Converter slag copper magnetic levitation beneficiation combined method

A converter slag and maglev technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of unfavorable energy efficient utilization, low screening efficiency, etc., so as to improve the comprehensive recovery rate of copper selection and reduce production costs. , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

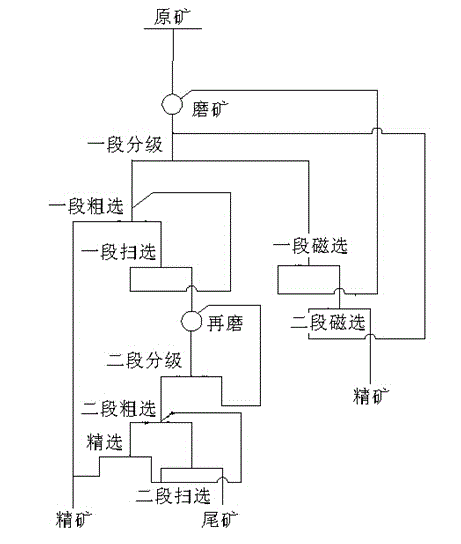

[0022] Such as figure 1 As shown, Fig. 1 is a process flow chart of the method for converter slag copper magnetic levitation combined beneficiation shown in Example 1.

[0023] A method for combined converter slag-copper magnetic-flotation beneficiation, comprising the following steps: raw ore undergoes ore grinding, regrinding, two classifications, two roughings, two sweepings, two magnetic separations and one beneficiation to obtain copper concentrate And copper tailings, copper concentrate is filtered to obtain final copper concentrate, and copper tailings are filtered to obtain slag tailings.

[0024] Further, the two magnetic separations include one-stage magnetic separation and two-stage magnetic separation; preferably, one-stage magnetic separation means that a stage of graded grit enters the magnetic separator for magnetic separation, and the bottom product of the first-stage magnetic separation enters the second-stage magnetic separation. The separator performs two-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com