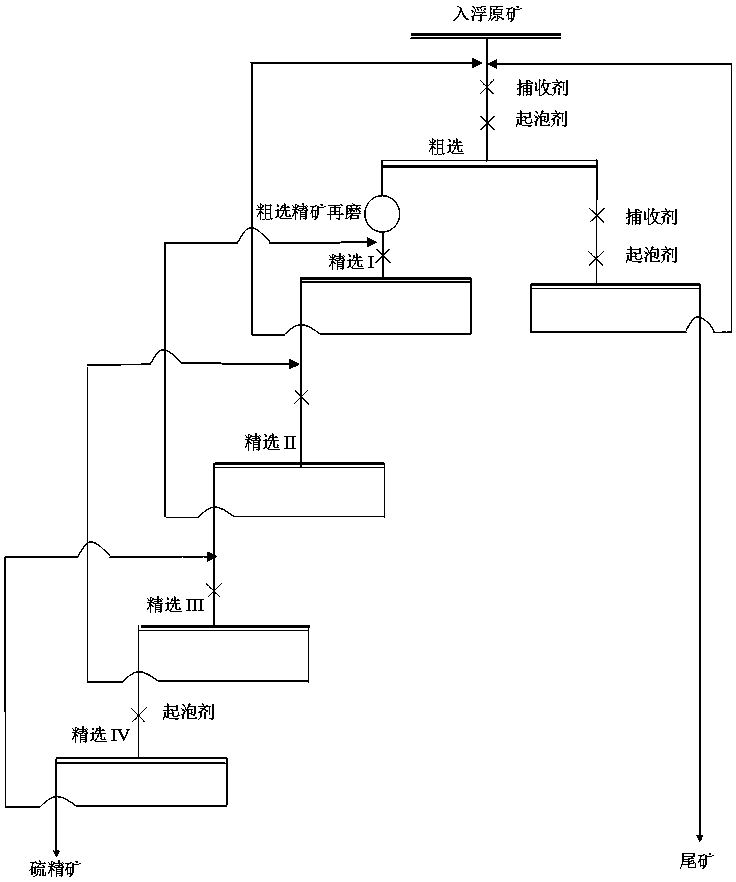

Flotation method for sulfur in associated pyrites

InactiveCN108144744AReduce sulfur contentEfficient recyclingFlotationWet separationFoaming agentSulfur

The invention provides a flotation method for sulfur in associated pyrites. The flotation method comprises the following steps that (1) roughing is conducted on a floating raw ore; (2) scavenging is conducted on a roughing bottom flow; (3) regrinding is conducted on roughing concentrate; and (4) four-time concentration is conducted on the roughing concentrate obtained after regrinding, the concentration bottom flow returns back in sequence every time, wherein a certain amount of foaming agent is added in the fourth time of concentration process, and finally sulfur concentrate and iron tailingsare obtained. According to the flotation method for the sulfur in the associated pyrites, the content of the sulfur in iron ore concentrate is reduced, and meanwhile, sulfur concentrate products withthe high quality are obtained; and the recovery rate of sulfur resources is increased, and the flotation method has important practical and theoretical significance for desulfurization of a high sulfur-iron ore and efficient utilization of the sulfur resources.

Owner:NANJING MEISHAN METALLURGY DEV +1

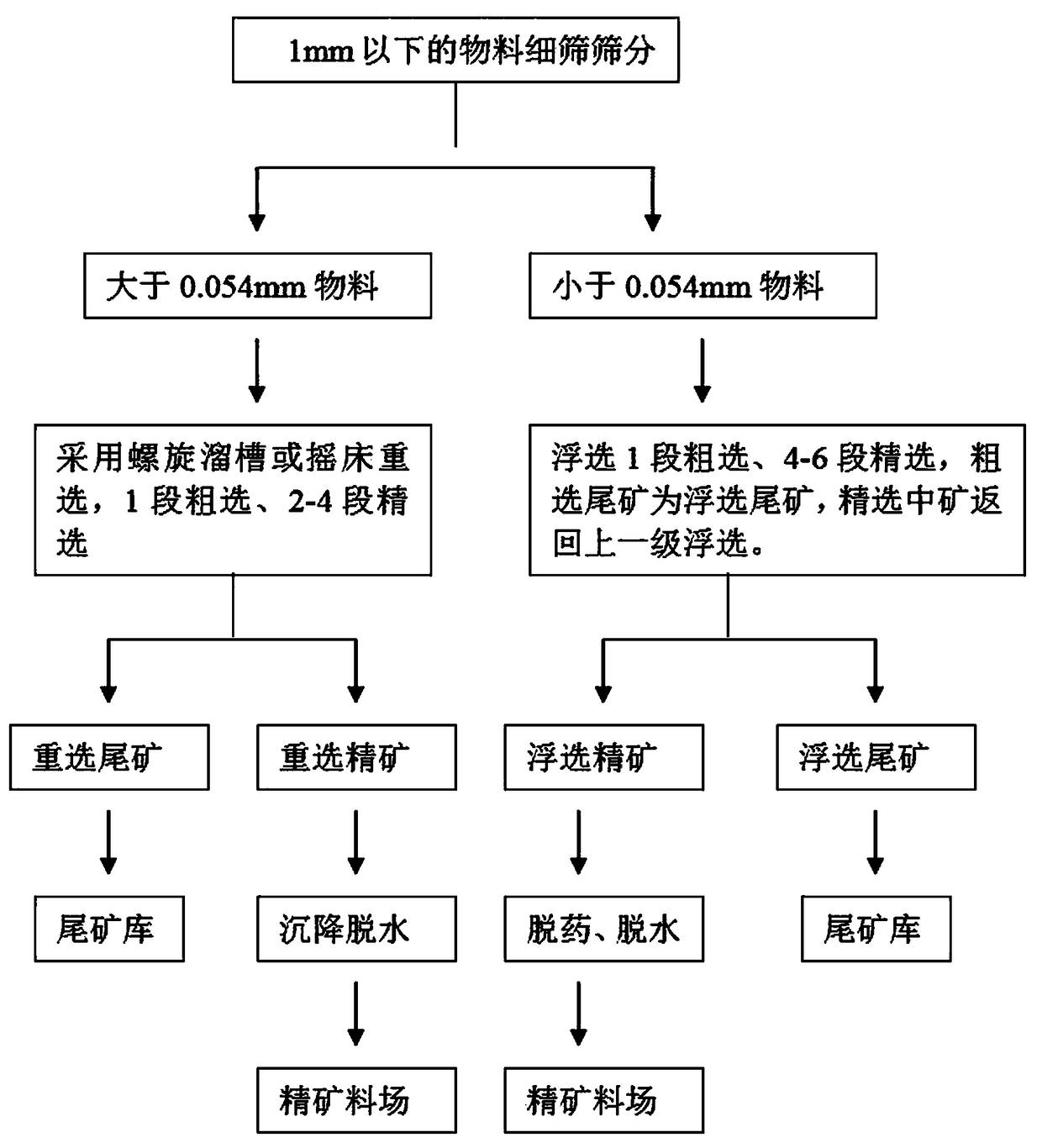

Fine-fraction low-grade barite separate beneficiation technology

The invention discloses a fine-fraction low-grade barite separate beneficiation technology. The fine-fraction low-grade barite separate beneficiation technology includes the steps that (1) raw ore issubjected to primary screening; (2) fine-fraction sample ore is subjected to flotation, the technological process comprises one time of rougher concentration for discarding tailings and 4-6 times of selection so that flotation concentrate can be obtained, selected middlings return to the upper-level closed-circuit flotation process so that flotation concentrate and flotation tailings can be obtained, and the flotation tailings enter a tailings pond; (3) barite foam obtained through flotation is subjected to reagent removal, filtration and drying, and accordingly fine-fraction barite concentrate fines are obtained; (4) coarse-fraction sample ore is subjected to gravity separation, gravity separation equipment such as a table concentrator and a spiral chute is adopted in the gravity separation technology to conduct one time of roughing and 2-4 times of concentration so that barite concentrate can be obtained, and gravity separation tailings enter the tailings pond; and (5) barite concentrate fines obtained in the two separate beneficiation technologies are combined to obtain an acceptable product. According to the fine-fraction low-grade barite separate beneficiation technology, fine-fraction low-grade barite is subjected to separate beneficiation, the tailings grade is low, the recovery rate is high and ore grinding cost is low.

