In-situ leaching uranium exploitation comprehensive recovery technology

A technology for in-situ leaching and mining of uranium, which is applied in the field of in-situ leaching and mining of uranium, and can solve the problems of effective recovery of difficult metal rhenium, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

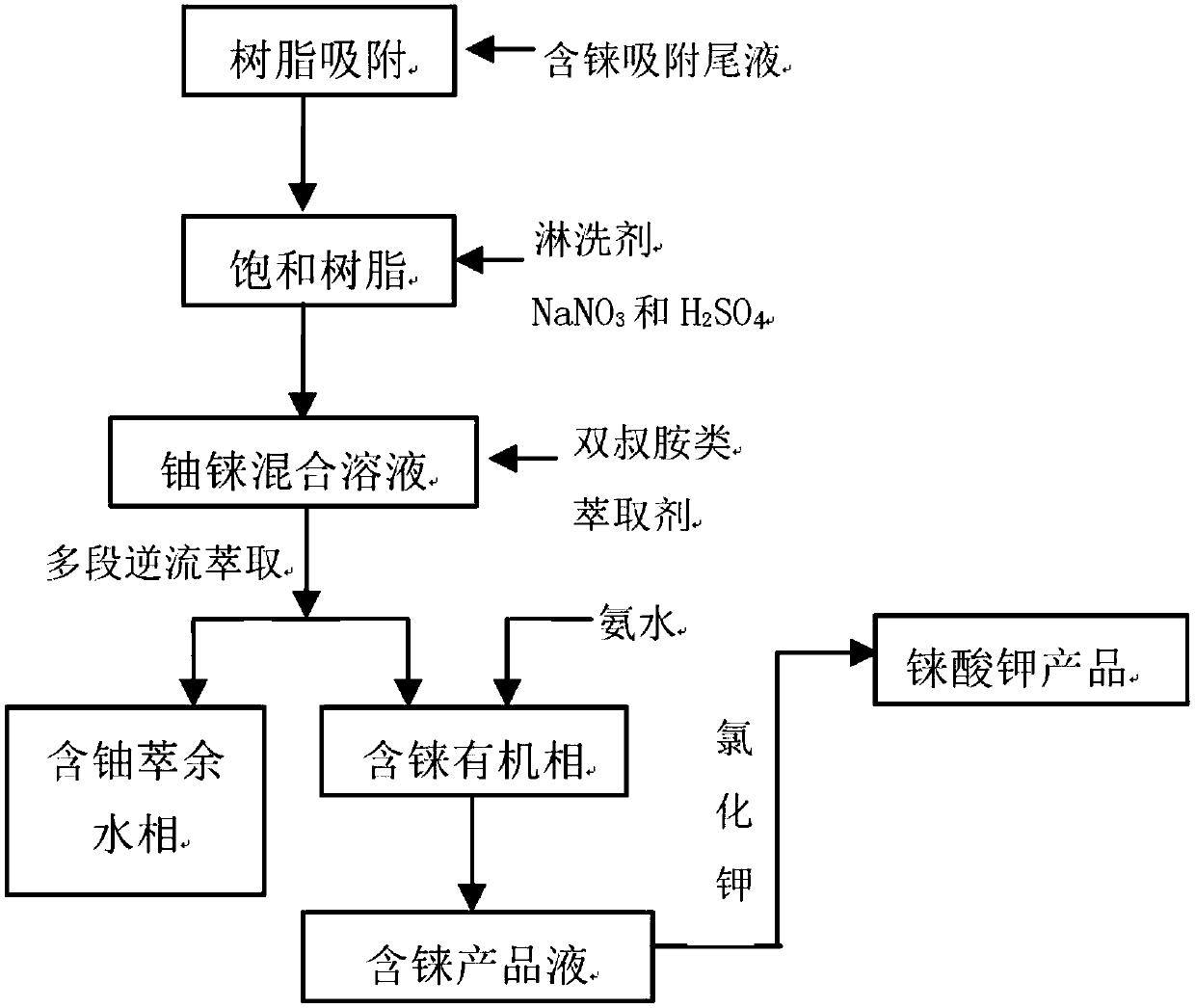

[0045] A comprehensive recovery process for uranium from in-situ leaching, comprising the following process steps:

[0046] 1. Adsorption of rhenium

[0047] The rhenium-containing adsorption tail liquid passes through the adsorption tower, and the flow rate is controlled at 5BV / h; the rhenium concentration in the adsorption tail liquid is 0.74mg / L, the uranium concentration is 0.92mg / L, and the pH value is 2.10; the macroporous anion exchange resin D355 adsorption solution is used rhenium in the adsorption tower, until the concentration difference of rhenium in the outlet liquid of the adsorption tower and the rhenium in the liquid inlet is ≤2%, the adsorption is stopped to obtain a rhenium-containing saturated resin.

[0048] 2. Rhenium-containing saturated resin leaching

[0049] Use 42g / L NaNO at 40°C 3 and 60g / LH 2 SO 4 The mixed solution is used as eluting agent to elute the rhenium-containing saturated resin; the flow rate is controlled at 0.4BV / h to obtain a uraniu...

Embodiment 2

[0057] A comprehensive recovery process for uranium from in-situ leaching, comprising the following process steps:

[0058] 1. Adsorption of rhenium

[0059] The rhenium-containing adsorption tail liquid passes through the adsorption tower, and the flow rate is controlled at 6BV / h; the rhenium concentration in the adsorption tail liquid is 0.54 mg / L, the uranium concentration is 0.56 mg / L, and the pH value is 1.95; Rhenium, until the concentration difference between the concentration of rhenium in the effluent of the adsorption tower and the influent is ≤ 2%, the adsorption is stopped.

[0060] 2. Rhenium-containing saturated resin leaching

[0061] Use 50g / L NaNO at 50℃ 3 and 80g / L H 2 SO 4The mixed solution was used as eluent to wash the saturated resin; the flow rate was controlled at 0.3BV / h to obtain a uranium-rhenium mixed solution with a leaching volume of 3.8BV; the uranium concentration was 98.6mg / L, and the rhenium concentration was 23.2mg / L.

[0062] 3. Uranium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com