Owner:JIUQUAN IRON & STEEL GRP

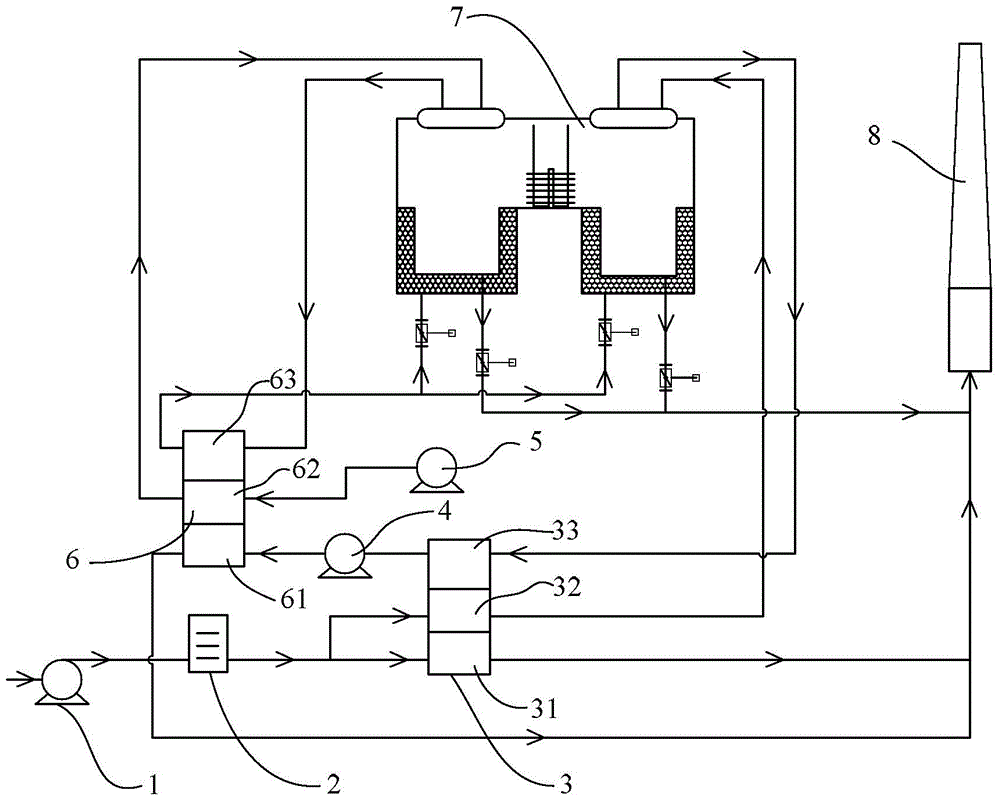

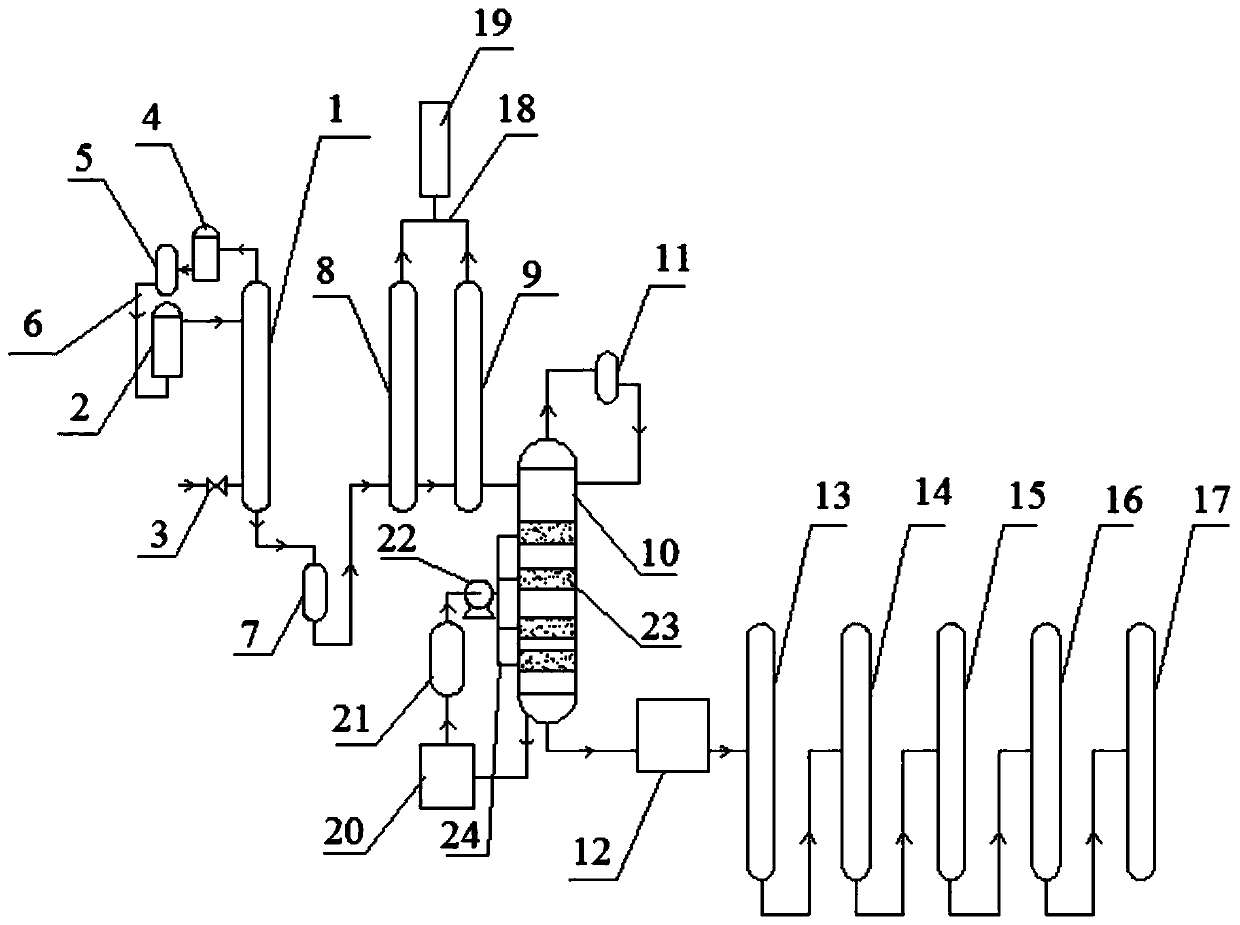

Paint waste gas processing system and use method thereof

InactiveCN104971593AThorough treatmentReduce lossesDispersed particle separationThermal energyDesorption

The invention relates to a paint waste gas processing system including a first concentration turning wheel, a second concentration turning wheel and a heat exchange oxidation device; the first concentration turning wheel includes a first turning wheel and a first shell body, and the second concentration turning wheel includes a second turning wheel and a second shell body; the first shell body internally includes a first adsorption zone, a first desorption zone and a first cooling zone, and the second shell body internally includes a second adsorption zone, a second desorption zone and a second cooling zone; the heat exchange oxidation device includes a heat exchanger and an oxygenizer; waste gas enters the oxygenizer after being treated by the first concentration turning wheel and the second concentration turning wheel, and is discharged to the atmosphere after being treated by the oxygenizer. The paint waste gas processing system provided by the invention performs two times of concentration treatments on hydrocarbons in the waste gas, and is more thorough in treatment of the waste gas. In addition, the system allows the heat exchanger and the heat storage oxygenizer to be in integrated design, and the heat energy cyclic utilization in the heat storage oxygenizer makes the heat loss reduced to the minimum.

Owner:BAY ENVIRONMENTAL TECH BEIJING

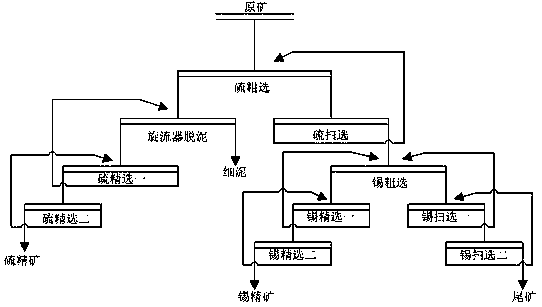

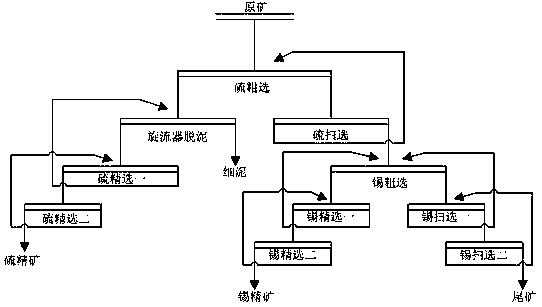

Method for recovering fine-grained cassiterite

The invention discloses a method for recovering fine-grained cassiterite. According to the method, a sulfur mixed collecting agent and a tin mixed collecting agent are used for desulfurization and tinselection respectively, the collecting effect of the two mixed collecting agents is good, and compared with a traditional collecting agent, the cost is low. The method includes the steps that sulfurroughing is carried out, then sulfur roughing tailings are subjected to one time of roughing, two times of concentration and two times of scavenging of cassiterite, and tin concentrate is obtained; the sulfur roughing concentrate is subjected to two times of sulfur concentration after graded desliming to obtain sulfur concentrate. According to the method, desulfurization and flotation of the cassiterite are separately carried out, so that fine sand in the sulfur roughing concentrate cannot be circulated in flotation of the cassiterite. On the one hand, the technical process prevents the fine sand in the sulfur roughing concentrate from entering flotation of the cassiterite, so that the chemical consumption of the fine sand is avoided, and the production cost is reduced; on the other hand,the grade and operation recovery rate of the cassiterite are improved, and by means of the technical process, the sulfur concentrate with relatively high grade and the tin concentrate with relativelyhigh grade and recovery rate are obtained.

Owner:KUNMING UNIV OF SCI & TECH

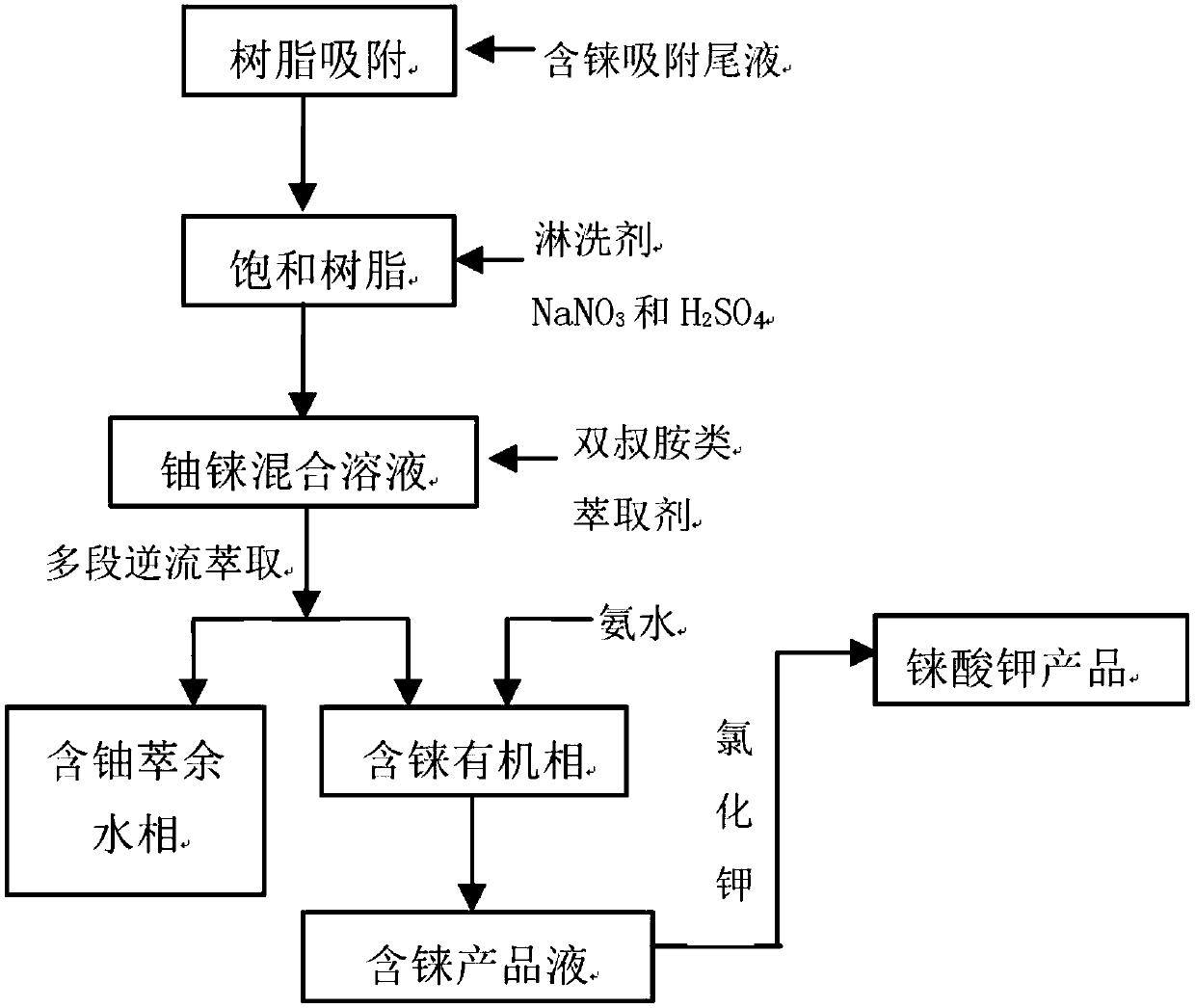

In-situ leaching uranium exploitation comprehensive recovery technology

The invention relates to the technical field of in-situ leaching uranium exploitation and particularly discloses an in-situ leaching uranium exploitation comprehensive recovery technology which comprises the following steps: 1, adopting resin to adsorb rhenium; 2, leaching saturated resin; 3,carrying out extraction on uranium-rhenium mixing solution; 4, carrying out back-extraction on a rhenium-containing organic phase; and 5, obtaining potassium rhenate. With adoption of the in-situ leaching uranium exploitation comprehensive recovery technology, rhenium enrichment is realized, concentrationof rhenium in rhenium-containing product solution reaches more than 1000 times of concentration of rhenium in rhenium-containing adsorption tail liquid, separation of uranium and rhenium is realized through the extraction technology, and more than 99% of uranium is left on an extraction raffinate water phase and does not enter the organic phase.

Owner:中核通辽铀业有限责任公司

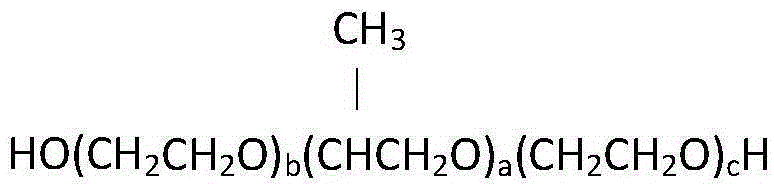

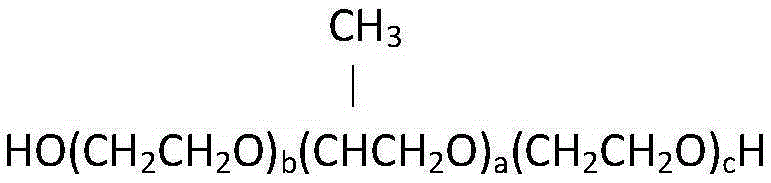

Normal-temperature short-process collecting agent for hematite reverse flotation

A normal-temperature short-process collecting agent for hematite reverse flotation comprises, by mass, 0-60% of sodium lignin sulfonate, 35%-90% of acid oil and 5%-20% of polyoxyethylene-polyoxypropylene block polyether. The structural formula of the polyoxyethylene-polyoxypropylene block polyether is shown in the specification, wherein a ranges from 15 to 19, b ranges from 8 to 12, and c ranges from 8 to 12. Through the collecting agent under the condition of the normal temperature ranging from 22 DEG C to 25 DEG C, the concentrate grade of feed mixed magnetic concentrate with the grade being 47.9% can be made to reach 67%-69% through one time of roughing, one time of concentration and one time of scavenging, and the concentrate iron yield reaches 88%-91.5%; the concentrate grade is high, the concentrate recovery rate is high, and the purposes of simplifying the process, increasing the yield and reducing the cost are realized.

Owner:ANSTEEL GRP MINING CO LTD

Citric acid crystal and production method thereof

InactiveCN103145547ALess polycrystallineUniform particle sizeCarboxylic compound separation/purificationStart timeSlurry

The invention discloses a citric acid crystal and a production method thereof. The method comprises the steps of concentrating and crystallizing multiple batches of citric acid feed liquid in sequence under the concentration and crystallization conditions, and carrying out solid-liquid separation on the crystal size obtained through concentration and crystallization in sequence in the same solid-liquid separation system, wherein the start time of concentration and crystallization of the latter batch of two adjacent batches of citric acid feed liquid is controlled so that the finish time of concentration and crystallization of the latter batch of citric acid feed liquid is not earlier than the finish time of separation of the former batch of crystal size by the solid-liquid separation system. According to the invention, as batch production is adopted, the problems in continuous production that as part of the crystals has long residence time in the system, the crystals seriously collide with each other and generate polycrystals, thus causing more polycrystals and nonuniform crystal grains of the crystal product, high moisture content, poor anti-caking performance and low bulk density do not exist. By adopting the technical scheme, the solid-liquid separation system can be ensured to work continuously, the production efficiency is improved and the energy consumption is reduced.

Owner:COFCO BIOTECHNOLOGY CO LTD

Reduction and reclamation recycled water reuse zero emission treating technology

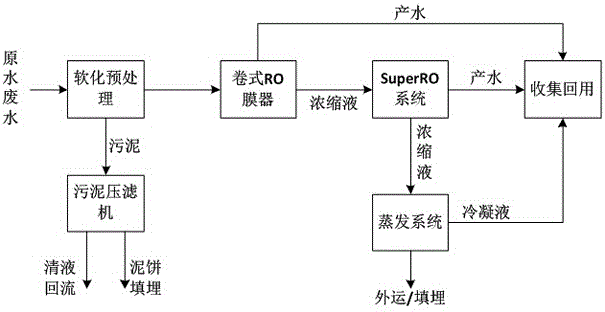

ActiveCN105036444AIncrease concentrationReduce processing difficultyMultistage water/sewage treatmentEvaporationProduced water

The invention discloses a reduction and reclamation recycled water reuse zero emission treating technology. The reduction and reclamation recycled water reuse zero emission treating technology comprises the steps that firstly, softening pretreatment is carried out on raw water waste water, and it is achieved that the concentration of calcium and magnesium ions is smaller than 100 mg / l, and the total hardness is smaller than 200 ml / l; secondly, outlet water enters a roll type RO membrane device to carry out first-time separation and concentration, and produced water of the outlet water is collected and reused; thirdly, concentration solution outlet water of the roll type RO membrane device enters a SuperRo system to carry out second-time concentration, evaporation condensate of the concentration solution outlet water is collected and reused, and the residual solid is transported out to be treated or treated in a landfill mode. An existing recycled water recycling technology is improved based on the special membrane technology, two times of concentration is carried out on biochemical outlet water through the roll type RO membrane device and the SuperRo system, the water producing efficiency is greatly improved, the treatment difficulty of an evaporation system is also lowered due to the fact that the concentration of the outlet water concentration liquid is increased, and the operation cost of all procedures is effectively reduced.

Owner:四川美峰环境治理有限责任公司

Corrosion inhibitor for circulating cooling water with high chlorine ion content of 3000mg/L-100000mg/L

ActiveCN106745858ANo pollution in the processNo investment requiredTreatment using complexing/solubilising chemicalsCarboxylic acidSodium salt

The invention provides a corrosion inhibitor for circulating cooling water with the high chlorine ion content of 3000mg / L-100000mg / L. The corrosion inhibitor comprises a liquid part and a solid part, wherein the liquid part is prepared from the following components by weight percent: 10%-30% of organic phosphonic acid, 10%-30% of organic carboxylic acid, 10%-25% of a substance with scale inhibition, corrosion inhibition and dispersion effects and the balance of water; and the solid part is prepared from the following components by weight percent: 15%-35% of tanning extract, 20%-35% of fulvic acid, 0-5% of sodium hydroxide and the balance of sodium salt. The corrosion inhibitor provided by the invention has high Cl<-> content tolerance in circulating water; when the Cl<-> content is 3000mg / L-100000mg / L, all technical index requirements including the scale inhibition rate, the metal corrosion rate and the bacterium and algae breeding rate required by an industrial circulating cooling water design specifications can be realized; and meanwhile, the number of times of concentration has a natural balance, the system is operated with zero emission, no wastewater is discharged, and the investment and operation costs of sewage treatment facilities can be greatly reduced.

Owner:樊霆

Flotation enriching method for willemite

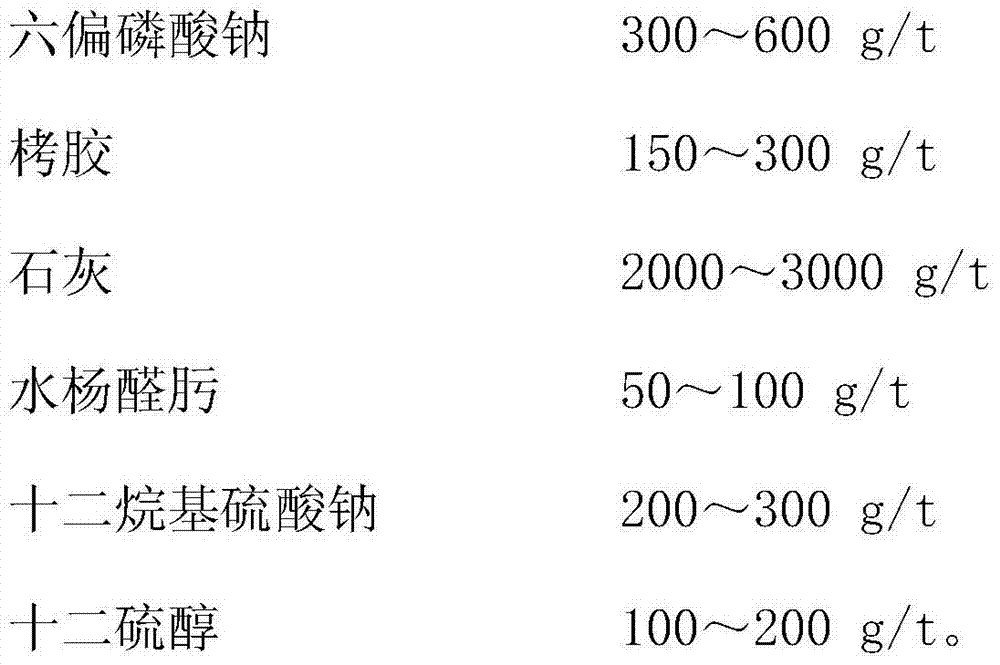

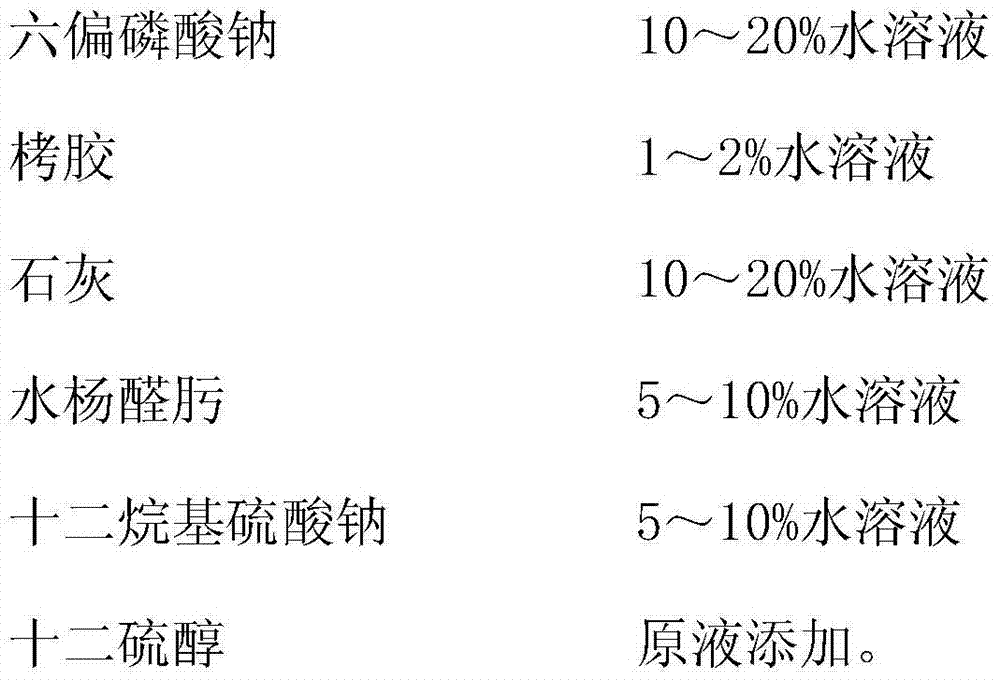

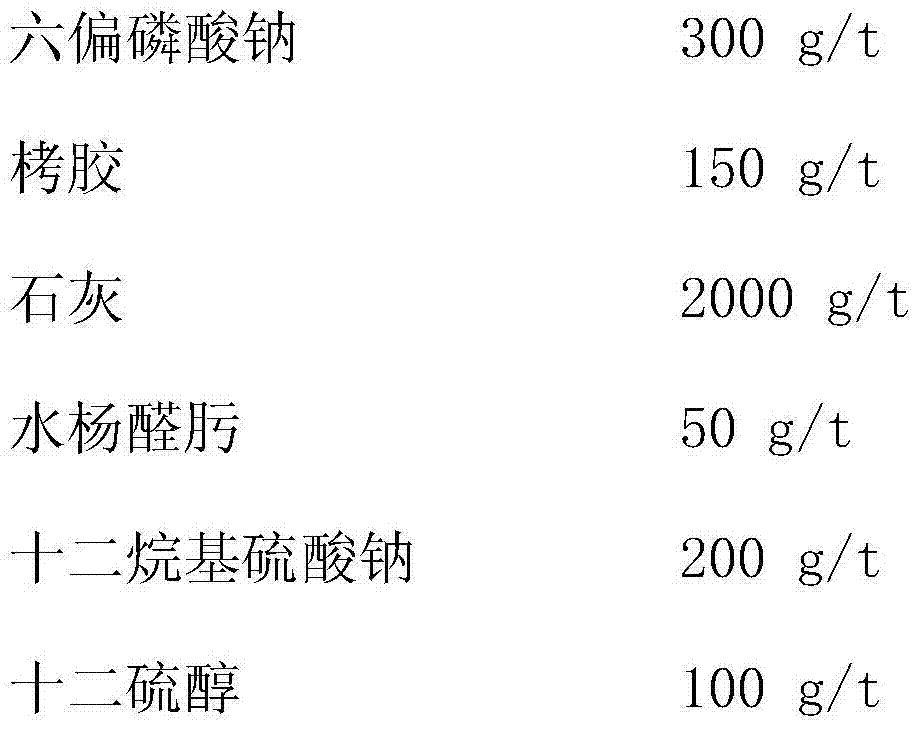

The invention discloses a flotation enriching method for willemite. According to the method, sodium hexametaphosphate and tannin extract are taken as gangue mineral inhibitors, lime and salicylaldoxime are taken as willemite activating agents, and lauryl sodium sulfate and lauryl mercaptan are taken as willemite collecting agents. Due to the adoption of the flotation enriching method, willemite minerals can be effectively floated and enriched. After one time of rougher flotation, four times of scavenging and three times of concentration are performed under the condition that the feed zinc content is 8.78-15.66 percent, zinc silicate concentrate of which the zinc content is 45.67-46.74 percent and the recovery rate is 83.15-85.61 percent is obtained.

Owner:GUANGXI UNIV

Converter slag copper magnetic levitation beneficiation combined method

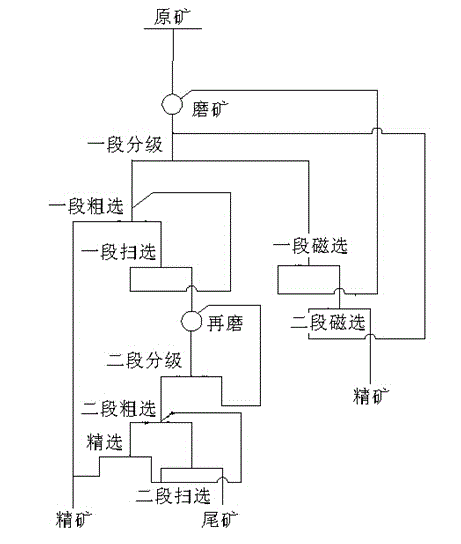

The invention discloses a converter slag copper magnetic levitation beneficiation combined method. The converter slag copper magnetic levitation beneficiation combined method includes the following steps: ore grinding, regrinding, two times of grading, two times of roughing, two times of scavenging, two times of magnetic separation and a time of concentration are carried out on raw ore, and copper concentrates and copper tailings are obtained; the copper concentrates are filtered to obtain a final copper concentrate product, and the copper tailings are filtered to obtain a slat tailing product. According to the method, the step of two times of magnetic separation is additionally set, after magnetic separation is carried out, elementary substance copper most of which can not be grinded to be fine is firstly produced, the ore grinding classifying burden is reduced, the grinding and levitation working procedure capacity is improved, the production cost is reduced, and the slag ore dressing recovery percentage is improved.

Owner:HUBEI DABEIJIANG ENVIRONMENTAL TECH CO LTD

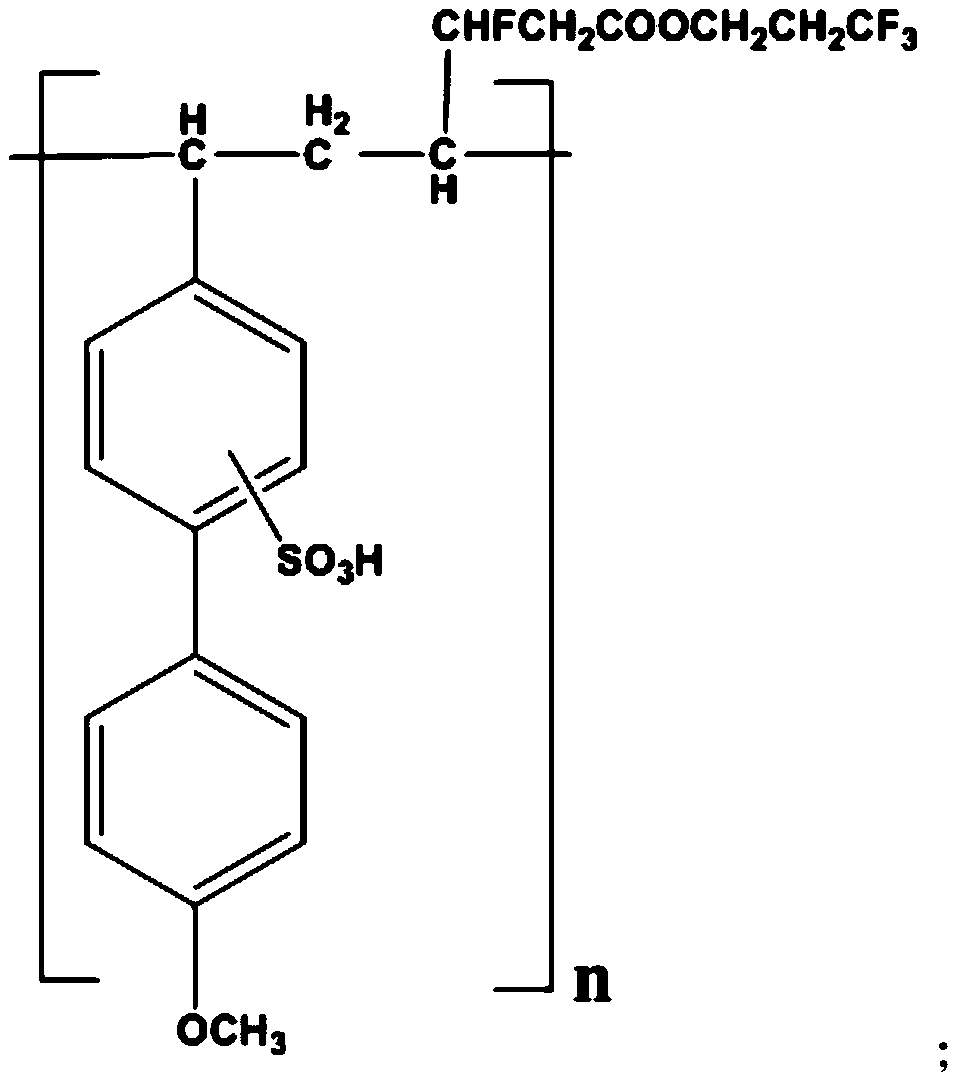

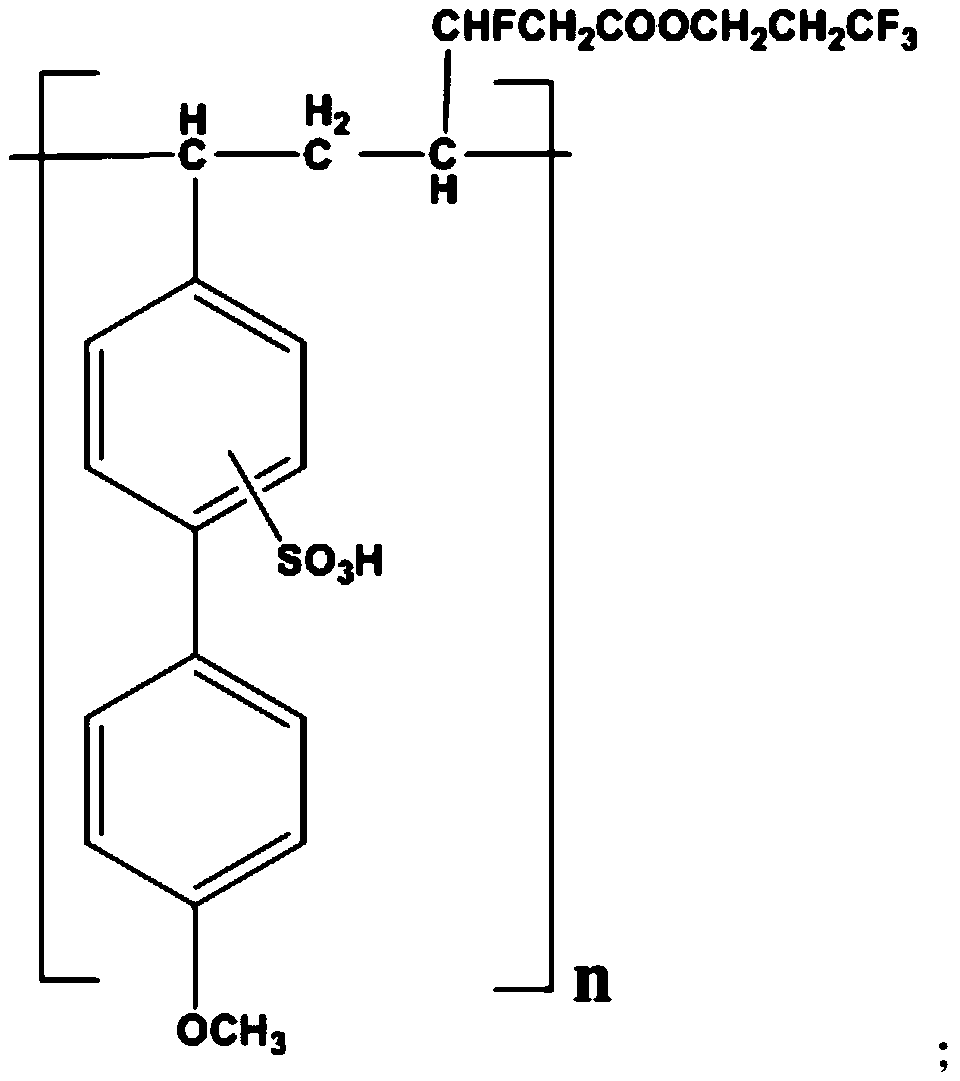

Manufacturing method of phenol and acetone

InactiveCN109776274ALower surface energyPlay a role of shielding protectionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic decompositionEvaporation

The invention discloses a manufacturing method for phenol and acetone, and relates to the technical field of chemical raw material synthesis. The manufacturing method comprises the steps that improvement is conducted on the basis of an existing method that phenol and acetone are synthesized through isopropyl benzene oxidation and selective acid catalytic decomposition, isopropyl benzene obtained after alkalization and pressurized air are subjected to a countercurrent contact reaction in an oxidation tower, falling film evaporation and two times of concentration are conducted, and then refinedcumene hydroperoxide is obtained; the refined cumene hydroperoxide is decomposed into the phenol and acetone in a moving bed reactor through catalysis of an acid resin catalyst, and then the refined phenol and acetone are obtained through water washing for deacidification, acetone roughing, acetone refining, coke cutting and secondary dealkylation. The manufacturing method has the good selectivityand yield of the phenol and acetone, the reaction conditions are not harsh and easy to control, the resin catalyst can be reused multiple times after collection and regeneration, and thus the production cost is lowered.

Owner:实友化工(扬州)有限公司

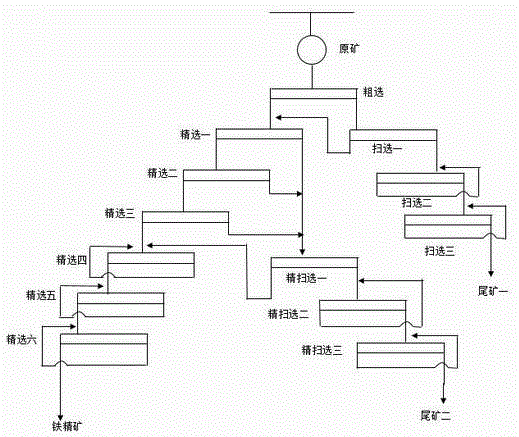

Beneficiation method for high-phosphor oolitic hematite

The invention relates to a beneficiation method for high-phosphor oolitic hematite. The beneficiation method is characterized in that reverse-flotation dephosphorization is carried out by use of a mixed collector which consists of a cationic collector, namely dodecyloxy propyl ether amine, an anionic collector, namely oleic acid, and an emulsifier, namely tween-20 in proportion, wherein after ore-grinding, mixing and size-mixing, once rough concentrationroughing and three-time scavenging are carried out to abandon tailings; rough concentration bottom flow and bottom flow obtained by primary scavenging are combined and six-time concentration is carried out; bottom flow obtained by the last three times of concentration is subjected to centralized concentration and scavenging to abandon the tailings; foams obtained by secondary scavenging and tertiary scavenging are returned to last operation; bottom flow obtained by primary concentration and scavenging and bottom flow obtained by tertiary concentration are combined, and four-time concentration, five-time concentration and six-time concentration are carried out; foams obtained by secondary concentration and scavenging and tertiary concentration and scavenging are returned to the last operation; the mixed collector is good in selectivity, the foams are high in quality, and the tailings are abandoned twice in the flotation process, so that the return pressure of the process is reduced, the problem that foams, due to a large quantity, cannot be smoothly returned in an oxidized ore flotation process is solved, and therefore, the process is smooth, the phosphor content in the iron ore concentrate can be effectively reduced, and the qualified iron ore concentrates which meet industrial application are obtained.

Owner:CENT SOUTH UNIV

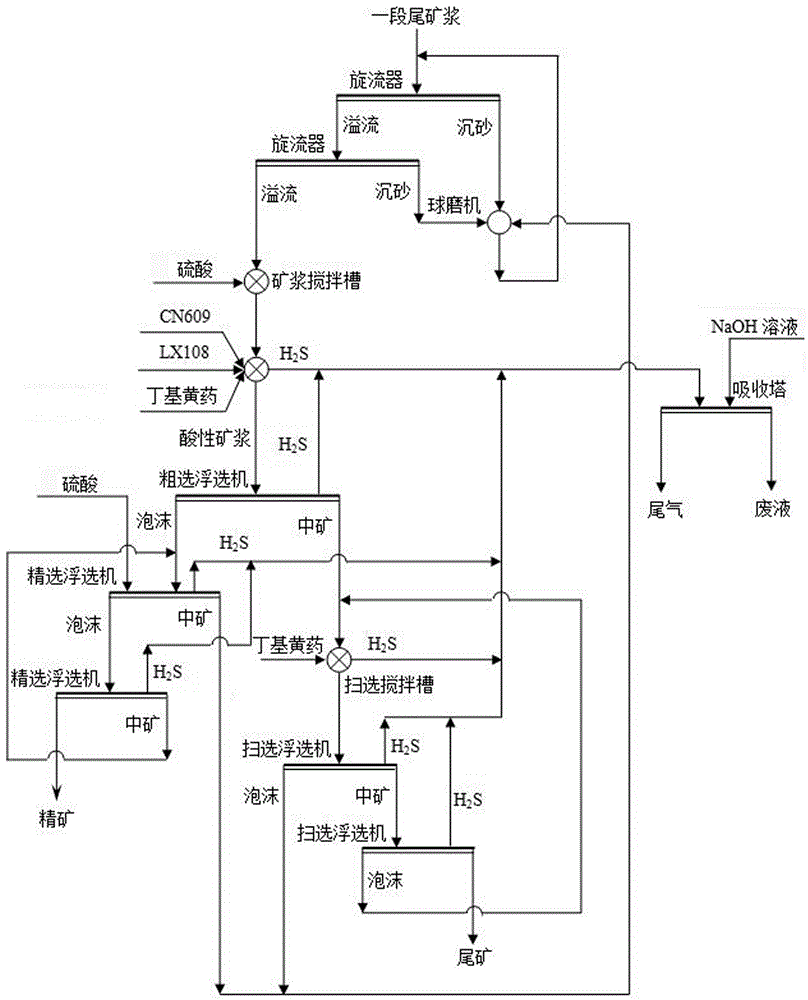

Two-stage acidification and flotation process of nickel-copper sulfide ore

ActiveCN106583061AHas a cleaning effectReduce buoyancyFlotationGrain treatmentsEngineeringNickel sulfide

The invention relates to a two-stage acidification and flotation process of nickel-copper sulfide ore. According to the two-stage acidification and flotation process of the nickel-copper sulfide ore, after a section of tailings are grinded and graded, acid is added to ore pulp to adjust the ore pulp, then an efficient capture agent CN609, an acid-resistant efficient foaming agent LX108 and a butyl xanthate capture agent are added, and after the flotation process including one time of roughing, two times of concentration and two times of scavenging, the final concentrate product and tailing waste are obtained. Hydrogen sulfide gas generated after the sulfuric acid is added to the ore pulp is absorbed through a sodium hydroxide solution, so that exhaust gas exhausted to the atmosphere meets the requirement of environment protection.

Owner:JINCHUAN GROUP LIMITED

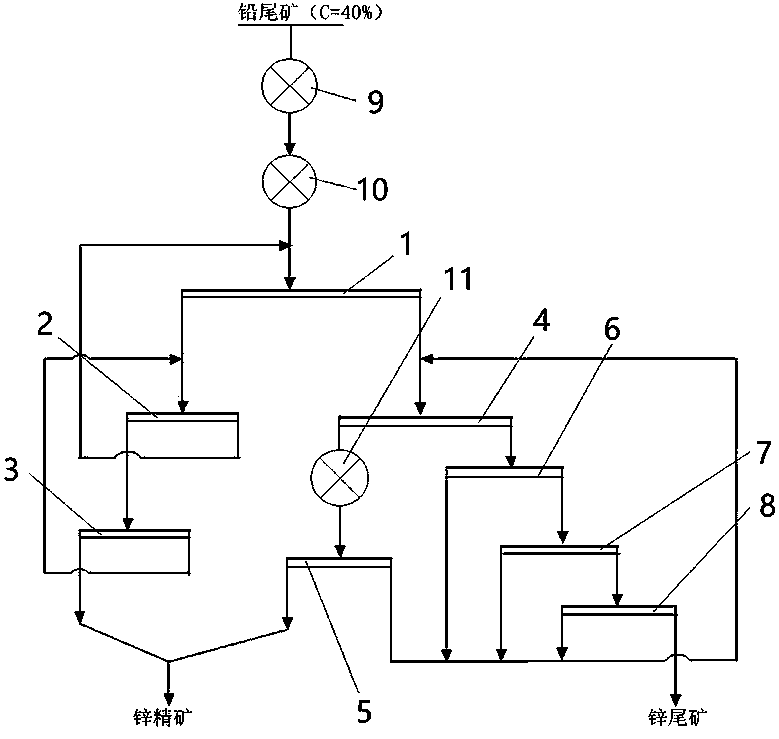

Machine-column-machine rapid and efficient zinc flotation method and system

The invention discloses a machine-column-machine rapid and efficient zinc flotation method. The method adopts the flotation procedure of one time of roughing and two times of concentration of a flotation machine, one time of roughing and one time of concentration of a flotation column and three times of sweeping of the flotation machine. Firstly, coarse particle zinc which is easy to float is rapidly produced through the flotation machine, then zinc which is floated in medium difficulty is produced in concentration of the flotation column through the flotation column, zinc which is very difficult to float is produced under synergy of the flotation column through the long-time excitation and capturing functions in the flotation machine, the floating time and procedure of the zinc minerals which are easy to float are shortened, the cyclic loss of the medium minerals is reduced, and the zinc minerals difficult to float have longer time and much chance to float. The method not only well solves the problem that the same kind of minerals have different floatability, but also solves the problem that zinc minerals of different size fractions have different floatability, achieves refine selection, remarkably improves the zinc recovery rate, achieves efficient zinc flotation, and has great importance significance for improving the zinc recovery rate and concentrate quality, saving energy, reducing consumption and achieving clean production.

Owner:南京银茂铅锌矿业有限公司

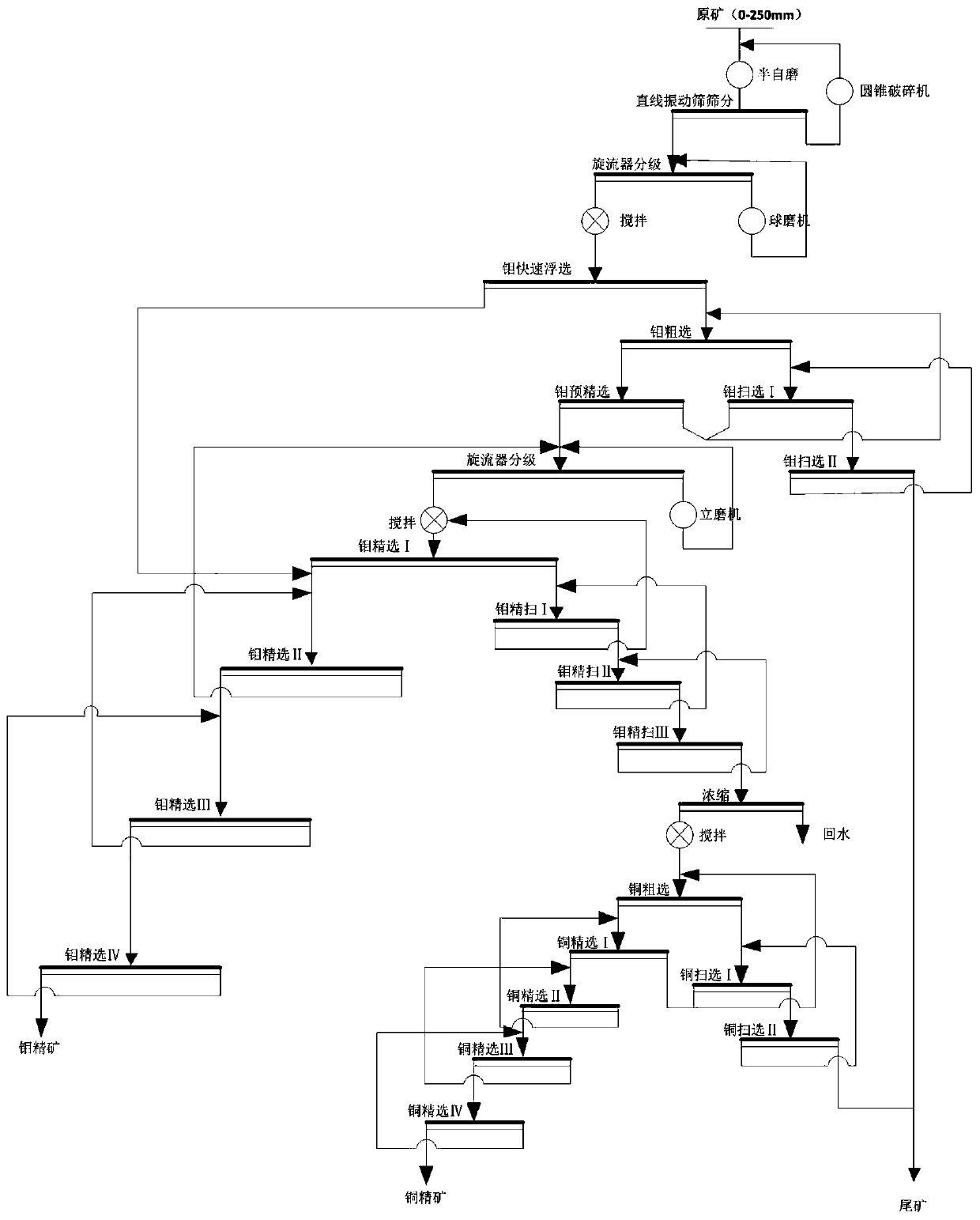

Ore grinding mineral dressing process for large molybdenum ore

ActiveCN109865587AImprove quality and reduce impuritiesPlay a role in environmental protectionWet separationGrade systemCopper

The invention provides an ore grinding mineral dressing process for a large molybdenum ore, and belongs to the technical field of molybdenum ore dressing. The ore grinding mineral dressing process forthe large molybdenum ore comprises the steps that raw ore is fed into a SABC closed circuit grinding and grading system; a ground product is fed into copper and molybdenum bulk flotation operation composed of operations of rapid flotation, roughing, scavenging and preconcentration, rapid flotation concentrate and preconcentrated concentrate are obtained, and the rapid flotation concentrate is directly fed into secondary concentration; the preconcentrated concentrate is fed into closed circuit fine grinding operation, a fine-ground product is fed into molybdenum and copper separating flotationoperation; and tailings after fine scavenging is densely fed into a copper flotation process composed of one time of roughing, four times of concentration and two times of scavenging to obtain a final copper concentrate. Compared with a traditional molybdenum flotation multi-stage process, the molybdenum concentration adopts a flotation column, the advantages of high beneficiation efficiency, energy saving, low running cost, convenient maintenance, simple operation, high degree of automation and the like are achieved, the beneficiation enrichment ratio is large, and the stable concentrate products can be obtained.

Owner:伊春鹿鸣矿业有限公司

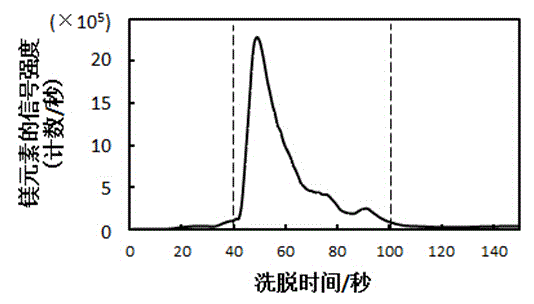

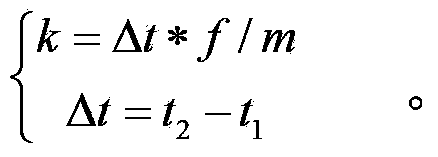

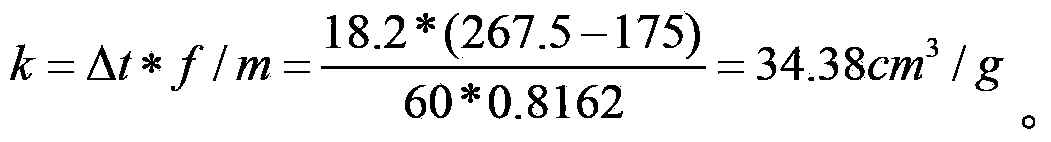

Measuring method of material's dynamic adsorption coefficient in vacuum state

The invention belongs to the technical field of physical and chemical performance measurement of a material and specifically relates to a measuring method of a material's dynamic adsorption coefficient in a vacuum state. The method provided by the invention comprises the following steps: a, a carrier gas and a gas to be adsorbed are mixed, and temperature adjustment and humidity adjustment are carried out; b, the gas mixture which has undergone temperature adjustment and humidification passes through an adsorbing material bed without an adsorbing material and an adsorbing material bed with an adsorbing material respectively, and then the gas mixture undergoes dehumidification; the gas which has undergone dehumidification is processed by a gas chromatography-mass spectrometric method, and the time of concentration of the gas to be adsorbed in the gas mixture reaching the peak is recorded; and c, the dynamic adsorption coefficient is calculated. By the method, the technical problem that it is hard to directly measure inert-gas dynamic adsorption coefficient of activated carbon under the negative pressure condition in the prior art is solved; and by means of vacuum adjustment, temperature and humidity adjustment and the like, the dynamic adsorption coefficient of an adsorbing material under different environmental conditions is measured.

Owner:JIANGSU NUCLEAR POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com